|

|

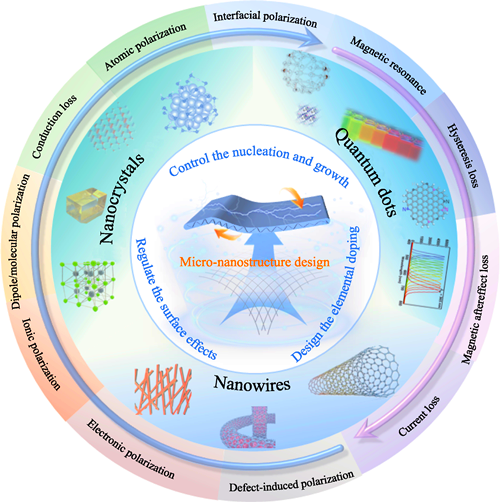

Research Progress on Modulation of Electromagnetic Performance through Micro-nanostructure Design

HUANG Jie, WANG Liuying, WANG Bin, LIU Gu, WANG Weichao, GE Chaoqun

2024 Vol. 39 (8): 853–870

Abstract

Abstract(

315 )

HTML

HTML(

13)

PDF

PDF(11086KB)(

354

)

Absorptive materials, by absorbing electromagnetic wave energy, effectively mitigate electromagnetic interference through reduction or elimination of wave reflection. The electromagnetic parameters of materials determine their electromagnetic wave absorption performance. Traditional control strategies, such as adjusting filler ratio, changing macroscopic morphology, and regulating composite methods, have certain limitations to control their structure and cannot fundamentally alter their electromagnetic parameters, which severely hinders their further development. Now, micro-nanostructure design strategies can basically change electromagnetic parameters of the materials by altering their electrical conductivity, charge density and magnetic properties, showing significant advantages in controlling electromagnetic wave absorption capacity. However, the precise micro-nanostructure design and the mass production still face challenges to be overcome. Additionally, structure-property relationship between micro-nanostructures and electromagnetic wave response, and its underline mechanisms are still not fully understood. Herein, a comprehensive review on these relationships was introduced to elucidate the advantages of micro-nanostructure design strategies for regulating electromagnetic wave absorption capacity. Moreover, by introducing these strategies, such as element doping, surface effect modulation and nucleation-controlled growth, this review provides researchers with deep insights and theoretical guidance for modulating electromagnetic properties through micro-nanostructure design. Finally, the research progresses on electromagnetic performance modulation through micro-nanostructure design based on the case of quantum dots, nanocrystals and nanowires, as well as the current research status and prospects in the field of electromagnetic absorption were summarized, providing a theoretical foundation and strategic support for the development of micro-nanoparticles.

|

|

|

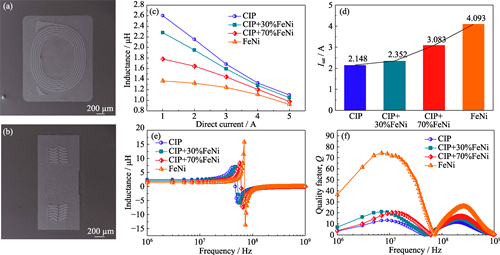

Fe/Submicron FeNi Soft Magnetic Composites with High Working Frequency and Low Loss

HE Sizhe, WANG Junzhou, ZHANG Yong, FEI Jiawei, WU Aimin, CHEN Yifeng, LI Qiang, ZHOU Sheng, HUANG Hao

2024 Vol. 39 (8): 871–878

Abstract

Abstract(

169 )

HTML

HTML(

11)

PDF

PDF(5039KB)(

128

)

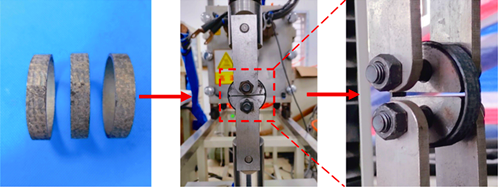

Application of high-power electronic equipment requires inductors with greater high-frequency performance and higher energy efficiency than ever, and thus it is urgent to develop new soft magnetic composites to meet these requirements. To reduce the eddy current loss of soft magnetic composites and obtain molded inductors with high working frequency, low loss and high power, high purity submicron FeNi particles were prepared by plasma torch, and effect of these particles on eddy current loss of soft magnetic composites was examined by simplified finite element model. Soft magnetic composites and molded inductors were prepared by mixing carbonyl iron powder and submicron FeNi particles with different mass fractions. The influence of submicron FeNi particles on the properties of soft magnetic composites and molded inductors is analyzed emphatically. With 30% of mass fraction of submicron FeNi particles, the imaginary part of permeability (μ") of the ring core decreases from 1.57 to 1.36 (reduced by 13.4%), compared with that of the soft magnetic composite made by only pure carbonyl iron powder. The quality factor Q of the molded inductors at 10 MHz increases from 13 to 20 (increased by 53.8%), while the self-resonance frequency increases by 12.7% and the saturation current increases from 2.148 A to 2.352 A. Submicron FeNi particles can effectively reduce eddy current loss and improve stability of the high frequency permeability of soft magnetic composites by increasing the internal resistance of materials and reducing the size of eddy current flow region. Therefore, this study demonstrates that compounding submicron FeNi particles is a promising method to obtain molded inductors with high frequency, low loss, and good comprehensive performance at low cost on a large scale.

|

|

|

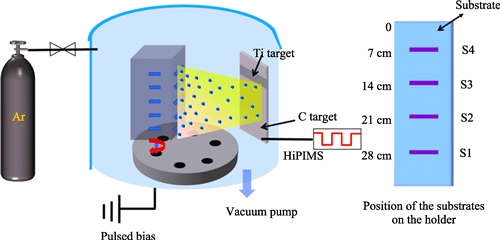

Ti Doped Diamond Like Carbon Films: Piezoresistive Properties and Carrier Transport Behavior

ZHAO Zhihan, GUO Peng, WEI Jing, CUI Li, LIU Shanze, ZHANG Wenlong, CHEN Rende, WANG Aiying

2024 Vol. 39 (8): 879–886

Abstract

Abstract(

172 )

HTML

HTML(

5)

PDF

PDF(3284KB)(

207

)

Diamond like carbon (DLC) film was a promising candidate for microelectromechanical system (MEMS) piezoresistive sensors owing to its excellent mechanical properties and sensitivity. The effects of carrier transport behavior and the role of operating conditions (such as temperature, humidity, etc.) on piezoresistive performance of metal-doped DLC were still unclear. In this work, Ti doped diamond like carbon (Ti-DLC) films with Ti atom fraction ranging from 0.43% to 4.11% were prepared using high-power pulse magnetron sputtering, where the high-throughput conception was introduced for film deposition. Effects of the doped Ti content on microstructure, electrical behavior and piezoresistive properties of the films were studied under various humidity environments. The results indicated that the doped Ti atoms were uniformly dissolved in the diamond like carbon matrix, accompanying typical amorphous characteristics for the Ti-DLC films regardless of Ti atom fraction changing from 0.43% to 4.11%. Furthermore, all the Ti-DLC films demonstrated distinct semiconductor feature, where the electrical resistivity was reduced with the increase of temperature in the range of 200-350 K. Particularly, the carrier transport was dominated by Mott type conduction with three-dimensional range hopping conduction from 200 to 270 K, while the thermal activation transport served as the conductive mechanism in the temperature range of 270-350 K. For the Ti-DLC films, the highest gauge factor (GF) was 95.1, and GF value increased with increasing relative humidity from 20% to 80%. This can be explained from reduction of the average distance between conductive cluster by introducing Ti atoms and a change in electrical resistance caused by adsorption of water molecules.

|

|

|

Effects of W/Cr Co-doping on the Crystal Structure and Electric Properties of CaBi2Nb2O9 Piezoceramics

HUANG Jianfeng, LIANG Ruihong, ZHOU Zhiyong

2024 Vol. 39 (8): 887–894

Abstract

Abstract(

210 )

HTML

HTML(

11)

PDF

PDF(1953KB)(

156

)

Calcium bismuth niobate (CaBi2Nb2O9) is a typical bismuth layered structure piezoelectric material with high Curie temperature (about 943 ℃) and high stability, which is an important candidate functional element for high temperature vibration sensors above 600 ℃. However, its low piezoelectric coefficient and high temperature resistivity seriously limit the signal acquisition of high-temperature piezoelectric vibration sensor. To improve the comprehensive performance, in this work, W/Cr co-doped CaBi2Nb1.975W0.025O9-x%Cr2O3 (CBNW-xCr, 0<x≤0.2) Aurivillius phase ceramics were prepared via conventional solid-state sintering route. The effects of W/Cr co-doping on the crystal structure and electrical properties of CBN piezoelectric ceramics were investigated. The results show that co-doping of W/Cr elements transforms crystal structure of the ceramics from orthorhombic to tetragonal crystal system, enhances distortion of the crystal structure, and significantly improves piezoelectric and insulating properties of the piezoelectric ceramics. When x=0.1, the Curie temperature is 931 ℃, the piezoelectric coefficient is 15.6 pC/N, the resistivity reaches the order of 106 Ω∙cm at 600 ℃, and the dielectric loss is only 0.029, which endows the system an important potential application in the field of high-temperature piezoelectricity.

|

|

|

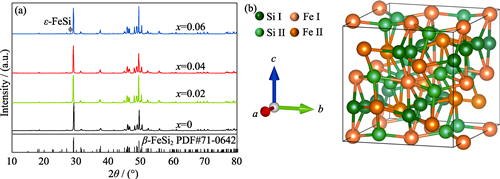

Preparation and Thermoelectric Transport Properties of P-doped β-FeSi2

CHENG Jun, ZHANG Jiawei, QIU Pengfei, CHEN Lidong, SHI Xun

2024 Vol. 39 (8): 895–902

Abstract

Abstract(

229 )

HTML

HTML(

8)

PDF

PDF(3162KB)(

217

)

β-FeSi2, an environmentally friendly and high temperature oxidation-resistant thermoelectric material, has potential applications in the field of industrial waste heat recovery. Previous studies have shown that phosphorus (P), an ideal n-type dopant in the silicon (Si) site of β-FeSi2, can easily lead to the formation of a secondary phase, thereby limiting the enhancement of thermoelectric performance. In this study, a series of FeSi2-xPx (x=0, 0.02, 0.04, 0.06) samples were synthesized using an induction melting method, which greatly inhibited the formation of the secondary phase. Then, the influence of P doping on the electrical and thermal transport properties of β-FeSi2 was studied. The results indicate that the solubility limit of P in β-FeSi2 is about 0.04, consistent with earlier theoretical predictions based on the defect formation energy. It is also discovered that P doping enhanced the thermoelectric performance of β-FeSi2, culminating in an optimal figure of merit (ZT) of FeSi1.96P0.04 approximately 0.12 at 850 K, which is much higher than the previous results (ZT about 0.03 at 673 K). However, compared to β-FeSi2 doped with other n-type elements like cobalt (Co) and iridium (Ir), which can achieve carrier concentrations up to 1022 cm-3, P-doped β-FeSi2 exhibits lower carrier concentrations, with the highest of only 1020 cm-3. This results in a weaker electron-phonon scattering effect, which in turn constrains the overall enhancement of the thermoelectric performance. If the carrier concentration could be further increased, the thermoelectric performance of the material is expected to evolve significantly.

|

|

|

Interface Layer of Te-based Thermoelectric Device: Abnormal Growth and Interface Stability

MIAO Xin, YAN Shiqiang, WEI Jindou, WU Chao, FAN Wenhao, CHEN Shaoping

2024 Vol. 39 (8): 903–910

Abstract

Abstract(

150 )

HTML

HTML(

4)

PDF

PDF(5981KB)(

175

)

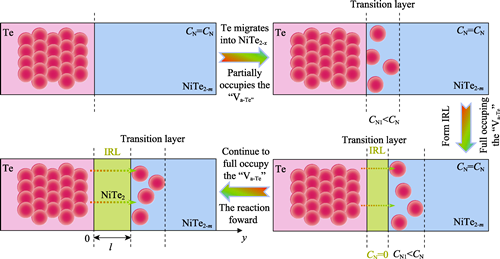

Though Te has excellent figure of merit (ZT), the severe element diffusion and reaction at the Te/metallic-electrodes interface render high contact resistivity (ρc) and low device conversion efficiency (η). Therefore, it is critical to develop suitable barrier layers for optimizing the bonding between Te and metallic electrodes. In this work, an appropriate barrier layer, NiTe2-m (NixTe (x=0.500~0.908)), was screened based on gradient structure. No reaction layers and defects at the interface of Ni0.5Te/Te0.985Sb0.015/Ni0.5Te were detected before and after aging at 473 K. Low ρc (less than 10 μΩ·cm2) and high η (about 75% of the theoretical value under a temperature difference of 180 K (hot end: 473 K)) were achieved and maintained stable during aging, showing excellent thermal stability of the interface. When x>0.500, the thickness of the interface reaction layer decreased with x increasing, showing the retarding effect dominating the growth behavior of interface reaction layer not from the usual thermodynamic factors, such as interface reaction energy and composition gradient, but from the “atom vacancy” on formation of the reaction layer.

|

|

|

High Stability/Catalytic Activity Co-based Perovskite as SOFC Anode: In-situ Preparation by Fuel Reducing Method

PAN Jianlong, MA Guanjun, SONG Lemei, HUAN Yu, WEI Tao

2024 Vol. 39 (8): 911–919

Abstract

Abstract(

153 )

HTML

HTML(

5)

PDF

PDF(1813KB)(

290

)

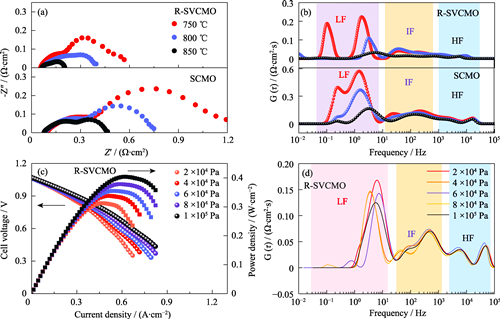

Taking inspiration from the in-situ reduction technique employed for exsolved nano-metal as anodes in solid oxide fuel cells (SOFCs), this study utilized Sr2V0.1Co0.9MoO6, which was synthesized in an ambient air environment, with perovskites of other phases to co-fire with the electrolyte under atmospheric conditions for direct fabrication of a single cell. By this way, the procedure of subjecting the cell to harsh preparative conditions in a reducing/inert atmosphere to prevent its anodic oxidation can be circumvented. After preparation of the anode precursor on the electrolyte sheet, we adopted a simple process of in-situ reduction at 750 ℃ for 4 h on the fuel side to achieve formation of a pure phase Sr2V0.1Co0.9MoO6 (R-SVCMO) as anode. The results demonstrate a significant reduction in the activation energy of R-SVCMO, accompanied by an increase in conductivity from 2.7 to 21.6 S•cm-1. Moreover, when employing R-SVCMO as anode in a single cell with H2 and wet CH4 as fuel gases, the maximum power density (Pmax) at 850 ℃ can reach up to 862 and 514 mW·cm-2, respectively, showcasing exceptional catalytic performance. The anodes before and after reduction exhibit average thermal expansion coefficient (TEC) of 1.15×10-5 and 1.23×10-5 K-1, respectively, within the temperature range of 100-850 ℃, comparable to those observed in conventional SOFC electrolytes. Therefore, the reduction process does not induce any volumetric changes in the anode layer, significantly enhancing its structural stability. Meanwhile, degradation rate of only 0.13% is occurred. It is worth noting that this R-SVCMO synthesis method can result in remarkable long-term stability and high catalytic activity as an anode material. The obtained R-SVCMO can achieve a 60% catalytic efficiency for wet CH4 and last for 1450 h. Based on this R-SVCMO, the single cell can maintain stability for 450 h at 0.7 V. In conclusion, this study demonstrates an effective way of employing an in-situ fuel reduction method to prepare a single cell with exceptional electrochemical performance and structural stability.

|

|

|

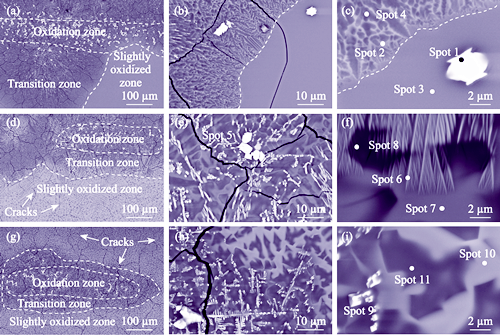

Oxidation Behavior and Meso-macro Model of Tubular C/SiC Composites in High-temperature Environment

QUAN Wenxin, YU Yiping, FANG Bing, LI Wei, WANG Song

2024 Vol. 39 (8): 920–928

Abstract

Abstract(

128 )

HTML

HTML(

7)

PDF

PDF(6815KB)(

148

)

Oxidation damage is one of the main factors affecting the life of C/SiC composite nozzle used in rocket engines. To accurately predict the oxidation damage of C/SiC composite nozzle, we explored the oxidation behavior of the tubular C/SiC composites which had a similar shape to nozzle. Evolution of their composition, structure, and mechanical properties was investigated at different temperatures ranging from 900 to 1300 ℃. The results showed that the tubular C/SiC composites exhibited diffusion-controlled oxidation characteristics under the high-temperature environment. Their mass and residual strength decreased as a power function with time, and decline rate was positively correlated with temperature. Moreover, based on the theory of oxidation kinetics and mass transfer, a macro-meso oxidation model was established to simulate the oxidation process of tubular C/SiC composites in high-temperature environment to timely predict the evolution of their mass and residual strength. Consequentely, all the predicted results of the model fitted well with the experimental data. Our investigation consolidate that this macro-meso oxidation model is powerfull to predict the oxidation behavior and the life-span of C/SiC composite nozzle.

|

|

|

Preparation of Y2O3 Coating by Suspension Plasma Spraying and Its Resistance to Plasma Etching

MA Wen, SHEN Zhe, LIU Qi, GAO Yuanming, BAI Yu, LI Rongxing

2024 Vol. 39 (8): 929–936

Abstract

Abstract(

151 )

HTML

HTML(

4)

PDF

PDF(11857KB)(

163

)

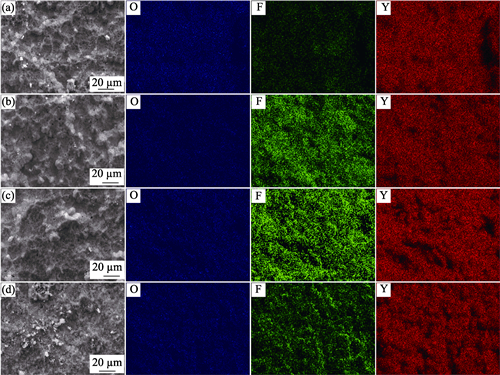

With the fierce competition of high-end chips, Y2O3 coating is an important component of plasma etching cavity, corresponding research gradually becomes a research hotspot. Y2O3 coating was prepared on aluminum alloy surface by suspension plasma spraying (SPS). The effects of different process parameters on the phase composition, mechanical properties, microstructure, and dielectric strength of the coating were studied. The effect of microscopic porosity of Y2O3 coating on etching rate was analyzed after etching in CF4/Ar/O2 mixture for 30, 60 and 120 min, respectively. The microhardness, the porosity, the bonding strength, and the dielectric strength of Y2O3 coating prepared by the optimal process 1 (spraying distance 80 mm, liquid feed rate 35 mL/min, atomizing gas flow rate 15 L/min, horizontal gun moving speed 700 mm/s, vertical moving step 1 mm/step) is (3.78±0.36) GPa, (2.35±0.24)%, (36.0±3.6) MPa, and (29.74±2.01) kV/mm, respectively. In the mixed plasma gas composed of CF4/Ar/O2, the Y2O3 coating undergoes physical and chemical reactions, while Ar+ strongly shocks and bombards the coating to break the chemical bond on the surface. CF2* and F* make Y2O3 continuously etched to form YF3 attaching to the coating surface. At the same time, the physical impact of Ar+ constantly acts on the surface of the coating, removing the YF3 layer, and a small amount of residual YF3 on the surface of the coating is oxidized and finally forms YOF, resulting in a coating etching rate as low as (11.48±5.21) nm/min. Y2O3 coating with high density, low porosity and high uniformity can effectively improve the resistance of parts to plasma etching, which is of great significance in semiconductor industry.

|

|

|

ZIF-8/TiO2 Composite Mesocrystals: Preparation and Photocatalytic Activity

MA Binbin, ZHONG Wanling, HAN Jian, CHEN Liangyu, SUN Jingjing, LEI Caixia

2024 Vol. 39 (8): 937–944

Abstract

Abstract(

182 )

HTML

HTML(

6)

PDF

PDF(1883KB)(

181

)

Microstructure, particle size and specific surface area of TiO2 are crucial factors influencing its photocatalytic activity. Mesocrystals represent a type of superstructural material formed by inorganic nanoparticles aligned along a common crystallographic axis, holding significant research potential in the field of photocatalysis. This study employed ammonium hexafluorotitanate and boric acid as titanium precursor and fluorine ion scavenger, respectively, and used a blend of anhydrous ethanol and deionized water as reaction medium. NH4TiOF3 mesocrystals precursors were prepared by a facile green method. Subsequently, washing with boric acid solution enabled the transformation of NH4TiOF3 mesocrystals into TiO2 mesocrysals through topotaxial conversion. Ultimately, the TiO2 mesocrystals were functionalized with ZIF-8 nanoparticles, and the photocatalytic degradation activity of the obtained ZIF-8/TiO2 composite mesocrystals was studied. The experimental results shows that ZIF-8 nanoparticles can uniformly nucleate on the surface of TiO2 mesocrystals, resulting in a relatively dense coating layer. ZIF-8/TiO2 composite photocatalyst exhibits a higher specific surface area and a narrower band gap. Meanwhile, the separation efficiency of photogenerated electrons and holes is also improved to a certain extent. Notably, the sample M-TiZIF-2 (with addition of 4 mmol Zn(NO3)2) demonstrated superior photocatalytic activity, and achieved a first-order reaction rate of 42-fold that of TiO2 mesocrystals and 16-fold that of pristine ZIF-8 nanoparticles. In conclusion, the synergistic effect of ZIF-8 nanoparticles and TiO2 mesocrystals significantly augments the photocatalytic performance of the ZIF-8/TiO2 composite mesocrystal materials.

|

|

|

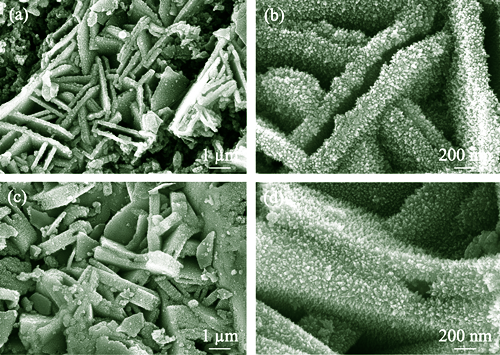

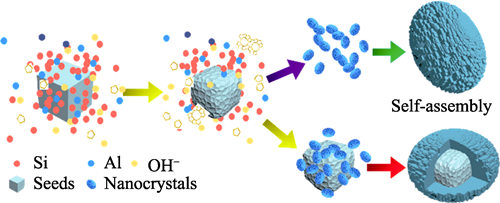

Polycrystalline ZSM-5 Aggregates Induced by Seed and Catalytic Performance in Methanol to Hydrocarbon

WANG Xuchang, JIAO Chuyu, JI Zhuo, JIAO Qirui, QIN Bo, DU Yanze, ZHENG Jiajun, LI Ruifeng

2024 Vol. 39 (8): 945–954

Abstract

Abstract(

149 )

HTML

HTML(

4)

PDF

PDF(6362KB)(

59

)

Synthesis of ZSM-5 zeolite typically utilizes small molecule polyamines or quaternary ammonium salts as organic structure guiding agent (OSDA). By contrast, the OSDA-free hydrothermal synthesis system eliminates the use of organic templates and the subsequent calcination procedure. This not only reduces the cost of synthesis, but also prevents environmental pollution from the combustion of organic templates, representing an eco-friendly approach. Despite this, literature suggests that even so-called template-free synthesis systems often involve trace amount of organic substances like alcohol. In the present work, a calcined commercial ZSM-5 zeolite was served as seed, with sodium aluminate as aluminum source and silica sol as silicon source, ensuring an entirely template-free synthesis system. Polycrystalline ZSM-5 aggregates consisted of rod-like nanocrystals were successfully prepared in the completely OSDA-free system. Effects of the Si/Al ratio in ZSM-5 seed, dosage and crystallization conditions such as crystallization temperature and crystallization time on ZSM-5 synthesis were investigated. The results show that a highly crystallinity ZSM-5 aggregate consisting of primary nano-sized crystals less than 100 nm is produced from a gel precursor with 5.6% (in mass) seed after hydrothermal treatment for 48 h. Furthermore, the Si/Al ratio in ZSM-5 seed has little effect on the topological structure and pore structure of the synthesized samples. However, the seeds with a low Si/Al ratio facilitate faster crystallization of zeolite and enhance the acidity, especially the strong acid centers, of the catalyst. The catalytic performance of the synthesized polycrystalline ZSM-5 was evaluated during dehydration of methanol and compared with a commercial reference ZSM-5r. The results exhibit that as compared with the reference catalyst, the fabricated sample has a longer catalytic lifetime (16 h vs 8 h) attributed to its hierarchical pores derived from the loosely packed primary nanoparticles. Additionally, the prepared polycrystalline catalyst also exhibits a higher aromatics selectivity (28.1%-29.8% vs 26.5%).

|

|

|

Microstructure and Oxidation Behavior of ZrB2-SiC Ceramics Fabricated by Tape Casting and Reactive Melt Infiltration

TAN Min, CHEN Xiaowu, YANG Jinshan, ZHANG Xiangyu, KAN Yanmei, ZHOU Haijun, XUE Yudong, DONG Shaoming

2024 Vol. 39 (8): 955–964

Abstract

Abstract(

157 )

HTML

HTML(

11)

PDF

PDF(14093KB)(

103

)

ZrB2-based ceramics typically necessitate high temperature and pressure for sintering, whereas ZrB2-SiC ceramics can be fabricated at 1500 ℃ using the process of reactive melt infiltration with Si. In comparison to the conventional preparation method, reactive synthesis allows for the more facile production of ultra-high temperature ceramics with fine particle size and homogeneous composition. In this work, ZrSi2, B4C, and C were used as raw materials to prepare ZrB2-SiC via combination of tape casting and reactive melt infiltration herein referred to as ZBC ceramics. Control sample of ZrB2-SiC was also prepared using ZrB2 and SiC as raw materials through an identical process designated as ZS ceramics. Microscopic analysis of both ceramic groups revealed smaller and more uniformly distributed particles of the ZrB2 phase in ZBC ceramics compared to the larger particles in ZS ceramics. Both sets of ceramics underwent cyclic oxidation testing in the air at 1600 ℃ for a cumulative duration of 5 cycles, each cycle lasting 2 h. Analysis of the oxidation behavior showed that both ZBC ceramics and ZS ceramics developed a glassy SiO2-ZrO2 oxide layer on their surfaces during the oxidation. This layer severed as a barrier against oxygen. In ZBC ceramics, ZrO2 is finely distributed in SiO2, whereas in ZS ceramics, larger ZrO2 particles coexist with glassy SiO2. The surface oxide layer of ZBC ceramics maintains a dense structure because the well-dispersed ZrO2 increases the viscosity of glassy SiO2, preventing its crystallization during the cooling. Conversely, some SiO2 in the oxide layer of ZS ceramics may crystallize and form a eutectic with ZrO2, leading to the formation of ZrSiO4. This leads to cracking of the oxide layer due to differences in thermal expansion coefficients, weakening its barrier effect. An analysis of the oxidation resistance shows that ZBC ceramics exhibit less increase in oxide layer thickness and mass compared to ZS ceramics, suggesting superior oxidation resistance of ZBC ceramics.

|

|