|

|

Structural Ceramics—the Cornerstone of Human Civilization

DONG Shaoming, WANG Jingyang, NI Dewei

2024 Vol. 39 (6): 569–570

Abstract

Abstract(

223 )

HTML

HTML(

16)

PDF

PDF(227KB)(

238

)

Ceramics are one of the earliest synthetic materials in human civilization, which is originated in China. They represent not only the nation's glory but also the testament to the wisdom and innovation of her people. After millennia, ceramics have evolved into a vital material system encompassing both traditional and advanced varieties, with structural ceramics holding a key position. Their high-temperature resistance, corrosion resistance, and superior mechanical properties endow them indispensable in harsh environments where metals and polymers are still in struggle, underscoring their role as a cornerstone of modern technological progress. Ceramic matrix composites have mitigated the brittleness of structural ceramics, garnering global attention for their irreplaceable advantages, particularly in extreme conditions like ultra-high temperatures, intense radiation, and severe corrosion, across sectors such as aerospace, transportation, and advanced nuclear energy.

Despite peaking in the 1980s with innovations like ceramic engines and high-performance cutting tools, the development of structural ceramics encountered a slump due to limitations in fabrication techniques and reduced industrial demand. Nevertheless, persistent research efforts have led to significant advancements, broadening application scope of these materials.

Invited by Journal of Inorganic Materials, we have curated the special issue of “Frontiers of Structural Ceramics” featuring contributions from eminent domestic research groups, including Northwestern Polytechnical University, Wuhan University of Technology, Harbin Institute of Technology, Nanjing University of Aeronautics and Astronautics, Beihang University, National University of Defense Technology, Jilin University, Northeastern University, Zhengzhou University, Chang’an University, Institute of Metal Research, Chinese Academy of Sciences, and Shanghai Institute of Ceramics, Chinese Academy of Sciences, etc. The special issue is delving into the design, preparation, simulation, performance evaluation, and exploration for damage mechanisms of new structural ceramics.

We aim for this publication to deepen researchers’ insights into structural ceramics, provide a platform for exploring recent advancements, and foster the progression of the field. We extend our heartfelt gratitude to the experts who contributed despite their busy schedules, acknowledging their dedication and support that made this publication possible.

|

|

|

Research Progress on Ultra-high Temperature Ceramic Composites

ZHANG Xinghong, WANG Yiming, CHENG Yuan, DONG Shun, HU Ping

2024 Vol. 39 (6): 571–590

Abstract

Abstract(

768 )

HTML

HTML(

47)

PDF

PDF(21049KB)(

759

)

In response to the evolving landscape of high-speed aircraft, characterized by an expansive airspace, prolonged flight durations, and increased velocities, the thermal protection requirements for key structures such as the nose cone, leading edge, and engine combustion chamber have become more exacting. This necessitates a concerted focus on the development of high-performance thermal protection materials capable of withstanding extreme conditions. Ultra-high temperature ceramic composites have emerged as noteworthy candidates, showcasing exceptional oxidation and ablation resistance. Despite their commendable properties, the inherent brittleness of these composites poses a significant obstacle to widespread engineering applications. To address this limitation, there is a growing emphasis on toughening through structural modulation. Simultaneously, the imperative to enhance aircraft payload capacity underscores the demand for lightweight ultra-high temperature ceramic composites. This paper provides a systematic overview of the major research advances made in recent years on ultra-high temperature ceramic composites, including preparation methods such as pressure sintering, slurry infiltration, precursor impregnation and pyrolysis, reactive melt infiltration, chemical vapor infiltration/deposition, and “solid-liquid” combination process, toughening methods such as particles, whiskers, soft-phase materials, short-cut fibers, and continuous fibers, as well as oxidation ablation resistant properities and mechanisms, and lightweighting design. The relationship between the components, microstructures and properties of ultra-high temperature ceramic composites is discussed in depth, and the current challenges as well as the future development trends of ultra-high temperature ceramic composites are presented.

|

|

|

Research Progress of High-entropy Carbide Ultra-high Temperature Ceramics

CAI Feiyan, NI Dewei, DONG Shaoming

2024 Vol. 39 (6): 591–608

Abstract

Abstract(

591 )

HTML

HTML(

23)

PDF

PDF(24425KB)(

585

)

The development of high-speed flight technology has put forward an urgent demand for high- performance thermal structure materials. High-entropy carbides (HECs) ceramics are a fast-emerging family of materials that combine the excellent properties of high-entropy ceramics and ultra-high temperature ceramics. HECs have a broad application prospect in extreme service environments, which has received extensive attention from scholars in recent years. Compared with traditional ultra-high temperature carbides containing only one or two transition metal elements, HECs have a greater potential for development because of their improved comprehensive performance and greater designability of composition and properties. After successive exploration of HECs in recent years, researchers have obtained many interesting results, developed a variety of preparation methods, and gained comprehensive understanding of microstructure and properties. The basic theories and the laws on HECs obtained from experimental process are reviewed in this paper. Preparation methods of HECs including powders, blocks, coatings and films, as well as fiber-reinforced HECs-based composites are summarized. Research progress on the properties of HECs, such as the mechanical properties, thermal properties, and especially the oxidation and ablation resistance related to high-temperature applications, is reviewed and discussed. Finally, the scientific issues that need to be further explored in this area are emphasized, and the prospects are proposed.

|

|

|

Research Progress on In-situ Monitoring of Damage Behavior of SiCf/SiC Ceramic Matrix Composites at High Temperature Environments

WU Xiaochen, ZHENG Ruixiao, LI Lu, MA Haolin, ZHAO Peihang, MA Chaoli

2024 Vol. 39 (6): 609–622

Abstract

Abstract(

330 )

HTML

HTML(

16)

PDF

PDF(5747KB)(

605

)

Continuous SiC fiber-reinforced SiC (SiCf/SiC) composites possess high specific strength, high specific modulus, high-temperature resistance, and radiation resistance, making them suitable for applications in hot-end parts of advanced aero-engines and claddings of nuclear reactors. SiCf/SiC composites are composed of fibers, interfaces and matrix, endowing them with complex multi-scale structural characteristics. These composites are designed to serve in harsh environment, and their damage and failure process are complex. A profound understanding and accurate analysis of damage and failure mechanisms of SiCf/SiC composites under service environments are of great significance for the optimized design of materials and the reliable service of components. Traditional “post-mortem analysis” methods are incapable of acquiring data during the damage and failure process of materials under complex service environments. Therefore, there is an urgent need to develop in-situ characterization techniques for composites under high-temperature service environments. This paper reviewed the principles, advantages, and limitations of in-situ monitoring methods based on scanning electron microscopy, digital image correlation, micro computational tomography, acoustic emission, and electrical resistance. It focused on the latest research progress in the high-temperature mechanical characterization of SiCf/SiC composites using various in-situ monitoring methods and combinations thereof. It summarized the challenges in the in-situ monitoring technologies of SiCf/SiC composites under high-temperature environments and provided a preliminary outlook on the future development directions, such as the combined use of multiple in-situ monitoring techniques, new detection technologies like terahertz radiation, and in-situ damage monitoring methods for complex components.

|

|

|

Research Progress of Ceramic Matrix Composites Prepared by Improved Reactive Melt Infiltration through Ceramization of Porous Carbon Matrix

ZHAO Rida, TANG Sufang

2024 Vol. 39 (6): 623–633

Abstract

Abstract(

263 )

HTML

HTML(

19)

PDF

PDF(6748KB)(

437

)

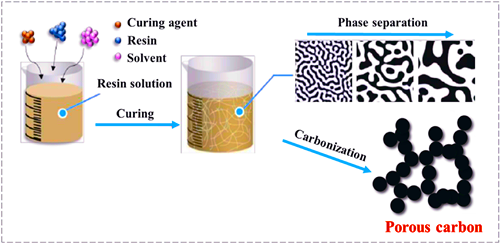

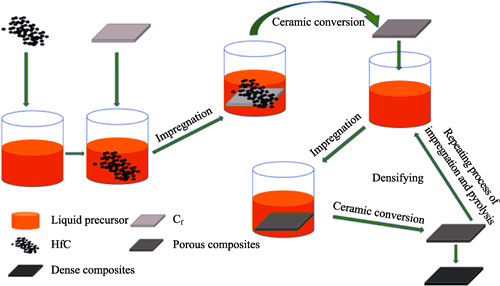

Owing to the high strength/toughness and excellent anti-oxidation ability, continuous fiber reinforced ceramic matrix composites have become the preferred candidates for high temperature structural materials in aerospace field. Reactive melt infiltration can achieve the large-scale, short-cycle and low-cost production of ceramic matrix composites, which has been widely considered to be one of the most promising technologies from a commercial perspective. However, the mechanical and anti-oxidation/ablation properties of obtained composites prepared by conventional reactive melt infiltration are not satisfactory due to the existence of residual carbon and corroded fibers. In order to address the problems, relevant researchers constructed porous carbon matrix to replace conventional densified structure to promote its ceramic transformation and the consumption of reactive melt, thus achieving the improved performance of ceramic matrix composites. This paper reviewed the research progress about the preparation of SiC ceramics, SiC/SiC composites, C/SiC composites, and ultra-high temperature ceramic matrix composites by porous carbon ceramization strategy. Besides, the superiority of the method was verified compared to conventional reactive melt infiltration. The development of preparation methods for porous carbon matrix was also summarized. Finally, in term of the requirements of basic theory and technology for advanced ceramic matrix composites, the prospect for the future development of improved reactive melt infiltration to prepared ceramic matrix composites was discussed.

|

|

|

Research Progress of High Thermal Conductivity Silicon Nitride Ceramics Prepared by Non-oxide Sintering Additives

WANG Weiming, WANG Weide, SU Yi, MA Qingsong, YAO Dongxu, ZENG Yuping

2024 Vol. 39 (6): 634–646

Abstract

Abstract(

320 )

HTML

HTML(

11)

PDF

PDF(12175KB)(

470

)

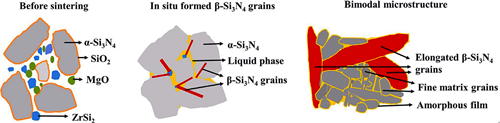

The development trend of high voltage, high current and high-power density of power semiconductor devices has raised the requirement for the heat dissipation capability and reliability of ceramic substrates in devices. Silicon nitride (Si3N4) ceramics, known for their high thermal conductivity and excellent mechanical properties, have emerged as a preferred thermal dissipation substrate material for high-power electronic devices. However, there is a significant gap between experimental and theoretical values of thermal conductivity in Si3N4 ceramics. The long period of heat preservation during preparation leads to excessive grain growth, compromising mechanical properties and increasing costs, which hinders large-scale application. Lattice oxygen defects act as main factor limiting thermal conductivity of Si3N4 ceramics. Now, researchers are exploring ways to promote removal of lattice oxygen and full development of bimodal morphology formation of Si3N4, by selecting non-oxide sintering additives to reduce the oxygen content in the system, adjusting the composition and properties of the liquid phase, constructing a “nitrogen-rich-oxygen-deficient” liquid phase, and regulating the dissolution and precipitation process in the liquid phase. These efforts aim to the synergistic optimization of thermal conductivity-mechanical properties of Si3N4 ceramics. Based on the elemental classification, we review the non-oxide sintering additives developed at domestic and abroad, explain how they improve the thermal conductivity of Si3N4 ceramics from liquid-phase modulation and microscopic morphology control, analyze the grain development and morphology evolution laws, and discusse the mechanism of lattice oxygen removal. The out look on future development of high thermal conductivity Si3N4 ceramics is also prospected.

|

|

|

Progress of Damage Coupling Mechanism and Integrated Design Method for CMC-EBC

FANG Guangwu, XIE Haoyuan, ZHANG Huajun, GAO Xiguang, SONG Yingdong

2024 Vol. 39 (6): 647–661

Abstract

Abstract(

181 )

HTML

HTML(

9)

PDF

PDF(7626KB)(

222

)

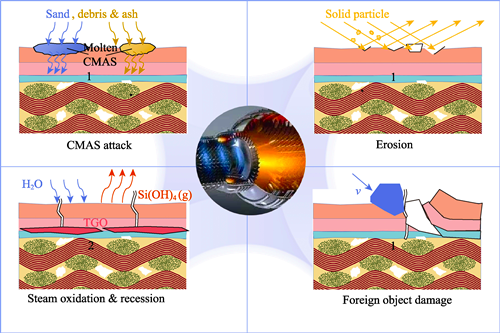

The integration of ceramic matrix composites with environmental barrier coatings (CMC-EBC) represents the most promising thermal structural material system in the aerospace field. This paper provides an overview of the advancements in research on the failure mechanisms and numerical models of CMC-EBC. It commences with a concise review of the evolution and primary fabrication techniques of CMC-EBC material system. Subsequently, it summarizes the typical damage modes and failure mechanisms of CMC-EBC under operational conditions, identifying that the interplay between the CMC preform structure, porosity defects, and EBC inner cracks is a critical determinant of the material’s lifespan. However, current mechanistic studies are chiefly focused on the performance evaluation of the coating itself and its susceptibility to environmental factors, disregarding the synergistic effects of the coating and composite architecture during damage progression. This review proceeds with an examination of the history and current status of research on failure simulation and prediction models for CMC-EBC, highlighting issues related to modeling environmental factors and simulating coupled damage evolution. Though much effort has directly developed separate failure models for CMC and EBC, predicting the failure of CMC-EBC components should account for the coupling effects between damage evolution and microstructure. In conclusion, this review offers a perspective on development and service performance prediction methods for CMC-EBC system, which points out that considering the interdependent failure modes of the CMC substrate and EBC is pivotal. Integrated design and analysis of structural and functional aspects are emerging trends in CMC-EBC component research.

|

|

|

Design, Fabrication and Properties of Periodic Ordered Structural Composites with TiB-Ti Units

SUN Haiyang, JI Wei, WANG Weimin, FU Zhengyi

2024 Vol. 39 (6): 662–670

Abstract

Abstract(

172 )

HTML

HTML(

12)

PDF

PDF(7529KB)(

240

)

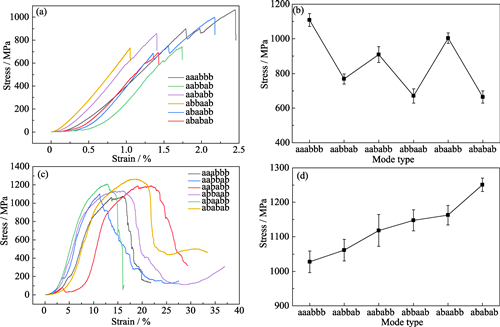

High-performance structural material components are widely researched because of their curcial applications in aerospace, transportation and automotive, electronic information, metallurgy, and other fields. Traditional methods for enhancing the overall performance of structural material components mainly include improving intrinsic material properties and optimizing structural composite design. However, research on enhancing the intrinsic mechanical properties of single structural materials is reaching its limits. This study aims to explore a new paradigm for the development of high-performance structural composites by proposing the concept of periodic ordered structural materials and preparing the structural composites with improved overall properties through integrated sintering. The TiB-Ti functional unit with high hardness of ceramics and strong toughness of metal was structured through periodical sequencing, and high-performance TiB-Ti structural composites with different periodical sequencing modes were designed and prepared. On this basis, the mechanical properties of these structures were investigated, and their fracture modes were analyzed to understand how different ordering modes affect the overall properties of the materials. The results show that periodic ordered structure can improve the overall performance of materials by altering their macroscopic fracture modes and stress distribution properties. This new paradigm of research provides valuable insights and guidance for the structural design and performance breakthrough of other structural composites. Future research may focus on the exploration of the complexity of the periodic ordered structure modes, identifying potential application scenarios for these materials, and conducting additional performance testing studies.

|

|

|

CMAS Corrosion Resistance of Y3Al5O12/Al2O3 Ceramic Coating Deposited by Atmospheric Plasma Spraying

LI Jie, LUO Zhixin, CUI Yang, ZHANG Guangheng, SUN Luchao, WANG Jingyang

2024 Vol. 39 (6): 671–680

Abstract

Abstract(

245 )

HTML

HTML(

15)

PDF

PDF(8789KB)(

277

)

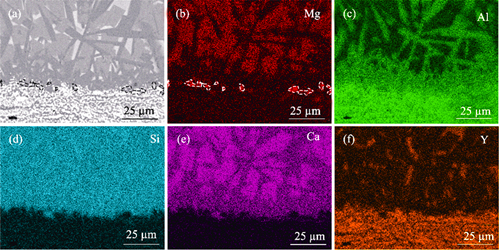

The investigation of novel materials exhibiting exceptional resistance to calcium-magnesium-aluminum- silicate (CMAS) corrosion at temperatures of 1300 ℃ and above has emerged as a pivotal objective in the advancement of environmental barrier coatings for aircraft engines in recent years. In this study, atmospheric plasma spraying (APS) technology was employed to fabricate YAG(Y3Al5O12)/Al2O3 coatings with eutectic composition, which was acknowledged as a promising material possessing outstanding CMAS corrosion resistance, thereby rendering it suitable for application in environmental barrier coatings. The as-deposited coatings were annealed at 1100, 1300, and 1500 ℃ to obtain different microstructures, and the corrosion resistance as well as mechanism of YAG/Al2O3 coatings against CMAS were investigated by comparing the corrosion results after exposure to CMAS at 1300 ℃. The reaction products between YAG/Al2O3 coatings and CMAS were found to be garnet-structure solid solution, CaAl2Si2O8, and Ca2MgSi2O7. The nearly continuous distribution of the garnet-structure solid solution layer at the reaction interface between YAG/Al2O3 coating annealed at 1100 ℃ and CMAS effectively impedes the diffusion of CMAS corrosion elements. For YAG/Al2O3 coating annealed at 1500 ℃, the increase in grain size and decrease in grain boundaries reduce the dissolution rate of the coating. Both of the above can affect the competitive precipitation of various products by influencing the ion transport rate in the corrosion process, and then improve the CMAS corrosion resistance of the coating. Moreover, heat-treatment temperature can tailor grain size, which influences both dissolution-precipitation rate and competitive precipitation of reaction products during CMAS corrosion. These findings provide guidance for selecting appropriate heat-treatment temperature and offer a novel approach to optimize CMAS corrosion resistance of YAG/Al2O3 coatings through microstructure optimization.

|

|

|

Preparation and Wave-absorbing Properties of Polymer-derived SiHfCN Ceramics

ZHANG Yuyu, WU Yicheng, SUN Jia, FU Qiangang

2024 Vol. 39 (6): 681–690

Abstract

Abstract(

169 )

HTML

HTML(

11)

PDF

PDF(4343KB)(

251

)

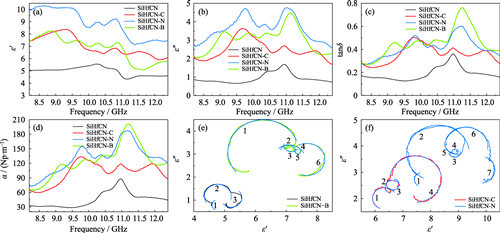

Polymer-derived SiCN ceramics benefiting from advantages of light mass and low coefficient of thermal expansion, have received wide attention in electromagnetic wave absorption field. However, the wave absorptive performance of SiCN ceramics needs to be further improved due to its monomer loss mechanism and insufficient temperature resistance. Enhancing their wave absorptive performance with the aid of multicomponent synergy is a feasible way, but still facing some challenges in preparation and wave absorption. In this work, four types of nanoceramics, SiHfCN, SiHfCN-C, SiHfCN-B, and SiHfCN-N were obtained by single-source modification of polysilazane combining different compounds. The results showed that SiHfCN generated HfO2 and SiO2 for up to 13.5% (in mass) oxygen content in the Hf source, resulting in the minimum reflection loss (RLmin) of only -13.8 dB and the effective absorption bandwidth (EAB) of only 0.42 GHz. Compared to SiHfCN, the co-modification of the Hf-containing polymer with C, B and N sources increased the interface and conductive phases of polymer-derived ceramics, real and imaginary parts of SiHfCN-C, SiHfCN-B, and SiHfCN-N gave rise to 1.4-1.8 and 2.7-3.9 times higher, respectively, with RLmin of -50.6, -57.3 and -63.5 dB, and EAB of 3.53, 3.99 and 4.01 GHz, showing a significant improvement in their wave absorptive properties. The SiHfCN-C inhibited the generation of HfO2 for massive free carbon, which could enhance the conductivity loss. The SiHfCN-B generated B-N and B-C bonds, and precipitated nanorods of HfSiO4 to provide more heterogeneous interfaces, increasing the polarization loss. The SiHfCN-N increased the content of N-C bond due to the introduction of abundant N, enhancing the dipole polarization loss, while the generated carbon nanosheets not only enhanced the conductivity loss but also provided rich interfaces, which improved the impedance matching and amplified the polarization loss, thus exhibiting excellent wave absorptive performance.

|

|

|

Preparation of Sub-micron Spherical Y2O3 Particles and Transparent Ceramics

LIU Yan, QIN Xianpeng, GAN Lin, ZHOU Guohong, ZHANG Tianjin, WANG Shiwei, CHEN Hetuo

2024 Vol. 39 (6): 691–696

Abstract

Abstract(

208 )

HTML

HTML(

11)

PDF

PDF(1644KB)(

483

)

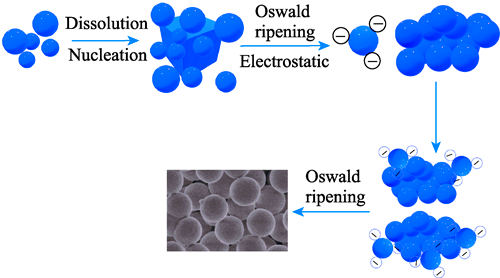

Y2O3 ceramics is widely used as laser medium or optical window due to its excellent physical and chemical properties and high transparency in wide frequency band of 280 nm-8 μm. However, preparation of highly transparent Y2O3 ceramics still remains challenge due to its synthetic precursor and nano-powders difficult to meet the requirements. In this work, a spherical monodispersed and submicron-sized Y2O3 powder was prepared by a homogeneous precipitation method using yttrium nitrate and urea as raw materials. Structure, phase evolution and morphology of Y2O3 precursor and the calcined powder were studied by different methods. The synthesized particle precursor exhibits a sphere morphology with diamension around 330 nm, and Y2O3 powder calcined at 800 ℃ for 2 h shows spherical, well-dispersed and uniformed particles with dimension around 260 nm. Based on this spherical Y2O3 powder, transparent Y2O3 ceramics were fabricated by vacuum sintering at 1780 ℃ using 0.3% (in atom) Nb2O5 as sintering additive. The in-line transmittances of Y2O3 ceramics with thickness of 1 mm reach 76.9% at a wavelength of 1100 nm and 65.6% at a wavelength of 400 nm. In conclusion, this study provides a new promising method for preparing Y2O3 transparent ceramics with excellent properties.

|

|

|

Effect of B4C Content on Mechanical Properties and Oxidation Resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C Ceramics

LIU Guoang, WANG Hailong, FANG Cheng, HUANG Feilong, YANG Huan

2024 Vol. 39 (6): 697–706

Abstract

Abstract(

196 )

HTML

HTML(

14)

PDF

PDF(13244KB)(

216

)

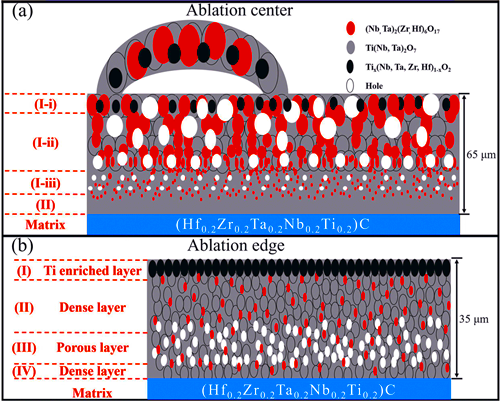

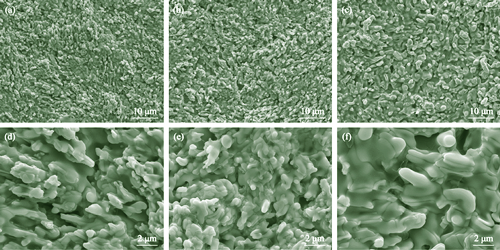

High-entropy boride ceramics (HEBs) consisting of four or more principle metallic elements rapidly develop in recent years due to their outstanding unique physical properties and excellent elevated temperature properties, showing extraordinary promise as potential thermal protection materials applied in extreme environments. However, on the basis of unclear role of each element on their oxidation reaction, HEBs are generally difficult to densify because of their low self-diffusion coefficients and possible sluggish diffusion effect, resulting in limited mechanical properties and low oxidation resistance. In this work, a novel type of HEBs, (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C composites, were prepared by boro/carbothermal reduction method combined with hot-pressing sintering at 1900 ℃. The effect of B4C at the volume fractions ranging from 10% to 30% on the mechanical properties and oxidation resistance of the composites was systematically investigated. Microstructure analyses indicate that homogenously distributed B4C can suppress grain growth of the HEBs matrix and promote toughening mechanisms such as crack deflection and crack branching, consequently resulting in strengthening and toughening composites. When the volume fraction of B4C is 20%, the as-prepared composite shows a high relative density (96.1%) and good mechanical properties with Vickers hardness of (24.6±1.1) GPa, flexural strength of (570.0±27.6) MPa and fracture toughness of (5.58±0.36) MPa·m1/2. In addition, exploration on the oxidation resistance of (Ti0.25Zr0.25Hf0.25Ta0.25)B2-B4C composites at temperatures ranging from 800 ℃ to 1400 ℃ shows that excellent oxidation resistance occurs at the chosen temperatures due to the formation of a dense and continuous oxidation scale, which acts as a barrier layer preventing oxygen inward diffusion. The main compositions of the oxide scale are TiOx, (Zr, Hf)O2 oxides and B2O3 at 800 ℃, while multicomponent oxidation products of (Zr, Hf, Ta)Ox, (Zr, Hf)O2 and TiTaO4 are formed in the oxide scale at 1100 ℃. As the temperature increased to 1400 ℃, thickness of the oxide layer significantly increases due to their volatilization of B2O3, while continuous B2O3 glassy phase plays a crucial role in the oxidation process of HEBs. When the B4C volume fraction not less than 20%, TiTa2O7 and TiO2 which were embedded in B2O3 glass, could effectively insulate inward oxygen and interfacial oxide thickness and enhance oxidation resistance of the composites. In summary, the primary work can be used as a reference to the researches relating to optimizing mechanical properties and oxidation resistance for HEBs.

|

|

|

Fabrication of Boron Carbide Ceramic Composites by Boronic Acid Carbothermal Reduction and Silicon Infiltration Reaction Sintering

ZHENG Yawen, ZHANG Cuiping, ZHANG Ruijie, XIA Qian, RU Hongqiang

2024 Vol. 39 (6): 707–714

Abstract

Abstract(

159 )

HTML

HTML(

10)

PDF

PDF(3552KB)(

235

)

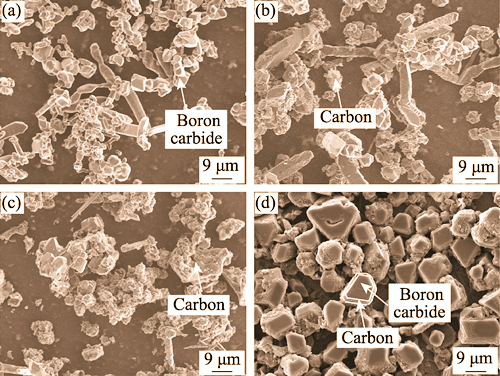

Boron carbide possesses excellent properties and has a wide range of applications, but its production cost is relatively high. To address this issue, boron carbide-C composite powder was directly used, synthesized by carbothermal reduction method, as the raw material without any crushing and purification. Boron carbide composites were prepared through silicon infiltration reaction sintering, yielding material properties comparable to those prepared from commercially available boron carbide powder, which effectively reduced its preparation cost. This study mainly investigated the influence of the molar ratio of carbon to boron in the synthesis of powder on the phase composition, microstructure and properties of boron carbide ceramic composite materials, and explored the toughening mechanism of boron carbide ceramic composites. With the increase of the molar ratio of carbon to boron, the atomic ratio of carbon to boron in the synthesized boron carbide powder increases, as well as the content of free C, which coats the surface of the boron carbide particles at the molar ratio of 2.01. The phase composition of the boron carbide composite materials is B12(C,Si,B)3, SiC and Si. With the increase of carbon-boron molar ratio, the content of boron carbide and free Si in the composite decrease, while the content of SiC, the size of large SiC region, and the number of large SiC regions and SiC nanoparticles increase. Formation of large SiC regions decreases the strength and toughness of the material, while creation of SiC nanoparticles contributes to improvement of strength and toughness. When the carbon to boron molar ratio is 1.35, the composite exhibits the highest flexural strength and fracture toughness, reaching 338 MPa and 4.06 MPa∙m1/2, respectively.

|

|

|

Nitrogen Vacancy Regulated Lattice Distortion on Improvement of (NbMoTaW)Nx Thin Films: Mechanical Properties and Wear Resistance

ZHANG Rui, ZHANG Kan, YUAN Mengya, GU Xinlei, ZHENG Weitao

2024 Vol. 39 (6): 715–725

Abstract

Abstract(

233 )

HTML

HTML(

8)

PDF

PDF(6120KB)(

160

)

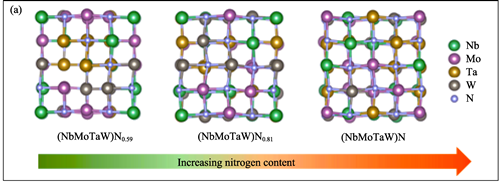

High-entropy transition metal nitrides (HENs) are renowned for their thermal stability, corrosion and oxidation resistance, and exceptional mechanical properties, endowing them suitable for use as surface protection films for structural and moving components. However, mapping relationship between broadly adjustable metal components and mechanical properties of HENs is quite complex due to their diversity of HENs components. Taking (NbMoTaW)Nx thin film as the research object, this study prepared (NbMoTaW)Nx (x = 0, 0.59, 0.80, 0.95) thin films with different nitrogen contents by regulating nitrogen flow velocity during the film growth process based on the magnetron sputtering technique. Following analysis of (NbMoTaW)Nx thin films' composition, structure, morphology, and performance, the primary influence mechanism that govern their mechanical properties were explored. The findings revealed that by manipulating nitrogen vacancy, coordinated regulation over the lattice distortions of the nitrogen and metal sublattices was achieved. Due to high degree of the nitrogen and metal sublattice distortions, the (NbMoTaW)N0.80 sample demonstrated the highest hardness and best wear resistance performance. After excluding factors such as electronic structure, residual stress, and grain size that affect mechanical properties, a direct relationship between lattice distortions and mechanical properties of HENs films was confirmed. In summary, this research has unearthed a straightforward strategy for controlling the lattice distortions, offering a novel approach to adjust and optimize the performance of nitride films, and ultimately providing a more effective solution to address the mechanical damage issues that arise in the context of complex service environments.

|

|

|

Microstructure and Properties of C/HfC-SiC Composites Prepared by Slurry Impregnation Assisted Precursor Infiltration Pyrolysis

SU Yi, SHI Yangfan, JIA Chenglan, CHI Pengtao, GAO Yang, MA Qingsong, CHEN Sian

2024 Vol. 39 (6): 726–732

Abstract

Abstract(

225 )

HTML

HTML(

7)

PDF

PDF(5372KB)(

319

)

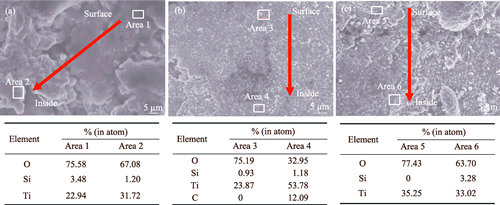

In response to the urgent demand for ultra-high temperature ceramic matrix composites with integrated thermal protection and load-bearing capabilities for high-speed aircrafts, this study prepared stable ceramic slurry from submicron HfC ceramic powder, and utilized the slurry pressure impregnation-assisted precursor infiltration pyrolysis (PIP) process to fabricate C/HfC-SiC composites with uniformly distributed HfC matrix to overcome the shortcomings of the existing reaction-derived HfC precursor, such as high cost, low efficiency, and poor densification effect. The influence of HfC content on the microstructure, mechanical properties, and ablation resistance of composites was investigated. Results showed that the composites had density of 2.20-2.58 g·cm-3 and open porosity of approximately 5% when the actual volume fraction of HfC was in range of 13.1%-20.3%. Utilizing a single layer of carbon cloth to impregnate the ceramic slurry with pressure, HfC particles were able to disperse into the interior of the fiber bundle and distributed relatively evenly in the composites. Increasing the HfC content resulted in reducted fiber content, and decreased mechanical properties of composites. Specifically, when HfC volume fraction was 20.3%, the composites exhibited density, tensile strength and fracture toughness of 2.58 g·cm-3, 147 MPa and 9.3 MPa·m1/2, respectively. Following 60 s of ablation under an oxygen acetylene flame, the composites demonstrated linear ablation rate of 0.0062 mm/s and mass ablation rate of 0.005 g/s. The molten phase HfxSiyOz formed during the ablation process could effectively cover the composites surface and provide protection.

|

|

|

Preparation and Thermal Stability of Ti3SiC2 Ceramics by Polymer Derived Ceramics Method

ZHENG Bin, KANG Kai, ZHANG Qing, YE Fang, XIE Jing, JIA Yan, SUN Guodong, CHENG Laifei

2024 Vol. 39 (6): 733–740

Abstract

Abstract(

174 )

HTML

HTML(

4)

PDF

PDF(4103KB)(

202

)

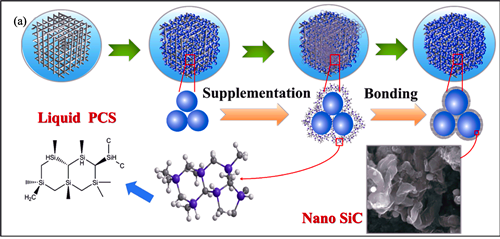

Ti3SiC2 compound can enhance the oxidation resistance of C/C composites as a modifying material, thanks for its superior high-temperature stability, indicating significant potential for applications. In this work, titanium powder and liquid polycarbosilane (LPCS) were served as starting materials for producing Ti3SiC2 ceramics with four different phase contents by polymer derived ceramics (PDC) method at temperatures of 1200, 1300, 1400, and 1500 ℃, respectively. Effects of sintering temperature on the phase compositions and morphology of the ceramics were studied. Additionally, the impact of varying Ti3SiC2 phase contents on oxidation resistance and thermal shock resistance were also explored. The results showed that layered Ti3SiC2 formed at Ti : Si molar ratio of 3 : 1.5 when sintered at 1300, 1400, and 1500 ℃, respectively. After sintered at 1400 ℃, the mass fraction of Ti3SiC2 in the ceramic product reached 92.10% with the bending strength of 172.68 MPa. When subjected to a static air environment of 1300 ℃ for 7 h, the oxidation weight of the ceramics obtained progressively reduction with the increase of Ti3SiC2 phase content. During the oxidation process, a protective film primarily consisted of TiO2 was formed on the surface, which effectively slowed down the oxygen diffusion into the interior. Air thermal shock tests at 1300 ℃ and flexural strength assessments demonstrated that the residual strength of all materials decreased with the increase of thermal shock times. Nevertheless, the thermal shock resistance and residual strength of the samples were enhanced with the increase of Ti3SiC2 phase content. After 30 times thermal shock, the sample with the mass fraction of Ti3SiC2 phase of 92.10% experienced 30.66% weight loss and retained residual strength of 120.18 MPa, primarily due to the layered structure of Ti3SiC2 which is significantly extends the crack propagation path and its superior oxidation resistance.

|

|