Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (3): 303-309.DOI: 10.15541/jim20210569

• RESEARCH ARTICLE • Previous Articles Next Articles

WANG Yaning1( ), ZHANG Yuqi1, SONG Suocheng2, CHEN Ruomeng1,3, LIU Yaxiong4(

), ZHANG Yuqi1, SONG Suocheng2, CHEN Ruomeng1,3, LIU Yaxiong4( ), DUAN Yugang1

), DUAN Yugang1

Received:2021-09-15

Revised:2021-10-12

Published:2022-03-20

Online:2021-12-24

Contact:

LIU Yaxiong, professor. E-mail: yaxiongliu@163.com

About author:WANG Yaning (1989-), male, PhD candidate. E-mail: 905488248@qq.com

Supported by:CLC Number:

WANG Yaning, ZHANG Yuqi, SONG Suocheng, CHEN Ruomeng, LIU Yaxiong, DUAN Yugang. Laser Stereolithography for Zirconia Ceramic Fabrication and Its Debinding and Sintering Process[J]. Journal of Inorganic Materials, 2022, 37(3): 303-309.

| Component | Mass percentage/% |

|---|---|

| Bifunctional monomer (HDDA, Curease, China) | 38.0 |

| Trifunctional monomer (TMPTA, Curease, China) | 28.5 |

| Hexafunctional monomer (DPHA, Curease, China) | 28.5 |

| Oligomer (NeoRadU Curease, China) | 5.0 |

Table 1 Component proportion of hybrid resin

| Component | Mass percentage/% |

|---|---|

| Bifunctional monomer (HDDA, Curease, China) | 38.0 |

| Trifunctional monomer (TMPTA, Curease, China) | 28.5 |

| Hexafunctional monomer (DPHA, Curease, China) | 28.5 |

| Oligomer (NeoRadU Curease, China) | 5.0 |

| Component | Proportion |

|---|---|

| Zirconia powder | Volume ratio to resin: 11 : 9 |

| Resin | Volume ratio to ceramic: 9 : 11 |

| Photoinitiator (819, Curease, China) | 0.3% (mass percentage) of resin |

| Dispersant (TEGO685, TEG, China) | 2% (mass percentage) of ceramic |

| Defoamer (TEGO900, TEG, China) | 1% (mass percentage) of resin |

Table 2 Component proportion of ceramic slurry

| Component | Proportion |

|---|---|

| Zirconia powder | Volume ratio to resin: 11 : 9 |

| Resin | Volume ratio to ceramic: 9 : 11 |

| Photoinitiator (819, Curease, China) | 0.3% (mass percentage) of resin |

| Dispersant (TEGO685, TEG, China) | 2% (mass percentage) of ceramic |

| Defoamer (TEGO900, TEG, China) | 1% (mass percentage) of resin |

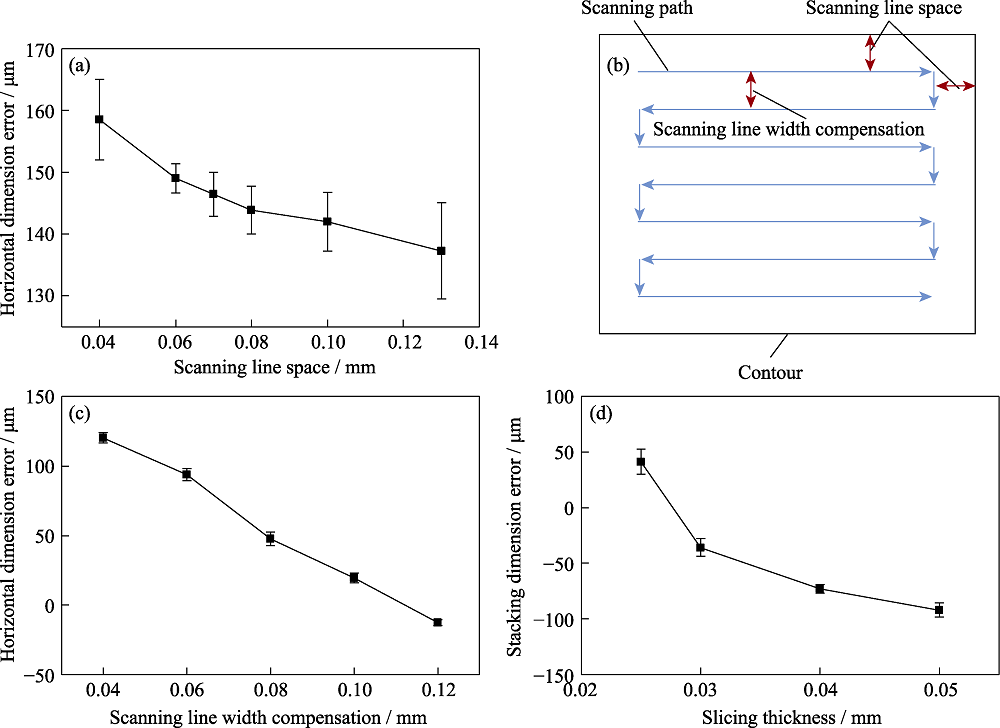

Fig. 3 Horizontal dimension error vs. scanning line space (a), schematic diagram of scanning strategy (b), horizontal dimension error vs. scanning line width compensation (c), and stacking dimension error vs. slicing thickness (d)

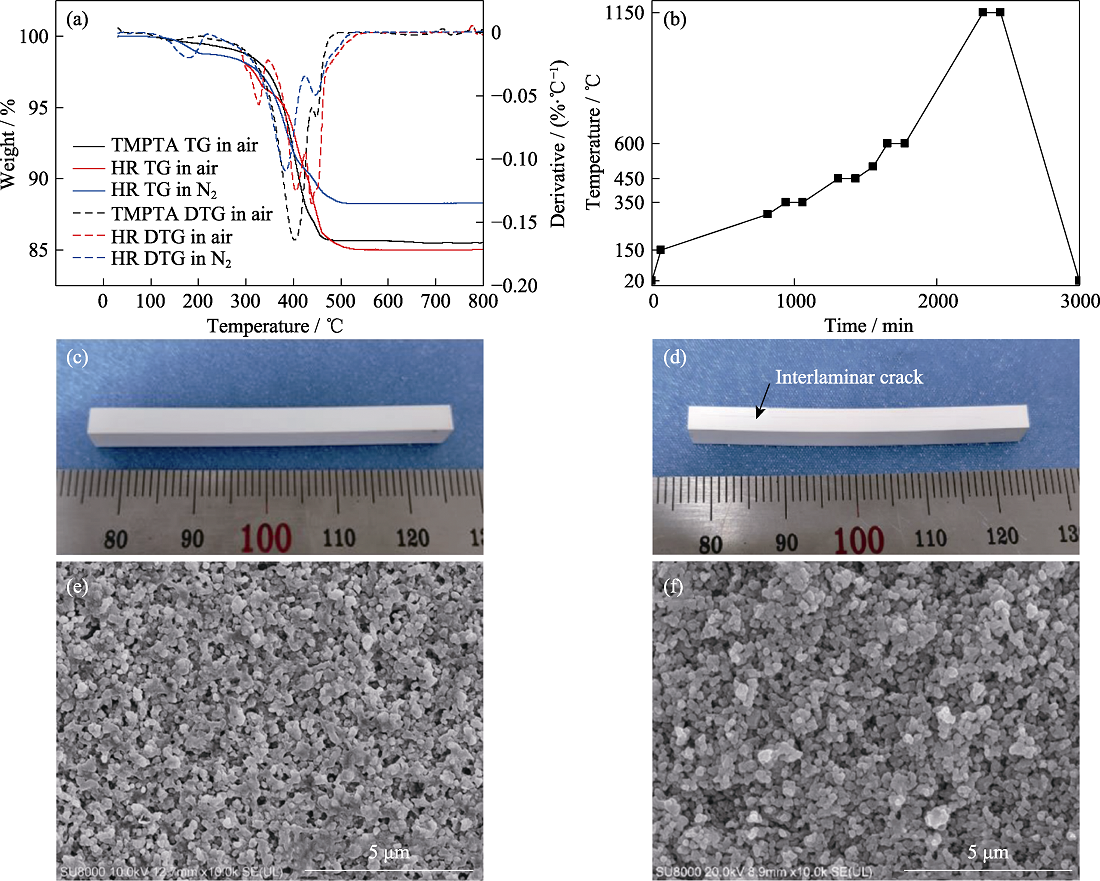

Fig. 4 TG and DTG curves of different resin in different atmosphere (a), debinding curve of green body (b), pictures of strip parts after debinding in nitrogen (c) and air (d) atmospheres, and SEM images of green part (e) and debinded part (f) Colorful figures are availuable on the website

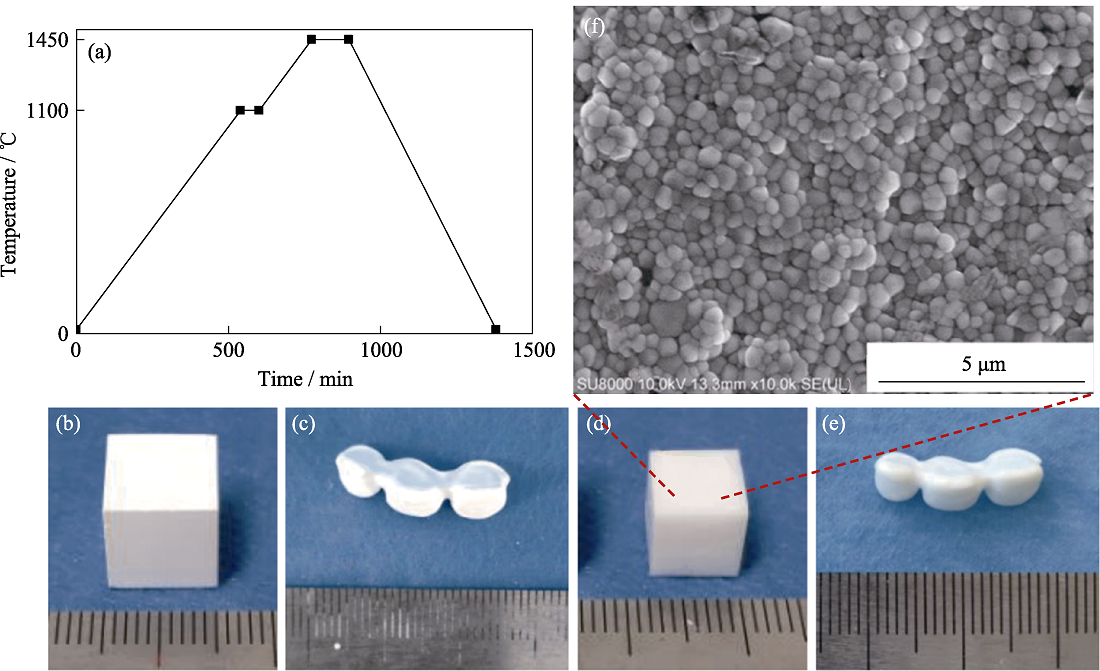

Fig. 5 Sintering curve (a), pictures of green parts of cube (b) and three units dental bridge (c), sintered parts of cube (d) and three units dental bridge (e), and SEM image of sintered part (f)

| [1] |

WATAHA J C. Alloys for prosthodontic restorations. Journal of Prosthetic Dentistry, 2002, 87(4): 351-363.

DOI URL |

| [2] |

MÖLLER H. Dental gold alloys and contact allergy. Contact Dermatitis, 2002, 47(2): 63-66.

DOI URL |

| [3] | UPADHYAY D, PANCHAL M A, DUBEY R S, et al. Corrosion of alloys used in dentistry: a review. Materials Science & Engineering A, 2006, 432(1/2): 1-11. |

| [4] |

CHEN Y W, MOUSSI J, DRURY J L, et al. Zirconia in biomedical applications. Expert. Rev. Med. Devices, 2016, 13(10): 945-963.

DOI URL |

| [5] |

ZARONE F, RUSSO S, SORRENTINO R. From porcelain-fused- to-metal to zirconia: clinical and experimental considerations. Dental Materials, 2011, 27(1): 83-96.

DOI URL |

| [6] |

STRUB J R, REKOW E D, WITKOWSKI S. Computer-aided design and fabrication of dental restorations: current systems and future possibilities. Journal of the American Dental Association, 2006, 137(9): 1289-1296.

DOI URL |

| [7] |

CHEN Z, LI Z, LI J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661-687.

DOI URL |

| [8] |

RASAKI S A, XIONG D, XIONG S, et al. Photopolymerization- based additive manufacturing of ceramics: a systematic review. Journal of Advanced Ceramics, 2021, 10(3): 442-471.

DOI URL |

| [9] |

FU X, ZOU B, XING H, et al. Effect of printing strategies on forming accuracy and mechanical properties of ZrO2 parts fabricated by SLA technology. Ceramics International, 2019, 45(14): 17630-17637.

DOI URL |

| [10] |

XING H, ZOU B, LI S, et al. Study on surface quality, precision and mechanical properties of 3D printed ZrO2 ceramic components by laser scanning stereolithography. Ceramics International, 2017, 43(18): 16340-16347.

DOI URL |

| [11] | WANG W, QIAN C, ADILIJIANG Y, et al. Study of zirconia crowns fabricated by stereolithography method. Chinese Journal of Prosthodontics, 2018, 19(5): 7-11. |

| [12] |

SUN J, BINNER J, BAI J. Effect of surface treatment on the dispersion of nano zirconia particles in non-aqueous suspensions for stereolithography. Journal of the European Ceramic Society, 2018, 39(4): 1660-1667.

DOI URL |

| [13] |

CHEN Z, LI D, ZHOU W, et al. Curing characteristics of ceramic stereolithography for an aqueous-based silica suspension. Proceedings of the Institution of Mechanical Engineers Part B-Journal of Engineering Manufacture, 2010, 224(4): 641-651.

DOI URL |

| [14] |

CHEN Z, LI D, ZHOU W. Process parameters appraisal of fabricating ceramic parts based on stereolithography using the Taguchi method. Proceedings of the Institution of Mechanical Engineers Part B-Journal of Engineering Manufacture, 2012, 226(7): 1249-1258.

DOI URL |

| [15] | 张玉琪. 氧化锆牙冠的高固相激光光固化成形与力学性能调控工艺研究. 西安: 西安交通大学硕士学位论文, 2020. |

| [16] |

LEE I H, CHO D W. Micro-stereolithography photopolymer solidification patterns for various laser beam exposure conditions. International Journal of Advanced Manufacturing Technology, 2003, 22(5/6): 410-416.

DOI URL |

| [17] | XU G, ZHAO W, LU B. Fabrication of microstructures using high-resolution stereolithography system. Journal of Mechanical Engineering, 2005, 9: 86-89. |

| [18] | LU Z, JIANG S, ZHANG K. Fundamental research on debinding and sintering of submicron pillar arrays made by ceramic micro powder injection molding. Journal of Netshape Forming Engineering, 2015(3): 33-36. |

| [19] | PFAFFINGER M, MITTERAMSKOGLER G, GMEINER R, et al. Thermal debinding of ceramic-filled photopolymers. Materials Science Forum, 2015, 825- 826(Pt.1): 75-81. |

| [1] | FENG Jingjing, ZHANG Youran, MA Mingsheng, LU Yiqing, LIU Zhifu. Current Status and Development Trend of Cold Sintering Process [J]. Journal of Inorganic Materials, 2023, 38(2): 125-136. |

| [2] | JIN Xihai, DONG Manjiang, KAN Yanmei, LIANG Bo, DONG Shaoming. Fabrication of Transparent AlON by Gel Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2023, 38(2): 193-198. |

| [3] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [4] | CHEN Yongqiang, WANG Yixue, ZHANG Fan, LI Hongxia, DONG Binbin, MIN Zhiyu, ZHANG Rui. Preparation of Special Ceramics by Microwave Heating: a Review [J]. Journal of Inorganic Materials, 2022, 37(8): 841-852. |

| [5] | LIU Qiang, WANG Qian, CHEN Penghui, LI Xiaoying, ZHANG Lixuan, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Red Ce-doped 8YSZ Transparent Ceramics by Two-step Sintering [J]. Journal of Inorganic Materials, 2022, 37(8): 911-917. |

| [6] | WEI Tingting, XU Huarui, ZHU Guisheng, LONG Shenfeng, ZHANG Xiuyun, ZHAO Yunyun, JIANG Xupeng, SONG Jinjie, GUO Ningjie, GONG Yipeng. Preparation and Properties of BaTiO3 Ceramics by Low Temperature Cold Sintering [J]. Journal of Inorganic Materials, 2022, 37(8): 903-910. |

| [7] | LIU Jinling, LIU Dianguang, REN Ke, WANG Yiguang. Research Progress on the Flash Sintering Mechanism of Oxide Ceramics and Its Application [J]. Journal of Inorganic Materials, 2022, 37(5): 473-480. |

| [8] | CAO Jiwei, WANG Pei, LIU Zhiyuan, LIU Changyong, WU Jiamin, CHEN Zhangwei. Research Progress on Powder-based Laser Additive Manufacturing Technology of Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 241-254. |

| [9] | YANG Yong, GUO Xiaotian, TANG Jie, CHANG Haotian, HUANG Zhengren, HU Xiulan. Research Progress and Prospects of Non-oxide Ceramic in Stereolithography Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 267-277. |

| [10] | ZHOU Ganghuai, LIU Yao, SHI Yuan, LIU Shaojun. Slurry Preparation and Stereolithography for Activated Alumina Catalyst Carrier [J]. Journal of Inorganic Materials, 2022, 37(3): 297-302. |

| [11] | ZHU Junyi, ZHANG Cheng, LUO Zhongqiang, CAO Jiwei, LIU Zhiyuan, WANG Pei, LIU Changyong, CHEN Zhangwei. Influence of Debinding Process on the Properties of Photopolymerization 3D Printed Cordierite Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 317-324. |

| [12] | LI Qiaolei, GU Yue, YU Xuehua, ZHANG Chaowei, ZOU Mingke, LIANG Jingjing, LI Jinguo. Effect of Sintering Temperature on Surface Morphology and Roughness of 3D-printed Silicon Ceramic Cores [J]. Journal of Inorganic Materials, 2022, 37(3): 325-332. |

| [13] | ZENG Yong, ZHANG Zijia, SUN Lijun, YAO Haihua, CHEN Jiming. Atmosphere Debinding Heat Treatment of 3D Printed Alumina Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 333-337. |

| [14] | HUANG Longzhi, YIN Jie, CHEN Xiao, WANG Xinguang, LIU Xuejian, HUANG Zhengren. Selective Laser Sintering of SiC Green Body with Low Binder Content [J]. Journal of Inorganic Materials, 2022, 37(3): 347-352. |

| [15] | LIU Guoqian, YAN Changhai, ZHANG Keqiang, JIN Hua, HE Rujie. Effect of Solid Loading on the Property of Al2O3 Ceramics in Stereolithographic Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 353-360. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||