Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (3): 255-266.DOI: 10.15541/jim20210608

Special Issue: 【虚拟专辑】增材制造及3D打印(2021-2022); 【结构材料】超高温结构陶瓷

• REVIEW • Previous Articles Next Articles

LIU Haifang1,2( ), SU Haijun1,2(

), SU Haijun1,2( ), SHEN Zhonglin1, JIANG Hao1, ZHAO Di1, LIU Yuan1, ZHANG Jun1, LIU Lin1, FU Hengzhi1

), SHEN Zhonglin1, JIANG Hao1, ZHAO Di1, LIU Yuan1, ZHANG Jun1, LIU Lin1, FU Hengzhi1

Received:2021-10-02

Revised:2021-11-05

Published:2022-03-20

Online:2021-12-24

Contact:

SU Haijun, professor. E-mail: shjnpu@nwpu.edu.cn

About author:LIU Haifang (1987-), male, PhD candidate. E-mail: liuhaifang@mail.nwpu.edu.cn

Supported by:CLC Number:

LIU Haifang, SU Haijun, SHEN Zhonglin, JIANG Hao, ZHAO Di, LIU Yuan, ZHANG Jun, LIU Lin, FU Hengzhi. Research Progress on Ultrahigh Temperature Oxide Eutectic Ceramics by Laser Additive Manufacturing[J]. Journal of Inorganic Materials, 2022, 37(3): 255-266.

| Technology | Scanning control | Molten pool size/mm | Energy density /(W·cm-2) | Building rate /(cm3·min-1) | Manufacturing precision | Preferred applications |

|---|---|---|---|---|---|---|

| SLM | Scanner | <0.2 | 106-107 | ~1.3 | High | Net-shaping small- and medium-sized components |

| LDED | Laser nozzle | >3 | ~105 | 11.5 | Low | Preparing large-scale components |

Table 1 Comparison of the SLM and LDED technologies[28]

| Technology | Scanning control | Molten pool size/mm | Energy density /(W·cm-2) | Building rate /(cm3·min-1) | Manufacturing precision | Preferred applications |

|---|---|---|---|---|---|---|

| SLM | Scanner | <0.2 | 106-107 | ~1.3 | High | Net-shaping small- and medium-sized components |

| LDED | Laser nozzle | >3 | ~105 | 11.5 | Low | Preparing large-scale components |

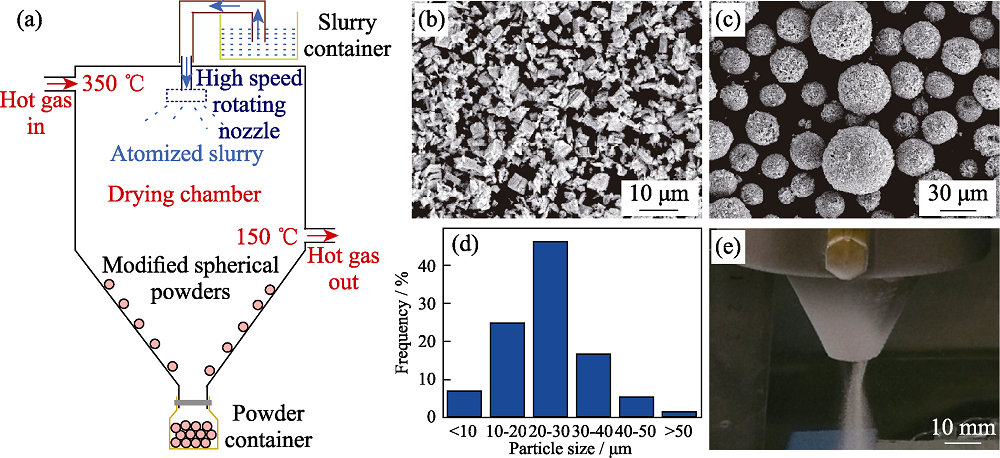

Fig. 3 Preparation technology and characteristics of spherical ceramic powders[68] (a) Schematic diagram of centrifugal spray drying method; (b) Morphology of the initial ceramic powders; (c) Morphology of the modified ceramic powders; (d) Particle size distribution of the modified ceramic powders; (e) Powder feeding test

Fig. 6 Al2O3/GAP/ZrO2 eutectic ceramics prepared at different environments (a) Atmospheric atmosphere; (b) Ar atmosphere with oxygen content >200 μg/L; (c) Ar atmosphere with oxygen content <50 μg/L

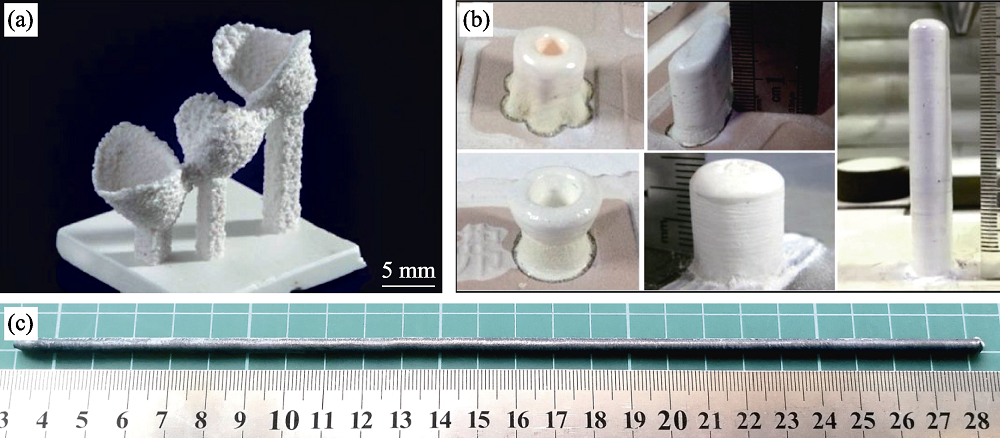

Fig. 7 Oxide eutectic ceramics prepared by laser additive manufacturing (a) SLM-processed Al2O3/ZrO2 eutectic ceramic with shape of framework for a dental restoration[30]; (b) LDED-processed Al2O3/ZrO2 eutectic ceramics with various shapes[43]; (c) LDED-processed Al2O3/GAP/ZrO2 eutectic ceramic rod[70]

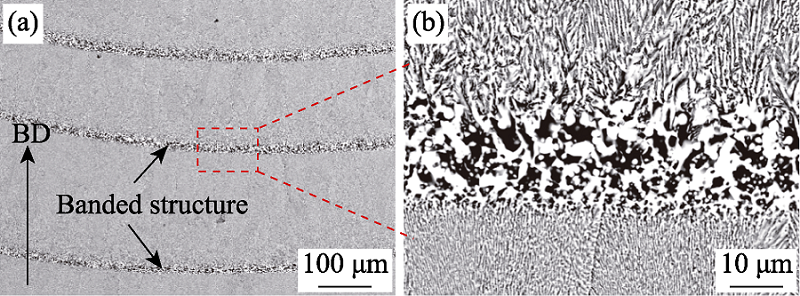

Fig. 8 Microstructure characteristics of the LAM-processed oxide eutectic ceramic along the building direction[68] (a) Periodic banded structure; (b) Magnified image of the banded structure

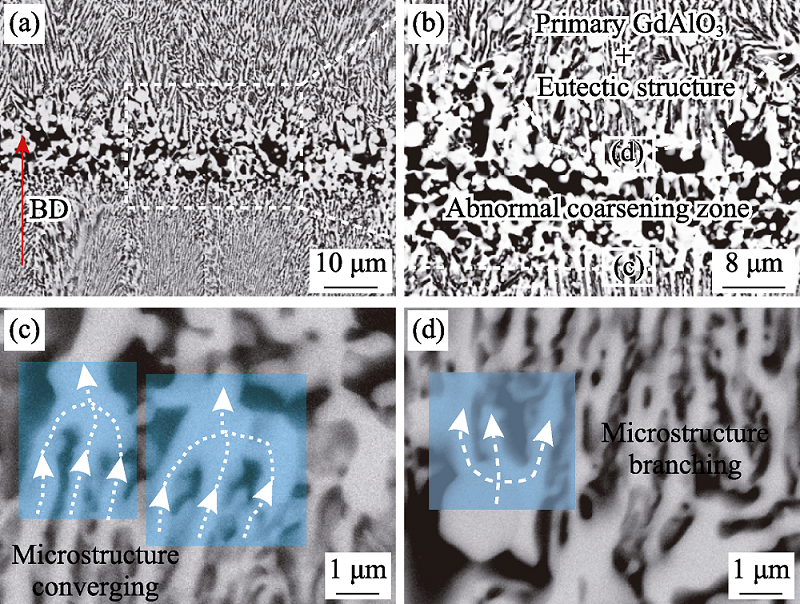

Fig. 9 Microstructure characteristics in vicinity of the banded structure of the LDED-processed Al2O3/GAP/ZrO2 eutectic ceramic[68] (a) Banded structure; (b) Microstructure characteristic of the banded structure; (c) Microstructure at the lower boundary of the banded structure; (d) Microstructure at the upper boundary of the banded structure

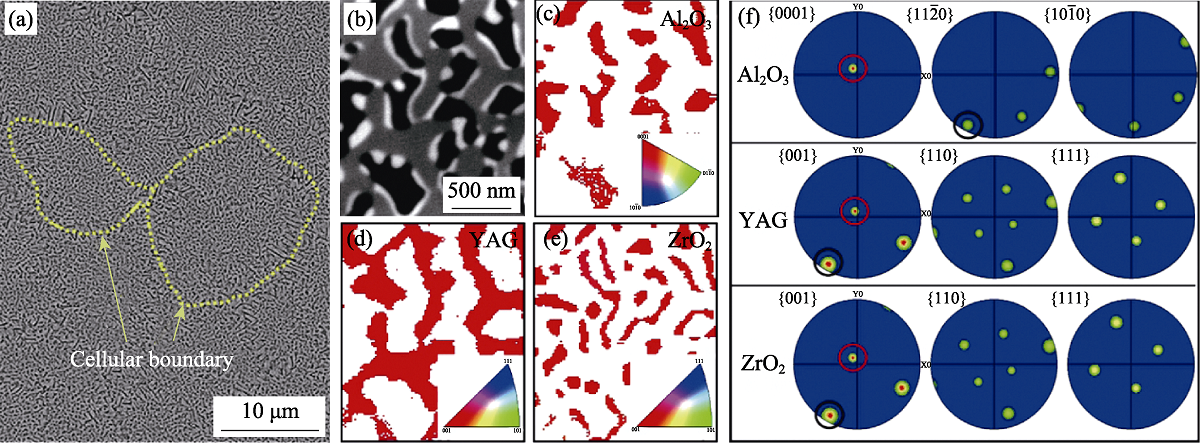

Fig. 10 Microstructure characteristics of the LDED-processed Al2O3/YAG/ZrO2 eutectic ceramic in a deposited layer[47] (a) Eutectic colony structure; (b) Microstructure inside the colony; (c-e) TKD (Transmission kikuchi diffraction) orientation maps of the phases of Al2O3, YAG and ZrO2, respectively; (f) Pole figures of Al2O3, YAG and ZrO2, corresponding to (c-e), respectively

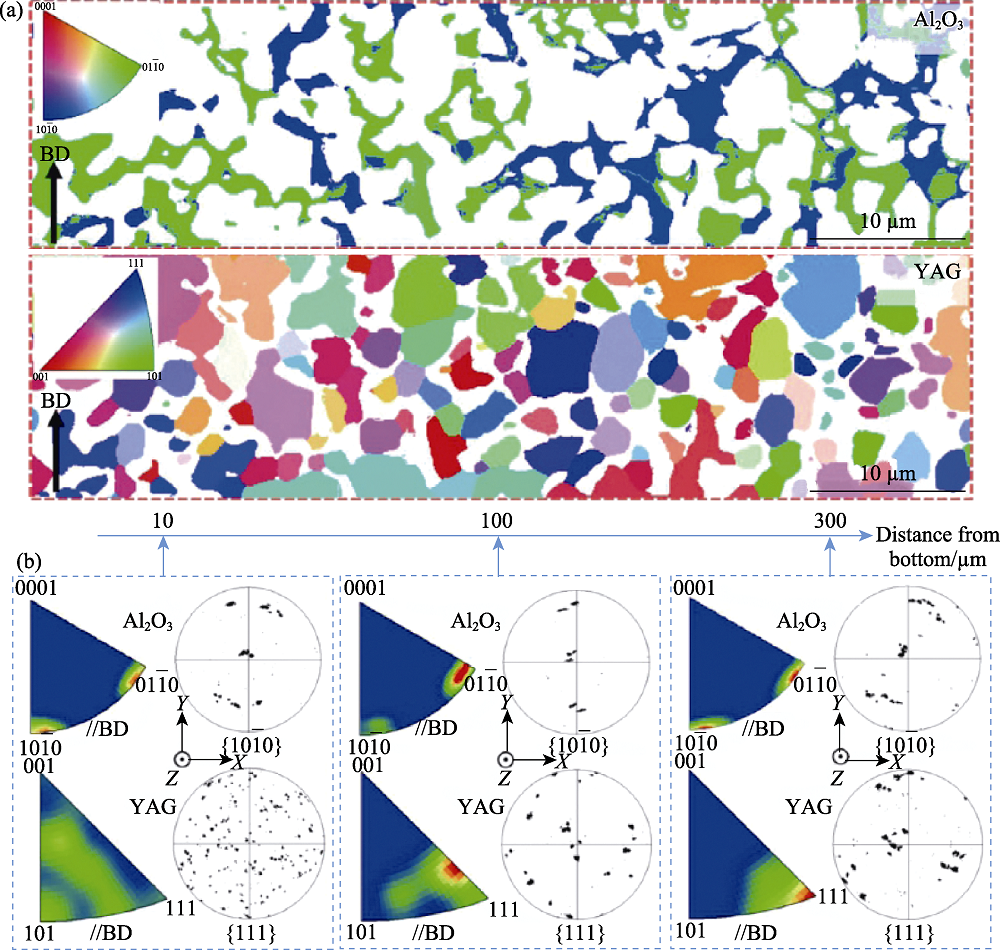

Fig. 11 Orientation variations of eutectic phases of the LDED-processed Al2O3/YAG eutectic ceramic during solidification process[46] (a) EBSD orientation maps of Al2O3 and YAG in bottom zone of the molten pool; (b) Orientation variations of Al2O3 and YAG along the height direction of the molten pool

| Eutectic system | Hardness /GPa | Fracture toughness /(MPa·m1/2) | Preparation method |

|---|---|---|---|

| Al2O3/YAG | 21.50 | 5.86 | LDED[ |

| Al2O3/ZrO2 | 16.22 | 7.67 | LDED[ |

| Al2O3/YAG/ZrO2 | 18.90 | 3.84 | LDED[ |

| Al2O3/GAP/ZrO2 | 15.30 | 7.80 | SLM[ |

| Al2O3/YAG | 17.50 | 3.60 | DS[ |

| Al2O3/ZrO2 | 16.53 | 6.50 | DS[ |

| Al2O3/YAG/ZrO2 | 16.70 | 8.00 | DS[ |

| Al2O3/GAP/ZrO2 | 17.90 | 8.50 | DS[ |

Table 2 Mechanical property comparison of the oxide eutectic ceramics prepared by laser additive manufacturing and directional solidification (DS)

| Eutectic system | Hardness /GPa | Fracture toughness /(MPa·m1/2) | Preparation method |

|---|---|---|---|

| Al2O3/YAG | 21.50 | 5.86 | LDED[ |

| Al2O3/ZrO2 | 16.22 | 7.67 | LDED[ |

| Al2O3/YAG/ZrO2 | 18.90 | 3.84 | LDED[ |

| Al2O3/GAP/ZrO2 | 15.30 | 7.80 | SLM[ |

| Al2O3/YAG | 17.50 | 3.60 | DS[ |

| Al2O3/ZrO2 | 16.53 | 6.50 | DS[ |

| Al2O3/YAG/ZrO2 | 16.70 | 8.00 | DS[ |

| Al2O3/GAP/ZrO2 | 17.90 | 8.50 | DS[ |

| [1] |

JAMES C W, EDGAR A S. Progress in structural materials for aerospace systems. Acta Materialia, 2003, 51(19): 5775-5799.

DOI URL |

| [2] |

WAKU Y, SAKUMA T. Dislocation mechanism of deformation and strength of Al2O3-YAG single crystal composites at high temperatures above 1500 ℃. Journal of the European Ceramic Society, 2000, 20(10): 1453-1458.

DOI URL |

| [3] |

PASTOR J Y, MARTIN A, MOLINA-ALDAREGUIA J M, et al. Superplastic deformation of directionally solidified nanofibrillar Al2O3-Y3Al5O12-ZrO2 eutectics. Journal of the European Ceramic Society, 2013, 33(13/14): 2579-2586.

DOI URL |

| [4] |

OCHIAI S, UEDA T, SATO K, et al. Deformation and fracture behavior of an Al2O3/YAG composite from room temperature to 2023 K. Composites Science and Technology, 2001, 61(14): 2117-2128.

DOI URL |

| [5] |

WAKU Y, NAKAGAWA N, WAKAMOTO T, et al. A ductile ceramic eutectic composite with high strength at 1873 K. Nature, 1997, 389(6646): 49-52.

DOI URL |

| [6] |

LLORCA J, ORERA V M. Directionally solidified eutectic ceramic oxides. Progress in Materials Science, 2006, 51(6): 711-809.

DOI URL |

| [7] |

WANG X, ZHANG W, ZHONG Y J, et al. Introduction of low strain energy GdAlO3 grain boundaries into directionally solidified Al2O3/GdAlO3 eutectics. Acta Materialia, 2021, 221: 117355.

DOI URL |

| [8] | MA W D, ZHANG J, SU H J, et al. Phase growth patterns for Al2O3/GdAlO3 eutectics over wide ranges of compositions and solidification rates. Journal of Materials Science & Technology, 2021, 65: 89-98. |

| [9] | SU H J, LIU Y, REN Q, et al. Distribution control and formation mechanism of gas inclusions in directionally solidified Al2O3-Er3Al5O12-ZrO2 ternary eutectic ceramic by laser floating zone melting. Journal of Materials Science & Technology, 2021, 66: 21-27. |

| [10] |

SUN L C, ZHOU C, DU T F, et al. Directionally solidified Al2O3/Er3Al5O12 and Al2O3/Yb3Al5O12 eutectic ceramics prepared by optical floating zone melting. Journal of Inorganic Materials, 2021, 36(6): 652-658.

DOI URL |

| [11] |

NAKAGAWA N, OHSSUBO H, MITANI A, et al. High temperature strength and thermal stability for melt growth composite. Journal of the European Ceramic Society, 2005, 25(8): 1251-1257.

DOI URL |

| [12] |

NAKAGAWA N, OHSSUBO H, WAKU Y, et al. Thermal emission properties of Al2O3/Er3Al5O12 eutectic ceramics. Journal of the European Ceramic Society, 2005, 25(8): 1285-1291.

DOI URL |

| [13] |

OTSUKA A, WAKU Y, TANAKA R. Corrosion of a unidirectionally solidified Al2O3/YAG eutectic composite in a combustion environment. Journal of the European Ceramic Society, 2005, 25(8): 1269-1274.

DOI URL |

| [14] | ZHANG F Y, GAO P P, TAN H, et al. Tailoring grain morphology in Ti-6Al-3Mo through heterogeneous nucleation in directed energy deposition. Journal of Materials Science & Technology, 2021, 88: 132-142. |

| [15] | CHAKRABORTY A, TANGESTANI R, BATMAZ R, et al. In-process failure analysis of thin-wall structures made by laser powder bed fusion additive manufacturing. Journal of Materials Science & Technology, 2022, 98: 233-243. |

| [16] | KIM Y K, KIM M C, LEE K A. 1.45 GPa ultrastrong cryogenic strength with superior impact toughness in the in-situ nano oxide reinforced CrMnFeCoNi high-entropy alloy matrix nanocomposite manufactured by laser powder bed fusion. Journal of Materials Science & Technology, 2022, 97: 10-19. |

| [17] | XING L L, ZHAO C C, CHEN H, et al. Microstructure of a Ti-50wt% Ta alloy produced via laser powder bed fusion. Acta Metallurgica Sinica, 2020, 33(7): 981-990. |

| [18] | EBRAHIMNIA M, XIE Y J, CHI C T. Effect of laser power and deposition environment on the microstructure and properties of direct laser metal-deposited 12CrNi2 steel. Acta Metallurgica Sinica, 2020, 33(4): 528-538. |

| [19] | YU C F, ZHONG Y, ZHANG P, et al. Effect of build direction on fatigue performance of L-PBF 316L stainless steel. Acta Metallurgica Sinica, 2020, 33(4): 539-550. |

| [20] | WANG X, LÜ F, SHEN L D, et al. Influence of island scanning strategy on microstructures and mechanical properties of direct laser-deposited Ti-6Al-4V structures. Acta Metallurgica Sinica, 2019, 32(9): 1173-1180. |

| [21] | SHEN Z L, SU H J, LIU H F, et al. Research progress on laser additive manufacturing technology and its defect control for ultra-high temperature oxide ceramics. Acta Materiae Compositae Sinica, 2021, 38(3): 668-679. |

| [22] | GU D D, ZHANG H M, CHEN H Y, et al. Laser additive manufacturing of high-performance metallic aerospace components. Chinese Journal of Lasers, 2020, 47(5): 32-55. |

| [23] | SU H J, WEI K C, GUO W, et al. New development of laser rapid forming and its application in high performance materials processing. The Chinese Journal of Nonferrous Metals, 2013, 23(6): 1567-1574. |

| [24] |

LAKHDAR Y, TUCK C, BINNER J, et al. Additive manufacturing of advanced ceramic materials. Progress in Materials Science, 2021, 116: 100736.

DOI URL |

| [25] |

CHEN Z W, LI Z Y, LI J J, et al. 3D printing of ceramics: a review. Journal of the European Ceramic Society, 2019, 39(4): 661-687.

DOI URL |

| [26] |

TAMEZ M B A, TAHA I. A review of additive manufacturing technologies and markets for thermosetting resins and their potential for carbon fiber integration. Additive Manufacturing, 2021, 37: 101748.

DOI URL |

| [27] |

SUN C, WANG Y, MCMURTREY M D, et al. Additive manufacturing for energy: a review. Applied Energy, 2021, 282: 116041.

DOI URL |

| [28] | GU D D, SHI X Y, POPRAWE R, et al. Material-structure- performance integrated laser-metal additive manufacturing. Science, 2021, 372(6545): 932-947. |

| [29] |

SU H J, ZHANG J, LIU L, et al. Rapid growth and formation mechanism of ultrafine structural oxide eutectic ceramics by laser direct forming. Applied Physics Letters, 2011, 99(22): 221913.

DOI URL |

| [30] |

WILKES J, HAGEDORN Y, MEINERS W, et al. Additive manufacturing of ZrO2-Al2O3 ceramic components by selective laser melting. Rapid Prototyping Journal, 2013, 19(1): 51-57.

DOI URL |

| [31] |

NIU F Y, WU D J, MA G Y, et al. Nanosized microstructure of Al2O3-ZrO2(Y2O3) eutectics fabricated by laser engineered net shaping. Scripta Materialia, 2015, 95: 39-41.

DOI URL |

| [32] | NIU F Y, WU D J, MA G Y, et al. Rapid fabrication of eutectic ceramic structures by laser engineered net shaping. ISEM XVIII, 2016, 42: 91-95. |

| [33] |

YAN S, WU D J, MA G Y, et al. Formation mechanism and process optimization of nano Al2O3-ZrO2 eutectic ceramic via laser engineered net shaping (LENS). Ceramics International, 2017, 43(17): 14742-14747.

DOI URL |

| [34] |

MA G Y, YAN S, NIU F Y, et al. Microstructure and mechanical properties of solid Al2O3-ZrO2 (Y2O3) eutectics prepared by laser engineered net shaping. Journal of Laser Applications, 2017, 29(2): 022305.

DOI URL |

| [35] |

YAN S, WU D J, NIU F Y, et al. Al2O3-ZrO2 eutectic ceramic via ultrasonic-assisted laser engineered net shaping. Ceramics International, 2017, 43(17): 15905-15910.

DOI URL |

| [36] |

YAN S, WU D J, MA G Y, et al. Nano-sized Al2O3-ZrO2 eutectic ceramic structures prepared by ultrasonic-assisted laser engineered net shaping. Materials Letters, 2018, 212: 8-11.

DOI URL |

| [37] |

YAN S, WU D J, NIU F Y, et al. Effect of ultrasonic power on forming quality of nano-sized Al2O3-ZrO2 eutectic ceramic via laser engineered net shaping (LENS). Ceramics International, 2018, 44(1): 1120-1126.

DOI URL |

| [38] |

WU D J, LU F, ZHAO D K, et al. Effect of doping SiC particles on cracks and pores of Al2O3-ZrO2 eutectic ceramics fabricated by directed laser deposition. Journal of Materials Science, 2019, 54(13): 9321-9330.

DOI URL |

| [39] |

WU D J, SAN J D, NIU F Y, et al. Directed laser deposition of Al2O3-ZrO2 melt-grown composite ceramics with multiple composition ratios. Journal of Materials Science, 2020, 55(16): 6794-6809.

DOI URL |

| [40] |

WU D J, SAN J D, NIU F Y, et al. Effect and mechanism of ZrO2 doping on the cracking behavior of melt-grown Al2O3 ceramics prepared by directed laser deposition. International Journal of Applied Ceramic Technology, 2020, 17(1): 227-238.

DOI URL |

| [41] |

WU D J, LIU H C, LU F, et al. Al2O3-YAG eutectic ceramic prepared by laser additive manufacturing with water-cooled substrate. Ceramics International, 2019, 45(3): 4119-4122.

DOI URL |

| [42] |

YAN S, WU D J, HUANG Y F, et al. C fiber toughening Al2O3-ZrO2 eutectic via ultrasonic-assisted directed laser deposition. Materials Letters, 2019, 235: 228-231.

DOI URL |

| [43] |

YAN S, HUANG Y F, ZHAO D K, et al. 3D printing of nano- scale Al2O3-ZrO2 eutectic ceramic: principle analysis and process optimization of pores. Additive Manufacturing, 2019, 28: 120-126.

DOI URL |

| [44] |

LI F Z, ZHANG X W, SUI C Y, et al. Microstructure and mechanical properties of Al2O3-ZrO2 ceramic deposited by laser direct material deposition. Ceramics International, 2018, 44(15): 18960-18968.

DOI URL |

| [45] |

LI F Z, LIU Z W, LI B, et al. Pore formation model for direct laser deposition of Al2O3-ZrO2 ceramic. Journal of the European Ceramic Society, 2022, 42(1): 207-215.

DOI URL |

| [46] |

FAN Z Q, ZHAO Y T, TAN Q Y, et al. New insights into the growth mechanism of 3D-printed Al2O3-Y3Al5O12 binary eutectic composites. Scripta Materialia, 2020, 178: 274-280.

DOI URL |

| [47] |

FAN Z Q, ZHAO Y T, TAN Q Y, et al. Nanostructured Al2O3-YAG-ZrO2 ternary eutectic components prepared by laser engineered net shaping. Acta Materialia, 2019, 170: 24-37.

DOI URL |

| [48] |

BARTLETT J L, LI X. An overview of residual stresses in metal powder bed fusion. Additive Manufacturing, 2019, 27: 131-149.

DOI URL |

| [49] |

FANG Z C, WU Z L, HUANG C G, et al. Review on residual stress in selective laser melting additive manufacturing of alloy parts. Optics and Laser Technology, 2020, 129: 106283.

DOI URL |

| [50] | ACEVEDO R, SEDLAK P, KOLMAN R, et al. Residual stress analysis of additive manufacturing of metallic parts using ultrasonic waves: state of the art review. Journal of Materials Research and Technology, 2020, 9(4): 9457-9477. |

| [51] |

CHEN W, XU L Y, HAN Y D, et al. Control of residual stress in metal additive manufacturing by low-temperature solid-state phase transformation: an experimental and numerical study. Additive Manufacturing, 2021, 42: 102016.

DOI URL |

| [52] | SONG X, FEIH S, ZHAI W, et al. Advances in additive manufacturing process simulation: residual stresses and distortion predictions in complex metallic components. Materials & Design, 2020, 193: 108779. |

| [53] |

HA K, KIM T, BAEK G Y, et al. Numerical study of the effect of progressive solidification on residual stress in single-bead-on-plate additive manufacturing. Additive Manufacturing, 2020, 34: 101245.

DOI URL |

| [54] |

ROEHLING J D, SMITH W L, ROEHLING T T, et al. Reducing residual stress by selective large-area diode surface heating during laser powder bed fusion additive manufacturing. Additive Manufacturing, 2019, 28: 228-235.

DOI URL |

| [55] |

HUANG H, MA N S, CHEN J, et al. Toward large-scale simulation of residual stress and distortion in wire and arc additive manufacturing. Additive Manufacturing, 2020, 34: 101248.

DOI URL |

| [56] |

ŞIRIN T B, KAYNAK Y. Prediction of residual stress and distortion in laser powder bed fusion additive manufacturing process of Inconel 718 alloy. Procedia CIRP, 2021, 99: 330-335.

DOI URL |

| [57] |

SUN J M, HENSEL J, KOHLER M, et al. Residual stress in wire and arc additively manufactured aluminum components. Journal of Manufacturing Processes, 2021, 65: 97-111.

DOI URL |

| [58] |

LI R S, WANG G L, ZHAO X S, et al. Effect of path strategy on residual stress and distortion in laser and cold metal transfer hybrid additive manufacturing. Additive Manufacturing, 2021, 46: 102203.

DOI URL |

| [59] | STRANTZA M, GANERIWALA R K, CLAUSEN B, et al. Effect of the scanning strategy on the formation of residual stresses in additively manufactured Ti-6Al-4V. Additive Manufacturing, 2021, 45: 102003.s |

| [60] |

NADAMMAL N, MISHUROVA T, FRITSCH T, et al. Critical role of scan strategies on the development of microstructure, texture, and residual stresses during laser powder bed fusion additive manufacturing. Additive Manufacturing, 2021, 38: 101792.

DOI URL |

| [61] | PROMOPPATUM P, UTHAISANGSUK V. Part scale estimation of residual stress development in laser powder bed fusion additive manufacturing of Inconel 718. Finite Elements in Analysis & Design, 2021, 189: 103528. |

| [62] |

LIU Q, DANLOS Y, SONG B, et al. Effect of high-temperature preheating on the selective laser melting of yttria-stabilized zirconia ceramic. Journal of Materials Processing Technology, 2015, 222: 61-74.

DOI URL |

| [63] | NIU F Y, WU D J, YAN S, et al. Process optimization for suppressing cracks in laser engineered net shaping of Al2O3 ceramics. The Journal of The Minerals, Metals & Materials Society, 2017, 69(3): 557-562. |

| [64] |

ZHANG K, LIU T T, LIAO W H, et al. Influence of laser parameters on the surface morphology of slurry-based Al2O3 parts produced through selective laser melting. Rapid Prototyping Journal, 2018, 24(2): 333-341.

DOI URL |

| [65] |

HU Y B, NING F D, CONG W L, et al. Ultrasonic vibration- assisted laser engineering net shaping of ZrO2-Al2O3 bulk parts: effects on crack suppression, microstructure, and mechanical properties. Ceramics International, 2018, 44(3): 2752-2760.

DOI URL |

| [66] |

ZHENG Y, ZHANG K, LIU T T, et al. Cracks of alumina ceramics by selective laser melting. Ceramics International, 2019, 45(1): 175-184.

DOI URL |

| [67] |

LIU H F, SU H J, SHEN Z L, et al. Effect of scanning speed on the solidification process of Al2O3/GdAlO3/ZrO2 eutectic ceramics in a single track by selective laser melting. Ceramics International, 2019, 45(14): 17252-17257.

DOI URL |

| [68] |

LIU H F, SU H J, SHEN Z L, et al. One-step additive manufacturing and microstructure evolution of melt-grown Al2O3/GdAlO3/ZrO2 eutectic ceramics by laser directed energy deposition. Journal of the European Ceramic Society, 2021, 41(6): 3547-3558.

DOI URL |

| [69] |

LIU H F, SU H J, SHEN Z L, et al. Direct formation of Al2O3/GdAlO3/ZrO2 ternary eutectic ceramics by selective laser melting: microstructure evolutions. Journal of the European Ceramic Society, 2018, 38(15): 5144-5152.

DOI URL |

| [70] | LIU H F, SU H J, SHEN Z L, et al. Preparation of large-size Al2O3/GdAlO3/ZrO2 ternary eutectic ceramic rod by laser directed energy deposition and its microstructure homogenization mechanism. Journal of Materials Science & Technology, 2021, 85: 218-223. |

| [71] | TRIANTAFYLLIDIS D, LI L, STOTT F H. Mechanisms of porosity formation along the solid/liquid interface during laser melting of ceramics. Applied Surface Science, 2003, 208: 458-462. |

| [72] |

OLIETE P B, PENA J I. Study of the gas inclusions in Al2O3/Y3Al5O12 and Al2O3/Y3Al5O12/ZrO2 eutectic fibers grown by laser floating zone. Journal of Crystal Growth, 2007, 304(2): 514-519.

DOI URL |

| [73] |

REN Q, SU H J, ZHANG J, et al. Eutectic growth behavior with regular arrangement in the faceted Al2O3/Er3Al5O12 irregular eutectic system at low growth rate. Scripta Materialia, 2019, 162: 49-53.

DOI URL |

| [74] |

MA W D, ZHANG J, SU H J, et al. Theoretical prediction and experimental comparison for eutectic growth of Al2O3/GdAlO3 faceted eutectics. Journal of the European Ceramic Society, 2019, 39(13): 3837-3842.

DOI URL |

| [75] |

REN Q, SU H J, ZHANG J, et al. Microstructure control, competitive growth and precipitation rule in faceted Al2O3/Er3Al5O12 eutectic in situ composite ceramics prepared by laser floating zone melting. Journal of the European Ceramic Society, 2019, 39(5): 1900-1908.

DOI URL |

| [76] |

SU H J, REN Q, ZHANG J, et al. Microstructures and mechanical properties of directionally solidified Al2O3/GdAlO3 eutectic ceramic by laser floating zone melting with high temperature gradient. Journal of the European Ceramic Society, 2017, 37(4): 1617-1626.

DOI URL |

| [77] |

SU H J, ZHANG J, CUI C J, et al. Rapid solidification behaviour of Al2O3/Y3Al5O12(YAG) binary eutectic ceramic in situ composites. Materials Science and Engineering A, 2008, 479(1/2): 380-388.

DOI URL |

| [78] |

FAN G R, SU H J, ZHANG J, et al. Microstructure and cytotoxicity of Al2O3-ZrO2 eutectic bioceramics with high mechanical properties prepared by laser floating zone melting. Ceramics International, 2018, 44(15): 17978-17985.

DOI URL |

| [79] |

SU H J, ZHANG J, CUI C J, et al. Rapid solidification of Al2O3/Y3Al5O12/ZrO2 eutectic in situ composites by laser zone remelting. Journal of Crystal Growth, 2007, 307(2): 448-456.

DOI URL |

| [80] |

MAZEROLLES L, PIQUET N, TRICHET M, et al. New microstructures in ceramic materials from the melt for high temperature applications. Aerospace Science and Technology, 2008, 12(7): 499-505.

DOI URL |

| [1] | DING Ling, JIANG Rui, TANG Zilong, YANG Yunqiong. MXene: Nanoengineering and Application as Electrode Materials for Supercapacitors [J]. Journal of Inorganic Materials, 2023, 38(6): 619-633. |

| [2] | YANG Zhuo, LU Yong, ZHAO Qing, CHEN Jun. X-ray Diffraction Rietveld Refinement and Its Application in Cathode Materials for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2023, 38(6): 589-605. |

| [3] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [4] | LIN Junliang, WANG Zhanjie. Research Progress on Ferroelectric Superlattices [J]. Journal of Inorganic Materials, 2023, 38(6): 606-618. |

| [5] | NIU Jiaxue, SUN Si, LIU Pengfei, ZHANG Xiaodong, MU Xiaoyu. Copper-based Nanozymes: Properties and Applications in Biomedicine [J]. Journal of Inorganic Materials, 2023, 38(5): 489-502. |

| [6] | YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(5): 477-488. |

| [7] | DU Jianyu, GE Chen. Recent Progress in Optoelectronic Artificial Synapse Devices [J]. Journal of Inorganic Materials, 2023, 38(4): 378-386. |

| [8] | YANG Yang, CUI Hangyuan, ZHU Ying, WAN Changjin, WAN Qing. Research Progress of Flexible Neuromorphic Transistors [J]. Journal of Inorganic Materials, 2023, 38(4): 367-377. |

| [9] | YOU Junqi, LI Ce, YANG Dongliang, SUN Linfeng. Double Dielectric Layer Metal-oxide Memristor: Design and Applications [J]. Journal of Inorganic Materials, 2023, 38(4): 387-398. |

| [10] | CHEN Kunfeng, HU Qianyu, LIU Feng, XUE Dongfeng. Multi-scale Crystallization Materials: Advances in in-situ Characterization Techniques and Computational Simulations [J]. Journal of Inorganic Materials, 2023, 38(3): 256-269. |

| [11] | ZHANG Chaoyi, TANG Huili, LI Xianke, WANG Qingguo, LUO Ping, WU Feng, ZHANG Chenbo, XUE Yanyan, XU Jun, HAN Jianfeng, LU Zhanwen. Research Progress of ScAlMgO4 Crystal: a Novel GaN and ZnO Substrate [J]. Journal of Inorganic Materials, 2023, 38(3): 228-242. |

| [12] | QI Zhanguo, LIU Lei, WANG Shouzhi, WANG Guogong, YU Jiaoxian, WANG Zhongxin, DUAN Xiulan, XU Xiangang, ZHANG Lei. Progress in GaN Single Crystals: HVPE Growth and Doping [J]. Journal of Inorganic Materials, 2023, 38(3): 243-255. |

| [13] | LIN Siqi, LI Airan, FU Chenguang, LI Rongbing, JIN Min. Crystal Growth and Thermoelectric Properties of Zintl Phase Mg3X2 (X=Sb, Bi) Based Materials: a Review [J]. Journal of Inorganic Materials, 2023, 38(3): 270-279. |

| [14] | LIU Yan, ZHANG Keying, LI Tianyu, ZHOU Bo, LIU Xuejian, HUANG Zhengren. Electric-field Assisted Joining Technology for the Ceramics Materials: Current Status and Development Trend [J]. Journal of Inorganic Materials, 2023, 38(2): 113-124. |

| [15] | XIE Bing, CAI Jinxia, WANG Tongtong, LIU Zhiyong, JIANG Shenglin, ZHANG Haibo. Research Progress of Polymer-based Multilayer Composite Dielectrics with High Energy Storage Density [J]. Journal of Inorganic Materials, 2023, 38(2): 137-147. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||