|

|

Recent Progress in Diamond-based Electrocatalysts for Fuel Cells

DONG Liang, WANG Yan-Hui, ZANG Jian-Bing

2017 Vol. 32 (7): 673–680

Abstract

Abstract(

828 )

HTML

HTML(

9)

PDF

PDF(420KB)(

1142

)

Attributed to highly stable structure of sp3 hybridized carbon atoms, diamond has excellent physical and chemical stabilities. As new conductive diamond materials, boron-doped diamond (BDD) films and particles, as well as undoped nanodiamond (ND) has become the ideal support of the high stability electrocatalysts for fuel cells. Futher investigation showed that the activity and stability of electrocatalysts could be futher improved if the new diamond materials were properly processed. The doping treatment, including doping into diamond and the graphite structure from conversion of diamond, was used to produce diamond-based non-Pt electrocatalysts for fuel cells. It was considered that the sp3 structure of diamond played a unique role in enhancing the stability of diamond-based non-Pt electrocatalysts. In this paper, related studies of diamond-based electrocatalysts were summarized for the references of future study.

|

|

|

Progress in Tuning of Metastable Vaterite Calcium Carbonate

JIANG Jiu-Xin, WU Yue, HE Yao, GAO Song, ZHANG Chen, SHEN Tong, LIU Jia-Ning

2017 Vol. 32 (7): 681–690

Abstract

Abstract(

1161 )

HTML

HTML(

20)

PDF

PDF(857KB)(

1868

)

Vaterite has broad application prospects in the field of daily necessities and biomedical science because of its unique mechanical, physical and chemical properties. However, vaterite is the thermodynamically least stable phase in the three anhydrous crystalline phases of calcium carbonate, and such thermal metastability often transforms it into more stable aragonite or calcite phases, so how to inhibit the phase transformation of vaterite is always a hot topic in the study of calcium carbonate. In this paper, structure, properties, application, and phase transformation from vaterite to aragonite and/or calcite are briefly introduced. Particularly, based on the three basic routes of synthesis of calcium carbonate, some traditional methods, such as carbonization, double decomposition, microemulsion, solvothermal method, and some latest progress, e.g. self-assembly of monolayer, biomimetic synthesis and thermal decomposition methods of tuning and preparation on vaterite are then summarized. Moreover, some analysis on the mechanism of formation and stabilization of vaterite by some additives are given. The aim of this review is to provide a more systematic theoretical and practical guidance to fabrication vaterite phase of calcium carbonate.

|

|

|

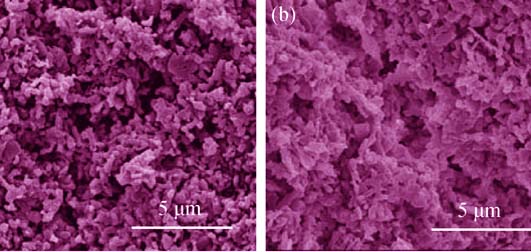

Hydrothermal Synthesis of FeS2/Reduced Graphene Oxide Nanocomposite with Enhanced Discharge Performance for Thermal Battery

YANG Kun-Kun, YANG Shao-Hua, ZHAO Ping, ZHAO Yan-Long

2017 Vol. 32 (7): 691–698

Abstract

Abstract(

1068 )

HTML

HTML(

23)

PDF

PDF(543KB)(

1434

)

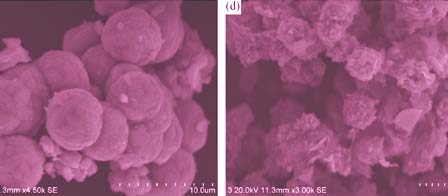

FeS2/reduced graphene oxide (RGO) composites were prepared through a facile hydrothermal method using FeCl2, Na2S2O3 and graphene oxide(GO) as the starting materials. X-ray diffractometer (XRD), scanning electron microscope (SEM), laser particle size distribution analyzer, and differential thermal analyzer (DTA) were used to characterize the prepared nanocomposites. The results show that graphene oxide prevents the aggregation of FeS2 particles during the hydrothermal synthesis, and make FeS2 form loose spherical particles. FeS2/RGO exhibits a high specific capacity of 314.9 mAh/g with a cut-off voltage of 1.5 V at constant current density of 100 mA/cm2 and temperature of 450℃ in LiCl-KCl melt, which is 65.6 mAh/g higher than that of FeS2. FeS2/RGO exhibits a high specific capacity of 302.3 mAh/g with a cut-off voltage of 1.5 V at constant current density of 100 mA/cm2 and temperature of 500℃ in LiF-LiCl-LiBr melt, which is 29.8 mAh/g higher than that of FeS2. In contrast with FeS2, the conductivity of the FeS2/RGO cathode material is improved, the resistance of the single cell is relatively lower during discharge process, thus FeS2/RGO cathode has a better battery discharge capacity.

|

|

|

Preparation and Electrochemical Performance of Si@C/SiOx as Anode Material for Lithium-ion Batteries

YANG Tao, LI Xiao, TIAN Xiao-Dong, SONG Yan, LIU Zhan-Jun, GUO Quan-Gui

2017 Vol. 32 (7): 699–704

Abstract

Abstract(

1078 )

HTML

HTML(

19)

PDF

PDF(490KB)(

1464

)

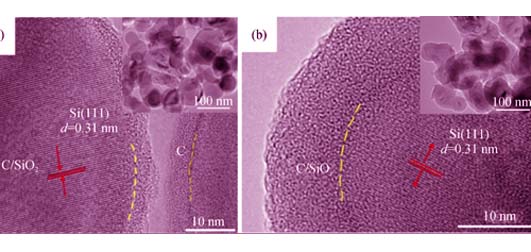

Silicon is one of candidates for graphite anode on account of its high theoretical specific capacity and low discharge plateau. But, the severe decay caused by huge volume change during the process of charge/discharge hinders the realization of Si commercial use in lithium-ion batteries (LIBs). A new material named Si@C/SiOx nanocomposite with core-shell structure was prepared via a facile one-step method and used as anode material for LIBs. The micromorphology, structure and electrochemical performance of Si@C/SiOx nanomaterial were investigated by SEM, TEM, XRD, and XPS measurements. It is found that the electrochemical performance of Si@C/SiOx is better than Si@C core-shell nanomaterial. After 45 cycles at current density of 200 mA/g, the capacity retentions of Si@C electrode and Si@C/SiOx electrode are 60.2% and 87.3%, respectively, and the reversible capacity of Si@C/SiOx electrode remains 787.2 mAh/g. The electrochemical performance improvement of Si@C/SiOx electrode is ascribed to the combination of carbon and SiOx, which maintains the integrity of electrode structure through buffering the big pressure more effectively. And it improves the possibility of commercial use for Si anodes.

|

|

|

Silicon/CNTs/Graphene Free-standing Anode Material for Lithium-ion Battery

BAI Xue-Jun, LIU Chan, HOU Min, WANG Biao, CAO Hui, FU Jun-Jie

2017 Vol. 32 (7): 705–712

Abstract

Abstract(

893 )

HTML

HTML(

11)

PDF

PDF(684KB)(

1458

)

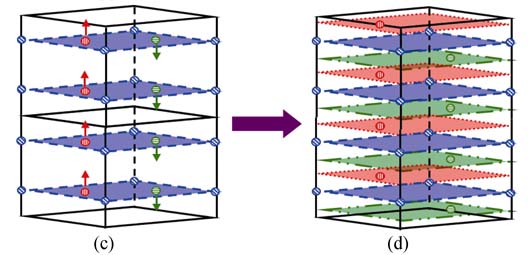

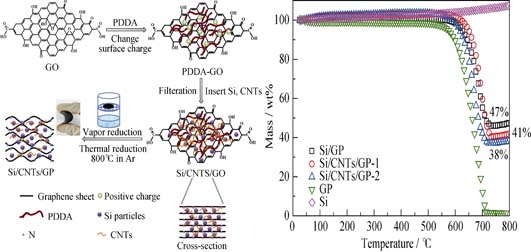

Porous 2D Silicon/CNTs/Graphene free-standing composites were prepared via a solution-based self-assembly process with vapor post-treatment and applied as anodes for lithium-ion batteries. Silicon nanoparticles (~50 nm) as active materials were uniformly embedded between graphene sheets without agglomeration. Graphene was used as electrical conductive carbon matrix to form a 2D conductive network for electrons. CNTs, with high electrical conductivity and mechanical strength, formed into a scaffold along with graphene to enhance the conductivity and mechanical properties of the carbon matrix. After vapor post-treatment, CNTs supported graphene film transferred from a tightly stacked film to a loose packed porous film. The porous structure of this free-standing composite anode provides large internal space to accommodate volumetric changes and provide abundant channels for diffusion of Li+, fast electron transport and easy penetration of electrolyte. The composites exhibite an outstanding rate performance and cyclic stability, delivering a capacity of 600 mAh/g at 4/A g and 1010 mAh/g after 100 cycles at 0.1 A/g. They also show high structure and mechanical stability after cycle test. It provides an exciting pathway to the rational design and fabrication of silicon anode and 2D graphene matrix for applications in lithium-ion batteries.

|

|

|

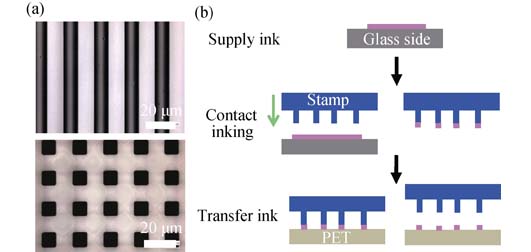

Stamp Structure on the Conductive Grid Patterns Prepared by Microcontact Printing

XIN Zhi-Qing, LI Xiu, JI Lei, LI Ze-Tao, XIANG Fei-Xiang, LIU Shi-Li, LI Lu-Hai

2017 Vol. 32 (7): 713–718

Abstract

Abstract(

781 )

HTML

HTML(

5)

PDF

PDF(496KB)(

907

)

Conductive grid patterns with fine line were achieved on the PET substrate via microcontact printing silver nanoparticle ink for its high resolution advantage. Conductive grids were patterned and compared by using the stamps with either line- or grid-structured patterns. When using line-structured stamp, the line width of the grid pattern was nearly the same as that on the stamp and the printed line edge was also smooth. The extra thickness at the cross of the grid which was due to two sequential stamp operations, was beneficial for higher conductivity. When using the grid-structured stamp, the conductive grid was acquired by only one stamp operation. However, the line width was broader than designed on the stamp and the line edge was poorer amid to liquid bridges formed between two adjacent lines on the stamp. The situation improved for the liquid bridge was easy to rupture when the line spacing of the grid line became bigger, but the conductivity was lowered as fewer conductive paths within the unit area. Hence, it is beneficial to acquire grid patterns using line-structured stamp, but the process is complicated and it will take longer time to complete two successive transfer processes.

|

|

|

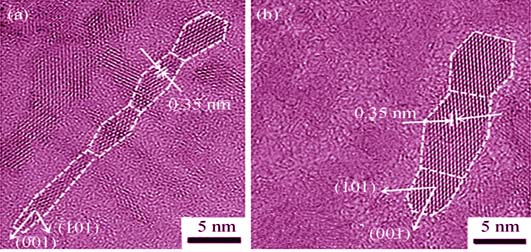

Solvothermal Synthesis and Morphological Control of TiO2 Nanorods Modified with Oleic Acid

LV Yu-Zhen, SUN Qian, LI Chao, SHAN Bing-Liang, QI Bo, LI Cheng-Rong

2017 Vol. 32 (7): 719–724

Abstract

Abstract(

568 )

HTML

HTML(

2)

PDF

PDF(492KB)(

1062

)

TiO2 nanorods were prepared by solvothermal method in two reaction systems. The structure, morphology and surface modification state of the as-obtained nanorods were characterized by X-ray diffractometer (XRD), transmission electron microscopy (TEM), Fourier transform infrared spectroscopy (FT-IR), and thermalgravimetric method (TG). The results indicate that the surface modification and crystallization process are the main factors that affect the morphology of TiO2 nanorods. In the nonaqueous reaction system, the aspect ratio of as-prepared TiO2 nanorods increase to 11.5 with the mole ratio of tetrabutyl titanate to oleic acid at 1: 10, which is 2.3 times of that obtained in the hydrolyzation system under the same ratio of reactants. The reason for this phenomenon is that the selective adsorption of oleic acid on the surface of TiO2 limits the one-dimensional orientation growth of crystals. The aspect ratio of TiO2 nanorods can be enhanced by increasing the amount of oleic acid. Furthermore, nonaqueous reaction facilitates the adequate growth of crystals and the oriented attachment of nanorods due to its lower reaction velocity, leading to the significant increase of aspect ratio of nanorods. The as-obtained nanorods with the optimum aspect ratio exhibit good modification effect on the positive impulse breakdown strength of transformer oil.

|

|

|

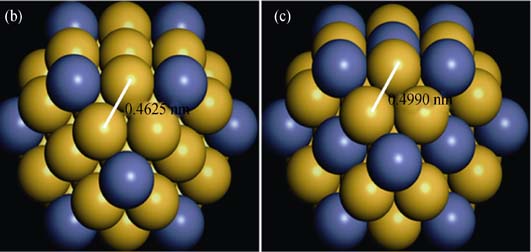

Low Temperature Catalytic Synthesis of β-SiC Powders via Microwave Heating

WANG Jun-Kai, ZHANG Yuan-Zhuo, LI Jun-Yi, ZHANG Hai-Jun, LI Fa-Liang, HAN Lei, SONG Shu-Peng

2017 Vol. 32 (7): 725–730

Abstract

Abstract(

729 )

HTML

HTML(

4)

PDF

PDF(538KB)(

1021

)

β-SiC powders were synthesized by a microwave heating method at 1150℃ for 30 min under Ar atomosphere using silicon powders and phenolic resin as raw materials, and nickel nitrate as catalyst precursor. The effects of temperature, catalyst content and holding time on the formation of SiC were investigated. XRD, SEM and TEM were used to characterize the phase and microstructure of the prepared samples. It indicated that β-SiC can be synthesized at 1150℃ for 0.5 h by using 1.0wt% Ni as catalysts. In contrast, for the sample prepared without Ni catalysts, corresponding preparation temperature of β-SiC was as high as 1250℃. Both β-SiC whiskers and particles were formed in the samples prepared with or without catalysts, and the length of formed β-SiC whiskers in the samples prepared with Ni catalysts were larger than those without catalyst. Density functional theory (DFT) calculation shows that the formation of Ni-Si alloy can elongate the length of Si-Si chemical bond, weaken its bond strength, and finally accelerate the carbonization reaction of Si powder at a relative low temperature.

|

|

|

Porous Alumina Ceramic Prepared by HEMA-TBA Gelcasting System

XIE Yu-Zhou, PENG Chao-Qun, WANG Xiao-Feng, WANG Ri-Chu, LUO Feng

2017 Vol. 32 (7): 731–738

Abstract

Abstract(

696 )

HTML

HTML(

1)

PDF

PDF(515KB)(

847

)

Porous alumina ceramics with high porosity and high strength were successfully fabricated by HEMA-TBA gelcasting system. Fabrication processes of slurries and ceramic were studied, effects of solid loading and dispersant contents on viscosity and stability of slurries, effects of drying and monomer content on green bodies, and effects of solid loading and sintering temperature on sintered bodies were investigated. The results show that optimum addition of citric acid of 2wt% decreases the viscosity and increases the stability of slurry. The viscosity and stability of the slurries increase with the increase of the solid loading of slurries. Green bodies with low solid loading can be dried with relatively small shrinkage less than 10% and its drying time is also relatively shorter than water based gelcasting system. The amount of monomer has great influence on green body and the strength of green body achieve high value at monomer content of 25%. By choosing the solid loading of slurries and sintering temperatures, ceramic microstructures and the porosity ranging from 40%-65% can be effectively controlled and strength of porous ceramics changes in the range of 5.7-91.2 MPa.

|

|

|

Crystallization Behavior of Hybrid Mullite Fiber Precursors

MA Xi-Fei, LIN Gen-Lian, KANG Zhuang, HUANG Xiao

2017 Vol. 32 (7): 739–743

Abstract

Abstract(

617 )

HTML

HTML(

6)

PDF

PDF(437KB)(

897

)

Glass free fine-grained microstructure is ideal for preparing mullite fibers with good high temperature mechanical properties. Single phase/diphasic mullite hybrid precursor was adopted to adjust crystalline microstructure of mullite fibers without adding any glass formers. The single phase precursor crystallized in situ to form mullite at 980℃ acting as seed crystals for diphasic components in hybrid precursors to induce the formation of mullite crystals at low temperatures. A series of spinnable hybrid mullite precursors were prepared by mixing single phase and diphasic mullite precursors, and their high temperature crystallization behaviors were investigated by XRD, DSC and SEM, with which optimum formulation of hybrid precursor was determined. The results reveal that hybrid precursor containing 70wt% single phase component has ideal crystalline properties and densification characteristics, with fine grain, uniform, and dense structure. Compared with the pure diphasic mullite precursor, the introduction of 70wt% single phase precursor resulted in an increase in apparent nucleation from 8×1012/cm3 to 1×1015/cm3, and a reduction in grain size from 360 nm to 120 nm after heat-treatment at 1400℃ for 20 h.

|

|

|

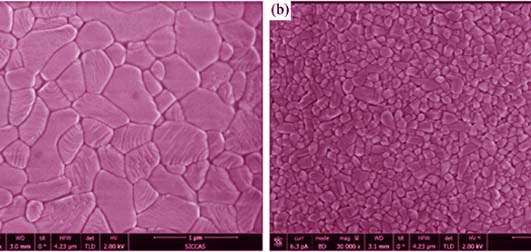

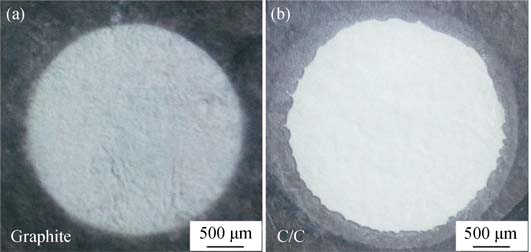

Corrosion Behavior of Carbon Materials Used in Crystalline Silicon Furnace in Silicon Vapor

SHI Wei, TAN Yi, HAO Jian-Jie, LI Jia-Yan

2017 Vol. 32 (7): 744–750

Abstract

Abstract(

613 )

HTML

HTML(

8)

PDF

PDF(928KB)(

1252

)

The experimental of silicon vapor corrosion under different corrosion conditions were carried out on different carbon materials (graphite, C/C, rigid carbon fiber felt (RCFF)), which were used as thermal field materials in silicon crystal growth furnace. The silicification corrosion behavior of the three carbon materials was studied. The results showed that the three carbon materials are easily corroded by silicon vapor at elevated temperature. The composition and microstructure of the three carbon materials have great influence on silicification corrosion behavior. Silicon vapor can infiltrate into interior of the carbon materials by pores and flaws, and then react with substrates to cause corrosion. After silicification corrosion, many cracks are observed on the surface of the three carbon materials, and the carbon fibers are severely destroyed in C/C composites and RCFF. Silicification corrosion level is affected by the form and strength of carbon fibers in C/C composites and RCFF. The corrosion of carbon fiber is necking and cleavage cracking for carbon fiber woven with high strength in C/C composites, while that is fragmenting and pulverizing for short carbon fiber with poor strength in RCFF. The corrosion parameters also have significant influence on degree of silicification corrosion. With the corrosion temperature increasing or corrosion time extending, the silicification corrosion degree for these carbon materials are all increased.

|

|

|

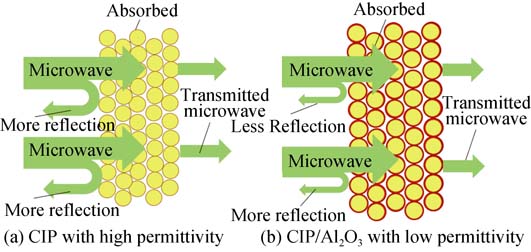

Corrosion Resistance and Wave Absorbing Property of Carbonyl Iron Powder Coating with Alumina by Atomic Layer Deposition

LIU Yan-Feng, LI Lei-Xiao, WANG Yun-Yu, LI Chang-Feng

2017 Vol. 32 (7): 751–757

Abstract

Abstract(

1010 )

HTML

HTML(

16)

PDF

PDF(549KB)(

2124

)

To improve the corrosion resistant capability and electromagnetic performance of carbonyl iron powders (CIPs), alumina thin films were coated on carbonyl iron powder by atomic layer deposition (ALD) using trimethylaluminum and water as precursors. Original and modified carbonyl iron powder was characterized comprehensively via scanning electron microscope (SEM), transmission electron microscope (TEM), thermogravimetric analyzer (TGA), Fourier Transform infrared spectroscope (FTIR), and vector network analyzer. The results indicated that nano-alumina films were conformably grown on the surface of carbonyl iron powders via ALD, forming an excellent core-shell CIP/alumina structure. Compared to the original sample, thermal stability and corrosion resistance of the modified carbonyl iron powders were greatly improved. Antioxidation capability of CIPs was found enhanced with the increase of alumina coating thickness, and the maximum antioxidation temperature can exceed 550℃. It was also found that the complex permittivity of core-shell CIP/alumina decreased greatly while the complex permeability was almost the same. Therefore, the electromagnetic parameters and microwave absorption properties of the modified CIPs was also improved.

|

|

|

Preparation of Coating Glass with High Visible Transmittance and High UV Cut-off

WANG Hong-Yan, ZHANG Hao, JIANG Hong, WANG Guo-Qing, XIONG Chun-Rong

2017 Vol. 32 (7): 758–764

Abstract

Abstract(

849 )

HTML

HTML(

3)

PDF

PDF(517KB)(

1078

)

A glass with a honeycomb surface was prepared by a reverse micellar solution etching technology. The honeycomb surface might reduce the light reflection and increase the average transmittance of visible light by nearly 7%. The chemical etching technology is environment friendly for unuse of HF or fluosilicate. To compare the visible light transmittance of the coated glass, CeO2/TiO2 films were deposited on the honeycomb surface glass and raw glass by radio frequency magnetron sputtering. A series of optimization experiments were carried out to obtain a coated glass with high visible transmittance and high UV cut-off. The samples were characterized by UV-Vis spectrophotometer, SEM, XRD, and XPS. When the UV cut-off ratios were 99% for both the honeycomb surface glass and the raw glass, the average transmittance of visible light was 85% for the coated honeycomb surface glass, and only 79% for the coated raw glass prepared under the same coating conditions. In addition, the porous structure on the glass surface also improved the contact area between the film and the substrate. Therefore, the binding force between film and substrate was increased by about 2 times.

|

|

|

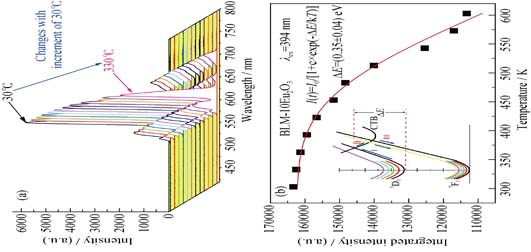

Optical Property and Thermal Stability of Eu3+ Ion Doped Borate Glass

YAN Shao-Feng, WU Zhong-Li, WU Hong-Mei, LIAO Guo-Jin, LI Yu, LIU Tong, ZHAO Xin-Bin

2017 Vol. 32 (7): 765–769

Abstract

Abstract(

589 )

HTML

HTML(

6)

PDF

PDF(407KB)(

1081

)

Fluorescent glass has advantages of homogeneous light emission, excellent thermal stability, and stable product quality as compared with traditional phosphors. Therefore, fluorescent glass in the field of LED has become a research hot spot in recent years. In this paper, Eu3+ doped borate glasses were synthesized via the conventional melt-quenching technique. The luminescence properties and thermal stability of the fluorescent glass samples were characterized by fluorescence spectra. The doping concentration of RE3+ ions is an important factor influencing the samples’ luminescent performance. Based on the Van Uitert model, concentration quenching behavior for the prepared glass samples was studied. It is found that the fluorescence quenching of the samples is attributed to the nonradiative energy transfer through cross-relaxation mechanism between energy levels of Eu3+. As is known to all, the temperature dependence of fluorescence glass’ luminescence is also important to the practical applications. The temperature quenching mechanism for the prepared glass samples was analyzed by Arrhenius model, and it was found that the temperature quenching could be ascribed to the crossover model. The activation energy for the prepared glass samples is obtained from fitting processes which is found to be (0.35±0.04) eV. The interaction between Eu3+ ion and glass host was also analyzed. The result shows that the interaction between Eu3+ ions and the glass host is weak coupling.

|

|

|

Facile Preparation of Nitrogen-doped Porous Carbons via Salt Melt Synthesis with Efficient Catalytic Desulfurization Performance

YU Zheng-Fa, WANG Xu-Zhen, HOU Ya-Nan, ZHAO Zong-Bin, Rui Li, QIU Jie-Shan

2017 Vol. 32 (7): 770–776

Abstract

Abstract(

763 )

HTML

HTML(

14)

PDF

PDF(606KB)(

1147

)

A series of N-doped porous carbons were prepared using biomass D-glucose and nitrogen-rich melamine as precursors via facile salt melt synthesis method. The obtained N-doped porous carbons exhibit developed porosity (BET surface area up to 1355 m2/g) and notablely high nitrogen content (20.73wt%). X-ray photoelectron spectroscope (XPS) results indicate that the nitrogen configurations in the carbons are mainly pyrrolic and pyridinic functional groups, which are in favor of catalytic oxidation of hydrogen sulfide to elemental sulfur. High sulfur capacity of 1.10 g/g is achieved over the optimized carbon materials at room temperature and ambient pressure, showing the excellent adsorptive-catalytic performance of N-doped porous carbons for hydrogen sulfide removal. The facile synthesis route enables a great potential for the scale-preparation of N-doped porous carbons and application in pollution control.

|

|

|

Effect of Gas-foaming Porogen-NaHCO3 and Citric Acid on the Properties of Injectable Macroporous Borate Bioactive Glass Cement

WU Ying-Ying, YE Song,YAO Ai-Hua, LI Hai-Bin, JIA Wei-Tao, HUANG Wen-Hai, WANG De-Ping

2017 Vol. 32 (7): 777–784

Abstract

Abstract(

707 )

HTML

HTML(

8)

PDF

PDF(800KB)(

868

)

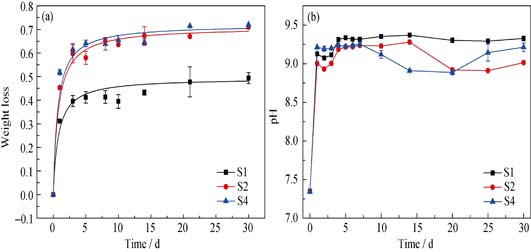

Borate bioactive glass (BBG) is a promising candidate material for bone tissue engineering. Mostly, it was applied in the form of scaffolds and granules. Till now, little work has been done to investigate the fabrication of porous borate bioactive glass cement (BBGC). In this work, we prepared an injectable macroporous BBGC via gas-foaming method, where NaHCO3 and citric acid were used as porogen. Porous structure was analyzed by using SEM. The properties of soaking products were characterized by XRD, FTIR and ATR. The injection test showed that the injection rate of BBGC was over 80%. SEM images presented that there were apparent pores in BBGC. The diameter of the macropores varied from 10 μm to 800 μm. Furthermore, the degradability of BBGC was greatly improved. After one month in vitro soaking, the weight loss of non-foamed BBGC was only 50wt%, while for the foamed samples, their weight loss reached 70wt%. Meanwhile, the XRD, FTIR and ATR results exhibited that there were hydroxyapatite (HA) formation and confirmed that the introduction of macropores into the BBGC did facilitate the mineralization reaction.

|

|