Journal of Inorganic Materials ›› 2022, Vol. 37 ›› Issue (4): 467-472.DOI: 10.15541/jim20210412

• RESEARCH LETTER • Previous Articles

LI Haiyan1,2( ), HAO Hongjian1,2, TIAN Yuan1,2, WANG Changan3, BAO Yiwang1,2(

), HAO Hongjian1,2, TIAN Yuan1,2, WANG Changan3, BAO Yiwang1,2( ), WAN Detian1,2(

), WAN Detian1,2( )

)

Received:2021-07-01

Revised:2021-07-30

Published:2021-07-31

Online:2021-07-20

Contact:

BAO Yiwang, professor. E-mail: ywbao@ctc.ac.cn;About author:LI Haiyan(1989–), PhD. E-mail: lihaiyan@ctc.ac.cn

Supported by:CLC Number:

LI Haiyan, HAO Hongjian, TIAN Yuan, WANG Changan, BAO Yiwang, WAN Detian. Effects of Residual Stresses on Strength and Crack Resistance in ZrO2 Ceramics with Alumina Coating[J]. Journal of Inorganic Materials, 2022, 37(4): 467-472.

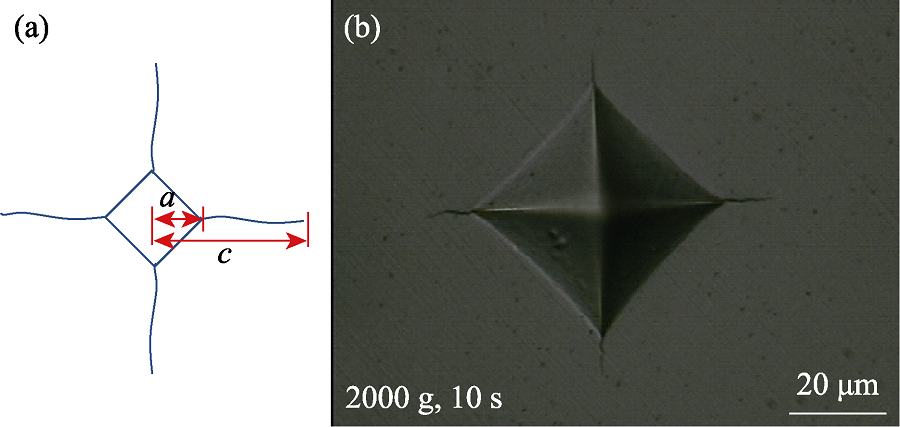

Fig. 2 (a) Typical Vickers indentation of ZrO2 ceramics; (b) Optical photograph of the indentation morphology for ZrO2 ceramics without residual stress

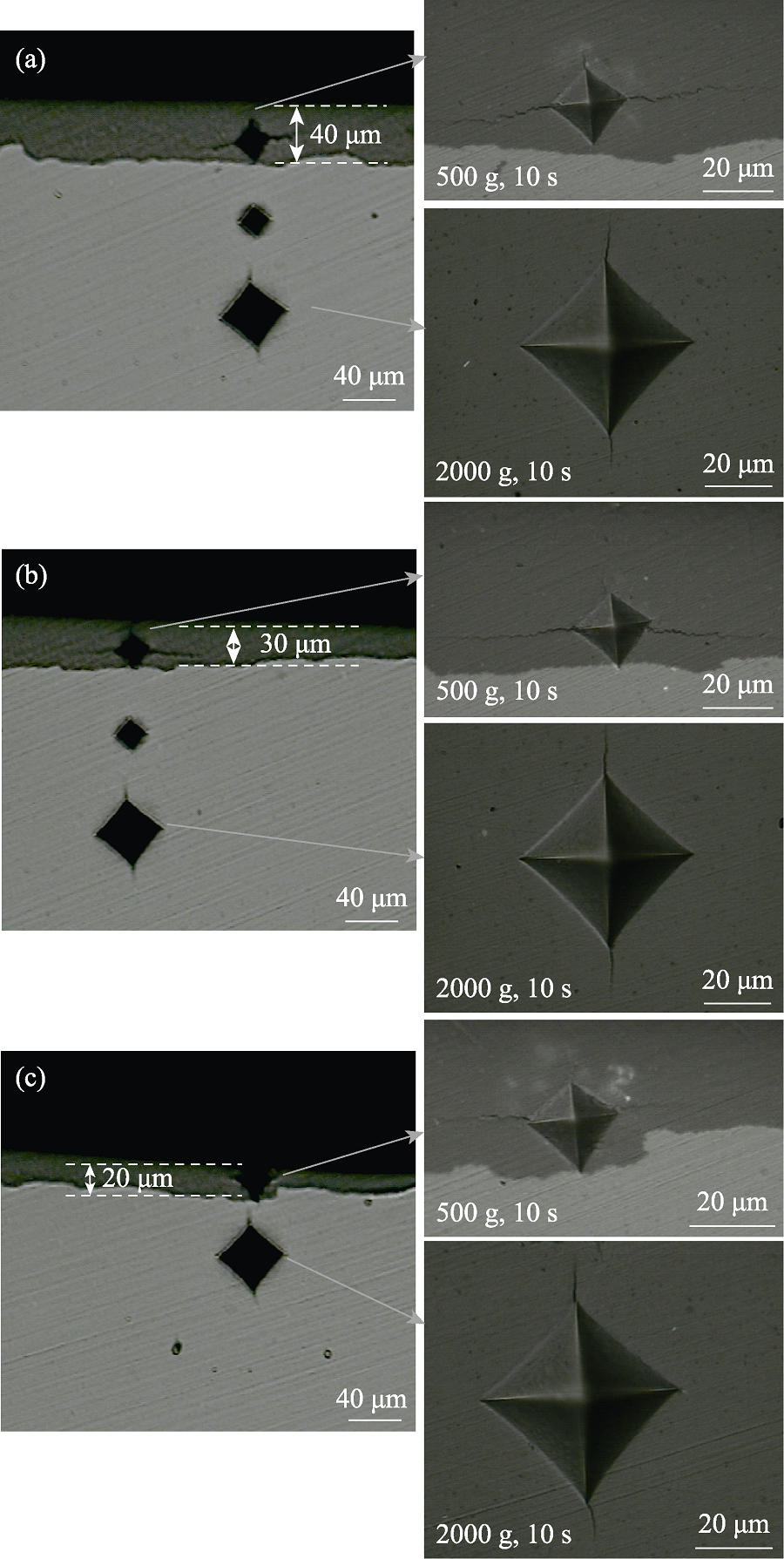

Fig. 3 Optical photographs of the indentation morphologies for ACZS pre-stressed ceramics with different ratios of the cross-sectional areas, showing the effects of the compressive stresses in the coating and tensile stresses in the substrate

| Elasticity modulus, E/GPa | p/N | a/μm | c/μm | HV/GPa | KI, IFR/(MPa·m1/2) | ||

|---|---|---|---|---|---|---|---|

| ZrO2 | ZrO2 | 220 | 19.62 | 26.80 | 35.20 | 12.66 | 9.10 |

| ACZS with 40 μm coating | Al2O3-40 | 350 | 4.91 | 11.25 | 47.50 | 17.98 | 1.52 |

| ZrO2-40 | 220 | 19.62 | 26.16 | 36.88 | 13.28 | 8.33 | |

| ACZS with 30 μm coating | Al2O3-30 | 350 | 4.91 | 11.09 | 44.38 | 18.49 | 1.67 |

| ZrO2-30 | 220 | 19.62 | 26.08 | 36.05 | 13.37 | 8.59 | |

| ACZS with 20 μm coating | Al2O3-20 | 350 | 4.91 | 10.94 | 25.00 | 19.02 | 3.89 |

| ZrO2-20 | 220 | 19.62 | 26.01 | 35.87 | 13.44 | 8.64 |

Table 1 Parameters used in formulas and the results of the experiment and simulation

| Elasticity modulus, E/GPa | p/N | a/μm | c/μm | HV/GPa | KI, IFR/(MPa·m1/2) | ||

|---|---|---|---|---|---|---|---|

| ZrO2 | ZrO2 | 220 | 19.62 | 26.80 | 35.20 | 12.66 | 9.10 |

| ACZS with 40 μm coating | Al2O3-40 | 350 | 4.91 | 11.25 | 47.50 | 17.98 | 1.52 |

| ZrO2-40 | 220 | 19.62 | 26.16 | 36.88 | 13.28 | 8.33 | |

| ACZS with 30 μm coating | Al2O3-30 | 350 | 4.91 | 11.09 | 44.38 | 18.49 | 1.67 |

| ZrO2-30 | 220 | 19.62 | 26.08 | 36.05 | 13.37 | 8.59 | |

| ACZS with 20 μm coating | Al2O3-20 | 350 | 4.91 | 10.94 | 25.00 | 19.02 | 3.89 |

| ZrO2-20 | 220 | 19.62 | 26.01 | 35.87 | 13.44 | 8.64 |

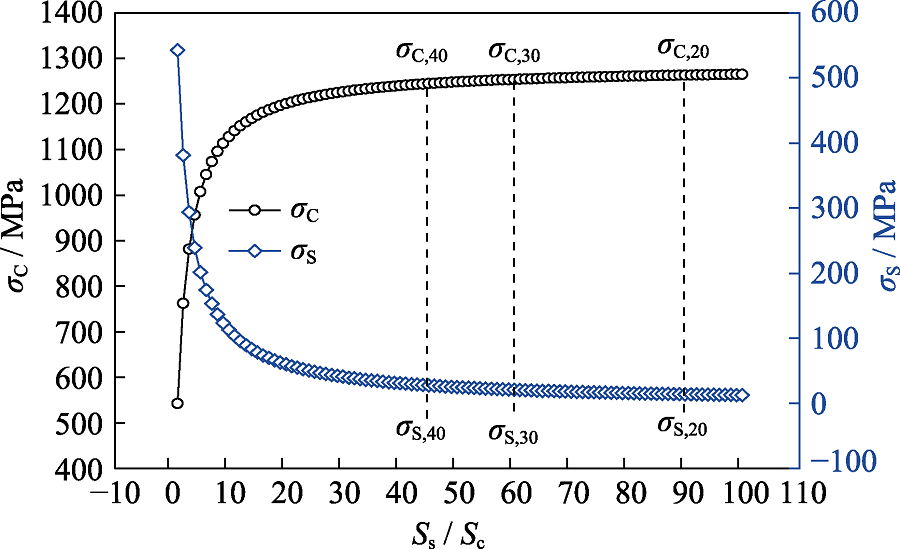

Fig. 5 Calculated residual stress in the Al2O3 coating and ZrO2 substrate of ACZS pre-stressed ceramics, as the function of the ratio of cross-sectional area of ZrO2 substrate to Al2O3 coating

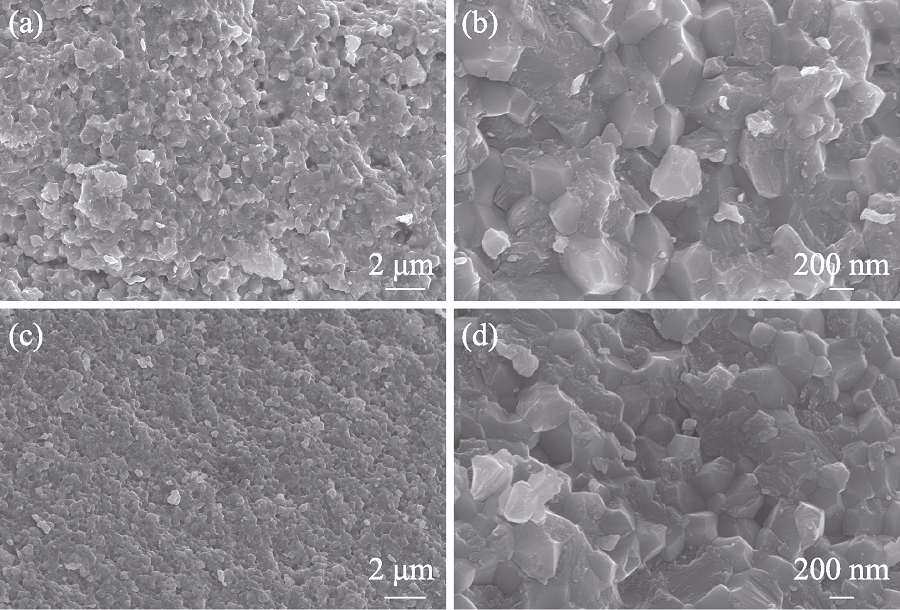

Fig. 6 SEM images of the fracture surfaces for monolithic ZrO2 ceramics (a, b) and ZrO2 substrate of ACZS pre-stressed ceramics (c, d) fabricated by the hot-pressing sintering method

| [1] |

DAHL P, KAUS I, ZHAO Z, et al. Densification and properties of zirconia prepared by three different sintering techniques. Ceramic International, 2007, 33(8): 1603-1610.

DOI URL |

| [2] |

MUKHOPADHYAY M, MUKHOPADHYAY J, SHARTNA A D, et al. High performance planar solid oxide fuel cell fabricated with Ni-yttria stabilized zirconia anode prepared by electroless technique. International Journal of Applied Ceramic Technology, 2012, 9(6): 999-1010.

DOI URL |

| [3] |

CHANG W G, SANG S H, JUN S H, et al. Investigation of stainless steel 316L/zirconia joint part fabricated by powder injection molding. International Journal of Applied Ceramic Technology, 2019, 16(1): 315-323.

DOI URL |

| [4] |

ZHU T B, XIE Z P, HAN Y, et al. A novel approach to improve flexural strength of Al2O3-20wt% ZrO2 composites by oscillatory pressure sintering. Journal of the American Ceramic Society, 2018, 101: 1397-1401.

DOI URL |

| [5] |

KARIHALOO B L. Contribution of t→m phase transformation to the toughening of ZTA. Journal of the American Ceramic Society, 1991, 74(7): 1703-1706.

DOI URL |

| [6] | WANG X Z, MA Z L, SUN X, et al. Effects of ZrO2, and Y2O3, on physical and mechanical properties of ceramic bond and ceramic CBN composites. International Journal of Refractory Metals & Hard Materials, 2018, 75: 18-24. |

| [7] |

BAO Y W, SU S B, YANG J J, et al. Pre-stressed ceramics and improvement of impact resistance. Materials Letters, 2002, 57: 518-524.

DOI URL |

| [8] |

BAO Y W, KUANG F H, SUN Y, et al. A simple way to make pre-stressed ceramics with high strength. Journal of Materiomics, 2019, 5: 657-662.

DOI URL |

| [9] | BAO Y W, SUN Y, KUANG F H, et al. Development and prospects of high strength pre-stressed ceramics. Journal of Inorganic Materials, 2020, 35(4): 399-408. |

| [10] |

LI L, WAN L L, ZHOU Q M. Crack propagation during Vickers indentation of zirconia ceramics. Ceramics International, 2020, 46: 21311-21318.

DOI URL |

| [11] |

GREEN D J. Compressive surface strengthening of brittle materials by a residual stress distribution. Journal of the American Ceramic Society, 1983, 66(11): 807-810.

DOI URL |

| [12] |

HIROYUKI M, YOSHIZAWA Y. A reinvestigation of the validity of the indentation fracture (IF) method as applied to ceramics. Journal of the European Ceramic Society, 2017, 37: 4437-4441.

DOI URL |

| [13] | Test Method for Fracture Resistance of Silicon Nitride Materials for Rolling Bearing Balls at Room Temperature by Indentation Fracture (IF) Method. ISO 14627-2012, 2012-07. |

| [14] |

HAN Y, LI S, ZHU T B, et al. Enhanced properties of pure alumina ceramics by oscillatory pressure sintering. Ceramics International, 2018, 44(5): 5238-5241.

DOI URL |

| [15] |

DU W Y, AI Y L, HE W, et al. Formation and control of “intragranular” ZrO2 strengthened and toughened Al2O3 ceramics. Ceramics International, 2020, 46(6): 8452-8461.

DOI URL |

| [16] |

LI Y L, HYOUN-EE K, YOUNG-HAG K. Improving the surface hardness of zirconia toughened alumina (ZTA) composites by surface treatment with a boehmite sol. Ceramics International, 2012, 38(4): 2889-2892.

DOI URL |

| [17] |

TEBALDO V, GAUTIER G. Influences of evaluation methods and testing load on microhardness and Young’s modulus of ZTA and ATZ ceramics. Ceramics International, 2013, 39(3): 2683-2693.

DOI URL |

| [18] | YAO Y, ZHANG G F. Experimental study on pre-stress grinding process for alumina ceramic. Mining and Metallurgical Engineering, 2017, 37(2): 125-129. |

| [19] |

CHAUDHRI M M, CHEN L Y. The catastrophic failure of thermally tempered glass caused by small-particle impact. Nature, 1986, 320(6057): 48-50.

DOI URL |

| [1] | LI Meng, HUANG Hailu, WU Jiamin, LIU Chunlei, WU Yaru, ZHANG Jingxian, SHI Yusheng. Effect of Solid Loading of Slurry on Properties of Si3N4 Ceramics Formed by Digital Light Processing [J]. Journal of Inorganic Materials, 2022, 37(3): 310-316. |

| [2] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [3] | WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive [J]. Journal of Inorganic Materials, 2021, 36(9): 959-966. |

| [4] | LIANG Hanqin, YIN Jinwei, ZUO Kaihui, XIA Yongfeng, YAO Dongxu, ZENG Yuping. Mechanical and Dielectric Properties of Hot-pressed Si3N4 Ceramics with BaTiO3 Addition [J]. Journal of Inorganic Materials, 2021, 36(5): 535-540. |

| [5] | BAO Yiwang,SUN Yi,KUANG Fenghua,LI Yueming,WAN Detian. Development and Prospects of High Strength Pre-stressed Ceramics [J]. Journal of Inorganic Materials, 2020, 35(4): 399-406. |

| [6] | XING Yuan-Yuan, WU Hai-Bo, LIU Xue-Jian, HUANG Zheng-Ren. Grain Composition on Solid-state-sintered SiC Ceramics [J]. Journal of Inorganic Materials, 2018, 33(11): 1167-1172. |

| [7] | LEI Zhuo-Yan, WANG Zhi, FAN Heng-Bing, MA Wen-Bin, CHEN Jian, WANG Xu. Effect of B2O3 Doping and Phosphate Impregnation on Oxidation Resistance and Mechanical Properties of Mesocarbon Microbead Composites [J]. Journal of Inorganic Materials, 2015, 30(7): 769-773. |

| [8] | HU Hai-Long, ZENG Yu-Ping, ZUO Kai-Hui, XIA Yong-Feng, YAO Dong-Xu. Effect of Sintering Additive Composition on the Mechanical and Tribological Properties of Si3N4/SiC Ceramics [J]. Journal of Inorganic Materials, 2014, 29(8): 885-890. |

| [9] | WANG Cui-Feng, CHIOU Shi-Yung, OU Keng-Liang, CAI Zhang-Ting. Optimal Process Parameters for 3Y-TZP/TiN Conductive Polycrystal by Taguchi Method [J]. Journal of Inorganic Materials, 2012, 27(5): 529-535. |

| [10] | LI Jun-Feng, LIN Hong, LI Jian-Bao. Influence Factors on the Porosity and Strength of SiC Porous Ceramic [J]. Journal of Inorganic Materials, 2011, 26(9): 944-948. |

| [11] | YAO Dong-Xu,ZENG Yu-Ping. High Flexural Strength Porous Silicon Nitride Prepared via Nitridation of Silicon Powder [J]. Journal of Inorganic Materials, 2011, 26(4): 422-426. |

| [12] | HE Yong-Gang,LI Ke-Zhi,WEI Jian-Feng,GUO Ling-Jun,ZHANG Lei-Lei. Study on the Microstructures and Mechanical Properties of 2D C/C Composites [J]. Journal of Inorganic Materials, 2010, 15(2): 173-176. |

| [13] | HU An-MinI Ming MAO Da-Li LIANG Kai-Ming. Formation and Characterization of Whisker-like β-spodumene in LAS Glass-ceramics [J]. Journal of Inorganic Materials, 2006, 21(1): 35-40. |

| [14] | LU Jun,ZHENG Zhi-Xiang,DING Hou-Fu,JIN Zhi-Hao. Surface Crack-Healing of Al2O3 Ceramic-Matrix Composites [J]. Journal of Inorganic Materials, 2001, 16(3): 535-540. |

| [15] | YAN Jun-Hui,ZHENG Xiu-Lin,ZHAO Kang,WANG Feng-Hui. Probability Distribution of Notch Strength of Ceramics (Ⅰ) Basic Expressions [J]. Journal of Inorganic Materials, 1998, 13(4): 449-456. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||