Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (10): 1118-1124.DOI: 10.15541/jim20210059

• RESEARCH LETTER • Previous Articles

ZHU Danyang1,2( ), QIAN Kang1,3, CHEN Xiaopu1,2, HU Zewang1,2, LIU Xin1,2, LI Xiaoying1,2, PAN Yubai3, MIHÓKOVÁ Eva4, NIKL Martin4, LI Jiang1,2(

), QIAN Kang1,3, CHEN Xiaopu1,2, HU Zewang1,2, LIU Xin1,2, LI Xiaoying1,2, PAN Yubai3, MIHÓKOVÁ Eva4, NIKL Martin4, LI Jiang1,2( )

)

Received:2021-02-01

Revised:2021-03-29

Published:2021-10-20

Online:2021-05-10

Contact:

LI Jiang, professor. E-mail: lijiang@mail.sic.ac.cn

Supported by:CLC Number:

ZHU Danyang, QIAN Kang, CHEN Xiaopu, HU Zewang, LIU Xin, LI Xiaoying, PAN Yubai, MIHÓKOVÁ Eva, NIKL Martin, LI Jiang. Fine-grained Ce,Y:SrHfO3 Scintillation Ceramics Fabricated by Hot Isostatic Pressing[J]. Journal of Inorganic Materials, 2021, 36(10): 1118-1124.

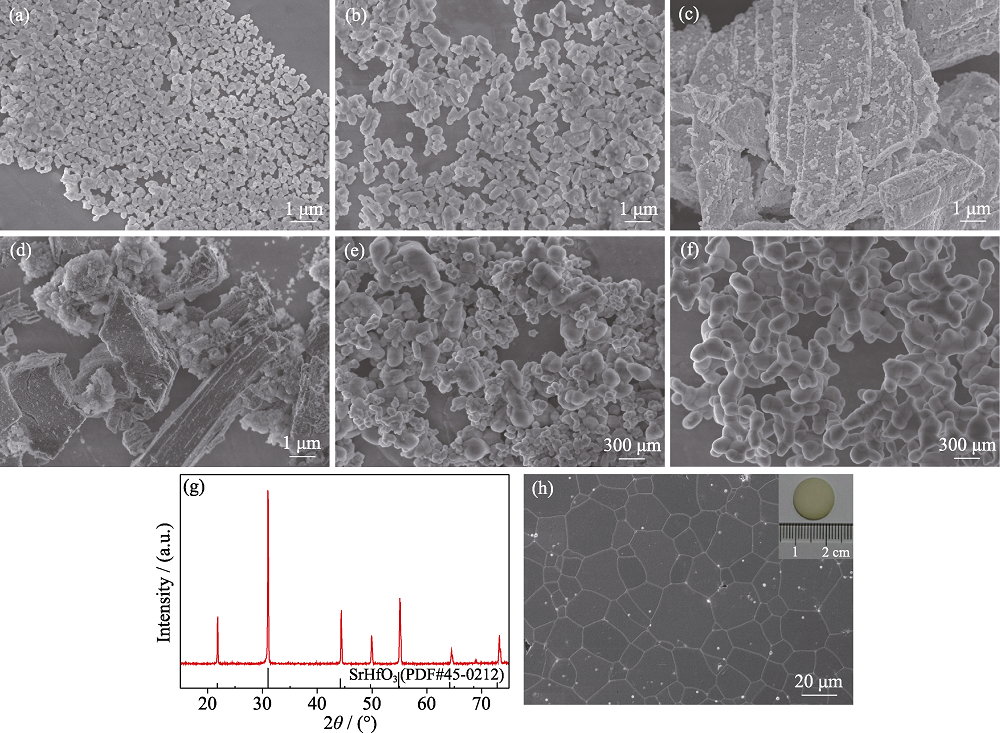

Fig. 1 FESEM micrographs of the starting powders ((a) HfO2, (b) SrCO3, (c) CeO2, (d) Y2O3, (e) ball-milled powder mixture, (f) Ce,Y:SrHfO3 powder calcined at 1200 ℃ for 8 h), (g) XRD patterns of the calcined powder, and (h) FESEM micrograph of the Ce,Y:SrHfO3 ceramics fabricated by vacuum sintering

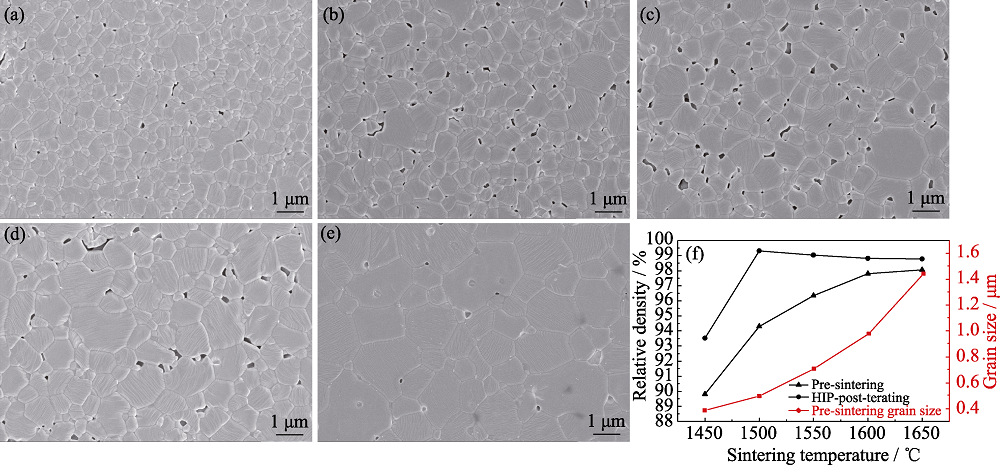

Fig. 2 FESEM images of the thermally etched surfaces of the Ce/Y:SrHfO3 ceramics pre-sintered at different temperatures for 2 h (a) 1450 ℃; (b) 1500 ℃; (c) 1550 ℃; (d) 1600 ℃; (e) 1650 ℃; (f) Relative densities and average grain sizes of the Ce,Y:SrHfO3 ceramics with different pre-sintering temperatures

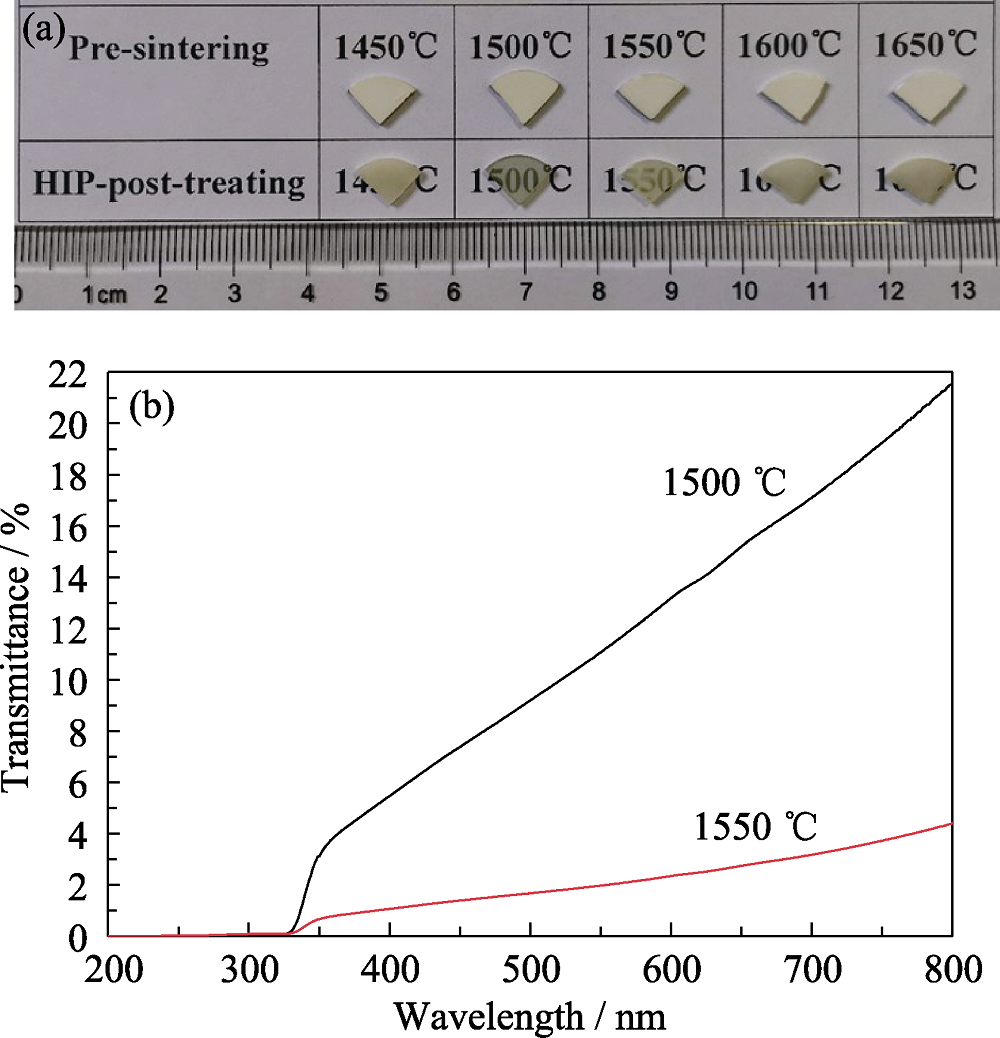

Fig. 3 (a) Photograph of the Ce,Y:SrHfO3 ceramics vacuum- sintered at different temperatures combined with the HIP post- treatment and (b) in-line transmittance of the HIP post-treated Ce,Y:SrHfO3 ceramics (1 mm thickness) pre-sintered at 1500 and 1550 ℃, respectively

| [1] |

NIKL M, YOSHIKAWA A. Recent R & D trends in inorganic single-crystal scintillator materials for radiation detection. Advanced Optical Materials, 2015, 3(4):463-481.

DOI URL |

| [2] |

NIKL M, MIHOKOVA E, PEJCHAL J, et al. Scintillator Materials—achievements, opportunities and puzzles. IEEE Transactions on Nuclear Science, 2008, 55(3):1035-1041.

DOI URL |

| [3] |

NIKL M. Scintillation detectors for X-rays. Measurement Science and Technology, 2006, 17:R37-R54.

DOI URL |

| [4] |

NIKL M, LAGUTA V V, VEDDA A A. Complex oxide scintillators: material defects and scintillation performance. Physica Status Solidi B-Basic Solid State Physics, 2008, 245(9):1701-1722.

DOI URL |

| [5] |

MAO RI-HUA, ZHANG LI-YUAN, ZHU REN-YUAN. Optical and scintillation properties of inorganic scintillators in high energy physics. IEEE Transactions on Nuclear Science, 2008, 55(4):2425-2431.

DOI URL |

| [6] |

SEIICHI Y, NITTA H. Development of an event-by-event based radiation imaging detector using GGAG:Ce ceramic scintillator for X-ray CT. Nuclear Instruments and Methods in Physics Research Section A: Accelerators, Spectrometers, Detectors and Associated Equipment, 2018, 900:25-31.

DOI URL |

| [7] |

LIU SHU-PING, MARES J A, FENG XI-QI, et al. Towards bright and fast Lu3Al5O12:Ce,Mg optical ceramics scintillators. Advanced Optical Materials, 2016, 4(5):731-739.

DOI URL |

| [8] | YANAGIDA T, FUKABORI A, FUJIMOTO Y A. et al. Scintillation properties of transparent Lu3Al5O12(LuAG) ceramics doped with different concentrations of Pr3+. Physica Status Solidi A-Applications and Materials Science, 2011, 8(1):140-143. |

| [9] |

JI Y M, JIANG D Y, CHEN J J, et al. Preparation, luminescence and sintering properties of Ce-doped BaHfO3 phosphors. Optical Materials, 2006, 28(4):436-440.

DOI URL |

| [10] |

SEFERIS I E, FIACZYK K, SPASSKY D, et al. Synthesis and luminescence properties of BaHfO3:Pr ceramics. Journal of Luminescence, 2016, 189:148-152.

DOI URL |

| [11] |

JI YA-MING, JIANG DAN-YU, SHI JIAN-LIN. La2Hf2O7:Ti4+ ceramic scintillator for X-ray imaging. Journal of Materials Research, 2005, 20(3):567-570.

DOI URL |

| [12] |

WAHID K, POKHREL M, MAO Y B. Structural, photoluminescence and radioluminescence properties of Eu3+ doped La2Hf2O7 nanoparticles. Journal of Solid State Chemistry, 2016, 245:89-97.

DOI URL |

| [13] |

YI HAI-LAN, ZOU XIAO-QING, YANG YAN, et al. Fabrication of highly transmitting LaGdHf2O7 ceramics. Journal of the American Ceramic Society, 2011, 94(12):4120-4122.

DOI URL |

| [14] |

WANG ZHENG-JUAN, ZHOU GUO-HONG, ZHANG JIAN, et al. Luminescence properties of Eu3+-doped lanthanum gadolinium hafnates transparent ceramics. Optical Materials, 2016, 71:5-8.

DOI URL |

| [15] |

AN L Q, ITO A, GOTO T. Fabrication of transparent Lu2Hf2O7 by reactive spark plasma sintering. Optical Materials, 2013, 35(4):817-819.

DOI URL |

| [16] |

ZHOU GUO-HONG, WANG ZHENG-JUAN, ZHOU BO-ZHU, et al. Fabrication of transparent Y2Hf2O7 ceramics via vacuum sintering. Optical Materials, 2013, 35(4):774-777.

DOI URL |

| [17] |

HAVLAK L, BOHACEK P, NIKL M, et al. Preparation and luminescence of Lu4Hf3O12 powder samples doped by trivalent Eu, Tb, Ce, Pr, Bi ions. Optical Materials, 2010, 32(10):1372-1374.

DOI URL |

| [18] | JOANNA J P, ZYCH E. Microwave-assisted hydrothermal synthesis and spectroscopic characteristics of Lu4Hf3O12:Pr scintillator. RSC Advances, 2016, 6(61):56101-56107. |

| [19] |

BOHÁCEK P, TRUNDA B, BEITLEROVÁ A, et al. Rare- earth-free luminescent non-stoichiometric phases formed in SrO-HfO2 ternary compositions. Journal of Alloys and Compounds, 2013, 580:468-474.

DOI URL |

| [20] |

JARÝ V, BOHÁČEK P, PEJCHAL J, et al. Scintillating ceramics based on non-stoichiometric strontium hafnate. Optical Materials, 2018, 77:246-252.

DOI URL |

| [21] |

JI Y M, JIANG D Y, QIN L S, et al. Preparation and luminescent properties of nanocrystals of Ce3+ activated SrHfO3. Journal of Crystal Growth, 2005, 280(1/2):93-98.

DOI URL |

| [22] |

LOEF E V V, HIGGINS W M, GLODO J, et al. Scintillation properties of SrHfO3:Ce3+ and BaHfO3:Ce3+ ceramics. IEEE Transactions on Nuclear Science, 2007, 54(3):741-743.

DOI URL |

| [23] |

KUROSAWA S, PEJCHAL J, WAKAHARA S, et al. Optical properties and radiation response of Ce:SrHfO3 prepared by the spark plasma sintering method. Radiation Measurements, 2013, 56:155-158.

DOI URL |

| [24] | MIHÓKOVÁ E, JARÝ V, FASOLI M, et al. Delayed recombination and excited state ionization of the Ce3+ activator in the SrHfO3 host. Chemical Physics Letters, 2013, 7(3):228-231. |

| [25] |

CHIBA H, KUROSAWA S, HARATA K, et al. Luminescence properties of the Mg co-doped Ce:SrHfO3 ceramics prepared by the spark plasma sintering method. Radiation Measurements, 2016, 90:287-291.

DOI URL |

| [26] |

KAMADA K, KUROSAWA S, SHOJI Y, et al. Luminescence and scintillation properties of Ce doped SrHfO3 based eutectics. Optical Materials, 2015, 41:41-44.

DOI URL |

| [27] |

LING JUN-RONG, ZHOU YOU-FU, XU WEN-TAO, et al. Red-emitting YAG:Ce,Mn transparent ceramics for warm WLEDs application. Journal of Advanced Ceramics, 2020, 9(1):45-54.

DOI URL |

| [28] |

LI XIAO-YING, LIU QIANG, HU ZE-WANG, et al. Influence of ammonium hydrogen carbonate to metal ions molar ratio on co-precipitated nanopowders for TGG transparent ceramics. Journal of Inorganic Materials, 2019, 34(7):791-796.

DOI URL |

| [29] |

MOHAMMADI F, MIRZAEE O, TAJALLY M, et al. The effects of ball milling time on the rheological, optical, and microstructural properties of YAG transparent ceramics. International Journal of Applied Ceramic Technology, 2020, 17(3):1119-1127.

DOI URL |

| [30] |

ZHANG LEI, YANG JUN, YU HONG-YU, et al. High performance of La-doped Y2O3 transparent ceramics. Journal of Advanced Ceramics, 2020, 9(4):493-502.

DOI URL |

| [31] |

LOEF E V V, WANG Y M, MILLER S R, et al. Effect of microstructure on the radioluminescence and transparency of Ce-doped strontium hafnate ceramics. Optical Materials, 2010, 33(1):84-90.

DOI URL |

| [32] |

KENNEDY B J, HOWARD C J, CHAKOUMAKOS B C. High- temperature phase transitions in SrHfO3. Physical Review B, 1999, 60:2972-2975.

DOI URL |

| [33] |

LOUREIRO S M, GAO Y, VENKATARAMANI V. Stability of Ce(III) activator and codopant effect in MHfO3 (M=Ba, Sr) scintillators by XANES. Journal of the American Ceramic Society, 2005, 88(1):219-221.

DOI URL |

| [34] |

LIU ZI-YU, TOCI G, PIRRI A, et al. Fabrication, microstructures, and optical properties of Yb:Lu2O3 laser ceramics from co-precipitated nano-powders. Journal of Advanced Ceramics, 2020, 9(6):674-682.

DOI URL |

| [35] |

QIAN KANG, PAN YU-BAI, HU ZE-WANG, et al. Influence of co-doped alumina on the microstructure and radioluminescence of SrHfO3:Ce ceramics. Journal of the European Ceramic Society, 2020, 40(2):449-455.

DOI URL |

| [1] | GUO Tianmin, DONG Jiangbo, CHEN Zhengpeng, RAO Mumin, LI Mingfei, LI Tian, LING Yihan. Enhanced Compatibility and Activity of High-entropy Double Perovskite Cathode Material for IT-SOFC [J]. Journal of Inorganic Materials, 2023, 38(6): 693-700. |

| [2] | JIN Sai, LIU Xiaogen, QI Shuang, ZHAO Runchang, LI Zhijun. Fused Silica Glass: Laser-induced Damage on Bending Strength Weakening and Safety Design [J]. Journal of Inorganic Materials, 2023, 38(6): 671-677. |

| [3] | WANG Bo, YU Jian, LI Cuncheng, NIE Xiaolei, ZHU Wanting, WEI Ping, ZHAO Wenyu, ZHANG Qingjie. Service Stability of Gd/Bi0.5Sb1.5Te3 Thermo-electro-magnetic Gradient Composites [J]. Journal of Inorganic Materials, 2023, 38(6): 663-670. |

| [4] | WU Rui, ZHANG Minhui, JIN Chenyun, LIN Jian, WANG Deping. Photothermal Core-Shell TiN@Borosilicate Bioglass Nanoparticles: Degradation and Mineralization [J]. Journal of Inorganic Materials, 2023, 38(6): 708-716. |

| [5] | LIN Junliang, WANG Zhanjie. Research Progress on Ferroelectric Superlattices [J]. Journal of Inorganic Materials, 2023, 38(6): 606-618. |

| [6] | YANG Yingkang, SHAO Yiqing, LI Bailiang, LÜ Zhiwei, WANG Lulu, WANG Liangjun, CAO Xun, WU Yuning, HUANG Rong, YANG Chang. Enhanced Band-edge Luminescence of CuI Thin Film by Cl-doping [J]. Journal of Inorganic Materials, 2023, 38(6): 687-692. |

| [7] | LI Yue, ZHANG Xuliang, JING Fangli, HU Zhanggui, WU Yicheng. Growth and Property of Ce3+-doped La2CaB10O19 Crystal [J]. Journal of Inorganic Materials, 2023, 38(5): 583-588. |

| [8] | ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(5): 561-568. |

| [9] | LUO Shuwen, MA Mingsheng, LIU Feng, LIU Zhifu. Corrosion Behavior and Mechanism of LTCC Materials in Ca-B-Si System [J]. Journal of Inorganic Materials, 2023, 38(5): 553-560. |

| [10] | YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(5): 477-488. |

| [11] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [12] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [13] | LI Yanran, XIE Dingdong, JIANG Jie. Bionic Research on Multistage Pain Sensitization Based on Ionic Oxide Transistor Array [J]. Journal of Inorganic Materials, 2023, 38(4): 429-436. |

| [14] | LIU Wenlong, ZHAO Jin, LIU Juan, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Microwave Drying of Spontaneous-Coagulation-Cast Wet Alumina Green Body [J]. Journal of Inorganic Materials, 2023, 38(4): 461-468. |

| [15] | DU Jianyu, GE Chen. Recent Progress in Optoelectronic Artificial Synapse Devices [J]. Journal of Inorganic Materials, 2023, 38(4): 378-386. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||