Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (10): 1116-1122.DOI: 10.15541/jim20210745

Special Issue: 【生物材料】骨骼与齿类组织修复

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHANG Hang1( ), HAN Kunyuan2, DONG Lanlan1, LI Xiang1(

), HAN Kunyuan2, DONG Lanlan1, LI Xiang1( )

)

Received:2021-12-07

Revised:2022-01-25

Published:2022-10-20

Online:2022-06-16

Contact:

LI Xiang, associate professor. E-mail: xiangliwj@sjtu.edu.cnAbout author:ZHANG Hang (1994-), male, PhD candidate. E-mail: hangzhang@sjtu.edu.cn

Supported by:CLC Number:

ZHANG Hang, HAN Kunyuan, DONG Lanlan, LI Xiang. Preparation and Characterization of β-tricalcium Phosphate/Nano Clay Composite Scaffolds via Digital Light Processing Printing[J]. Journal of Inorganic Materials, 2022, 37(10): 1116-1122.

| Materials and reagent | Chemical agent | Dosage/% (in mass) |

|---|---|---|

| Ceramic powder | β-TCP | 50-60 |

| Resin monomer | PEG200DA | 20-40 |

| Crosslinking agent | 3,3-Dimethylacrylic acid | 2-4 |

| Dispersant | DCA-1228 | 0.3-1.0 |

| Photoinitiator | TPO | 0.5 |

| Nano clay | Laponite | 0-10 |

Table 1 Main raw materials and reagents for preparation of porous bioceramics

| Materials and reagent | Chemical agent | Dosage/% (in mass) |

|---|---|---|

| Ceramic powder | β-TCP | 50-60 |

| Resin monomer | PEG200DA | 20-40 |

| Crosslinking agent | 3,3-Dimethylacrylic acid | 2-4 |

| Dispersant | DCA-1228 | 0.3-1.0 |

| Photoinitiator | TPO | 0.5 |

| Nano clay | Laponite | 0-10 |

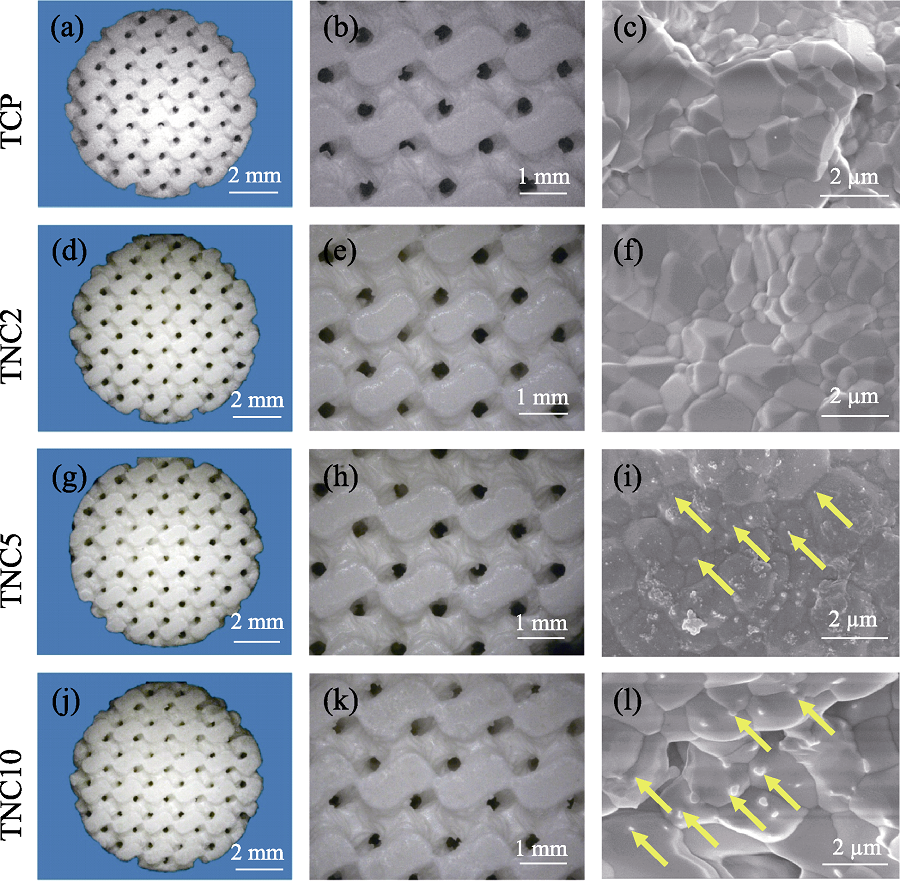

Fig. 2 Surface morphologies of scaffold (a, d, g, j) Microscope photos of scaffolds; (b, e, h, k) Microscope photos of scaffolds; (c, f, i, l) SEM images of scaffolds

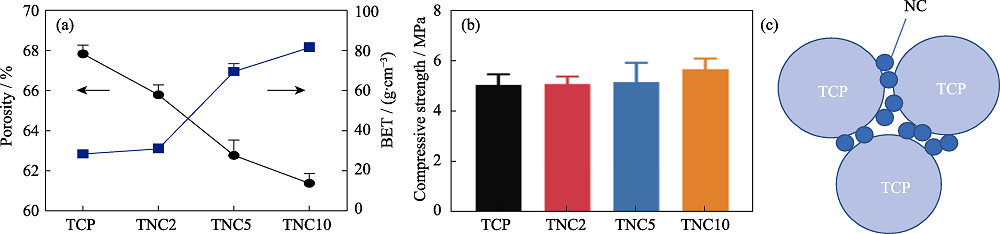

Fig. 5 Mechanical property analysis of porous scaffolds (a) Porosity and specific surface area of the scaffolds; (b) Compression strength of the scaffolds; (c) Schematic diagram of NC enhanced TCP

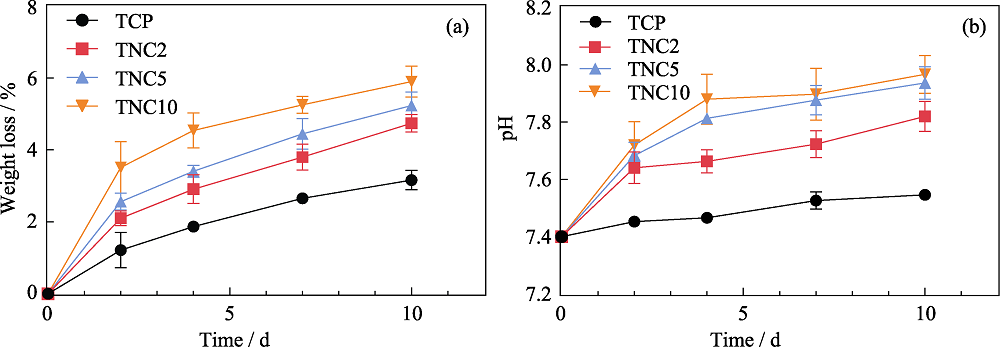

Fig. 6 Weight loss and pH change after scaffold degradation (a) Weight loss of scaffold after soaking in SBF for different time; (b) pH change of SBF after soaking the scaffolds

| [1] |

GAO C, WEI P, PEI F, et al. Nano SiO2 and MgO improve the properties of porous β-TCP scaffolds via advanced manufacturing technology. International Journal of Molecular Sciences, 2015, 16(4): 6818-6830.

DOI URL |

| [2] | LIU J, GAO C, FENG P, et al. Selective laser sintering of β-TCP/nano-58S composite scaffolds with improved mechanical properties. Materials & Design, 2015, 84: 395-401. |

| [3] |

LIU J, SHEN X, TANG S, et al. Improvement of rBMSCs responses to poly(propylene carbonate) based biomaterial through incorporation of nanolaponite and surface treatment using sodium hydroxide. ACS Biomaterials Science and Engineering, 2020, 6(1): 329-339..

DOI PMID |

| [4] | ZHANG Y H, CHEN M J, DAI Z B, et al. Sustained protein therapeutics enabled by self-healing nanocomposite hydrogels for non-invasive bone regeneration. J. Biomaterials Science, 2020, 8: 682-693. |

| [5] |

ZIMINSKA M, CHALANQUI M J, CHAMBERS P, et al. Nanocomposite-coated porous templates for engineered bone scaffolds: a parametric study of layer-by-layer assembly conditions. Biomedical Materials, 2019, 14(6): 065008.

DOI URL |

| [6] |

LEE C U, HWANG H S, KIM S, et al. Inspired by nature: facile design of nanoclay-organic hydrogel bone sealant with multifunctional properties for robust bone regeneration. Advanced Functional Materials, 2020, 30: 2003717.

DOI URL |

| [7] |

ZHAI X Y, HOU C Y, PAN H B, et al. Nanotechnology, nanoclay incorporated polyethylene-glycol nanocomposite hydrogels for stimulating in vitro and in vivo osteogenesis. Journal of Biomedical Nanotechnology, 2018, 14(4): 662-674.

DOI URL |

| [8] | GAO W, SUN L, ZHANG Z, et al. Progress, preparation, characterization and evaluation of biomass-based siliconcontaining composite scaffolds for bone repair. Chemical Industry and Engineering Progress, 2019, 38(10): 4595-4605. |

| [9] | DONG Q S, YANG L, JIANG H Q, et al. 3D-cubic interconnected porous Mg-based scaffolds for bone repair. Journal of Magnesium and Alloys, 2021, 9(4): 1336-1345. |

| [10] |

MIGUEZ-PACHECO V, BÜTTNER T, MAON A, et al. Development and characterization of lithium-releasing silicate bioactive glasses and their scaffolds for bone repair. Journal of Non-Crystalline Solids, 2016, 432(15): 65-72.

DOI URL |

| [11] |

PAREDES C, MARTÍNEZ-VÁZQUEZ F J, PAJARES A, et al. Novel strategy for toughening robocast bioceramic scaffolds using polymeric cores. Ceramics International, 2019, 45(15): 19572-19576.

DOI URL |

| [12] | LIU F H. Synthesis of bioceramic scaffolds for bone tissue engineering by rapid prototyping technique. Journal of Sol Gel Science & Technology, 2012, 64(3): 704-710. |

| [13] |

CHEN Q Z, THOUAS G A. Fabrication and characterization of Sol-Gel derived 45S5 Bioglass®-ceramic scaffolds. Acta Biomaterialia, 2011, 7(10): 3616-3626.

DOI URL |

| [14] |

ZHANG G, JIANG J, WANG H, et al. Continuous DLP-based ceramic 3D printing using a composite oxygen-rich film. Journal of Manufacturing Processes, 2021, 64(8): 341-348.

DOI URL |

| [15] |

MA Y, DAI H, HUANG X, et al. 3D printing of bioglass-reinforced β-TCP porous bioceramic scaffolds. Journal of Materials Science, 2019, 54: 10437-10446.

DOI URL |

| [16] |

GAO Y, DING J. Low solid loading, low viscosity, high uniform shrinkage ceramic resin for stereolithography based additive manufacturing. Procedia Manufacturing, 2020, 48: 749-754.

DOI URL |

| [17] |

LIU W, LI M, NIE J, et al. Technology, synergy of solid loading and printability of ceramic paste for optimized properties of alumina via stereolithography-based 3D printing. Journal of Materials Research and Technology, 2020, 9(5): 11476-11483.

DOI URL |

| [18] |

SHUAI X, ZENG Y, LI P, et al. Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. Journal of Materials Science, 2020, 55(3): 6771-6782.

DOI URL |

| [19] |

XH A, HDA C, YH A, et al. Development of a high solid loading β-TCP suspension with a low refractive index contrast for DLP-based ceramic stereolithography. Journal of the European Ceramic Society, 2020, 41(6): 3743-3754.

DOI URL |

| [20] |

ARIFIN A, SULONG A B, MUHAMAD N, et al. Material processing of hydroxyapatite and titanium alloy (HA/Ti) composite as implant materials using powder metallurgy: a review. Materials & Design, 2014, 55: 165-175.

DOI URL |

| [21] |

SEZER N, EVIS Z, KO M. Additive manufacturing of biodegradable magnesium implants and scaffolds: review of the recent advances and research trends. Journal of Magnesium and Alloys, 2020, 9(12): 392-415.

DOI URL |

| [22] |

FUH L J, HUANG Y J, CHEN W C, et al. Preparation of micro-porous bioceramic containing silicon-substituted hydroxyapatite and beta-tricalcium phosphate. Materials Science and Engineering C, 2017, 75: 798-806.

DOI URL |

| [23] | CHEN Y, WANG X, BING M, et al. 3D-printed bioactive Ca3SiO5 bone cement scaffolds with nano surface structure for bone regeneration. ACS Applied Materials & Interfaces, 2017, 9(7): 5757. |

| [24] |

COCKERILL I, SU Y, SINHA S, et al. Porous zinc scaffolds for bone tissue engineering applications: a novel additive manufacturing and casting approach. Materials Science and Engineering C, 2020, 110: 110738.

DOI URL |

| [25] |

MARYAM T, KINSELLA J M, GUINTO G C, et al. Silicon-doped hydroxyapatite prepared by a thermal technique for hard tissue engineering applications. Ceramics International, 2018, 44(15): 17612-17622.

DOI URL |

| [26] |

HE F, TIAN Y. Improvements in phase stability and densification of β-tricalcium phosphate bioceramics by strontium-containing phosphate-based glass additive. Ceramics International, 2018, 44(10): 11622-11627.

DOI URL |

| [27] |

CHEN Q, BAINO F, SPRIANO S, et al. Modelling of the strength-porosity relationship in glass-ceramic foam scaffolds for bone repair. Journal of the European Ceramic Society, 2014, 34(11): 2663-2673.

DOI URL |

| [28] |

BIAN W, LI D, LIAN Q, et al. Fabrication of a bio-inspired β-tricalcium phosphate/collagen scaffold based on ceramic stereolithography and gel casting for osteochondral tissue engineering. Rapid Prototyping Journal, 2012, 18(1): 68-80.

DOI URL |

| [29] |

SARKAR K, RAHAMAN M, AGARWAL S, et al. Degradability and in vivo biocompatibility of doped magnesium phosphate bioceramic scaffolds. Materials Letters, 2020, 259: 126892.

DOI URL |

| [1] | HUANG Ping, LI Peng, ZHAO Jun-Sheng, QU Shu-Xin, FENG Bo, WENG Jie. Mechanical Activation Reinforced Porous Calcium Phosphate Cement [J]. Journal of Inorganic Materials, 2015, 30(4): 432-438. |

| [2] | GONG Meng-An, Rao Qun-Li, WANG Hong-Lie. A Novel Technique to Prepare Porous 3D Fluoridated Hydroxyapatite Scaffold Using Pore-forming and Foaming Agents [J]. Journal of Inorganic Materials, 2014, 29(3): 289-293. |

| [3] | CAO Lie-Hui, YU Bao-Qing, WU Guo-Sheng, SU Jia-Can. Study on Adulterate Sodium Silica Apatite Cement Porous Scaffolds for Bone Defect Repair [J]. Journal of Inorganic Materials, 2011, 26(6): 591-596. |

| [4] | WANG Zhi-Wei, SU Jia-Can, MA Yu-Hai, ZHANG Xin, CAO Lie-Hu, LI Ming. Preparation and Properties of Nano Calcium Deficient Apatite/Poly (ε-caprolactone) Composite Scaffold [J]. Journal of Inorganic Materials, 2010, 25(5): 500-506. |

| [5] | XIE Lin,CHEN Xiao-Feng,ZHAO Na-Ru,GUO Chang-Liang. Study on Porous Bioglass Scaffold Prepared by Dipping with Polymer Foams [J]. Journal of Inorganic Materials, 2009, 24(2): 280-284. |

| [6] | WEI Jie,LIU Chang-Sheng,HONG Hua,YUAN Yuan,CHEN Fang-Ping. Novel Biodegradable Scaffold of Calcium Phosphate Cement [J]. Journal of Inorganic Materials, 2006, 21(4): 958-964. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||