Journal of Inorganic Materials ›› 2023, Vol. 38 ›› Issue (2): 213-218.DOI: 10.15541/jim20220155

Previous Articles Next Articles

ZHANG Wanwen1( ), LUO Jianqiang1(

), LUO Jianqiang1( ), LIU Shujuan1, MA Jianguo1, ZHANG Xiaoping1, YANG Songwang2(

), LIU Shujuan1, MA Jianguo1, ZHANG Xiaoping1, YANG Songwang2( )

)

Received:2022-03-21

Revised:2022-07-21

Published:2023-02-20

Online:2022-08-04

Contact:

LUO Jianqiang, professor. E-mail: luojianqiang@163.com;About author:: ZHANG Wanwen (1994-), male, Master candidate. E-mail: 2352937300@qq.com

Supported by:CLC Number:

ZHANG Wanwen, LUO Jianqiang, LIU Shujuan, MA Jianguo, ZHANG Xiaoping, YANG Songwang. Zirconia Spacer: Preparation by Low Temperature Spray-coating and Application in Triple-layer Perovskite Solar Cells[J]. Journal of Inorganic Materials, 2023, 38(2): 213-218.

Fig. 2 SEM images of the zirconia film prepared by spray- coating without urea (a), with w(zirconia) : w(urea)= 2 : 1 (b) and 1 : 1 (c), cross-sectional SEM images of PSCs containing zirconia layer prepared with w(zirconia) : w(urea)= 2 : 1(d) and 1 : 1 (e) Circled areas in (d) are not completely filled

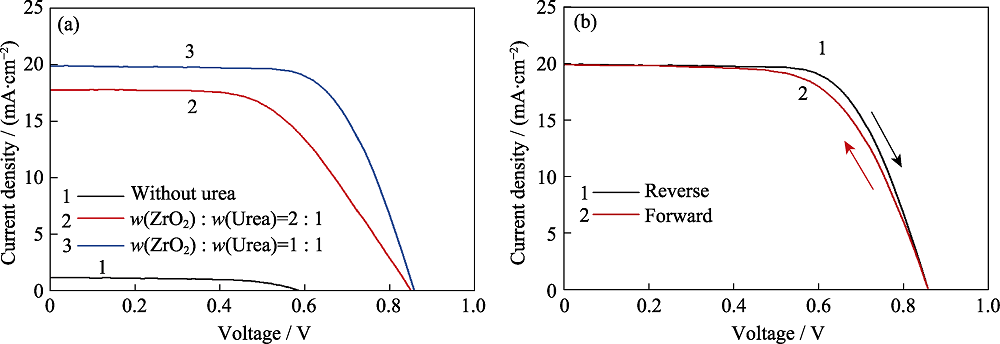

Fig. 3 J-V curves of PSCs prepared with w(zirconia) : w(urea)=2 : 1 and 1 : 1(a), and J-V curves from forward and reverse scanning of PSC prepared with w(zirconia) : w(urea)=1 : 1 (Zirconia layer thickness at ~1000 nm) (b)

Fig. 4 J-V curves of the triple-layer PSCs with spray-coated and screen-printed zirconia layer(a), IPCE spectrum and corresponding integrated current density of the PSC with 1100 nm thick zirconia layer(b), PCE distribution of 30 chips with three different thicknesses of zirconia layer(c), and stabilized power output of PSCs with optimized spray-coated zirconia layer (d)

Fig. S3 Cross-sectional SEM images of PSCs before filling perovskite with the zirconia thickness of (a, b) 750, (c, d) 1100 nm and (e, f) 1500 nm((a, c, e) before and (b, d, f) after filling perovkite)

Fig. S4 (a) J-V curves of the cell with different illumination areas with inset showing the tested cell photograph; (b) J-V curve of PSCs module with five cells connected in series with inset showing the tested cell photograph

| [1] |

KOJIMA A, TESHIMA K, SHIRAI Y, et al. Organometal halide perovskites as visible-light sensitizers for photovoltaic cells. J. Am. Chem. Soc., 2009, 131(17): 6050.

DOI PMID |

| [2] |

LEE M M, TEUSCHER J, MIYASAKA T, et al. Efficient hybrid solar cells based on meso-superstructured organometal halide perovskites. Science, 2012, 338(6107): 643.

DOI PMID |

| [3] |

BURSCHKA J, PELLET N, MOON S J, et al. Sequential deposition as a route to high-performance perovskite-sensitized solar cells. Nature, 2013, 499(7458): 316.

DOI URL |

| [4] | HUANG L, ZHOU X, XUE R, et al. Low-temperature growing anatase TiO2/SnO2 multi-dimensional heterojunctions at MXene conductive network for high-efficient perovskite solar cells. Nanomicro Lett., 2020, 12(1): 44. |

| [5] |

PATIL P, MANN D S, NAKATE U T, et al. Hybrid interfacial ETL engineering using PCBM-SnS2 for high-performance p-i-n structured planar perovskite solar cells. Chem. Eng. J., 2020, 397: 125504.

DOI URL |

| [6] |

JUNG E H, JEON N J, PARK E Y, et al. Efficient, stable and scalable perovskite solar cells using poly(3-hexylthiophene). Nature, 2019, 567(7749): 511.

DOI URL |

| [7] |

PARK M, CHO W, LEE G, et al. Highly reproducible large-area perovskite solar cell fabrication via continuous megasonic spray coating of CH3NH3PbI3. Small, 2019, 15(1): 1804005.

DOI URL |

| [8] |

MCMEEKIN D P, MAHESH S, NOEL N K, et al. Solution- processed all-perovskite multi-junction solar cells. Joule, 2019, 3(2): 387.

DOI URL |

| [9] |

YOO J J, SEO G, CHUA M R, et al. Efficient perovskite solar cells via improved carrier management. Nature, 2021, 590(7847): 587.

DOI URL |

| [10] |

MEI A, LI X, LIU L, et al. A hole-conductor-free, fully printable mesoscopic perovskite solar cell with high stability. Science, 2014, 345(6194): 295.

DOI PMID |

| [11] |

TAN H, JAIN A, VOZNYY O, et al. Efficient and stable solution- processed planar perovskite solar cells via contact passivation. Science, 2017, 355(6326): 722.

DOI URL |

| [12] |

LIU X, CHENG Y, LIU C, et al. 20.7% highly reproducible inverted planar perovskite solar cells with enhanced fill factor and eliminated hysteresis. Energy Environ. Sci., 2019, 12(5): 1622.

DOI URL |

| [13] |

ZHOU Z, LIAN H J, XIE J, et al. Non-selective adsorption of organic cations enables conformal surface capping of perovskite grains for stabilized photovoltaic operation. Cell Reports Physical Science, 2022, 3(2): 100760.

DOI URL |

| [14] |

LIU X, LIAN H, ZHOU Z, et al. Stoichiometric dissolution of defective CsPbI2Br surfaces for inorganic solar cells with 17.5% efficiency. Adv. Energy. Mater., 2022, 12(14): 2103933.

DOI URL |

| [15] |

RONG Y, HU Y, MEI A, et al. Challenges for commercializing perovskite solar cells. Science, 2018, 361(6408): eaat8235.

DOI URL |

| [16] |

LUO J, YANG H B, ZHUANG M, et al. Making fully printed perovskite solar cells stable outdoor with inorganic superhydrophobic coating. J. Energy Chem., 2020, 50: 332.

DOI URL |

| [17] |

YANG K, LIU S, DU J K, et al. Improving hole-conductor-free fully printable mesoscopic perovskite solar cells' performance with enhanced open-circuit voltage via the octyltrimethylammonium chloride additive. Solar RRL, 2021, 5(4): 2000825.

DOI URL |

| [18] |

WANG Y, ZHANG T, XU F, et al. A facile low temperature fabrication of high performance CsPbI2Br all-inorganic perovskite solar cells. Solar RRL, 2018, 2(1): 1700180.

DOI URL |

| [19] |

HU L, ZHAO Q, HUANG S, et al. Flexible and efficient perovskite quantum dot solar cells via hybrid interfacial architecture. Nat. Commun., 2021, 12(1): 466.

DOI URL |

| [20] |

YANG D, YANG R, ZHANG J, et al. High efficiency flexible perovskite solar cells using superior low temperature TiO2. Energy Environ. Sci., 2015, 8(11): 3208.

DOI URL |

| [21] |

DAGAR J, CASTRO-HERMOSA S, GASBARRI M, et al. Efficient fully laser-patterned flexible perovskite modules and solar cells based on low-temperature solution-processed SnO2/mesoporous-TiO2 electron transport layers. Nano Research, 2018, 11(5): 2669.

DOI URL |

| [22] |

YANG D, YANG R, PRIYA S, et al. Recent advances in flexible perovskite solar cells: fabrication and applications. Angew. Chem. Int. Ed., 2019, 58(14): 4466.

DOI PMID |

| [23] |

MATSUI T, SEO J Y, SALIBA M, et al. Room-temperature formation of highly crystalline multication perovskites for efficient, low-cost solar cells. Adv. Mater., 2017, 29(15): 1606258.

DOI URL |

| [24] |

DI GIACOMO F, FAKHARUDDIN A, JOSE R, et al. Progress, challenges and perspectives in flexible perovskite solar cells. Energy Environ. Sci., 2016, 9(10): 3007.

DOI URL |

| [25] | HAQUE S A, PALOMARES E, UPADHYAYA H M, et al. Flexible dye sensitised nanocrystalline semiconductor solar cells. Chem. Commun., 2003, (24): 3008. |

| [26] |

JIANG P, JONES T W, DUFFY N W, et al. Fully printable perovskite solar cells with highly-conductive, low-temperature, perovskite- compatible carbon electrode. Carbon, 2018, 129: 830.

DOI URL |

| [27] |

LUO J, CHEN J, WU B, et al. Surface rutilization of anatase TiO2 for efficient electron extraction and stable Pmax output of perovskite solar cells. Chem, 2018, 4(4): 911.

DOI URL |

| [28] |

RONG Y, HOU X, HU Y, et al. Synergy of ammonium chloride and moisture on perovskite crystallization for efficient printable mesoscopic solar cells. Nat. Commun., 2017, 8: 14555.

DOI PMID |

| [29] |

ZHANG Y H, LI Y. Interface materials for perovskite solar cells. Rare Met., 2021, 40(11): 2993.

DOI URL |

| [30] |

CHANG J H, LIU K, LIN S Y, et al. Solution-processed perovskite solar cells. Journal of Central South University, 2020, 27(4): 1104.

DOI URL |

| [31] |

DENG Y, PENG E, SHAO Y, et al. Scalable fabrication of efficient organolead trihalide perovskite solar cells with doctor-bladed active layers. Energy Environ Sci, 2015, 8(5): 1544.

DOI URL |

| [32] |

WU Y, YANG X, CHEN W, et al. Perovskite solar cells with 18.21% efficiency and area over 1 cm2 fabricated by heterojunction engineering. Nat Energy, 2016, 1(11): 16148.

DOI URL |

| [33] |

KIERMASCH D, GIL-ESCRIG L, BOLINK H J, et al. effects of masking on open-circuit voltage and fill factor in solar cells. Joule, 2019, 3(1): 16.

DOI URL |

| [1] | GUO Chunxia, CHEN Weidong, YAN Shufang, ZHAO Xueping, YANG Ao, MA Wen. Adsorption of Arsenate in Water by Zirconia-halloysite Nanotube Material [J]. Journal of Inorganic Materials, 2023, 38(5): 529-536. |

| [2] | JIAO Boxin, LIU Xingchong, QUAN Ziwei, PENG Yongshan, ZHOU Ruonan, LI Haimin. Performance of Perovskite solar cells Doped with L-arginine [J]. Journal of Inorganic Materials, 2022, 37(6): 669-675. |

| [3] | WANG Yaning, ZHANG Yuqi, SONG Suocheng, CHEN Ruomeng, LIU Yaxiong, DUAN Yugang. Laser Stereolithography for Zirconia Ceramic Fabrication and Its Debinding and Sintering Process [J]. Journal of Inorganic Materials, 2022, 37(3): 303-309. |

| [4] | CHEN Yaling, SHU Song, WANG Shaoxin, LI Jianjun. Mn-HAP SCR Catalyst: Preparation and Sulfur Resistance [J]. Journal of Inorganic Materials, 2022, 37(10): 1065-1072. |

| [5] | YANG Xinyue, DONG Qingshun, ZHAO Weidong, SHI Yantao. 4-Chlorobenzylamine-based 2D/3D Perovskite Solar Cells [J]. Journal of Inorganic Materials, 2022, 37(1): 72-78. |

| [6] | LIU Wenwen, HU Zhilei, WANG Li, CAO Mengsha, ZHANG Jing, ZHANG Jing, ZHANG Shuai, YUAN Ningyi, DING Jianning. Passiviation of L-3-(4-Pyridyl)-alanine on Interfacial Defects of Perovskite Solar Cell [J]. Journal of Inorganic Materials, 2021, 36(6): 629-636. |

| [7] | ZHANG Li, YANG Xianfeng, XU Xiewen, GUO Jinyu, ZHOU Zhe, LIU Peng, XIE Zhipeng. 3D Printed Zirconia Ceramics via Fused Deposit Modeling and Its Mechanical Properties [J]. Journal of Inorganic Materials, 2021, 36(4): 436-442. |

| [8] | WANG Yanxiang, GAO Peiyang, FAN Xueyun, LI Jiake, GUO Pingchun, HUANG Liqun, SUN Jian. Effect of SnO2 Annealing Temperature on the Performance of Perovskite Solar Cells [J]. Journal of Inorganic Materials, 2021, 36(2): 168-174. |

| [9] | MU Tinghai, XU Wentao, LING Junrong, DONG Tianwen, QIN Zixuan, ZHOU Youfu. Microstructure and Properties of ZrO2-AlN Composite Ceramics by Microwave Sintering [J]. Journal of Inorganic Materials, 2021, 36(11): 1231-1236. |

| [10] | ZHANG Xiaoxu,ZHU Dongbin,LIANG Jinsheng. Progress on Hydrothermal Stability of Dental Zirconia Ceramics [J]. Journal of Inorganic Materials, 2020, 35(7): 759-768. |

| [11] | YU Shouwu, ZHAO Zewen, ZHAO Jinjin, XIAO Shujuan, SHI Yan, GAO Cunfa, SU Xiao, HU Yuxiang, ZHAO Zhisheng, WANG Jie, WANG Lianzhou. Research Progress in Novel In-situ Integrative Photovoltaic-storage Tandem Cells [J]. Journal of Inorganic Materials, 2020, 35(6): 623-632. |

| [12] | LI Xing-Bang,ZHONG He,ZHANG Jing-Xian,DUAN Yu-Sen,JIANG Dong-Liang. Powder Characteristics on the Rheological Performance of Resin-based Zirconia Suspension for Stereolithography [J]. Journal of Inorganic Materials, 2020, 35(2): 231-235. |

| [13] | DAI Zhao,WANG Ming,WANG Shuang,LI Jing,CHEN Xiang,WANG Da-Lin,ZHU Ying-Chun. Zirconia Reinforced Trace Element Co-doped Hydroxyapatite Coating [J]. Journal of Inorganic Materials, 2020, 35(2): 179-186. |

| [14] | CHENG Yi-Tian, QIU Wan-Qi, ZHOU Ke-Song, LIU Zhong-Wu, JIAO Dong-Ling, ZHONG Xi-Chun, ZHANG Hui. Low-temperature Deposition of α-Al2O3 Films by Reactive Sputtering Al+α-Al2O3 Target [J]. Journal of Inorganic Materials, 2019, 34(8): 862-866. |

| [15] | XIAO Min, SUN Rui-Zhi, LI Yan-Fang, KANG Tong-Tong, QIN Jun, YANG Run, BI Lei. Transfer Printing of VO2 Thin Films Using MoS2/SiO2 van der Waals Heterojunctions [J]. Journal of Inorganic Materials, 2019, 34(11): 1161-1166. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||