|

|

Chemical Vapor Deposition of Vanadium Dioxide for Thermochromic Smart Window Applications

BAO Ke, LI Xijun

2024 Vol. 39 (3): 233–258

Abstract

Abstract(

483 )

HTML

HTML(

37)

PDF

PDF(5895KB)(

591

)

Smart windows have gained tremendous attention because of their ability to dynamically modulate the solar radiation to minimize energy consumption and improve indoor living comfort. Vanadium dioxide (VO2) is one of the most attractive thermochromic materials for energy-saving smart windows due to its reversible metal-to-insulator transition at a critical temperature of ~68 ℃ and accompanying great change of its optical transmittance. However, VO2 itself has a couple of significant limitations as a smart window material: high phase transition temperature (τc), low luminous transmittance (Tlum) and insufficient solar energy modulation ability (ΔTsol). Several methods have been used to grow VO2 thin films with improved properties to meet the specific requirements for smart windows applications. The phase transition temperature (τc) should be reduced to near room temperature, in the meantime luminous transmittance (Tlum) and solar energy modulation ability (ΔTsol) should be high enough for the modulation of indoor temperature self-adapted to seasons and climate. The most common way to reduce τc is by doping. To enhance Tlum and ΔTsol, multilayer structures and/or nanocomposite film have been widely adopted. Chemical vapor deposition (CVD) is a promising technique to produce high quality and highly uniform VO2 thin film with different morphologies in large scale and at low costs. In this paper, various CVD techniques, such as atmospheric pressure chemical vapor deposition (APCVD), aerosol-assisted chemical vapor deposition (AACVD), low-pressure chemical vapor deposition (LPCVD), metal-organic chemical vapor deposition (MOCVD), atomic layer deposition (ALD) and plasma-enhanced chemical vapor deposition (PECVD), are examined with respect to their advantages for VO2 deposition, film quality and the strategies for film quality improvement. Finally, challenges and opportunities for further research and development of VO2 thermochromic films using PECVD technique are emphasized.

|

|

|

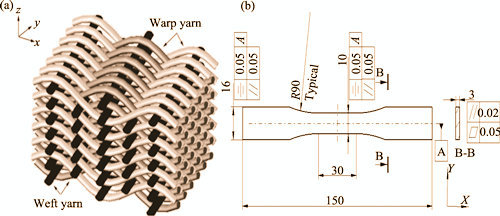

Interfacial Mechanical Properties of the Domestic 3rd Generation 2.5D SiCf/SiC Composite

GUAN Haoyang, ZHANG Li, JING Kaikai, SHI Weigang, WANG Jing, LI Mei, LIU Yongsheng, ZHANG Chengyu

2024 Vol. 39 (3): 259–266

Abstract

Abstract(

417 )

HTML

HTML(

20)

PDF

PDF(3095KB)(

564

)

Continuous silicon carbide fiber reinforced silicon carbide composite (SiCf/SiC) is a critical structural material for the development of next-generation aircraft engines. The interfacial property is one of the important factors determining the material mechanical properties. Therefore, this study characterized the interfacial mechanical properties of domestic third-generation 2.5D SiCf/SiC and investigated its relationship with tensile properties. The residual stress of the 2.5D SiCf/SiC constituents and interfacial sliding stress (IFSS) were quantitatively analyzed by hysteresis characteristics during the cyclic tension loading/unloading test. Statistical distributions of the in-situ fiber strength $({{\sigma }_{\text{fu}}})$ were obtained based on the fracture mirror radius of pull-out fibers. Interfacial shear strength (ISS) and interfacial debonding energy (Gi) were obtained through the push-in method. Results show that combination of macroscopic and microscopic methods can comprehensively describe the interfacial mechanical performance of 2.5D SiCf/SiC from crack initiation to final debonding. The IFSS, ISS, and Gi of 2.5D SiCf/SiC are 56 MPa, (28 ± 5) MPa, and (2.7 ± 0.6) J/m², respectively. Values of ISS and Gi indicate weak interface bonding, causing it susceptible to cracking under shear stress, while the large IFSS suggests that relative fiber sliding is inhibited after interface debonding, hindering fiber pull-out. The obtained interfacial properties can predict the proportional limit stress (${{\sigma }_{\text{PLS}}}$) accurately according to the ACK model. Based on the interfacial properties and the in-situ fiber strength (${{\sigma }_{\text{fu}}}$), the tensile strength of 2.5D SiCf/SiC is predicted to be higher than the experimental value, which is related to the interfacial radial compressive residual stress and residual tensile stress endured by the fiber.

|

|

|

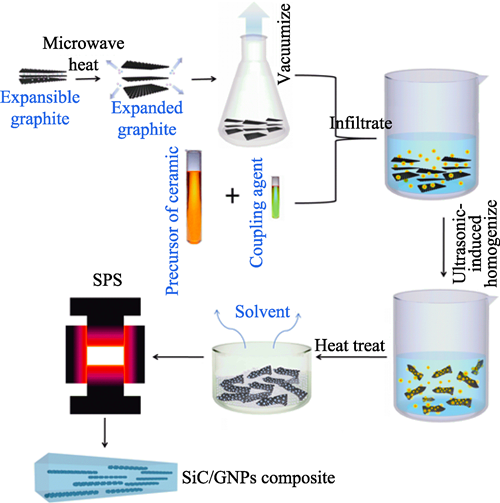

SiC-based Ceramic Materials Incorporating GNPs Array: Preparation and Mechanical Characterization

SUN Chuan, HE Pengfei, HU Zhenfeng, WANG Rong, XING Yue, ZHANG Zhibin, LI Jinglong, WAN Chunlei, LIANG Xiubing

2024 Vol. 39 (3): 267–273

Abstract

Abstract(

279 )

HTML

HTML(

28)

PDF

PDF(5877KB)(

311

)

Silicon carbide ceramics are important engineering materials, but their application is limited by the inherent brittleness. Two-dimensional graphene, with its excellent properties, can be used as a second phase to improve the performance of silicon carbide ceramics. However, due to poor dispersion of graphene in the ceramic matrix, it is a challenge to fully exploit the modifying effect of graphene in composite materials. To address these challenges, SiC-based ceramic materials incorporating graphene nanosheets (GNPs) were synthesized using ceramic organic precursor polycarbosilane and industrial expandable graphite as starting materials. The precursor intercalation technique was employed to fabricate SiC/GNPs ceramic composites with GNPs volume fraction of 1%, 3%, and 5%. The GNPs were uniformly arranged in an array-like parallel fashion in the SiC ceramic matrix, showing excellent orientation. With the GNPs content increasing, the spacing between GNPs within the array decreased, indicating tunable microstructural topology. The addition of GNPs greatly enhanced the fracture toughness of SiC ceramics. When the GNPs content was 3%, the relative density of the samples reached 98.5%, the bending strength reached 445 MPa, and the fracture toughness (KIC value) peaked at 5.67 MPa·m1/2, surpassing pure SiC ceramics by 40%, which was primarily attributed to crack deflection and bridging induced by the GNPs. However, further increase in GNPs content led to a decrease in fracture toughness to 4.37 MPa·m1/2. These SiC-based ceramic composites with a graphene array have potential application in design and development of novel “structure-function integration” SiC-based ceramic devices.

|

|

|

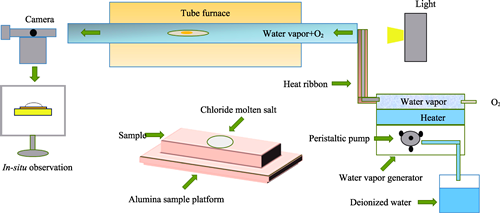

Corrosion Behavior of Si3N4 Ceramic in High-temperature Molten Salt-water Vapor Environment

QIU Zihao, TIAN Zhilin, ZHENG Liya, LI Bin

2024 Vol. 39 (3): 274–282

Abstract

Abstract(

326 )

HTML

HTML(

17)

PDF

PDF(2687KB)(

351

)

Molten salt electrolysis is the key technology for dry reprocessing of spent fuel in the nuclear energy industry. High-temperature molten salt can cause severe corrosion to crucible materials used for spent fuel, so the selection of the crucible material with good resistance to high temperature and corrosion is crucial for the development of the dry reprocessing method. Si3N4 is considered as a promising candidate for the crucible used in dry reprocessing, primarily due to its excellent high-temperature thermal and mechanical properties. However, its resistance to high-temperature molten salts and water vapor has not been fully investigated. In this work, the corrosion behavior of Si3N4 in LiCl-KCl and NaCl-2CsCl molten salt under Ar atmosphere and water vapor (5%H2O-10%O2-85%Ar) was investigated. The results show that in argon atmosphere, Si3N4 undergoes slight grain boundary corrosion in LiCl-KCl molten salt, while NaCl-2CsCl molten salt presents weak corrosion on Si3N4. In 5%H2O-10%O2-85%Ar water vapor environment, LiCl-KCl molten salt prefers to attack the grain boundary phase. Si3N4 shows serious corrosion degradation in the NaCl-2CsCl molten salt compared with the corrosion level in argon atmosphere. The water vapor environment significantly promotes the corrosion of Si3N4 in the molten salt environment, while the grain boundary phase is the most susceptible site for the corrosion of Si3N4. In addition, no direct correlation is found between the wettability and corrosion resistance of LiCl-KCl and NaCl-2CsCl molten salts. Results of this work elucidate the mechanism of high-temperature molten salt-water vapor-induced degradation of Si3N4, offering guidelines for the selection of crucibles in the dry reprocessing of spent fuel.

|

|

|

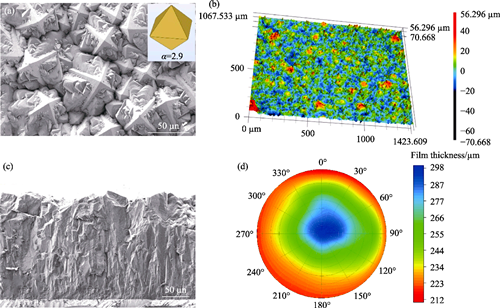

Preparation of 3-inch Diamond Film on Silicon Substrate for Thermal Management

YANG Zhiliang, YANG Ao, LIU Peng, CHEN Liangxian, AN Kang, WEI Junjun, LIU Jinlong, WU Lishu, LI Chengming

2024 Vol. 39 (3): 283–290

Abstract

Abstract(

213 )

HTML

HTML(

9)

PDF

PDF(2703KB)(

329

)

The diamond film material holds great potential as a heat sink for GaN electronic devices. The diamond film layer with low stress, large dimensions, high quality, and an atomically smooth surface is crucial for enhancing the overall heat transfer capacity of GaN devices. This study presents a technique for growing and polishing polycrystalline diamond films on 3-inch(1 inch=2.54 cm) silicon substrates to facilitate the use of large-sized diamond film materials in radiator applications. Firstly, the study carries out multi-physical field self-consistent modelling of plasma in a microwave resonator. It then analyses the feasibility of depositing large diamond films using a microwave plasma chemical vapour deposition (MPCVD) device with a 2.45 GHz multi-mode ellipsoid resonator through simulation technology. The growth process parameters are optimized accordingly. After that, the diamond film is polished to meet the bonding requirements of GaN devices. The simulation results show that under the same microwave power input, the increase of chamber pressure leads to the increase of number density of plasma core electrons and H atoms, but the uniformity of radial distribution becomes worse. Diamond film is deposited under optimized conditions and mensurates that the thickness inhomogeneity of diamond film is 17%. In this process, methane at high concentration leads to pyramidal morphology of diamond grains dominated by (111) planes, accompanied by formation of twins. Full width at half maximum (FWHM) of the first-order characteristic peak of diamond in Raman spectrum is 7.4 cm−1. After polishing, the surface roughness reaches 0.27 nm, the average bending degree of diamond film on silicon substrate is 13.84 μm, and the average internal stress is −40.7 MPa. Silicon substrate diamond wafers with large size, high crystal quality, low internal stress and atomically smooth surface are successfully prepared by the above method.

|

|

|

0.9BaTiO3-0.1Bi(Mg1/2Ti1/2)O3 Ferroelectric Thin Films: Preparation and Energy Storage

LIU Song, ZHANG Faqiang, LUO Jin, LIU Zhifu

2024 Vol. 39 (3): 291–298

Abstract

Abstract(

231 )

HTML

HTML(

10)

PDF

PDF(994KB)(

192

)

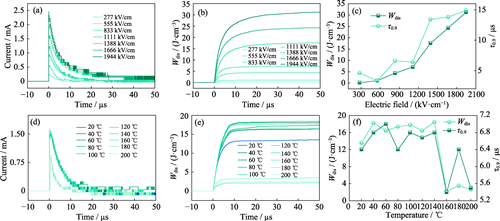

Dielectric thin film, one of the materials of which storage energy in the form of electrostatic field via dielectric polarization, can be widely used in electric equipment, due to their high power density and high charge/ discharge efficiency. Currently, the dielectric energy storage films perform lower energy density and weak temperature stability. In this work, 0.9BaTiO3-0.1Bi(Mg1/2Ti1/2) O3(0.9BT-0.1BMT) ferroelectric thin films were prepared via a Sol-Gel method on Pt/Ti/SiO2/Si substrates and annealed in the range of 700-900 ℃ to realize high energy storage density and wide-temperature stability by introducing BMT. The effect of annealing temperature on phase composition and microstructure was investigated. The results show that denseness of thin films reduce obviously when the annealing temperature is over 750 ℃ and their grain size increases gradually with the increase of treatment temperature. Additionally, the thin films annealed at 750 ℃ display optimized comprehensive feature: room-temperature dielectric constant of ~399, loss tangent of ~5.79% at 1 kHz, and ∆C/C25 ℃ ratio only within ±13.9%. Meanwhile, relaxor value, γ≈1.96 calculated according to Currie-Weiss law consolidates that the thin films possess obvious relaxor characteristics. Results of energy storage shows that the max value of Wrec is ~ 51.9 J/cm3, and the τ0.9 is below 15 μs at pulse charge measure. Moreover, results of temperature stability measurement show Wrec>20 J/cm3, η>65% (1600 kV/cm) and τ0.9<7.2 μs from room temperature to 200 ℃, demonstrating that the film still exists high and stable energy storage under high temperature. Therefore, the ferroelectric thin film 0.9BT-0.1BMT prepared in this work has a promising applications in energy storage under high temperature environment.

|

|

|

Construction and Electrochemical Properties of Yolk-shell Structured FeF3·0.33H2O@N-doped Graphene Nanoboxes

CHENG Jie, ZHOU Yue, LUO Xintao, GAO Meiting, LUO Sifei, CAI Danmin, WU Xueyin, ZHU Licai, YUAN Zhongzhi

2024 Vol. 39 (3): 299–305

Abstract

Abstract(

175 )

HTML

HTML(

11)

PDF

PDF(1465KB)(

215

)

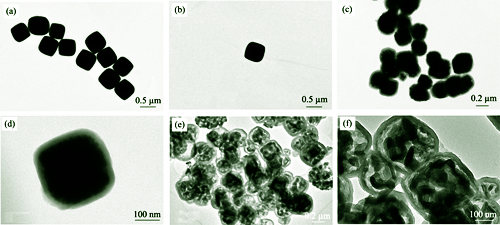

FeF3∙0.33H2O possesses the characteristics of high theoretical capacity and high voltage, but its electrochemical cycling performance is unsatisfactory due to its poor conductivity and serious volume change during redox reaction, resulting in limited application. In this study, by using the strategies of dopamine self-assembly coating, carbonization, HCl etching and HF fluorination, the yolk-shell structured composite FeF3∙0.33H2O@carbon nanoboxes (FeF3∙0.33H2O@CNBs) composed of N-doped graphene shell and nanocube FeF3∙0.33H2O core was synthesized. Its particle size is about 250 nm and thickness of carbon shell is 30-40 nm. FeF3∙0.33H2O@CNBs displays an initial charge-discharge capacity of 208 mAh·g-1 at a current density of 0.2C(1C=237 mA·g-1). After 50 cycles, the capacity remains 173 mAh·g-1, and the capacity attenuation rate per cycle is only 0.3%. In comparison, the initial capacity of bare FeF3∙0.33H2O is 112 mAh·g-1, and after 50 cycles, only 95 mAh·g-1 reserves, indicating superior cycle performance of FeF3·0.33H2O@CNBs. Furthermore, charging and discharging results at 0.1C-1C show that the rate performance is also significantly better than bare FeF3∙0.33H2O. It’s due to that N-doped graphene shell prepared by this strategy provides good electron/ion transport performance. At the same time, the carbon shell can not only buffer and inhibit the volume change of the core FeF3∙0.33H2O, but also shorten the ion migration distance and improve the Li+ migration rate on the electrolyte storage and retention performance of the electrolyte. As a result, the electrochemical performances are better than those of previous literature.

|

|

|

Improvement of Thermoelectric Performance of SnTe by Energy Band Optimization and Carrier Regulation

CHEN Hao, FAN Wenhao, AN Decheng, CHEN Shaoping

2024 Vol. 39 (3): 306–312

Abstract

Abstract(

246 )

HTML

HTML(

29)

PDF

PDF(2123KB)(

249

)

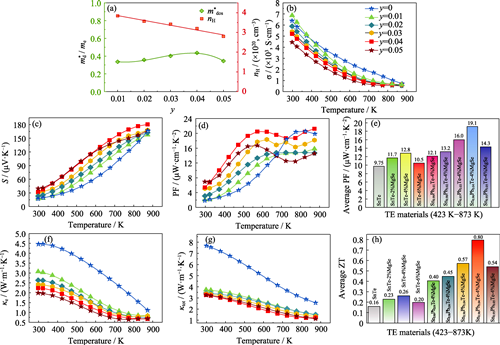

As group ⅣA tellurides, SnTe has the same crystal structure and similar bivalent band structure as PbTe, making it a promising thermoelectric material. However, the main concern of softening at elevated temperature and lower ZT at low temperatures has been hindering its application. Therefore, it is significant to expand the service temperature range of SnTe by improving its average ZT. It has been reported that the thermoelectric performance of SnTe is improved by regulating the power factor and lattice thermal conductivity based on band and lattice engineering. In this study, MgSe alloying strategy was used to prepare a series of Sn1-yPbyTe-x%MgSe(0.01≤y≤0.05, 0≤x≤6) samples by combining melting and Spark Plasma Sintering (SPS) techniques. The results show that alloying MgSe leads to an increase in the band gap, effectively suppressing the bipolar effect of intrinsic SnTe, improving the Seebeck coefficient in the high-temperature range, and reducing lattice thermal conductivity through phonon scattering as well. As a result, ZT at 873 K is improved by 100%. The incorporation of Pb effectively modulates the carrier concentration, successfully suppressing electronic thermal conductivity, and thereby improving average thermoelectric performance of SnTe. Among them, Sn0.96Pb0.04Te-4%MgSe possesses a ZT value of 1.5 at 873 K and an average ZT value of 0.8 at 423-873 K, displaying superior performance compared to literature.

|

|

|

In vitro Antibacterial and Osteogenic Properties of Manganese Doped Nano Hydroxyapatite

LI Chengyu, DING Ziyou, HAN Yingchao

2024 Vol. 39 (3): 313–320

Abstract

Abstract(

207 )

HTML

HTML(

16)

PDF

PDF(8301KB)(

287

)

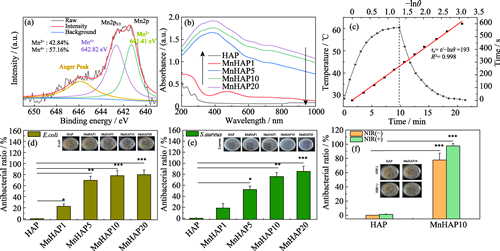

Hydroxyapatite (HAP), as a common bone repair material, still faces the risk of bacterial infection in the treatment of infectious bone defects, whose limited osteogenic properties also hinders its further application. This study used a coprecipitation method to prepare the manganese doped hydroxyapatite nanorod (MnHAP), which exhibited excellent cell biocompatibility, high antibacterial efficiency and osteogenic properties. Antibacterial experiments showed that the inhibition rates of MnHAP10(n(Mn)/n(Ca+Mn)=10%)) against Escherichia coli and Staphylococcus aureus can reach 77.85% and 75.92%, respectively. Moreover, the antibacterial efficiency of MnHAP10 against Escherichia coli can be further enhanced (97.63%) under 808 nm near-infrared light irradiation. Cell proliferation and related osteogenic gene experiments display that MnHAP is beneficial for the proliferation and differentiation of osteoblasts, which improves protein adsorption capacity, stimulates osteogenic activity, and promotes the expression of related osteogenic genes, demonstrating its good biocompatibility. Therefore, MnHAP nanorods are expected to provide a new approach in the treatment of infectious bone defects.

|

|

|

II/Z-type Bi2MoO6/Ag2O/Bi2O3 Heterojunction for Photocatalytic Degradation of Tetracycline under Visible Light Irradiation

YE Maosen, WANG Yao, XU Bing, WANG Kangkang, ZHANG Shengnan, FENG Jianqing

2024 Vol. 39 (3): 321–329

Abstract

Abstract(

167 )

HTML

HTML(

17)

PDF

PDF(7459KB)(

243

)

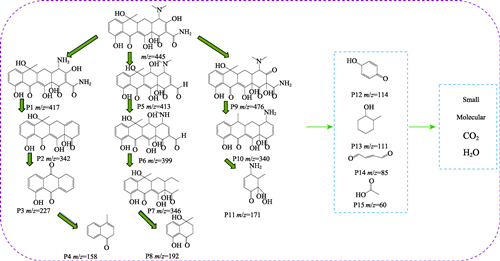

Construction of heterojunction can effectively suppress the swift recombination of photogenerated electrons and holes in photocatalyst. In this study, a II/Z-type Bi2MoO6/Ag2O/Bi2O3 heterojunction photocatalyst was synthesized using a solvothermal method combined with calcination. Various techniques were ultilized to examine the composition, morphology and photoelectrochemical properties of the as-prepared materials. The findings revealed that the optimal composition of the composite material was 25%ABOBM (with a mass ratio of Ag2O/Bi2O3 and Bi2MoO6 of 1 : 4). Under visible light irradiation, the degradation efficiency of tetracycline (TC) by 25%ABOBM reached 85.6%, which was significantly higher than that of Ag2O/Bi2O3 and Bi2MoO6, and maintained its good stability after three cycles of experiments. The enhanced photocatalytic performance of 25%ABOBM is attributed to the formation of heterojunctions and the unique morphologies among Ag2O, Bi2O3 and Bi2MoO6. Both h+ and ·O2- are significant contributors, while ·OH and 1O2 have secondary roles in the degradation process of TC, as indicated by free radical capture experiment and electron paramagnetic resonance spectroscopy (EPR). Furthermore, the related photocatalytic mechanisms were explored, and the potential degradation pathways of TC were analyzed using liquid chromatography-mass spectrometry (LC-MS). This study offers a novel approach to the preparation of photocatalysts with dual heterojunctions and demonstrates their application in the degrading organic pollutants.

|

|

|

Spectroscopic Properties and Optical Clusters in Erbium-doped CaF2, SrF2 and PbF2 Crystals

TAM YU Puy Mang, XU Yu, GAO Quanhao, ZHOU Haiqiong, ZHANG Zhen, YIN Hao, LI Zhen, LÜ Qitao, CHEN Zhenqiang, MA Fengkai, SU Liangbi

2024 Vol. 39 (3): 330–336

Abstract

Abstract(

224 )

HTML

HTML(

14)

PDF

PDF(1997KB)(

225

)

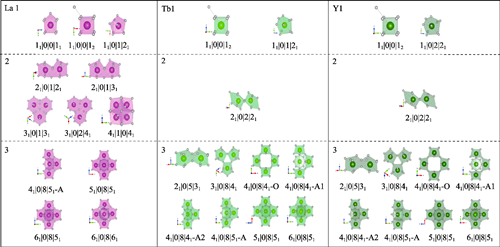

As a fundamental light source and a good window for atmospheric transmission, the mid-infrared 3 μm lasers have led many promising applications. The rare earth doped crystalline materials, such as erbium doped crystals, are some of the most important routes for generation of the lasers. However, they have an intrinsic shortcoming of self-termination because of their short lifetime of 4I11/2 and longer lifetime of 4I13/2. To eliminate this effect, a high concentration doping method is usually adopted to change the energy transfer process to decrease 4I13/2 lifetime. The efficiency and output power of Er3+-doped crystals were thus limited due to their degraded thermal properties. Trivalent erbium ions are easily clustering in fluoride crystals. Distances among the ions are short and therefore energy transfer processes could be significantly improved in the crystals even doping with low concentrations. Low doping concentrations could also alleviate the thermal effect in laser operations, which enable the erbium doped fluorides to be promising candidates for high power and high efficiency mid-infrared lasers. However, connection of spectral properties and erbium clusters is unknown. Here, the first principles calculation is utilized to model the erbium ion clusters in CaF2, SrF2 and PbF2 crystals, concerning the absorption and photoluminescence properties. The results reveal that spectral properties and structures of the erbium clusters, evolve gradually with matrix crystals. Relationship between spectral properties and optical erbium clusters is determined qualitatively, which could be used to design new erbium doped mid-infrared lasers.

|

|

|

Double Perovskite Sr2CoFeO5+δ: Preparation and Performance as Cathode Material for Intermediate-temperature Solid Oxide Fuel Cells

CHEN Zhengpeng, JIN Fangjun, LI Mingfei, DONG Jiangbo, XU Renci, XU Hanzhao, XIONG Kai, RAO Muming, CHEN Chuangting, LI Xiaowei, LING Yihan

2024 Vol. 39 (3): 337–344

Abstract

Abstract(

260 )

HTML

HTML(

15)

PDF

PDF(1889KB)(

302

)

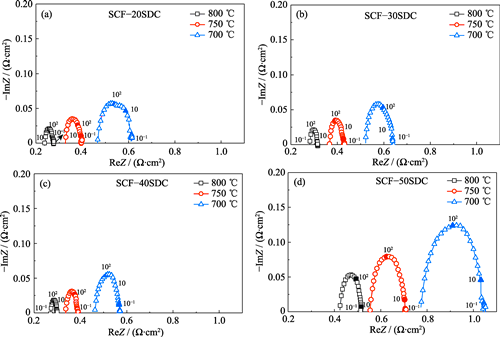

Intermediate-temperature solid oxide fuel cells (IT-SOFCs), as the operating temperature decreases, require cathode materials with high catalytic activity. In this study, double perovskite Sr2CoFeO5+δ (SCF) was synthesized by Sol-Gel method, and effect of SCF cathode compounded with 20% (molar fraction) Sm2O3 doped CeO2 (SDC) at different ratios on the electrode performance was elucidated. The SOFC single-cell performance was improved by optimized chemical expansion and area-specific resistance (ASR) from composite electrodes. Results show that, SCF cathode after annealing at 950 ℃ for 10 h exhibits good chemical compatibility with common electrolytes. For the composite of SCF and SDC at a mass ratio of 1 : 1, the average thermal expansion coefficient (TEC) can be significantly reduced from 2.44×10−5 K-1 of pure SCF to 1.54×10−5 K-1. ASR of SCF−xSDC (x=20, 30, 40, 50, x: mass percentage) composite cathodes are as low as 0.036, 0.034, 0.028 and 0.092 Ω·cm2 at 800 ℃, respectively. The SCF−40SDC composite cathode displays the lowest ASR value among SCF−xSDC in the whole temperature range. Based on the 0.3 mm-thick La0.9Sr0.1Ga0.8Mg0.2O3-δ (LSGM) electrolyte, the maximum power density of SOFC using SCF−40SDC (757 mW·cm−2) as a cathode is higher than that of pure SCF (684 mW·cm−2). These results demonstrate that the SCF−40SDC composite cathode is a promising candidate for application in IT-SOFCs.

|

|