Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (11): 1271-1280.DOI: 10.15541/jim20230143

Special Issue: 【结构材料】热障与环境障涂层(202312)

• RESEARCH ARTICLE • Previous Articles Next Articles

CAI Jia1,2( ), ZHAO Fangxia1(

), ZHAO Fangxia1( ), FAN Dong1,2, HUANG Liping2, NIU Yaran2(

), FAN Dong1,2, HUANG Liping2, NIU Yaran2( ), ZHENG Xuebin2, ZHANG Zhenzhong1

), ZHENG Xuebin2, ZHANG Zhenzhong1

Received:2023-03-21

Revised:2023-06-07

Published:2023-07-17

Online:2023-07-17

Contact:

ZHAO Fangxia, professor. E-mail: fangxiazhao@126.com;About author:CAI Jia(1998-), female, Master candidate. E-mail: cj15850730899@163.com

Supported by:CLC Number:

CAI Jia, ZHAO Fangxia, FAN Dong, HUANG Liping, NIU Yaran, ZHENG Xuebin, ZHANG Zhenzhong. Pyrolysis Behavior and Laser Ablation Resistance of PCS in Polycarbosilane Composite Coatings[J]. Journal of Inorganic Materials, 2023, 38(11): 1271-1280.

| Coatings | YSZ | NiCrAlY |

|---|---|---|

| Ar/slpm | 30−40 | 30−40 |

| H2/slpm | 5−15 | 5−15 |

| Spray distance/mm | 90−130 | 200−300 |

| Feed rate/(r·min-1) | 15−30 | 15−30 |

| Power/kW | 38−48 | 30−40 |

Table 1 Spray parameters of YSZ and NiCrAlY coatings[18]

| Coatings | YSZ | NiCrAlY |

|---|---|---|

| Ar/slpm | 30−40 | 30−40 |

| H2/slpm | 5−15 | 5−15 |

| Spray distance/mm | 90−130 | 200−300 |

| Feed rate/(r·min-1) | 15−30 | 15−30 |

| Power/kW | 38−48 | 30−40 |

Fig. 9 Surface SEM morphologies of YPT and YPY coatings after 425 W/cm2, 5 s laser ablation (a, d) Original morphologies; (b, e) Central ablative zone; (c, f) Transition zone; (g) EDS results of A1, A2 and P1 points

Fig. 10 Cross-sectional original SEM morphologies (a, d), cross-sectional morphologies (b, c, e, f) and EDS results (g, h) of YPT and YPY coatings after 425 W/cm2, 5 s laser ablation

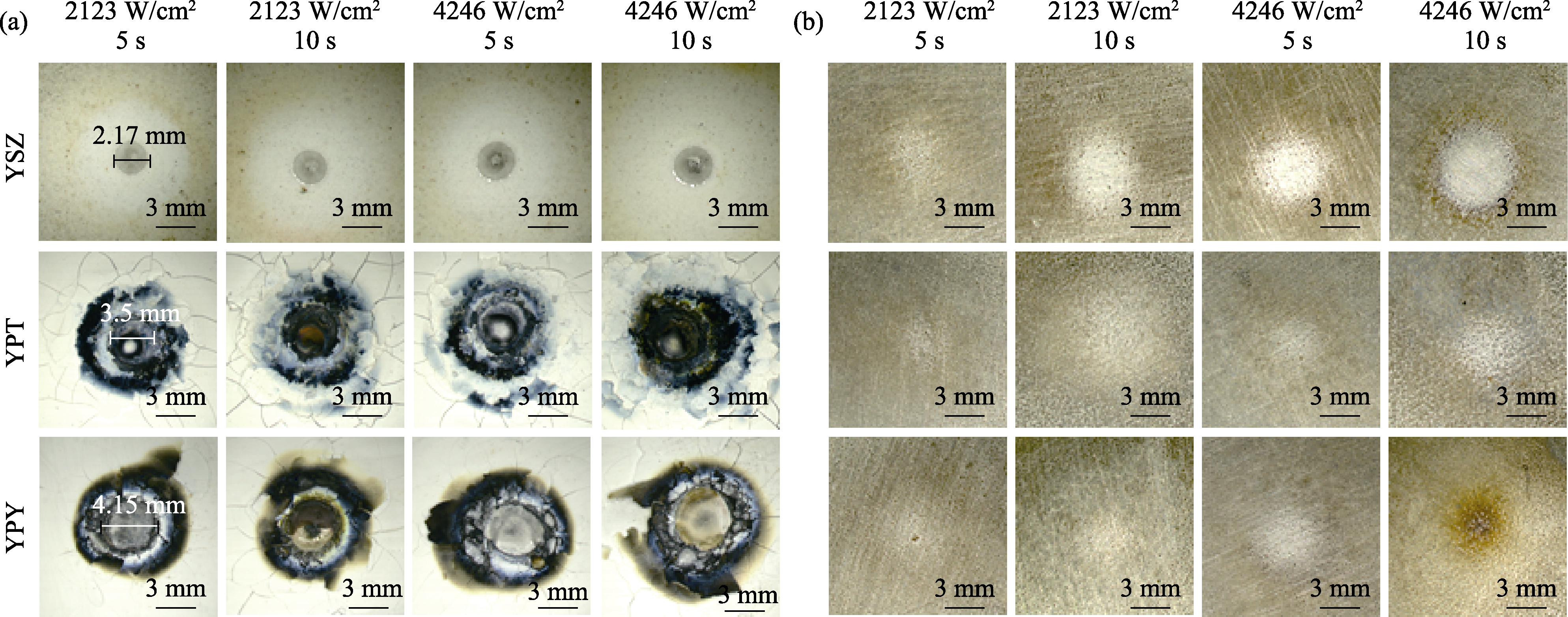

Fig. 11 Surface morphologies (a) and back surface morphologies (b) of YSZ, YPT and YPY coatings ablated by 2123 and 4246 W/cm2 laser for 5 and 10 s, respectively

Fig. 13 SEM surface morphologies and EDS analyses of YSZ, YPT and YPY coatingsafter 4246 W/cm2, 10 s laser ablation (a, e, i) Original coatings; (b, f, j) High magnification of central ablation areas; (c, g, k) Low magnification of central ablation areas; (d, h, l) Transition areas; (m) EDS results; (n) YPT element mappings ; (o) YPY element mappings

Fig. 14 Cross-sectional SEM morphologies and corresponding elements mapping of the central ablation area of YSZ (a), YPT (b) and YPY (c) coatings after 4246 W/cm2, 10 s laser ablation

| [1] | 郑佳艺, 马壮, 高丽红, 等. 智能化高能激光防护材料新进展. 现代技术陶瓷, 2020, 41(3): 121. |

| [2] | Hambling D. US Army laser weapon to be most powerful ever. The New Scientist, 2021, 249(3323): 12. |

| [3] | 杨剑波, 宗思光, 陈利斐, 等. 高功率激光武器进展与启示. 激光与红外, 2021, 51(6): 695. |

| [4] |

XIONG Y, YAN K, YU H Y, et al. Comparative investigation on the hot corrosion failure of YSZ and GdYb-YSZ double-ceramic- layer thermal barrier coatings under Na2SO4+V2O5 molten salts. Ceramics International, 2023, 49(11): 18678.

DOI URL |

| [5] | SHAO J, JITSUNO T, RUDOLPH W, et al. Study on high power CW laser's irradiation effect on yttria-stabilized zirconia coating. Society of Photo-Optical Instrumentation Engineers (SPIE) Conference Series, 2017, 10339: 1. |

| [6] |

ZOU Y, ZHAO L L, YOU L J, et al. Preparation and numerical simulation investigation of high reflectance anti-laser-ablation coating. Journal of Inorganic Materials, 2016, 31(8): 869.

DOI |

| [7] |

CHEN Y, PING C, HONG C, et al. Improved ablation resistance of carbon-phenolic composites by introducing zirconium diboride particles. Composites Part B, 2013, 47: 320.

DOI URL |

| [8] |

CHEN S, ZHANG C, ZHANG Y, et al. Effects of polymer derived SiC interphase on the properties of C/ZrC composites. Materials and Design, 2014, 58: 102.

DOI URL |

| [9] |

HORCHER A, TANGERMANN-GERK K, BARROSO G, et al. Laser and furnace pyrolyzed organosilazane-based glass/ZrO2 composite coating system-a comparison. Journal of the European Ceramic Society, 2019, 40(7): 2642.

DOI URL |

| [10] |

LIU R, LIU X Y, WANG Y F, et al. Laser ablation behavior and mechanism of Cf/SiC-ZrC ultra-high temperature ceramic matrix composite prepared by PIP method. Ceramics International, 2021, 47(16): 23610.

DOI URL |

| [11] | Kiyohito, Okamura, Tadao, et al. Application of radiation curing in the preparation of polycarbosilane-derived SiC fibers. Journal of Inorganic & Organometallic Polymers, 1992, 2(1): 171. |

| [12] | FEI Y W, YU X F, TANG W H, et al. Study on SiC fine ceramic anti-laser reinforcement material. Ordnance Material Science and Engineering, 2001, 24(1): 39. |

| [13] |

NIU J H, MENG S H, JIN H, et al. Thermal stability and nanostructure evolution of amorphous SiCN ceramics during laser ablation in an argon atmosphere. Journal of the European Ceramic Society, 2019, 39(15): 4535.

DOI URL |

| [14] | 李静, 郑轶, 罗晋, 等. 航空复合涂层材料的激光烧蚀效应. 强激光与粒子束, 2014, 26(2): 029003. |

| [15] | XIE Z F, CHEN Z H, LI Y Q, et al. Application of active fillers in the preparation of polycarbosilane derived ceramics. Journal of National University of Defense Technology, 2000, 4: 27. |

| [16] |

TINGA C C, CHENA S Y, LIUB D M, et al. Preferential growth of thin rutile TiO2 films upon thermal oxidation of sputtered Ti films. Thin Solid Films, 2002, 402: 290.

DOI URL |

| [17] |

PAN Y Y, LIANG B, HONG D, et al. High temperature long-term service performance of TiAlCrY/YSZ coating on TiAl alloy. Journal of Inorganic Materials, 2023, 38(1): 105.

DOI |

| [18] | PAN Y Y, LIANG B, NIU Y R, et al. Thermal shock behaviors of plasma sprayed YSZ/TiAlCrY system on TiAl alloy. Ceramics International, 2022, 5: 6199. |

| [19] |

LY H Q, TAYLOR R, DAY R J, et al. Conversion of polycarbosilane (PCS) to SiC-based ceramic Part 1. Characterisation of PCS and curing products. Journal of Materials Science, 2001, 36(16): 4037.

DOI URL |

| [20] | YUAN Q, SONG Y C, LI Y Q, et al. Synthesis and properties of a high ceramic yield thermosetting polycarbosilane. Silicone Material, 2011, 25(6): 380. |

| [21] |

FANG Y H, HUANG M H, YU Z Y, et al. Synthesis, characterization and pyrolytic conversion of a novel liquid polycarbosilane. Journal of the American Ceramic Society, 2008, 91(10): 3298.

DOI URL |

| [22] | CABEZAS-RODRIGUEZ R, CIRIA D, MARTINEZ-FERNANDEZ J, et al. High temperature mechanical properties of polycrystalline Y2SiO5. Journal of the Spanish Ceramic and Glass Society, 2022, 61(S1): 60. |

| [23] | 王扬, 袁哲俊, 胡广义, 等. 陶瓷表面激光加热温度场的分析. 哈尔滨工业大学学报, 1999, (3):71. |

| [24] | 孙承纬. 激光辐照效应. 北京: 国防工业出版社, 2002. |

| [1] | CHEN Mingyue, YAN Zhichao, CHEN Jing, LI Minjuan, LIU Zhiyong, CAI Chuanbing. YBa2Cu3O7-δ Thin Film: Preparation by BaCl2/BaF2-MOD Method and Superconducting Property [J]. Journal of Inorganic Materials, 2023, 38(2): 199-204. |

| [2] | HONG Du, NIU Yaran, LI Hong, ZHONG Xin, ZHENG Xuebin. Tribological Properties of Plasma Sprayed TiC-Graphite Composite Coatings [J]. Journal of Inorganic Materials, 2022, 37(6): 643-650. |

| [3] | LUO Yi, XIA Shuhai, NIU Bo, ZHANG Yayun, LONG Donghui. Preparation and High Temperature Inorganic Transformation of Flexible Silicone Aerogels [J]. Journal of Inorganic Materials, 2022, 37(12): 1281-1288. |

| [4] | WANG Yuanjie, PEI Xueliang, LI Haoyi, XU Xin, HE Liu, HUANG Zhengren, HUANG Qing. Crosslinking of Active Polycarbosilane Initiated by Free Radical and Its Application in the Preparation of SiC Fibers [J]. Journal of Inorganic Materials, 2021, 36(9): 967-973. |

| [5] | ZHANG Bingyu,WANG ling,WANG Xiaomeng,QIU Haipeng. Effect of Precursors on Impregnation Behaviors of C/SiC Composites [J]. Journal of Inorganic Materials, 2020, 35(9): 1017-1022. |

| [6] | WANG Zhihu,ZHANG Jumei,BAI Lijing,ZHANG Guojun. Mg(OH)2 Film on Micro-arc Oxidation Ceramic Coating of AZ31 Magnesium Alloy: Preparation and Corrosion Resistance [J]. Journal of Inorganic Materials, 2020, 35(6): 709-716. |

| [7] | DU Juan, LIU Lei, YU Yifeng, ZHANG Yue, LÜ Haijun, CHEN Aibing. Hollow Carbon Sphere with Tunable Structure by Encapsulation Pyrolysis Synchronous Deposition for Cefalexin Adsorption [J]. Journal of Inorganic Materials, 2020, 35(5): 608-616. |

| [8] | FU Ya-Kang,WENG Jie,LIU Yao-Wen,ZHANG Ke-Hong. hBMP-2 Contained Composite Coatings on Titanium Mesh Surface: Preparation and hBMP-2 Release [J]. Journal of Inorganic Materials, 2020, 35(2): 173-178. |

| [9] | LI Xuqin, TAN Zhiyong, CHENG Laifei, ZHOU Lingke, GAO Jian. Tensile Behaviors and Matrix Cracking Mechanism of C/SiCN Composite Prepared by Precursor Infiltration Pyrolysis Method [J]. Journal of Inorganic Materials, 2020, 35(11): 1227-1233. |

| [10] | Yan-Zhe ZHOU, Min LIU, Kun YANG, Wei ZENG, Jin-Bing SONG, Chun-Ming DENG, Chang-Guang DENG. Microstructure and Property of MoSi2-30Al2O3 Electrothermal Coating Prepared by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2019, 34(6): 646-652. |

| [11] | WANG Guo-Dong, SONG Yong-Cai. Enhancing Mechanical Property of SiC Fiber by Decreasing Fiber Diameter through a Modified Melt-spinning Process [J]. Journal of Inorganic Materials, 2018, 33(7): 721-727. |

| [12] | WU Nan, WAN Lynn Yuqin, WANG Ying-De, FRANK KO. Electrospun Silicon Oxycarbide Ultrafine Fibers Derived from Polycarbosilane [J]. Journal of Inorganic Materials, 2018, 33(3): 357-362. |

| [13] | ZHANG Cheng, GONG Jun-Jie, DONG Zhi-Jun, MENG Jian, ZHOU Si-Cheng, YUAN Guan-Ming, LI Xuan-Ke. HfC Precursor: Synthesis and Pyrolysis Behavior [J]. Journal of Inorganic Materials, 2017, 32(10): 1095-1101. |

| [14] | HE Ling, LI Qian-Kun, LI Weng-Sheng, CUI Shuai. Synthesis and Properties of Self-sensitization Luminescent Composite Coatings [J]. Journal of Inorganic Materials, 2017, 32(1): 56-62. |

| [15] | GUO Wen, MI Guo-Ji, ZHANG Jin-Long, WANG Zhen-Ya. Friction and Wear Behavior of Ni-SiC Composite Coating Prepared on TA15 Alloy [J]. Journal of Inorganic Materials, 2016, 31(2): 195-200. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||