Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (9): 941-946.DOI: 10.15541/jim20210790

• RESEARCH ARTICLE • Previous Articles Next Articles

MU Licheng1,2,3( ), YANG Jinping1(

), YANG Jinping1( ), WANG Junping2, ZHAO Jin2, LIU Mengwei2, WANG Dewen2, ZHANG Jian2(

), WANG Junping2, ZHAO Jin2, LIU Mengwei2, WANG Dewen2, ZHANG Jian2( )

)

Received:2021-12-27

Revised:2022-03-03

Published:2022-09-20

Online:2022-06-16

Contact:

YANG Jinping, associate professor. E-mail: imjp_yang@163.com;About author:MU Licheng (1997-), male, Master candidate. E-mail: mulicheng1997@163.com

Supported by:CLC Number:

MU Licheng, YANG Jinping, WANG Junping, ZHAO Jin, LIU Mengwei, WANG Dewen, ZHANG Jian. Preparation of YAG Transparent Ceramics by Epoxy Resin Modified Spontaneous Coagulation Casting[J]. Journal of Inorganic Materials, 2022, 37(9): 941-946.

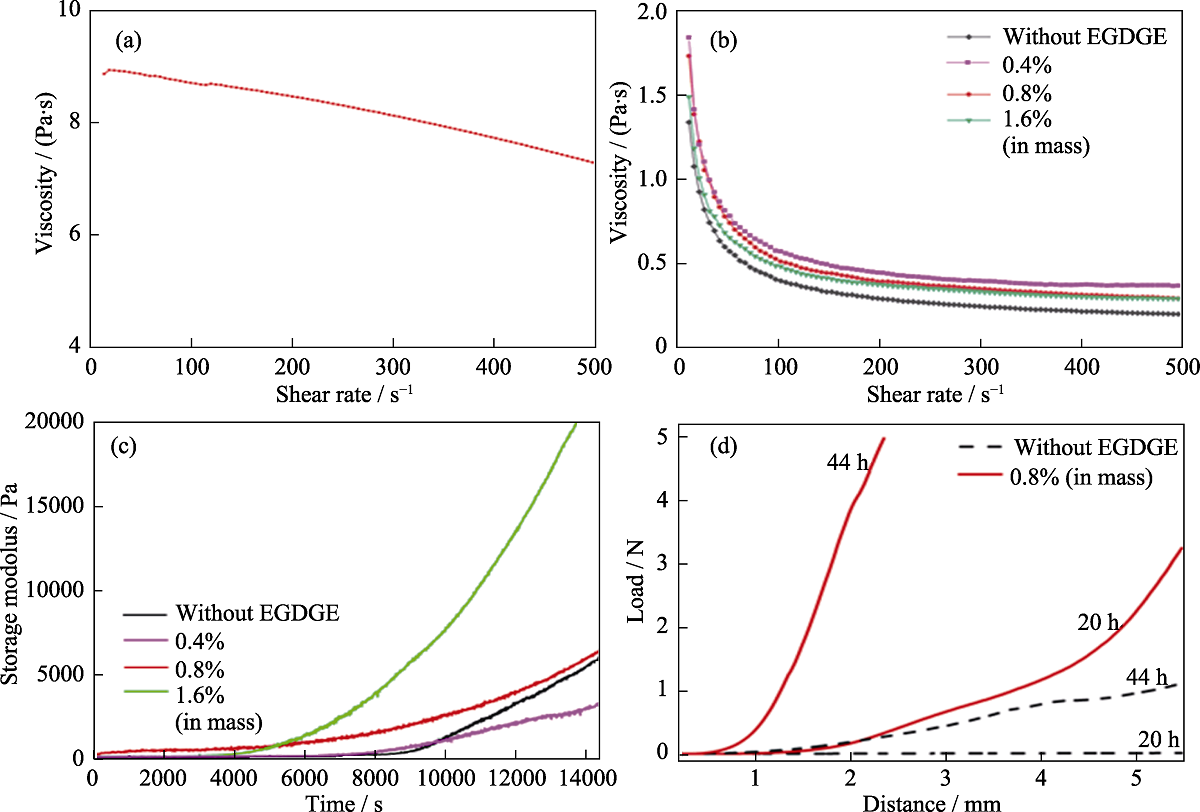

Fig. 2 Effects of EGDGE on the rheology of slurry (a) Viscosity curve of EGDGE; (b) Viscosity curves of the slurry after adding different contents of EGDGE; (c) Storage modulus of the slurry after adding different contents of EGDGE; (d) Load-displacement curves of the slurry (solid content 80%, IB104 0.25%, IB600 0.55% (in mass)). Colorful figures are available on website

| [1] |

TACHIWAKI T, YOSHINAKA M, HIROTA K, et al. Novel synthesis of Y3Al5O12 (YAG) leading to transparent ceramics. Solid State Communications, 2001, 119(10/11): 603-606.

DOI URL |

| [2] |

WANG S F, ZHANG J, LUO D W, et al. Transparent ceramics: processing, materials and applications. Progress in Solid State Chemistry, 2013, 41(1/2): 20-54.

DOI URL |

| [3] |

YANG H, QIN X, ZHANG J, et al. Fabrication of Nd:YAG transparent ceramics with both TEOS and MgO additives. Journal of Alloys and Compounds, 2011, 509(17): 5274-5279.

DOI URL |

| [4] |

LU J, PRABHU M, SONG J, et al. Optical properties and highly efficient laser oscillation of Nd: YAG ceramics. Applied Physics B, 2000, 71(4): 469-473.

DOI URL |

| [5] |

IKESUE A, KINOSHITA T, KAMATA K, et al. Fabrication and optical properties of high-performance polycrystalline Nd:YAG ceramics for solid-state lasers. Journal of the American Ceramic Society, 1995, 78(4): 1033.

DOI URL |

| [6] |

GEUSIC J E, MARCOS H M, UITERT L V. Laser oscillations in Nd-doped yttrium aluminum, yttrium gallium and gadolinium garnets. Applied Physics Letters, 1964, 4(10): 182-184.

DOI URL |

| [7] |

KOPF D, KRTNER F X, KELLER U, et al. Diode-pumped mode-locked Nd:glass lasers with an antiresonant Fabry-Perot saturable absorber. Optics Letters, 1995, 20(10): 1169-1171.

DOI URL |

| [8] |

FAN T Y. Heat generation in Nd:YAG and Yb:YAG. IEEE Journal of Quantum Electronics, 1993, 29(6): 1457-1459.

DOI URL |

| [9] |

LI J, WU Y, PAN Y, et al. Fabrication, microstructure and properties of highly transparent Nd: YAG laser ceramics. Optical Materials, 2008, 31(1): 6-17.

DOI URL |

| [10] |

SEKITA M, HANEDA H, YANAGITANI T, et al. Induced emission cross section of Nd:Y3Al5O12 ceramics. Journal of Applied Physics, 1990, 67(1): 453-458.

DOI URL |

| [11] |

SEKITA M, HANEDA H, SHIRASAKI S, et al. Optical spectra of undoped and rare-earth-(=Pr, Nd, Eu, and Er) doped transparent ceramic Y3Al5O12. Journal of Applied Physics, 1991, 69(6): 3709-3718.

DOI URL |

| [12] |

YAGI H, YANAGITANI T, TAKAICHI K, et al. Characterizations and laser performances of highly transparent Nd3+: Y3Al5O12 laser ceramics. Optical Materials, 2007, 29(10): 1258-1262.

DOI URL |

| [13] | LI M, HU H, GAO Q, et al. A 7.08-kW YAG/Nd: YAG/YAG composite ceramic slab laser with dual concentration doping. IEEE Photonics Journal, 2017, 9(4): 1-10. |

| [14] | OMATETE O O, JANNEY M A, STREHLOW R A. Gelcasting: a new ceramic forming process. American Ceramic Society Bulletin, 1991, 70(10): 1641-1649. |

| [15] |

GAUCKLER L J, GRAULE T, BAADER F H. Ceramic forming using enzyme catalyzed reactions. Materials Chemistry and Physics, 1999, 61(1): 78-102.

DOI URL |

| [16] | 杨燕, 岛井骏藏, 周国红. 等. 一种制备陶瓷坯体的方法. 中国, C04B35/622, CN103130509A. 2011.12.01. |

| [17] |

WAN T, YAO D, YIN J, et al. A novel method for preparing Si3N4 ceramics with unidirectional oriented pores from silicon aqueous slurries. Journal of the European Ceramic Society, 2017, 37(10): 3285-3291.

DOI URL |

| [18] | ZHANG P, LIU P, SUN Y, et al. Aqueous gelcasting of the transparent MgAl2O4 spinel ceramics. Journal of Alloys and Compounds, 2015, 646: 833-836. |

| [19] |

SUN Y, SHIMAI S, PENG X, et al. Fabrication of transparent Y2O3 ceramics via aqueous gelcasting. Ceramics International, 2014, 40(6): 8841-8845.

DOI URL |

| [20] |

QIN X P, ZHOU G H, YANG Y, et al. Gelcasting of transparent YAG ceramics by a new gelling system. Ceramics International, 2014, 40(8): 12745-12750.

DOI URL |

| [21] |

YIN J, LI Y, WU Y. Near-net-shape processed ZnS ceramics by aqueous casting and pressureless sintering. Ceramics International, 2016, 42(9): 11504-11508.

DOI URL |

| [22] |

SUN Y, SHIMAI S, QIN X P, et al. A method for gelcasting high-strength alumina ceramics with low shrinkage. Journal of Materials Research, 2014, 29(2): 247-251.

DOI URL |

| [23] | SUN Y, QIN X P, ZHOU G H, et al. Gelcasting and reactive sintering of sheet-like YAG transparent ceramics. Journal of Alloys and Compounds, 2015, 652: 250-253. |

| [24] | SUN Y, QIN X P, SHIMAI S, et al. Improved strength of alumina ceramic gel and green body based on addition-esterification reaction. Journal of Applied Ceramic Technology, 2016, 13(6): 1159-1163. |

| [25] | 章健, 刘梦玮, 赵瑾. 等. 一种陶瓷浆料凝胶固化行为的表征方法. 中国, 202110995468.9. 2021.08.27. |

| [1] | SHI Xiaotu, ZHANG Qingli, SUN Guihua, LUO Jianqiao, DOU Renqin, WANG Xiaofei, GAO Jinyun, ZHNAG Deming, LIU Jiandang, YE Bangjiao. Positron Annihilation Study of Yb:YAG Single Crystal Defects under Czochralski Method [J]. Journal of Inorganic Materials, 2023, 38(3): 316-321. |

| [2] | YANG Jiaxue, LI Wen, WANG Yan, ZHU Zhaojie, YOU Zhenyu, LI Jianfu, TU Chaoyang. Spectroscopic and Yellow Laser Features of Dy3+: Y3Al5O12 Single Crystals [J]. Journal of Inorganic Materials, 2023, 38(3): 350-356. |

| [3] | WANG Zhiqiang, WU Ji’an, CHEN Kunfeng, XUE Dongfeng. Large-size Er,Yb:YAG Single Crystal: Growth and Performance [J]. Journal of Inorganic Materials, 2023, 38(3): 329-334. |

| [4] | JIN Xihai, DONG Manjiang, KAN Yanmei, LIANG Bo, DONG Shaoming. Fabrication of Transparent AlON by Gel Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2023, 38(2): 193-198. |

| [5] | LI Wenjun, WANG Hao, TU Bingtian, CHEN Qiangguo, ZHENG Kaiping, WANG Weiming, FU Zhengyi. Preparation and Property of Mg0.9Al2.08O3.97N0.03 Transparent Ceramic with Broad Optical Transmission Range [J]. Journal of Inorganic Materials, 2022, 37(9): 969-975. |

| [6] | WANG Shiwei. Progress of Spontaneous Coagulation Casting of Ceramic Slurries Based on Hydrophobic Interaction [J]. Journal of Inorganic Materials, 2022, 37(8): 809-820. |

| [7] | LIU Qiang, WANG Qian, CHEN Penghui, LI Xiaoying, ZHANG Lixuan, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Red Ce-doped 8YSZ Transparent Ceramics by Two-step Sintering [J]. Journal of Inorganic Materials, 2022, 37(8): 911-917. |

| [8] | XIAO Shulin, DAI Zhonghua, LI Dingyan, ZHANG Fanbo, YANG Lihong, REN Xiaobing. Electrical and Optical Property of Lanthanum Oxide Doped Potassium Sodium Niobate Ceramics [J]. Journal of Inorganic Materials, 2022, 37(5): 520-526. |

| [9] | CHENG Ziqiu, WANG Yanbin, LIU Xin, DAI Zhengfa, CHEN Haohong, TIAN Feng, CHEN Penghui, LI Jiang. Component Regulation and Performance Optimization of Al2O3-YAG:Ce Composite Ceramic Phosphors for High-power Laser Lighting [J]. Journal of Inorganic Materials, 2022, 37(12): 1358-1364. |

| [10] | XU Xiaoke, DENG Mingxue, LIU Qian, YU Jianding, ZHOU Zhenzhen, ZHANG Xiang, HE Huan. Advanced Multi-laser-beam Parallel Heating System for Rapid High Temperature Treatment [J]. Journal of Inorganic Materials, 2022, 37(1): 107-112. |

| [11] | JING Yanqiu, LIU Qiang, SU Sha, LI Xiaoying, LIU Ziyu, WANG Jingya, LI Jiang. Fabrication of Highly Transparent Co:MgAl2O4 Ceramic Saturable Absorber for Passive Q-switching in 1.5 μm [J]. Journal of Inorganic Materials, 2021, 36(8): 877-882. |

| [12] | DU Aochen, DU Qiyuan, LIU Xin, YANG Yimin, XIA Chenyang, ZOU Jun, LI Jiang. Ce:YAG Transparent Ceramics Enabling High Luminous Efficacy for High-power LEDs/LDs [J]. Journal of Inorganic Materials, 2021, 36(8): 883-892. |

| [13] | DAI Yun, ZHANG Zhonghan, SU Liangbi, LI Jin, LONG Yong, DING Yuchong, WU Anhua. Growth of High-quality Yb3+-doped Y3Al5O12 Single Crystal Fiber by Laser Heated Pedestal Growth Method [J]. Journal of Inorganic Materials, 2021, 36(7): 761-765. |

| [14] | LIU Ziyu, TOCI Guido, PIRRI Angela, PATRIZI Barbara, FENG Yagang, CHEN Xiaopu, HU Dianjun, TIAN Feng, WU Lexiang, VANNINI Matteo, LI Jiang. Fabrication and Optical Property of Nd:Lu2O3 Transparent Ceramics for Solid-state Laser Applications [J]. Journal of Inorganic Materials, 2021, 36(2): 210-216. |

| [15] | HUANG Xinyou, LIU Yumin, LIU Yang, LI Xiaoying, FENG Yagang, CHEN Xiaopu, CHEN Penghui, LIU Xin, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Yb:YAG Transparent Ceramics Using Alcohol-water Co-precipitation Method [J]. Journal of Inorganic Materials, 2021, 36(2): 217-224. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||