Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (11): 1316-1322.DOI: 10.15541/jim20230127

Special Issue: 【能源环境】燃料电池(202312)

• RESEARCH ARTICLE • Previous Articles Next Articles

TIAN Yubin1( ), TIAN Chaofan1, LI Sen1, ZHAO Yongxin1, XING Tao2, LI Zhi2,3, CHEN Xiaoru1, XIANG Shuairong1, DAI Pengcheng1(

), TIAN Chaofan1, LI Sen1, ZHAO Yongxin1, XING Tao2, LI Zhi2,3, CHEN Xiaoru1, XIANG Shuairong1, DAI Pengcheng1( )

)

Received:2023-03-13

Revised:2023-05-28

Published:2023-06-16

Online:2023-06-16

Contact:

DAI Pengcheng (1986-), male, associate professor. E-mail: dpcapple@upc.edu.cnAbout author:TIAN Yubin (1997-), male, Master candidate. E-mail: yubinpeach@163.com

Supported by:CLC Number:

TIAN Yubin, TIAN Chaofan, LI Sen, ZHAO Yongxin, XING Tao, LI Zhi, CHEN Xiaoru, XIANG Shuairong, DAI Pengcheng. Biomass-derived High-conductivity Carbon Cloth: Preparation and Application as Gas Diffusion Layers in Fuel Cells[J]. Journal of Inorganic Materials, 2023, 38(11): 1316-1322.

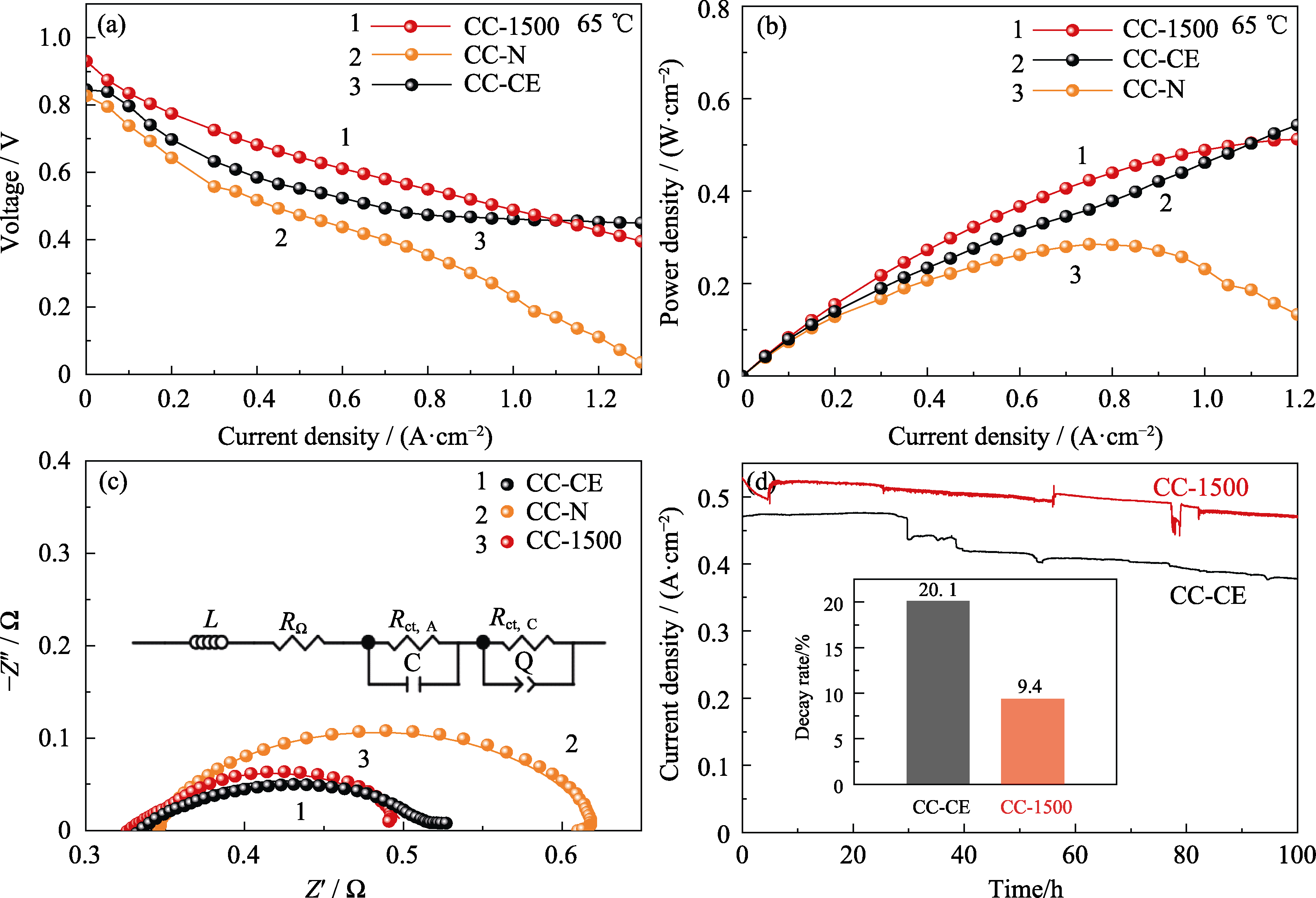

Fig. 7 Polarization curves (a) and power density curves (b), EIS plots (c), and long-term durability tests at 0.6 V, 65 ℃(d) of PEMFCs using different GDLs C: Capacitor; Q: Inductor

| GDL | RΩ/Ω | Rct,A/Ω | Rct,C/Ω |

|---|---|---|---|

| CC-1500 | 0.3123 | 0.0832 | 0.1047 |

| CC-CE | 0.3301 | 0.0658 | 0.1322 |

| CC-N | 0.3442 | 0.1081 | 0.1659 |

Table S1 EIS fitting data of CC-1500, CC-CE and CC-N

| GDL | RΩ/Ω | Rct,A/Ω | Rct,C/Ω |

|---|---|---|---|

| CC-1500 | 0.3123 | 0.0832 | 0.1047 |

| CC-CE | 0.3301 | 0.0658 | 0.1322 |

| CC-N | 0.3442 | 0.1081 | 0.1659 |

| [1] |

ZHANG J, WANG B, JIN J, et al. A review of the microporous layer in proton exchange membrane fuel cells: materials and structural designs based on water transport mechanism. Renewable and Sustainable Energy Reviews, 2022, 156: 111998.

DOI URL |

| [2] |

YOON K R, KIM J M, LEE K A, et al. Activity-stability benefits of Pt/C fuel cell electrocatalysts prepared via remote CeO2 interfacial doping. Journal of Power Sources, 2021, 496: 229798.

DOI URL |

| [3] |

VAN DAO D, ADILBISH G, LEE I H, et al. Enhanced electrocatalytic property of Pt/C electrode with double catalyst layers for PEMFC. International Journal of Hydrogen Energy, 2019, 44(45): 24580.

DOI URL |

| [4] |

PARK S, LEE J W, POPOV B N. A review of gas diffusion layer in PEM fuel cells: materials and designs. International Journal of Hydrogen Energy, 2012, 37(7): 5850.

DOI URL |

| [5] |

SIM J, KANG M, MIN K. Effects of basic gas diffusion layer components on PEMFC performance with capillary pressure gradient. International Journal of Hydrogen Energy, 2021, 46(54): 27731.

DOI URL |

| [6] |

PARK S B, PARK Y I. Fabrication of gas diffusion layer (GDL) containing microporous layer using flourinated ethylene prophylene (FEP) for proton exchange membrane fuel cell (PEMFC). International Journal of Precision Engineering and Manufacturing, 2012, 13(7): 1145.

DOI URL |

| [7] |

ZHAO H, KWAK J H, ZHANG Z C, et al. Studying cellulose fiber structure by SEM, XRD, NMR and acid hydrolysis. Carbohydrate Polymers, 2007, 68(2): 235.

DOI URL |

| [8] |

XIA L, NI M, HE Q, et al. Optimization of gas diffusion layer in high temperature PEMFC with the focuses on thickness and porosity. Applied Energy, 2021, 300: 117357.

DOI URL |

| [9] |

YUSOF N, ISMAIL A F. Post spinning and pyrolysis processes of polyacrylonitrile (PAN)-based carbon fiber and activated carbon fiber: a review. Journal of Analytical and Applied Pyrolysis, 2012, 93: 1.

DOI URL |

| [10] |

KO T H, LIAO Y K, LIU C H. Effects of graphitization of PAN-based carbon fiber cloth on its use as gas diffusion layers in proton exchange membrane fuel cells. New Carbon Materials, 2007, 22(2): 97.

DOI URL |

| [11] |

OUYANG T, CHEN Y, JIANG Z, et al. Evaluation of low density and highly thermal conductive carbon bonded carbon fiber network with mesophase pitch as binder. Journal of Inorganic Materials, 2019, 34(10): 1030.

DOI |

| [12] |

RAHAMAN M S A, ISMAIL A F, MUSTAFA A. A review of heat treatment on polyacrylonitrile fiber. Polymer Degradation and Stability, 2007, 92(8): 1421.

DOI URL |

| [13] |

YANG H, TU H C, CHIANG I L. Carbon cloth based on PAN carbon fiber practicability for PEMFC applications. International Journal of Hydrogen Energy, 2010, 35(7): 2791.

DOI URL |

| [14] |

MATHUR R B, MAHESHWARI P H, DHAMI T L, et al. Processing of carbon composite paper as electrode for fuel cell. Journal of Power Sources, 2006, 161(2): 790.

DOI URL |

| [15] |

WEI J, NING F, BAI C, et al. An ultra-thin, flexible, low-cost and scalable gas diffusion layer composed of carbon nanotubes for high-performance fuel cells. Journal of Materials Chemistry A, 2020, 8(12): 5986.

DOI URL |

| [16] |

YANG Y, KONG L, LU J, et al. A highly conductive MXene-based rubber composite with relatively stable conductivity under small deformation and high sensing sensitivity at large strain. Composites Part A: Applied Science and Manufacturing, 2023, 170: 107545.

DOI URL |

| [17] |

GAN H, FENG Y, DAI P, et al. Heteroatom-doped biochar for direct dehydrogenation of propane to propylene. Journal of Inorganic Materials, 2022, 37(10): 1058.

DOI |

| [18] | HE W, MA R, ZHU Y, et al. Renewable porous carbons prepared by KOH activation as oxygen reduction electrocatalysts. Journal of Inorganic Materials, 2019, 34(10): 1115. |

| [19] |

GELFOND J, MENG T, LI S, et al. Highly electrically conductive biomass-derived carbon fibers for permanent carbon sequestration. Sustainable Materials and Technologies, 2023, 35: e00573.

DOI URL |

| [20] |

DANG D, ZENG R, CHEN X, et al. Natural wood derived robust carbon sheets with perpendicular channels as gas diffusion layers in air-breathing proton exchange membrane fuel cells (PEMFCs). Catalysis Communications, 2021, 159: 106351.

DOI URL |

| [21] |

NAVARRO A J, GOMEZ M A, DAZA L, et al. Production of gas diffusion layers with cotton fibers for their use in fuel cells. Scientific Reports, 2022, 12: 4219.

DOI PMID |

| [22] |

FU X, LI T, TANG L, et al. Reticulated polyaniline nanowires as a cathode microporous layer for high-temperature PEMFCs. International Journal of Hydrogen Energy, 2021, 46(12): 8802.

DOI URL |

| [23] |

SUN W, LIU C, LI Y, et al. Rational construction of Fe2N@C yolk-shell nanoboxes as multifunctional hosts for ultralong lithium-sulfur batteries. ACS Nano, 2019, 13(10): 12137.

DOI URL |

| [24] |

ZHAO Y, FROST R L, MARTENS W N, et al. XRD, TEM and thermal analysis of Fe doped boehmite nanofibres and nanosheets. Journal of Thermal Analysis and Calorimetry, 2007, 90(3): 755.

DOI URL |

| [25] |

NO Y S, CHOI H K, KIM J S, et al. Layer number identification of CVD-grown multilayer graphene using Si peak analysis. Scientific Reports, 2018, 8: 571.

DOI |

| [26] |

CHEN Z, REN W, GAO L, et al. Three-dimensional flexible and conductive interconnected graphene networks grown by chemical vapour deposition. Nature Materials, 2011, 10(6): 424.

DOI PMID |

| [27] |

SUN Z, ZHENG M, HU H, et al. From biomass wastes to vertically aligned graphene nanosheet arrays: a catalyst-free synthetic strategy towards high-quality graphene for electrochemical energy storage. Chemical Engineering Journal, 2018, 336: 550.

DOI URL |

| [28] |

JIN H, ZHOU H, LI W, et al. In situ derived Fe/N/S-codoped carbon nanotubes from ZIF-8 crystals as efficient electrocatalysts for the oxygen reduction reaction and zinc-air batteries. Journal of Materials Chemistry A, 2018, 6(41): 20093.

DOI URL |

| [29] |

XU J, LIANG G, CHEN D, et al. Iron and nitrogen doped carbon derived from ferrocene and ZIF-8 as proton exchange membrane fuel cell cathode catalyst. Applied Surface Science, 2022, 573: 151607.

DOI URL |

| [30] |

LU F, FAN K, CUI L, et al. Engineering FeN4 active sites onto nitrogen-rich carbon with tubular channels for enhanced oxygen reduction reaction performance. Applied Catalysis B: Environmental, 2022, 313: 121464.

DOI URL |

| [31] | QI C Z, WU X, LIU J, et al. Highly conductive calcium ion-reinforced MXene/sodium alginate aerogel meshes by direct ink writing for electromagnetic interference shielding and Joule heating. Journal of Materials Science & Technology, 2023, 135: 213. |

| [32] |

JIN Y, MA Z, WU M, et al. Preparation of MXene with high conductivity and its application on conductive fabrics. Applied Nanoscience, 2022, 12(8): 2317.

DOI |

| [33] | GONG X, XIONG Z, CHEN X, et al. Multifunctional superamphiphobic cotton fabrics with highly efficient flame retardancy, self-cleaning, and electromagnetic interference shielding. ACS Applied Materials & Interfaces, 2023, 15(2): 3395. |

| [34] |

YANG M, CHEN P, QU X, et al. Robust neural interfaces with photopatternable, bioadhesive, and highly conductive hydrogels for stable chronic neuromodulation. ACS Nano, 2023, 17(2): 885.

DOI URL |

| [35] |

SHU L, WANG Z, ZHANG X F, et al. Highly conductive and anti-freezing cellulose hydrogel for flexible sensors. International Journal of Biological Macromolecules, 2023, 230: 123425.

DOI URL |

| [36] |

XU Q, ZHAO J, CHEN Y, et al. Effects of gas permeation on the sealing performance of PEMFC stacks. International Journal of Hydrogen Energy, 2021, 46(73): 36424.

DOI URL |

| [37] |

KIM K N, KANG J H, LEE S G, et al. Lattice Boltzmann simulation of liquid water transport in microporous and gas diffusion layers of polymer electrolyte membrane fuel cells. Journal of Power Sources, 2015, 278: 703.

DOI URL |

| [38] |

ANTOLINI E, PASSOS R R, TICIANELLI E A. Effects of the carbon powder characteristics in the cathode gas diffusion layer on the performance of polymer electrolyte fuel cells. Journal of Power Sources, 2002, 109(2): 477.

DOI URL |

| [39] |

KRAYTSBERG A, EIN-ELI Y. Review of advanced materials for proton exchange membrane fuel cells. Energy & Fuels, 2014, 28(12): 7303.

DOI URL |

| [40] |

DU H Y, WANG C H, HSU H C, et al. High performance of catalysts supported by directly grown PTFE-free micro-porous CNT layer in a proton exchange membrane fuel cell. Journal of Materials Chemistry, 2011, 21: 2512.

DOI URL |

| [1] | GUO Tianmin, DONG Jiangbo, CHEN Zhengpeng, RAO Mumin, LI Mingfei, LI Tian, LING Yihan. Enhanced Compatibility and Activity of High-entropy Double Perovskite Cathode Material for IT-SOFC [J]. Journal of Inorganic Materials, 2023, 38(6): 693-700. |

| [2] | YAO Yishuai, GUO Ruihua, AN Shengli, ZHANG Jieyu, CHOU Kuochih, ZHANG Guofang, HUANG Yarong, PAN Gaofei. In-situ Loaded Pt-Co High Index Facets Catalysts: Preparation and Electrocatalytic Performance [J]. Journal of Inorganic Materials, 2023, 38(1): 71-78. |

| [3] | WU Qiuqin, YAO Fenfa, JIN Chuanhong, ZHENG Yifan. One-dimensional Sub-stoichiometric W3O8 Nanowires Filled Carbon Nanotubes [J]. Journal of Inorganic Materials, 2022, 37(4): 413-419. |

| [4] | FAN Shuai, JIN Tian, ZHANG Shanlin, LUO Xiaotao, LI Chengxin, LI Changjiu. Effect of Li2O Sintering Aid on Sintering Characteristics and Electrical Conductivity of LSGM Electrolyte for Solid Oxide Fuel Cell [J]. Journal of Inorganic Materials, 2022, 37(10): 1087-1092. |

| [5] | LIU Fangfang, CHUAN Xiuyun, YANG Yang, LI Aijun. Influence of N/S Co-doping on Electrochemical Property of Brucite Template Carbon Nanotubes [J]. Journal of Inorganic Materials, 2021, 36(7): 711-717. |

| [6] | CAO Dan,ZHOU Mingyang,LIU Zhijun,YAN Xiaomin,LIU Jiang. Fabrication and Characterization of Anode-supported Solid Oxide Fuel Cell Based on Proton Conductor Electrolyte [J]. Journal of Inorganic Materials, 2020, 35(9): 1047-1052. |

| [7] | DONG Longhao,ZHANG Haijun,ZHANG Jun,WU Wenhao,JIA Quanli. Carbon Nanotube Modified Sepiolite Porous Ceramics for High-efficient Oil/Water Separation [J]. Journal of Inorganic Materials, 2020, 35(6): 689-696. |

| [8] | XIA Tian, MENG Xie, LUO Ting, ZHAN Zhongliang. La 3+-substituted Sr2Fe1.5Ni0.1Mo0.4O6-δ as Anodes for Solid Oxide Fuel Cells [J]. Journal of Inorganic Materials, 2020, 35(5): 617-622. |

| [9] | LUO Yi,FENG Junzong,FENG Jian,JIANG Yonggang,LI Liangjun. Research Progress on Advanced Carbon Materials as Pt Support for Proton Exchange Membrane Fuel Cells [J]. Journal of Inorganic Materials, 2020, 35(4): 407-415. |

| [10] | LI Ya-Hui, ZHANG Jian-Feng, CAO Hui-Yang, ZHANG Xin, JIANG Wan. PtRu Particles Supported on Two-dimensional Titanium Carbide/Carbon Nanotubes: Preparation and Electrocatalytic Properties [J]. Journal of Inorganic Materials, 2020, 35(1): 79-85. |

| [11] | Kai LI, Xiao LI, Jian LI, Jia-Miao XIE. Structural Stability of Ni-Fe Supported Solid Oxide Fuel Cells Based on Stress Analysis [J]. Journal of Inorganic Materials, 2019, 34(6): 611-617. |

| [12] | Wei WANG, Li-Li YUAN, Qian-Yuan QIU, Ming-Yang ZHOU, Mei-Lin LIU, Jiang LIU. A Direct Carbon Solid Oxide Fuel Cell Stack Based on a Single Electrolyte Plate Fabricated by Tape Casting Technique [J]. Journal of Inorganic Materials, 2019, 34(5): 509-514. |

| [13] | HE Wang-Tao, MA Ru-Guang, ZHU Yu-Fang, YANG Ming-Jie, WANG Jia-Cheng. Renewable Porous Carbons Prepared by KOH Activation as Oxygen Reduction Electrocatalysts [J]. Journal of Inorganic Materials, 2019, 34(10): 1115-1122. |

| [14] | XIA Tian, MENG Xie, LUO Ting, ZHAN Zhong-Liang. Synthesis and Evaluation of Ca-doped Sr2Fe1.5Mo0.5O6-δ as Symmetrical Electrodes for High Performance Solid Oxide Fuel Cells [J]. Journal of Inorganic Materials, 2019, 34(10): 1109-1114. |

| [15] | LIU Tian-Tian, WANG Qing-Hua, LIU Xi-Li, GAO Feng, WANG Qing-Xiang. Synthesis and Pseudocapacitive Behavior of Nickel Molybdate/Mutiwalled Carbon Nanotubes Composite [J]. Journal of Inorganic Materials, 2018, 33(7): 735-740. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||