Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (7): 764-772.DOI: 10.15541/jim20210616

• RESEARCH ARTICLE • Previous Articles Next Articles

CHENG Weijie1,2( ), WANG Minglei1,2, LIN Guoqiang1,2(

), WANG Minglei1,2, LIN Guoqiang1,2( )

)

Received:2021-10-08

Revised:2021-11-10

Published:2022-07-20

Online:2021-11-18

Contact:

LIN Guoqiang, professor. E-mail: gqlin@dlut.edu.cnAbout author:CHENG Weijie (1997-), male, Master candidate. E-mail: 737289840@qq.com

Supported by:CLC Number:

CHENG Weijie, WANG Minglei, LIN Guoqiang. Composition, Structure and Properties of CrAlN-DLC Hard Composite Films Deposited by Arc Ion Plating[J]. Journal of Inorganic Materials, 2022, 37(7): 764-772.

| Sample | Arc current/A | Arc current ratio, IC/ICrAl | Gas flow/sccm | Pulsed bias | Deposition time/min | ||||

|---|---|---|---|---|---|---|---|---|---|

| CrAl | C | N2 | Ar | Frequency/Hz | Amplitude/V | Duty cycle/% | |||

| CrAlN-DLC 1# | 90 | 30 | 0.33 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 2# | 80 | 40 | 0.5 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 3# | 70 | 50 | 0.71 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 4# | 55 | 65 | 1.18 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 5# | 50 | 70 | 1.4 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 6# | 40 | 80 | 2 | 10 | 90 | 30 | -200 | 40 | 90 |

Table 1 Deposition parameters of CrAlN-DLC films

| Sample | Arc current/A | Arc current ratio, IC/ICrAl | Gas flow/sccm | Pulsed bias | Deposition time/min | ||||

|---|---|---|---|---|---|---|---|---|---|

| CrAl | C | N2 | Ar | Frequency/Hz | Amplitude/V | Duty cycle/% | |||

| CrAlN-DLC 1# | 90 | 30 | 0.33 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 2# | 80 | 40 | 0.5 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 3# | 70 | 50 | 0.71 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 4# | 55 | 65 | 1.18 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 5# | 50 | 70 | 1.4 | 10 | 90 | 30 | -200 | 40 | 90 |

| CrAlN-DLC 6# | 40 | 80 | 2 | 10 | 90 | 30 | -200 | 40 | 90 |

| Sample | IC/ICrAl | Thickness/μm |

|---|---|---|

| CrAlN-DLC 1# | 0.33 | (0.99±0.03) |

| CrAlN-DLC 2# | 0.50 | (1.09±0.02) |

| CrAlN-DLC 3# | 0.71 | (1.09±0.02) |

| CrAlN-DLC 4# | 1.18 | (1.08±0.01) |

| CrAlN-DLC 5# | 1.40 | (1.02±0.02) |

| CrAlN-DLC 6# | 2.00 | (1.04±0.02) |

Table 2 Thickness of CrAlN-DLC films with different arc current ratios

| Sample | IC/ICrAl | Thickness/μm |

|---|---|---|

| CrAlN-DLC 1# | 0.33 | (0.99±0.03) |

| CrAlN-DLC 2# | 0.50 | (1.09±0.02) |

| CrAlN-DLC 3# | 0.71 | (1.09±0.02) |

| CrAlN-DLC 4# | 1.18 | (1.08±0.01) |

| CrAlN-DLC 5# | 1.40 | (1.02±0.02) |

| CrAlN-DLC 6# | 2.00 | (1.04±0.02) |

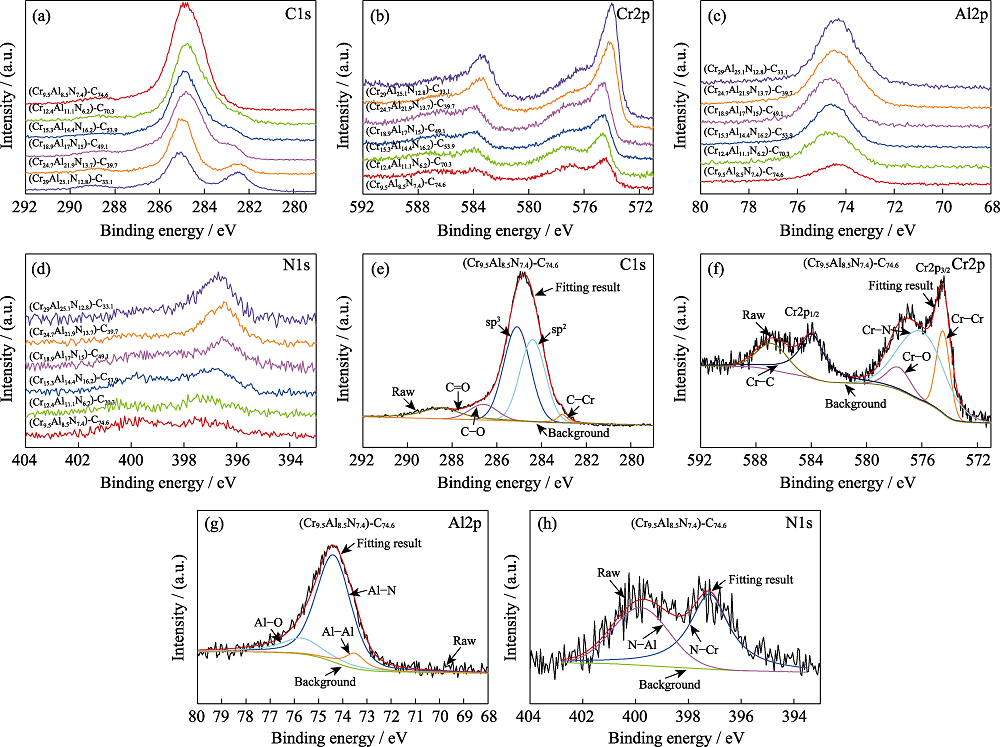

Fig. 7 (a) C1s, (b) Cr2p, (c) Al2p, and (d) N1s XPS spectra of CrAlN-DLC films, and fitting results of (e) C1s, (f) Cr2p, (g) Al2p, and (h) N1s XPS peaks for (Cr9.5Al8.5N7.4)-C74.6 film

| Area Sample | C1s | Cr2p | Al2p | N1s | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-Cr | C-C | C-O | Cr-N | Cr-C | Cr-O | Cr-Cr | Al-N | Al-O | Al-Al | Cr | N-Al | ||

| sp2 | sp3 | ||||||||||||

| (Cr29Al25.1N12.8)-C33.1 | 18.9 | 42.3 | 33.8 | 5.0 | 40.5 | 32.8 | 6.2 | 20.5 | 64.5 | 15.5 | 20.0 | 79.4 | 20.6 |

| (Cr24.7Al21.9N13.7)-C39.7 | 15.4 | 43.3 | 36.0 | 5.3 | 42.6 | 35.5 | 6.9 | 16.0 | 70.9 | 14.8 | 14.3 | 73.9 | 26.1 |

| (Cr18.9Al17N15)-C49.1 | 12.5 | 42.6 | 38.0 | 6.8 | 44.2 | 35.4 | 6.3 | 14.1 | 76.2 | 13.0 | 10.8 | 67.4 | 32.6 |

| (Cr15.3Al14.4N16.2)-C53.9 | 9.8 | 42.7 | 40.0 | 7.5 | 47.7 | 34.6 | 6.1 | 11.6 | 78.3 | 14.2 | 7.5 | 62.8 | 37.2 |

| (Cr12.4Al11.1N6.2)-C70.3 | 7.5 | 41.4 | 42.3 | 8.7 | 40.4 | 36.0 | 7.3 | 18.3 | 63.8 | 17.9 | 18.6 | 59.2 | 40.8 |

| (Cr9.5Al8.5N7.4)-C74.6 | 4.3 | 39.0 | 47.0 | 10.0 | 45.0 | 31.6 | 7.7 | 15.7 | 71.7 | 17.3 | 11.0 | 55.5 | 44.5 |

Table 3 Fitting results of C1s, Cr2p, Al2p and N1s XPS peak of CrAlN-DLC films (atomic percentage/%)

| Area Sample | C1s | Cr2p | Al2p | N1s | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| C-Cr | C-C | C-O | Cr-N | Cr-C | Cr-O | Cr-Cr | Al-N | Al-O | Al-Al | Cr | N-Al | ||

| sp2 | sp3 | ||||||||||||

| (Cr29Al25.1N12.8)-C33.1 | 18.9 | 42.3 | 33.8 | 5.0 | 40.5 | 32.8 | 6.2 | 20.5 | 64.5 | 15.5 | 20.0 | 79.4 | 20.6 |

| (Cr24.7Al21.9N13.7)-C39.7 | 15.4 | 43.3 | 36.0 | 5.3 | 42.6 | 35.5 | 6.9 | 16.0 | 70.9 | 14.8 | 14.3 | 73.9 | 26.1 |

| (Cr18.9Al17N15)-C49.1 | 12.5 | 42.6 | 38.0 | 6.8 | 44.2 | 35.4 | 6.3 | 14.1 | 76.2 | 13.0 | 10.8 | 67.4 | 32.6 |

| (Cr15.3Al14.4N16.2)-C53.9 | 9.8 | 42.7 | 40.0 | 7.5 | 47.7 | 34.6 | 6.1 | 11.6 | 78.3 | 14.2 | 7.5 | 62.8 | 37.2 |

| (Cr12.4Al11.1N6.2)-C70.3 | 7.5 | 41.4 | 42.3 | 8.7 | 40.4 | 36.0 | 7.3 | 18.3 | 63.8 | 17.9 | 18.6 | 59.2 | 40.8 |

| (Cr9.5Al8.5N7.4)-C74.6 | 4.3 | 39.0 | 47.0 | 10.0 | 45.0 | 31.6 | 7.7 | 15.7 | 71.7 | 17.3 | 11.0 | 55.5 | 44.5 |

| [1] |

SOROKA E, LYASHENKO B, QIAO S, et al. Tribological behaviour and cutting performance of PVD-TiN coating/substrate system with discontinuous surface architecture. Rare Metal Materials and Engineering, 2011, 40(4): 580-584.

DOI URL |

| [2] |

CHANG Z K, WAN X S, PEI Z L, et al. Microstructure and mechanical properties of CrN coating deposited by arc ion plating on Ti6Al4V substrate. Surface & Coatings Technology, 2011, 205(19): 4690-4696.

DOI URL |

| [3] |

BERTRAND G, SAVALL C, MEUNIER C, et al. Properties of reactively RF magnetron-sputtered chromium nitride coatings. Surface & Coatings Technology, 1997, 96(2): 323-329.

DOI URL |

| [4] |

WANG L, ZHANG G, WOOD R, et al. Fabrication of CrAlN nanocomposite films with high hardness and excellent anti-wear performance for gear application. Surface & Coatings Technology, 2010, 204(21): 3517-3524.

DOI URL |

| [5] | KIM M W, KIM K H, KANG M C, et al. Mechanical properties and cutting performance of Cr-Al-N hybrid coated micro-tool for micro high-speed machining of flexible fine die. Current Applied Physics, 2012, 12: S14-S18. |

| [6] |

REN X, ZHU H, LIU M, et al. Comparison of microstructure and tribological behaviors of CrAlN and CrN film deposited by DC magnetron sputtering. Rare Metal Materials and Engineering, 2018, 47(4): 1100-1106.

DOI URL |

| [7] |

DING X Z, ZENG X T, LIU Y C, et al. Cr1-xAlxN coatings deposited by lateral rotating cathode arc for high speed machining applications. Thin Solid Films, 2007, 516(8): 1710-1715.

DOI URL |

| [8] |

MO J L, ZHU M H, LEI B, et al. Comparison of tribological behaviours of AlCrN and TiAlN coatings-deposited by physical vapor deposition. Wear, 2007, 263(7): 1423-1429.

DOI URL |

| [9] |

SCHEERER H, HOCHE H, BROSZEIT E, et al. Effects of the chromium to aluminum content on the tribology in dry machining using (Cr,Al)N coated tools. Surface & Coatings Technology, 2005, 200(1-4): 203-207.

DOI URL |

| [10] | JFCA B, WA C, JCC A, et al. Structural, mechanical and tribological behavior of TiCN, CrAlN and BCN coatings in lubricated and non-lubricated environments in manufactured devices. Materials Chemistry and Physics, 2020, 252: 123164. |

| [11] | MO Y J, WANG M L, CHEN W J. Composition, structure and properties of the Cr1-xAlxN hard films deposited by arc ion plating. Journl of Inorgamic Materials, 2020, 35(6): 675-681. |

| [12] | ROBERTSON J. Diamond-like amorphous carbon. Materials Science & Engineering R, 2002, 37(4): 129-281. |

| [13] |

TILLMANN W, STANGIER D, SCHRDER P, et al. Investigation and optimization of the tribo-mechanical properties of CrAlCN coatings using design of experiments. Surface & Coatings Technology, 2016, 308: 147-157.

DOI URL |

| [14] |

ZHANG M, ZHOU F, FANG H, et al. Structure and tribological properties of CrTiAlCN coatings with various carbon contents. Journal of Materials Engineering and Performance, 2019, 28(3): 1509-1521.

DOI URL |

| [15] | LIN G Q, ZHAO Y H, GUO H M, et al. Experiments and theoretical explanation of droplet elimination phenomenon in pulsed-bias arc deposition. Acta Ophthalmologica, 2004, 22(4): 288-303. |

| [16] | 赵彦辉, 林国强, 董闯, 等. 脉冲工艺在薄膜制备中的应用. 中国真空学会. 薄膜技术学术研讨会论文集. 中国真空学会: 中国真空学会, 2003: 5. |

| [17] |

DAI W, HE Z, WU G, et al. Effect of bias voltage on growth property of Cr-DLC film prepared by linear ion beam deposition technique. Vacuum, 2010, 85(2): 231-235.

DOI URL |

| [18] |

FERRARI A C. Determination of bonding in diamond-like carbon by Raman spectroscopy. Diam. Relat. Mater., 2002, 11: 1053-1061.

DOI URL |

| [19] |

ZHOU Y, GUO P, SUN L, et al. Microstructure and property evolution of diamond-like carbon films co-doped by Al and Ti with different ratios. Surface & Coatings Technology, 2019, 361: 83-90.

DOI URL |

| [20] |

CHOI J H, LEE S C, LEE K R. A first-principles study on the bond characteristics in carbon containing Mo, Ag, or Al impurity atoms. Carbon, 2007, 46(2): 185-188.

DOI URL |

| [21] |

WU D, REN S, PU J, et al. A comparative study of tribological characteristics of hydrogenated DLC film sliding against ceramic mating materials for helium applications. Applied Surface Science, 2018, 441: 884-894.

DOI URL |

| [1] | SU Dongliang, CUI Jin, ZHAI Pengbo, GUO Xiangxin. Mechanism Study on Garnet-type Li6.4La3Zr1.4Ta0.6O12 Regulating the Solid Electrolyte Interphases of Si/C Anodes [J]. Journal of Inorganic Materials, 2022, 37(7): 802-808. |

| [2] | ZHANG Ye, YAO Dongxu, ZUO Kaihui, XIA Yongfeng, YIN Jinwei, ZENG Yuping. Combustion Synthesis of Si3N4-BN-SiC Composites by in-situ Introduction of BN and SiC [J]. Journal of Inorganic Materials, 2022, 37(5): 574-578. |

| [3] | CHEN Xiaomei, CHEN Ying, YUAN Xia. Decomposition of Cyclohexyl Hydroperoxide Catalyzed by Core-shell Material Co3O4@SiO2 [J]. Journal of Inorganic Materials, 2022, 37(1): 65-71. |

| [4] | PENG Junhui, TIKHONOV Evgenii. Vacancy on Structures, Mechanical and Electronic Properties of Ternary Hf-Ta-C System: a First-principles Study [J]. Journal of Inorganic Materials, 2022, 37(1): 51-57. |

| [5] | LI Bangxin, ZHANG Qian, XIAO Jie, XIAO Wenyan, ZHOU Ying. Iron-doping Enhanced Basic Nickel Carbonate for Moisture Resistance and Catalytic Performance of Ozone Decomposition [J]. Journal of Inorganic Materials, 2022, 37(1): 45-50. |

| [6] | MO Yajie,WANG Minglei,CHEN Weijie,LIN Guoqiang. Composition, Structure and Properties of the Cr1-xAlxN Hard Films Deposited by Arc Ion Plating [J]. Journal of Inorganic Materials, 2020, 35(6): 675-681. |

| [7] | ZHANG Li-Yan, LI Hong, HU Li-Li, WANG Ya-Jie. Structure Modeling of Genes in Glass: Composition-structure-property Approach [J]. Journal of Inorganic Materials, 2019, 34(8): 885-892. |

| [8] | GOU Sheng-Lian, NAI Xue-Ying, XIAO Jian-Fei, YE Jun-Wei, DONG Ya-Ping, LI Wu. Preparation and Thermal Decomposition of Basic Magnesium Chloride Whiskers [J]. Journal of Inorganic Materials, 2019, 34(7): 781-785. |

| [9] | LIAO Chun-Jing, DONG Shao-Ming, JIN Xi-Hai, HU Jian-Bao, ZHANG Xiang-Yu, WU Hui-Xia. Deposition Temperature and Heat Treatment on Silicon Nitride Coating Deposited by LPCVD [J]. Journal of Inorganic Materials, 2019, 34(11): 1231-1237. |

| [10] | GUO Sheng-Qiang, WANG Hao, TU Bing-Tian, WANG Bin, XU Peng-Yu, WANG Wei-Min, FU Zheng-Yi. Fabrication and Property of Fine-grained MgO·1.44Al2O3 Spinel Transparent Ceramic [J]. Journal of Inorganic Materials, 2019, 34(10): 1067-1071. |

| [11] | LI Hong-Mei, LAN Li, CHEN Shan-Hu, LIU Da-Yu, WANG Wei, CHEN Yao-Qiang. Preparation of CexZr1-xO2 with Combined Composition for Improved Pd-only Three-way Catalyst [J]. Journal of Inorganic Materials, 2018, 33(7): 798-804. |

| [12] | FAN Wen, WU Li-Min. Controllable Preparation of Nano-TiO2 Lens by Silicon Oil Two-step Dehydration Method [J]. Journal of Inorganic Materials, 2018, 33(12): 1337-1342. |

| [13] | LI Jia-Ke, HAN Xiao-Qi, LIU Xin, WANG Yan-Xiang, GUO Ping-Chun, YANG Zhi-Sheng. Preparation of High Specific Surface Area Micro/Meso-porous SiOC Ceramics by the Low Temperature Phase Separation Method [J]. Journal of Inorganic Materials, 2018, 33(12): 1360-1364. |

| [14] | XING Yuan-Yuan, WU Hai-Bo, LIU Xue-Jian, HUANG Zheng-Ren. Grain Composition on Solid-state-sintered SiC Ceramics [J]. Journal of Inorganic Materials, 2018, 33(11): 1167-1172. |

| [15] | CUI Feng-Dan, MA Tian, LI Wei-Ping, WU Guo-Qing. Damage Characteristics of SiC and B4C Ballistic Insert Plates Subjected to Multi-hi [J]. Journal of Inorganic Materials, 2017, 32(9): 967-972. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||