Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (3): 317-324.DOI: 10.15541/jim20210624

Special Issue: 增材制造专题(2022); 【虚拟专辑】增材制造及3D打印(2021-2022)

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHU Junyi( ), ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei(

), ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei( )

)

Received:2021-10-08

Revised:2021-10-21

Published:2022-03-20

Online:2021-11-01

Contact:

CHEN Zhangwei, professor. E-mail: chen@szu.edu.cn

About author:ZHU Junyi (1996-), male, Master candidate. E-mail: 386398374@qq.com

Supported by:CLC Number:

ZHU Junyi, ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei. Influence of Debinding Process on the Properties of Photopolymerization 3D Printed Cordierite Ceramics[J]. Journal of Inorganic Materials, 2022, 37(3): 317-324.

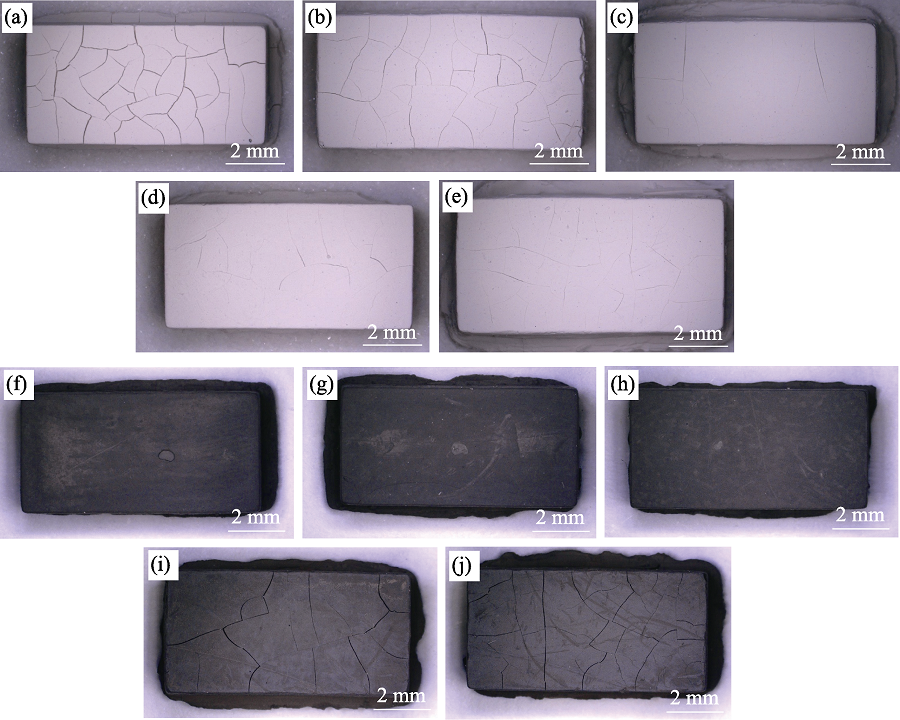

Fig. 3 Surface macro-graphs of sample after debinding at different heating rates In air: (a) 0.1 ℃/min; (b) 0.5 ℃/min; (c) 1 ℃/min; (d) 3 ℃/min; (e) 5 ℃/min; In argon: (f) 0.1 ℃/min; (g) 0.5 ℃/min; (h) 1 ℃/min; (i) 3 ℃/min; (j) 5 ℃/min

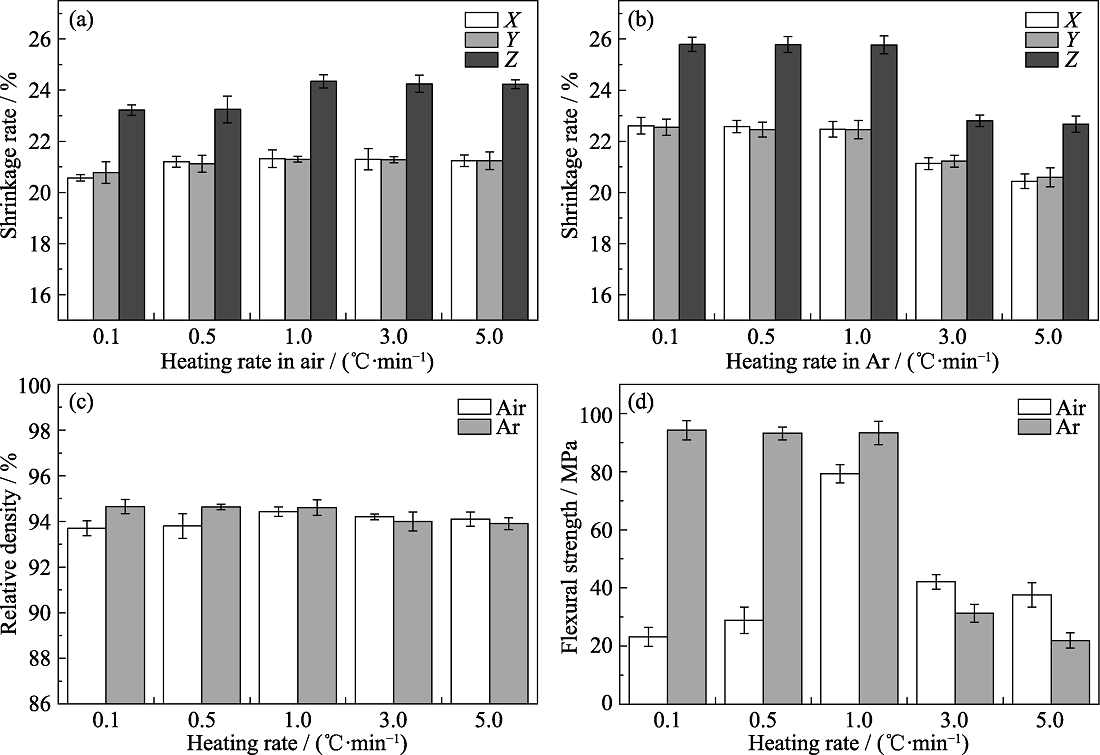

Fig. 7 Properties of samples after debinding in different atmospheres followed by sintering (a) Shrinkage rate-debinding in air; (b) Shrinkage rate-debinding in argon; (c) Relative density; (d) Bending strength

Fig. 8 Final cordierite ceramics prepared with optimized debinding scheme followed by sintering (a, b) Dense rectangular sample; (c) Honeycomb structures with complex inter-crossing channels

| [1] |

CAMERUCCI M A, URRETAVIZCAYA G, CASTRO M S, et al. Electrical properties and thermal expansion of cordierite and cordierite- mullite materials. Journal of the European Ceramic Society, 2001, 21(16): 2917-2923.

DOI URL |

| [2] |

LAMARA S, REDAOUI D, SAHNOUNE F, et al. Microstructure, thermal expansion, hardness and thermodynamic parameters of cordierite materials synthesized from Algerian natural clay minerals and magnesia. Boletín de la Sociedad Española de Cerámica y Vidrio, 2020, 60(5): 291-306.

DOI URL |

| [3] | SITTIAKKARANON S. Thermal shock resistance of mullite- cordierite ceramics from kaolin, talc and alumina raw materials. Materials Today: Proceedings, 2019, 17(4): 1864-1871. |

| [4] |

CHEN Z, LIU C, LI J, et al. Mechanical properties and microstructures of 3D printed bulk cordierite parts. Ceramics International, 2019, 45(15): 19257-19267.

DOI URL |

| [5] |

GÖKÇE H, AĞAOĞULLARI D, ÖVEÇOĞLU M L, et al. Characterization of microstructural and thermal properties of steatite/ cordierite ceramics prepared by using natural raw materials. Journal of the European Ceramic Society, 2011, 31(14): 2741-2747.

DOI URL |

| [6] |

AVILA P, MONTES M, MIRÓ E E. Monolithic reactors for environmental applications: a review on preparation technologies. Chemical Engineering Journal, 2005, 109(1/2/3): 11-36.

DOI URL |

| [7] |

DAS R N, MADHUSOODANA C D, OKADA K, Rheological studies on cordierite honeycomb extrusion. Journal of the European Ceramic Society, 2002, 22(16): 2893-2900.

DOI URL |

| [8] |

LIANG Q, LI D, YANG G. Rapid fabrication of diamond-structured ceramic photonic crystals with graded dielectric constant and its controllable stop band properties. Ceramics International, 2013, 39(1): 153-157.

DOI URL |

| [9] |

MELCHELS F P W, FEIJEN J, GRIJPMA D W. A review on stereolithography and its applications in biomedical engineering. Biomaterials, 2010, 31(24): 6121-6130.

DOI URL |

| [10] |

ZHOU W, LI D, CHEN Z. Direct fabrication of an integral ceramic mould by stereolithography. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2010, 224(2): 237-243.

DOI URL |

| [11] |

ZOCCA A, COLOMBO P, GOMES C M, et al. Additive manufacturing of ceramics: issues, potentialities, and opportunities. Journal of the American Ceramic Society, 2015, 98(7): 1983-2001.

DOI URL |

| [12] |

CHEN Z, LI Z, LI J, et al. 3D printing of ceramics: a review. Journal of the European Ceramics Society, 2019, 39(4): 661-687.

DOI URL |

| [13] |

CHEN Z, LI D, ZHOU W. Process parameters appraisal of fabricating ceramic parts based on stereolithography using the Taguchi method. Proceedings of the Institution of Mechanical Engineers, Part B: Journal of Engineering Manufacture, 2012, 226(7): 1249-1258.

DOI URL |

| [14] |

LIU Y, CHEN Z, LI J, et al. 3D printing of ceramic cellular structures for potential nuclear fusion application. Additive Manufacturing, 2020, 35: 101348.

DOI URL |

| [15] |

RASAKI S A, XIONG D, XIONG S, et al. Photopolymerization- based additive manufacturing of ceramics: a systematic review. Journal of Advanced Ceramics, 2021, 10(3): 442-471.

DOI URL |

| [16] |

LIU C, XU F, LIU Y, et al. High mass loading ultrathick porous Li4Ti5O12 electrodes with improved areal capacity fabricated via low temperature direct writing. Electrochimica Acta, 2019, 314: 81-88.

DOI URL |

| [17] |

WU Z, HUAN Z, ZHU Y, et al. 3D printing and characterization of microsphere hydroxyapatite scaffolds. Journal of Inorganic Materials, 2021, 36(6): 601-607.

DOI URL |

| [18] |

CHEN Z, BRANDON N. Inkjet printing and nanoindentation of porous alumina multilayers. Ceramics International, 2016, 42(7): 8316-8324.

DOI URL |

| [19] |

CHEN Z, OUYANG J, LIANG W, et al. Development and characterizations of novel aqueous-based LSCF suspensions for inkjet printing. Ceramics International, 2018, 44(11): 13381-13388.

DOI URL |

| [20] |

ZHANG L, YANG X, XU X, et al. 3D printed zirconia ceramics via fused deposit modeling and its mechanical properties. Journal of Inorganic Materials, 2021, 36(4): 436-442.

DOI |

| [21] |

LIU S, LI M, WU J, et al. Preparation of high-porosity Al2O3 ceramic foams via selective laser sintering of Al2O3 poly-hollow microspheres. Ceramics International, 2020, 46(4): 4240-4247.

DOI URL |

| [22] |

FERRAGE L, BERTRAND G, LENORMAND P. Dense yttria- stabilized zirconia obtained by direct selective laser sintering. Additive Manufacturing, 2018, 21: 472-478.

DOI URL |

| [23] |

MINASYAN T, LIU L, AGHAYAN M, et al. A novel approach to fabricate Si3N4 by selective laser melting. Ceramics International, 2018, 44(12): 13689-13694.

DOI URL |

| [24] |

CHEN Z, LI J, LIU C, et al. Preparation of high solid loading and low viscosity ceramic slurries for photopolymerization-based 3D printing. Ceramics International, 2019, 45(9): 11549-11557.

DOI URL |

| [25] |

SHUAI X, ZENG Y, LI P, et al. Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. Journal of Materials Science, 2020, 55: 6771-6782.

DOI URL |

| [26] | LI H, SONG L, SUN J, et al. Stereolithography-fabricated zirconia dental prostheses: concerns based on clinical requirements. Journal of Advances in Applied Ceramics, 2020, 119(5/6): 236-243. |

| [27] |

FENG C, ZHANG C, HE R, et al. Additive manufacturing of hydroxyapatite bioceramic scaffolds: dispersion, digital light processing, sintering, mechanical properties, and biocompatibility. Journal of Advanced Ceramics, 2020, 9: 360-373.

DOI URL |

| [28] |

HE R, DING G, ZHANG K, et al. Fabrication of SiC ceramic architectures using stereolithography combined with precursor infiltration and pyrolysis. Ceramics International, 2019, 45(11): 14006-14014.

DOI URL |

| [29] |

ZHANG C, LUO Z, LIU C, et al. Dimensional retention of photocured ceramic units during 3D printing and sintering processes. Ceramics International, 2021, 47(8): 11097-11108.

DOI URL |

| [30] |

CHEN Z, LIU C, LI J, et al. Mechanical properties and microstructures of 3D printed bulk cordierite parts. Ceramics International, 2019, 45(15): 19257-19267.

DOI URL |

| [1] | FENG Jingjing, ZHANG Youran, MA Mingsheng, LU Yiqing, LIU Zhifu. Current Status and Development Trend of Cold Sintering Process [J]. Journal of Inorganic Materials, 2023, 38(2): 125-136. |

| [2] | JIN Xihai, DONG Manjiang, KAN Yanmei, LIANG Bo, DONG Shaoming. Fabrication of Transparent AlON by Gel Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2023, 38(2): 193-198. |

| [3] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [4] | CHEN Yongqiang, WANG Yixue, ZHANG Fan, LI Hongxia, DONG Binbin, MIN Zhiyu, ZHANG Rui. Preparation of Special Ceramics by Microwave Heating: a Review [J]. Journal of Inorganic Materials, 2022, 37(8): 841-852. |

| [5] | LIU Qiang, WANG Qian, CHEN Penghui, LI Xiaoying, ZHANG Lixuan, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Red Ce-doped 8YSZ Transparent Ceramics by Two-step Sintering [J]. Journal of Inorganic Materials, 2022, 37(8): 911-917. |

| [6] | DENG Taoli, CHEN Hexin, HEI Lingli, LI Shuxing, XIE Rongjun. Achieving High Light Uniformity Laser-driven White Lighting Source by Introducing Secondary Phases in Phosphor Converters [J]. Journal of Inorganic Materials, 2022, 37(8): 891-896. |

| [7] | WEI Tingting, XU Huarui, ZHU Guisheng, LONG Shenfeng, ZHANG Xiuyun, ZHAO Yunyun, JIANG Xupeng, SONG Jinjie, GUO Ningjie, GONG Yipeng. Preparation and Properties of BaTiO3 Ceramics by Low Temperature Cold Sintering [J]. Journal of Inorganic Materials, 2022, 37(8): 903-910. |

| [8] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [9] | YAO Xiaogang, PENG Haiyi, GU Zhongyuan, HE Fei, ZHAO Xiangyu, LIN Huixing. Polyphenylene Oxide/Ca0.7La0.2TiO3 Microwave Composite Substrate [J]. Journal of Inorganic Materials, 2022, 37(5): 493-498. |

| [10] | LIU Jinling, LIU Dianguang, REN Ke, WANG Yiguang. Research Progress on the Flash Sintering Mechanism of Oxide Ceramics and Its Application [J]. Journal of Inorganic Materials, 2022, 37(5): 473-480. |

| [11] | CAO Jiwei, WANG Pei, LIU Zhiyuan, LIU Changyong, WU Jiamin, CHEN Zhangwei. Research Progress on Powder-based Laser Additive Manufacturing Technology of Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 241-254. |

| [12] | WANG Yaning, ZHANG Yuqi, SONG Suocheng, CHEN Ruomeng, LIU Yaxiong, DUAN Yugang. Laser Stereolithography for Zirconia Ceramic Fabrication and Its Debinding and Sintering Process [J]. Journal of Inorganic Materials, 2022, 37(3): 303-309. |

| [13] | ZENG Yong, ZHANG Zijia, SUN Lijun, YAO Haihua, CHEN Jiming. Atmosphere Debinding Heat Treatment of 3D Printed Alumina Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 333-337. |

| [14] | HUANG Longzhi, YIN Jie, CHEN Xiao, WANG Xinguang, LIU Xuejian, HUANG Zhengren. Selective Laser Sintering of SiC Green Body with Low Binder Content [J]. Journal of Inorganic Materials, 2022, 37(3): 347-352. |

| [15] | SUN Yangshan, YANG Zhihua, CAI Delong, ZHANG Zhengyi, LIU Qi, FANG Shuqing, FENG Liang, SHI Lifen, WANG Youle, JIA Dechang. Crystallization Kinetics, Properties of α-cordierite Based Glass-ceramics Prepared by Glass Powder Sintering [J]. Journal of Inorganic Materials, 2022, 37(12): 1351-1357. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||