Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (10): 1183-1192.DOI: 10.15541/jim20230013

• RESEARCH ARTICLE • Previous Articles Next Articles

WU Dongjiang1( ), ZHAO Ziyuan1, YU Xuexin1, MA Guangyi1, YOU Zhulin2, REN Guanhui3,4, NIU Fangyong1(

), ZHAO Ziyuan1, YU Xuexin1, MA Guangyi1, YOU Zhulin2, REN Guanhui3,4, NIU Fangyong1( )

)

Received:2023-01-09

Revised:2023-03-06

Published:2023-10-20

Online:2023-03-09

Contact:

NIU Fangyong, associate professor. E-mail: niufangyong@dlut.edu.cnAbout author:WU Dongjiang (1964-), male, professor. E-mail: djwudut@dlut.edu.cn

Supported by:CLC Number:

WU Dongjiang, ZHAO Ziyuan, YU Xuexin, MA Guangyi, YOU Zhulin, REN Guanhui, NIU Fangyong. Direct Additive Manufacturing of Al2O3-TiCp Composite Ceramics by Laser Directed Energy Deposition[J]. Journal of Inorganic Materials, 2023, 38(10): 1183-1192.

| Al2O3 | Composition | Al2O3 | SiO2 | Fe2O3 | Na2O | CaO |

|---|---|---|---|---|---|---|

| Content/% | >99.9 | 0.0041 | 0.0021 | 0.0014 | <0.001 | |

| TiCp | Composition | TiCp | Si/Ca | K/Na | Fe | Al |

| Content/% | >99.1 | <0.01 | <0.005 | <0.09 | <0.01 |

Table 1 Composition and mass fraction of two raw materials powder

| Al2O3 | Composition | Al2O3 | SiO2 | Fe2O3 | Na2O | CaO |

|---|---|---|---|---|---|---|

| Content/% | >99.9 | 0.0041 | 0.0021 | 0.0014 | <0.001 | |

| TiCp | Composition | TiCp | Si/Ca | K/Na | Fe | Al |

| Content/% | >99.1 | <0.01 | <0.005 | <0.09 | <0.01 |

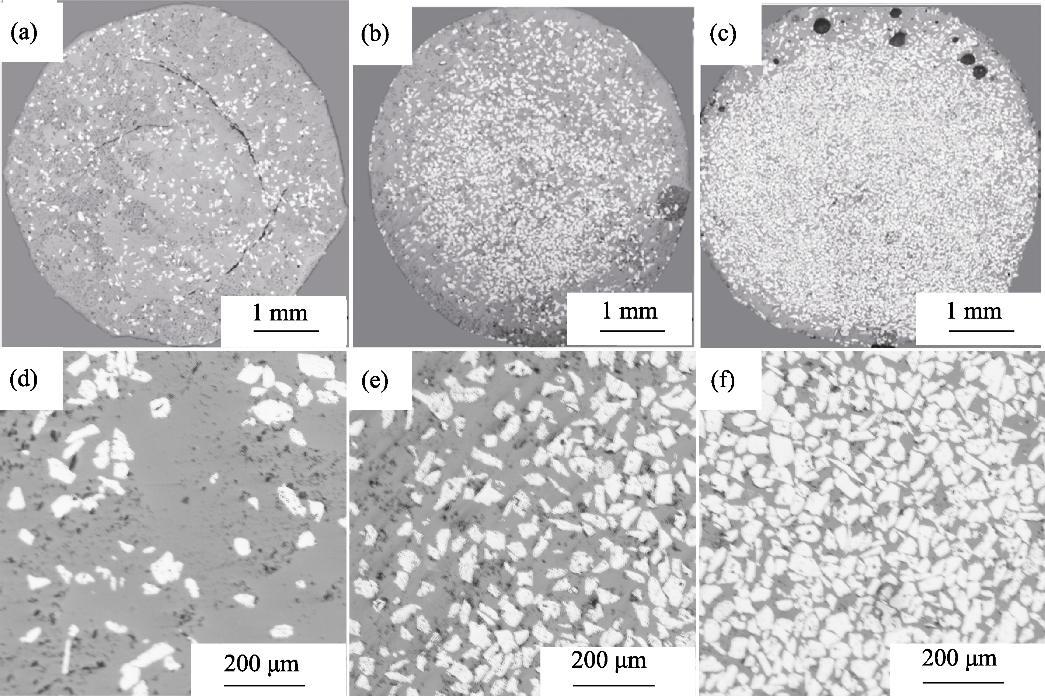

Fig. 5 Full cross-sections and particle distributions of samples (a-c) Full views of (a) AT10, (b) AT30 and (c) AT50;(d-f) Particle distributions of (d) AT10, (e) AT30 and (f) AT50

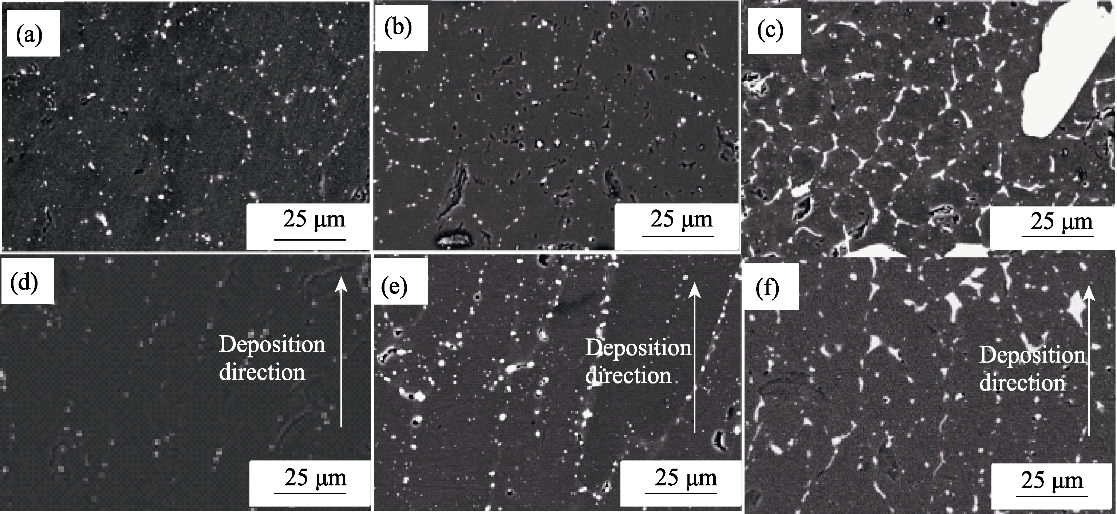

Fig. 7 Microstructures of the sample (a-c) Cross-sectional images of (a) AT10, (b) AT30 and (c) AT50; (d-f) Longitudinal section images of (d) AT10, (e) AT30 and (f)AT50

| [1] | 申仲琳, 苏海军, 刘海方, 等. 超高温氧化物陶瓷激光增材制造技术与缺陷控制研究进展. 复合材料学报, 2021, 38(3): 668. |

| [2] |

GOLDSTEIN A, SINGURINDI A. Al2O3/TiC based metal cutting tools by microwave sintering followed by hot isostatic pressing. Journal of the American Ceramic Society, 2010, 83(6): 1530.

DOI URL |

| [3] | 赵喆, 龚江宏, 苗赫濯, 等. TiC颗粒弥散Al2O3复合材料的阻力曲线行为. 硅酸盐学报, 2000, 28(4): 371. |

| [4] |

EVANS A G, CANNON R M. Toughening of brittle solids by martensitic transformations. Acta Metallurgica, 1986, 34(5): 761.

DOI URL |

| [5] |

CAI K F, MCLACHLAN D S, AXEN N, et al. Preparation, microstructures and properties of Al2O3-TiC composites. Ceramics International, 2002, 28(2): 217.

DOI URL |

| [6] |

GEVORKYAN E, RUCKI M, PANCHENKO S, et al. Effect of SiC addition to Al2O3 ceramics used in cutting tools. Materials, 2020, 13(22): 5195.

DOI URL |

| [7] | 程寓, 孙士帅. 一种氧化铝-碳化钛微米复合陶瓷刀具材料及其微波烧结方法. CN104131208A. 2014-11-05. |

| [8] | 高纪明, 陈松年. 氧化铝/碳化钛复合材料的无压烧结. 湖南大学学报:自然科学版, 1996, 23(4): 46. |

| [9] |

XIA T, MUNIR Z, TANG Y, et al. Structure formation in the combustion synthesis of Al2O3/TiC composites. Journal of the American Ceramic Society, 2000, 83(3): 507.

DOI URL |

| [10] | 苏海军, 王恩缘, 任群, 等. 超高温氧化物共晶复合陶瓷研究进展. 中国材料进展, 2018, 37(6): 437. |

| [11] | 吴甲民. 方兴未艾的陶瓷增材制造. 硅酸盐学报, 2021, 49(09): 1785. |

| [12] | 刘雨, 陈张伟. 陶瓷光固化3D打印技术研究进展. 材料工程, 2020, 48(9): 1. |

| [13] |

WU D, YU X, ZHAO Z. Direct additive manufacturing of TiCp reinforced Al2O3-ZrO2 eutectic functionally graded ceramics by laser directed energy deposition. Journal of the European Ceramic Society, 2023, 43(6): 2718.

DOI URL |

| [14] |

LIU H, SU H, SHEN Z, et al. Research progress on ultrahigh temperature oxide eutectic ceramics by laser additive manufacturing. Journal of Inorganic Materials, 2022, 37(3): 255.

DOI |

| [15] | WU D, YU C, WANG Q, et al. Synchronous-hammer-forging- assisted laser directed energy deposition additive manufacturing of high-performance 316L samples. Journal of Materials Processing Technology, 2022, 307: 117695. |

| [16] | 苏海军, 尉凯晨, 郭伟, 等. 激光快速成形技术新进展及其在高性能材料加工中的应用. 中国有色金属学报, 2013, 23(6): 1567. |

| [17] | 吴甲民, 陈敬炎, 陈安南, 等. 陶瓷零件增材制造技术及在航空航天领域的潜在应用. 航空制造技术, 2017, 11(10): 40. |

| [18] |

WU D, SHI J, NIU F, et al. Direct additive manufacturing of melt growth Al2O3-ZrO2 functionally graded ceramics by laser directed energy deposition. Journal of the European Ceramic Society, 2022, 42(6): 2957.

DOI URL |

| [19] | HUANG Y, WU D, ZHAO D, et al. Process optimization of melt growth alumina/aluminum titanate composites directed energy deposition: effects of scanning speed. Additive Manufacturing, 2020, 35: 101210. |

| [20] | WU D, ZHAO D, HUANG Y, et al. Shaping quality, microstructure, and mechanical properties of melt-grown mullite ceramics by directed laser deposition. Journal of Alloys and Compounds, 2021, 871: 159609. |

| [21] | SU H, ZHANG J, LIU L, et al. Rapid growth and formation mechanism of ultrafine structural oxide eutectic ceramics by laser direct forming. Applied Physics Letters, 2011, 99(22): 1174. |

| [22] | ZHAO D, WU D, NIU F, et al. Heat treatment of melt-grown alumina ceramics with trace glass fabricated by laser directed energy deposition. Materials Characterization, 2023, 196: 112639. |

| [23] | HUANG Y, WU D, ZHAO D, et al. Investigation of melt-growth alumina/aluminum titanate composite ceramics prepared by directed energy deposition. International Journal of Extreme Manufacturing, 2021, 3: 035101. |

| [24] |

WEI X, JIN M, YANG H, et al. Advances in 3D printing of magnetic materials: fabrication, properties, and their applications. Journal of Advanced Ceramics, 2022, 11(5): 665.

DOI |

| [25] | 刘安丽, 隋长有, 李发智, 等. 陶瓷激光增材制造等离子体特征与成形缺陷的相关性研究. 中国激光, 2020, 47(6): 146. |

| [26] | 中国建筑材料工业协会. 精细陶瓷弯曲强度试验方法: GB/T 6569-2006. 中国标准出版社, 2006. |

| [27] | 龚江宏. 陶瓷材料断裂力学. 北京: 清华大学出版社, 2001: 101- 117. |

| [28] |

VOIGT W. Ueber die beziehung zwischen den beiden elasticitätsconstanten isotroper körper. Annalen Der Physik, 1889, 274(12): 573.

DOI URL |

| [29] |

REUSS A. Berechnung der fleissgrenze von mischkristallen auf grund der plastizitats bedingung für einkrisalle. Zeitschrift für Angewandte Mathematik und Mechanik, 1929, 9(1): 49.

DOI URL |

| [30] |

YUAN P, GU D. Molten pool behaviour and its physical mechanism during selective laser melting of TiC/AlSi10Mg nanocomposites: simulation and experiments. Journal of Physics D: Applied Physics, 2015, 48(3): 035303.

DOI URL |

| [31] |

YUAN P, GU D, DAI D. Particulate migration behavior and its mechanism during selective laser melting of TiC reinforced Al matrix nanocomposites. Materials and Design, 2015, 82(5): 46.

DOI URL |

| [32] |

张进, 黄云涛, 岳新艳, 等. TiC含量对无压烧结TiC-Al2O3导电陶瓷复合材料微观结构与性能的影响. 机械工程材料, 2023, 47(1): 70.

DOI |

| [33] | GOINS P E, FRAZIER W E. A model of grain boundary complexion transitions and grain growth in yttria-doped alumina. Acta Materialia, 2020, 188: 79. |

| [34] | 胡晓清, 曾照强. Al2O3/TiC陶瓷中Al2O3与TiC化学反应抑制的研究. 硅酸盐通报, 1998, 17(5): 45. |

| [35] |

KIM Y W, LEE J G. Pressureless sintering of alumina-titanium carbide composites. Journal of the American Ceramic Society, 1989, 72(8): 1333.

DOI URL |

| [36] |

ISHIDA K. Effect of grain size on grain boundary segregation. Journal of Alloys and Compounds, 1996, 235(2): 244.

DOI URL |

| [37] |

TERWILLIGER C D, CHIANG Y M. Size-dependent solute segregation and total solubility in ultrafine polycrystals: Ca in TiO2. Acta Metallurgica Et Materialia, 1995, 43(1): 319.

DOI URL |

| [38] | NIU F, WU D, YAN S, et al. Process optimization for suppressing cracks in laser engineered net shaping of Al2O3 ceramics. The Journal of The Minerals, Metals & Materials Society, 2016, 69(3): 557. |

| [39] | LAWN B R, WILSHAW T R. Fracture of brittle solids. Cambridge: Cambridge University Press, 1975: 47. |

| [40] |

WU D, YU X, ZHAO Z, et al. One-step additive manufacturing of TiCp reinforced Al2O3-ZrO2 eutectic ceramics composites by laser directed energy deposition. Ceramics International, 49(8): 12758.

DOI URL |

| [41] | LANGE F F, Fracture mechanics of ceramics. Ceramurgia International, 1978, 4(3): 142. |

| [42] | GUO J K. The Exploration on new approach of strengthening and toughening of ceramic materials. Journal of Inorganic Materials, 1998, 13(1): 23. |

| [43] | AHSAN M N, BRADLEY R, PINKERTON A J. Microcomputed tomography analysis of intralayer porosity generation in laser direct metal deposition and its causes. Journal of Laser Applications, 2011, 23(2): 807. |

| [44] |

KOBRYN P A, MOORE E H. The effect of laser power and traverse speed on microstructure, porosity, and build height in laser-deposited Ti6A14V. Scripta materialia, 2000. 43(4): 299.

DOI URL |

| [45] |

SUSAN D F, PUSKAR J D, BROOKS J A, et al. Quantitative characterization of porosity in stainless steel LENS powders and deposits. Materials Characterization, 2006. 57(1): 36.

DOI URL |

| [46] |

NIU F, WU D, LU F, et al. Microstructure and macro properties of Al2O3 ceramics prepared by laser engineered net shaping. Ceramics International, 2018, 44(12): 14303.

DOI URL |

| [47] |

FRANCISCO I D, MERINO R I, ORERA V M, et al. Growth of Al2O3/ZrO2(Y2O3) eutectic rods by the laser floating zone technique: effect of the rotation. Journal of the European Ceramic Society, 2005, 25(8): 1341.

DOI URL |

| [48] |

WU D, HUANG Y, NIU F, et al. Effects of TiO2 doping on microstructure and properties of directed laser deposition alumina/ aluminum titanate composites. Virtual and Physical Prototyping, 2019, 14(4): 371.

DOI URL |

| [49] |

ZHAO D, WU D, SHI J, et al. Microstructure and mechanical properties of melt-grown alumina-mullite/glass composites fabricated by directed laser deposition. Journal of Advanced Ceramics, 2022, 11(1): 75.

DOI |

| [50] | PETCH N J. The cleavage strength of polycrystals. Journal of the Iron and Steel Institute, 1953, 174(1): 25. |

| [51] | HALL E O. The deformation and ageing of mild steel: III discussion of results. Proceedings of the Physical Society of London, 1951, 64(381): 747. |

| [1] | NI Xiaoshi, LIN Ziyang, QIN Muyan, YE Song, WANG Deping. Bioactivity and Mechanical Property of PMMA Bone Cement: Effect of Silanized Mesoporous Borosilicate Bioglass Microspheres [J]. Journal of Inorganic Materials, 2023, 38(8): 971-977. |

| [2] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [3] | YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(5): 477-488. |

| [4] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [5] | FU Shi, YANG Zengchao, LI Jiangtao. Progress of High Strength and High Thermal Conductivity Si3N4 Ceramics for Power Module Packaging [J]. Journal of Inorganic Materials, 2023, 38(10): 1117-1132. |

| [6] | WANG Lukai, FENG Junzong, JIANG Yonggang, LI Liangjun, FENG Jian. Direct-ink-writing 3D Printing of Ceramic-based Porous Structures: a Review [J]. Journal of Inorganic Materials, 2023, 38(10): 1133-1148. |

| [7] | SUN Xiaofan, CHEN Xiaowu, JIN Xihai, KAN Yanmei, HU Jianbao, DONG Shaoming. Fabrication and Properties of AlN-SiC Multiphase Ceramics via Low Temperature Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2023, 38(10): 1223-1229. |

| [8] | LI Wenjun, WANG Hao, TU Bingtian, CHEN Qiangguo, ZHENG Kaiping, WANG Weiming, FU Zhengyi. Preparation and Property of Mg0.9Al2.08O3.97N0.03 Transparent Ceramic with Broad Optical Transmission Range [J]. Journal of Inorganic Materials, 2022, 37(9): 969-975. |

| [9] | AN Wenran, HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang. Effect of Heat-treatment Temperature on Thermal and Mechanical Properties of LaMgAl11O19 Coating [J]. Journal of Inorganic Materials, 2022, 37(9): 925-932. |

| [10] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [11] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [12] | NAN Bo, ZANG Jiadong, LU Wenlong, YANG Tingwang, ZHANG Shengwei, ZHANG Haibo. Recent Progress on Additive Manufacturing of Piezoelectric Ceramics [J]. Journal of Inorganic Materials, 2022, 37(6): 585-595. |

| [13] | HONG Du, NIU Yaran, LI Hong, ZHONG Xin, ZHENG Xuebin. Tribological Properties of Plasma Sprayed TiC-Graphite Composite Coatings [J]. Journal of Inorganic Materials, 2022, 37(6): 643-650. |

| [14] | XU Puhao, ZHANG Xiangzhao, LIU Guiwu, ZHANG Mingfen, GUI Xinyi, QIAO Guanjun. Microstructure and Mechanical Properties of SiC Joint Brazed by Al-Ti Alloys as Filler Metal [J]. Journal of Inorganic Materials, 2022, 37(6): 683-690. |

| [15] | DING Jianxiang, ZHANG Kaige, LIU Dongming, ZHENG Wei, ZHANG Peigen, SUN Zhengming. Ag-based Electrical Contact Material Reinforced by Ti3AlC2 Ceramic and Its Derivative Ti3C2Tx [J]. Journal of Inorganic Materials, 2022, 37(5): 567-573. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||