Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (1): 105-112.DOI: 10.15541/jim20220327

• RESEARCH ARTICLE • Previous Articles

PAN Yangyang1,2( ), LIANG Bo1(

), LIANG Bo1( ), HONG Du2, QI Zhixiang3, NIU Yaran2, ZHENG Xuebin2

), HONG Du2, QI Zhixiang3, NIU Yaran2, ZHENG Xuebin2

Received:2022-06-11

Revised:2022-07-26

Published:2022-08-04

Online:2022-08-04

Contact:

LIANG Bo, professor. E-mail: liangbo@ysu.edu.cnAbout author:PAN Yangyang (1991-), male, PhD candidate. E-mail: panyangyang4155@163.com

Supported by:CLC Number:

PAN Yangyang, LIANG Bo, HONG Du, QI Zhixiang, NIU Yaran, ZHENG Xuebin. High Temperature Long-term Service Performance of TiAlCrY/YSZ Coating on TiAl Alloy[J]. Journal of Inorganic Materials, 2023, 38(1): 105-112.

| Al | Cr | Y | Ti | Ni | Zr | O | Source | |

|---|---|---|---|---|---|---|---|---|

| TiAlCrY | 55.0 | 20.0 | 0.4 | 24.6 | — | — | — | Nanjing University of Science and Technology |

| NiCrAlY | 14.5 | 20.5 | 1.0 | — | 64.0 | — | — | Institute of Metal Research, Chinese Academy of Sciences |

| YSZ | — | — | 3.7 | — | — | 30.3 | 66.0 | Sulzer Metco |

Table 1 Compositions of YSZ, TiAlCrY and NiCrAlY powders (%, in atom)

| Al | Cr | Y | Ti | Ni | Zr | O | Source | |

|---|---|---|---|---|---|---|---|---|

| TiAlCrY | 55.0 | 20.0 | 0.4 | 24.6 | — | — | — | Nanjing University of Science and Technology |

| NiCrAlY | 14.5 | 20.5 | 1.0 | — | 64.0 | — | — | Institute of Metal Research, Chinese Academy of Sciences |

| YSZ | — | — | 3.7 | — | — | 30.3 | 66.0 | Sulzer Metco |

| Coating | Ar/slpm | H2/slpm | Spray distance/mm | Feed rate/(r·min-1) | Power/kW | Vacuum pressure/Pa |

|---|---|---|---|---|---|---|

| TiAlCrY/ NiCrAlY | 30-40 | 5-15 | 200-300 | 15-30 | 30-40 | 1-3 |

| YSZ | 30-40 | 5-15 | 90-130 | 15-30 | 38-48 | — |

Table 2 Spray parameters of YSZ, TiAlCrY and NiCrAlY coatings

| Coating | Ar/slpm | H2/slpm | Spray distance/mm | Feed rate/(r·min-1) | Power/kW | Vacuum pressure/Pa |

|---|---|---|---|---|---|---|

| TiAlCrY/ NiCrAlY | 30-40 | 5-15 | 200-300 | 15-30 | 30-40 | 1-3 |

| YSZ | 30-40 | 5-15 | 90-130 | 15-30 | 38-48 | — |

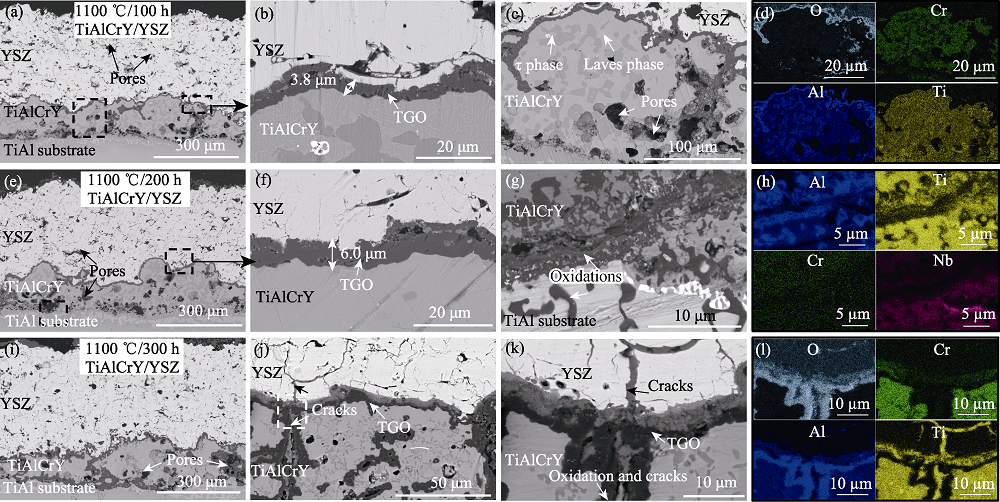

Fig. 4 Cross-sectional morphologies and EDS results of TiAlCrY/YSZ coating after heat-treatment at 1100 ℃ for 100 h (a-d), 200 h (e-h) and 300 h (i-l)

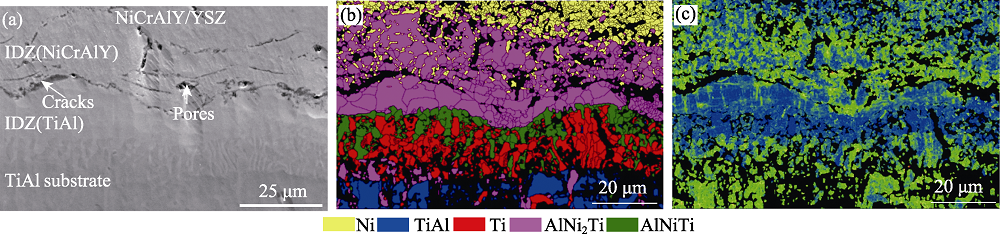

Fig. 6 Cross-sectional morphologies (a) and EBSD results (b, c) of NiCrAlY/YSZ coating after 100 h thermal-treatment at 1100 ℃. Colorful images are available on the website

| [1] |

DIMIDUK D M. Gamma titanium aluminide alloys—an assessment within the competition of aerospace structural materials. Materials Science and Engineering: A, 1999, 263(2): 281.

DOI URL |

| [2] |

CLEMENS HELMUT, MAYER SVEA. Design, processing, microstructure, properties, and applications of advanced intermetallic TiAl alloys. Advanced Engineering Materials, 2013, 15(4): 191.

DOI URL |

| [3] |

CLEMENS HELMUT, KESTLER HEINRICH. Processing and applications of intermetallic γ-TiAl-based alloys. Advanced Engineering Materials, 2000, 2(9): 551.

DOI URL |

| [4] | 彭小敏, 夏长清, 王志辉. TiAl 基合金高温氧化及防护的研究进展. 中国有色金属学报, 2010, 20(6): 1116. |

| [5] |

CLARKE DAVID R, OECHSNER M, PADTURE N P, et al. Thermal-barrier coatings for more efficient gas-turbine engines. MRS Bulletin, 2012, 37(10): 891.

DOI URL |

| [6] |

GLEESON B. Thermal barrier coatings for aeroengine applications. Journal of Propulsion and Power, 2006, 22(2): 375.

DOI URL |

| [7] |

LEYENS C, VAN LIERE J W, PETERS M, et al. Magnetron- sputtered Ti-Cr-Al coatings for oxidation protection of titanium alloys. Surface & Coatings Technology, 1998, 108-109(10): 30.

DOI URL |

| [8] |

FOX-RABINOVICH G S, WILKINSON D S, VELDHUIS S C, et al. Oxidation resistant Ti-Al-Cr alloy for protective coating applications. Intermetallic, 2006, 14(2): 189.

DOI URL |

| [9] | ZHOU C G, YANG Y, GONG S K, et al. Effect of Ti-Al-Cr coatings on the high temperature oxidation behavior of TiAl alloys. Materials Science & Engineering A, 2001, 307(1/2): 182. |

| [10] | BRAUN R, BRAUE W, FROHLICH M, et al. Thermally grown oxide scales on gamma-TiAl coated with thermal protection systems. High Temperature Technology, 2009, 26(3): 305. |

| [11] |

BRAUN R, FRÖHLICH M, BRAUE W, et al. Oxidation behaviour of gamma titanium aluminides with EB-PVD thermal barrier coatings exposed to air at 900 ℃. Surface & Coatings Technology, 2007, 202(4-7): 676.

DOI URL |

| [12] | 唐兆麟, 王福会, 吴维. TiAlCr涂层对TiAl金属间化合物抗高温氧化性能的影响. 中国腐蚀与防护学报, 1998, 18(1): 35. |

| [13] |

PAN Y Y, LIANG B, NIU Y R, et al. Thermal shock behaviors of plasma sprayed TiAlCrY/YSZ system on TiAl alloys. Ceramics International, 2022, 48(5): 6199.

DOI URL |

| [14] |

PAN Y Y, LIANG B, HONG D, et al. Effect of TiAlCrNb buffer layer on thermal cycling behavior of TiAlCrY/YSZ coatings on γ-TiAl alloys. Surface & Coatings Technology, 2021, 431(15): 128000.

DOI URL |

| [15] |

RACHELEH A P, REZA S R, REZA M, et al. Improving the thermal shock resistance of plasma sprayed CYSZ thermal barrier coatings by laser surface modification. Opt. Laser. Eng., 2012, 50(5): 780.

DOI URL |

| [16] | 许世鸣, 张小锋, 刘敏, 等. APS制备7YSZ热障涂层镀铝改性的抗氧化性. 材料导报, 2019, 33(1): 283. |

| [17] |

JAMALI H, MOZAFARINIA R, RAZAVI R S, et al. Comparison of thermal shock resistances of plasma-sprayed nanostructured and conventional yttria stabilized zirconia thermal barrier coatings, Ceramics International, 2012, 38(8): 6705.

DOI URL |

| [18] |

ZHANG X F, ZHOU K S, ZHANG J F, et al. Structure evolution of 7YSZ thermal barrier coating during thermal shock testing. Journal of Inorganic Materials, 2015, 30(12): 1261.

DOI URL |

| [19] |

BRADY M P, SMIALEK J L, HUMPHREY D L, et al. The role of Cr in promoting protective alumina scale formation by γ-based Ti-Al-Cr alloys—II. Oxidation behavior in air. Acta Materialia, 1997, 45(6): 2371.

DOI URL |

| [20] |

LIU C T, ZHU J H, BRADY M P, et al. Physical metallurgy and mechanical properties of transition-metal Laves phase alloys. Intermetallic, 2000, 8(9/10/11):1119.

DOI URL |

| [21] | TAKEYAMA M, LIU C T. Microstructure and mechanical properties of Laves-phase alloys based on Cr2Nb. Materials Science & Engineering A, 1991, 132(91): 61. |

| [22] |

WEISS M, LU M, P VAN DER HEIDE, et al. Radiation enhanced diffusion of Ti in Al2O3. Journal of Chemical Physics, 2000, 113(12): 5058.

DOI URL |

| [23] |

KLIAUGA A M, Ferrante M. Interface compounds formed during the diffusion bonding of Al2O3 to Ti. Journal of Materials Science, 2000, 35(17): 4243.

DOI URL |

| [24] |

HILLE T S, TURTELTAUB S, SUIKER A S J, et al. Oxide growth and damage evolution in thermal barrier coatings. Engineering Fracture Mechanics, 2011, 78(10): 2139.

DOI URL |

| [25] |

CUI Y J, GUO M Q, WANG C L, et al. Evolution of the residual stress in porous ceramic abradable coatings under thermal exposure. Surface and Coatings Technology, 2020, 394(25): 125915.

DOI URL |

| [26] |

ABBA A A, ABUL F M A, SOHAIL A. Evolution of internal cracks and residual stress during deposition of TBC. Ceramics International, 2020, 46(17): 26731.

DOI URL |

| [27] |

LI D, PENG B Z, QU W, et al. Finite-element simulation of residual stress in zirconia thermal barrier coating. Advanced Materials Research, 2011, 311-313: 210.

DOI URL |

| [28] |

HILLE T S, TURTELTAUB S, SUIKER A S J. Oxide growth and damage evolution in thermal barrier coatings. Engineering Fracture Mechanics, 2011, 78(10): 2139.

DOI URL |

| [29] |

KARUNARATNE M S A, KYAW S, JONES A, et al. Modelling the coefficient of thermal expansion in Ni-based superalloys and bond coatings. Journal of Materials Science, 2016, 51(9): 4213.

DOI URL |

| [30] |

LASSEUR V, GOUTIER S, GARCIA V M, et al. Residual stress evolution in zirconia (Y2O38%) coatings during atmospheric plasma spraying for substrates under rotating kinematic. Journal of Thermal Spray Technology, 2020, 29(5/6): 1313.

DOI URL |

| [31] | ARAI M, WADA E, KISHIMOTO K. Residual stress analysis of ceramic thermal barrier coating based on thermal spray process. Transactions of the Japan Society of Mechanical Engineers, 2007, 72(717): 1251. |

| [1] | HONG Du, NIU Yaran, LI Hong, ZHONG Xin, ZHENG Xuebin. Tribological Properties of Plasma Sprayed TiC-Graphite Composite Coatings [J]. Journal of Inorganic Materials, 2022, 37(6): 643-650. |

| [2] | DAI Zhao,WANG Ming,WANG Shuang,LI Jing,CHEN Xiang,WANG Da-Lin,ZHU Ying-Chun. Zirconia Reinforced Trace Element Co-doped Hydroxyapatite Coating [J]. Journal of Inorganic Materials, 2020, 35(2): 179-186. |

| [3] | FAN Jia-Feng,ZHANG Xiao-Feng,ZHOU Ke-Song,LIU Min,DENG Chang-Guang,DENG Chun-Ming,NIU Shao-Peng,DENG Zi-Qian. Influence of Al-modification on CMAS Corrosion Resistance of PS-PVD 7YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2019, 34(9): 938-946. |

| [4] | XIE Ling-Ling, NIU Ya-Ran, WANG Liang, CHEN Wen-Liang, ZHENG Xue-Bin, HUANG Zhen-Yi. Residual Stresses of Plasma Sprayed ZrC-Based Coatings during Path-by-path and Layer-by-layer Deposition: Simulation and Experimental Verification [J]. Journal of Inorganic Materials, 2019, 34(7): 768-774. |

| [5] | Yan-Zhe ZHOU, Min LIU, Kun YANG, Wei ZENG, Jin-Bing SONG, Chun-Ming DENG, Chang-Guang DENG. Microstructure and Property of MoSi2-30Al2O3 Electrothermal Coating Prepared by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2019, 34(6): 646-652. |

| [6] | CHEN Shu-Ying, MA Guo-Zheng, HE Peng-Fei, LIU Zhe, LIU Ming, XING Zhi-Guo, WANG Hai-Dou, WANG Hai-Jun. Pore Formation Mechanism of WC-10Co4Cr Coatings Based on Collected In-flight Particles and Individual Splat [J]. Journal of Inorganic Materials, 2018, 33(8): 895-902. |

| [7] | ZHANG Xiao-Feng, ZHOU Ke-Song, LIU Min, DENG Chun-Ming, NIU Shao-Peng, XU Shi-Ming. Preparation of Si/Mullite/Yb2SiO5 Environment Barrier Coating (EBC) by Plasma Spray-Physical Vapor Deposition (PS-PVD) [J]. Journal of Inorganic Materials, 2018, 33(3): 325-330. |

| [8] | LI Da-Chuan, ZHAO Hua-Yu, ZHONG Xing-Hua, TAO Shun-Yan. Research Progresses of Atmospheric Plasma Sprayed Splat [J]. Journal of Inorganic Materials, 2017, 32(6): 571-580. |

| [9] | SUN Xu-Xuan, CHEN Hong-Fei, YANG Guang, LIU Bin, GAO Yan-Feng. YSZ- Ti3AlC2 Thermal Barrier Coating and Its Self-healing Behavior under High Temperatures [J]. Journal of Inorganic Materials, 2017, 32(12): 1269-1274. |

| [10] | YU Fang-Li, BAI Yu, WU Xiu-Ying, Wang Hai-Jun, WU Jiu-Hui. Corrosion Resistance and Anti-wear Property of Nickel Based Abradable Sealing Coating Deposited by Plasma Spraying [J]. Journal of Inorganic Materials, 2016, 31(7): 687-693. |

| [11] | LIN Chu-Cheng, KONG Ming-Guang, ZHU Hui-Ying, HUANG Li-Ping, ZHENG Xue-Bin, ZENG Yi. Tribological Behavior of Vacuum Plasma Sprayed B4C-Mo Composite Coating [J]. Journal of Inorganic Materials, 2016, 31(1): 100-106. |

| [12] | MAO Jin-Yuan, LIU Min, MAO Jie, DENG Chun-Min, ZENG De-Chang, XU Lin. Oxidation-resistance of ZrB2-MoSi2 Composite Coatings Prepared by Atmospheric Plasma Spraying [J]. Journal of Inorganic Materials, 2015, 30(3): 282-286. |

| [13] | ZHANG Xiao-Feng, ZHOU Ke-Song, SONG Jin-Bing, DENG Chun-Ming, NIU Shao-Peng, DENG Zi-Qian. Deposition and CMAS Corrosion Mechanism of 7YSZ Thermal Barrier Coatings Prepared by Plasma Spray-Physical Vapor Deposition [J]. Journal of Inorganic Materials, 2015, 30(3): 287-293. |

| [14] | CHEN Dan, WANG Yu, BAI Yu, WANG Yun-Hui, ZHAO Lei, Fu Qian-Qian, WANG Hai-Jun, HAN Zhi-Hai. Effect of Reynolds Number of Molten Particle on Splat Formation in Plasma Spraying [J]. Journal of Inorganic Materials, 2015, 30(1): 65-70. |

| [15] | YI De-Liang, WU Cheng-Tie, MA Xu-Bing, JI Heng, ZHENG Xue-Bin, CHANG Jiang. A Comparative Study of Vacuum and Air Plasma Sprayed Bioactive Akermanite Coating [J]. Journal of Inorganic Materials, 2014, 29(2): 172-178. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||