Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (11): 1185-1192.DOI: 10.15541/jim20210032

Special Issue: 【结构材料】热障与环境障涂层

• RESEARCH ARTICLE • Previous Articles Next Articles

ZHANG Yachen1,2( ), MENG Jia1(

), MENG Jia1( ), CAI Kun3, SHENG Xiaochen1, LE Jun1, SONG Lixin1,2(

), CAI Kun3, SHENG Xiaochen1, LE Jun1, SONG Lixin1,2( )

)

Received:2021-01-18

Revised:2021-02-25

Published:2021-11-20

Online:2021-03-15

Contact:

MENG Jia, senior engineer. E-mail: jiameng@mail.sic.ac.cn;SONG Lixin, professor. E-mail: lxsong@mail.sic.ac.cn

About author:ZHANG Yachen (1995-), female, Master candidate. E-mail: zhangych2@shanghaitech.edu.cn

Supported by:CLC Number:

ZHANG Yachen, MENG Jia, CAI Kun, SHENG Xiaochen, LE Jun, SONG Lixin. Bending Failure Mechanism Study of Si-Cr-Ti High Temperature Oxidation Resistance Coating via Acoustic Emission Technique[J]. Journal of Inorganic Materials, 2021, 36(11): 1185-1192.

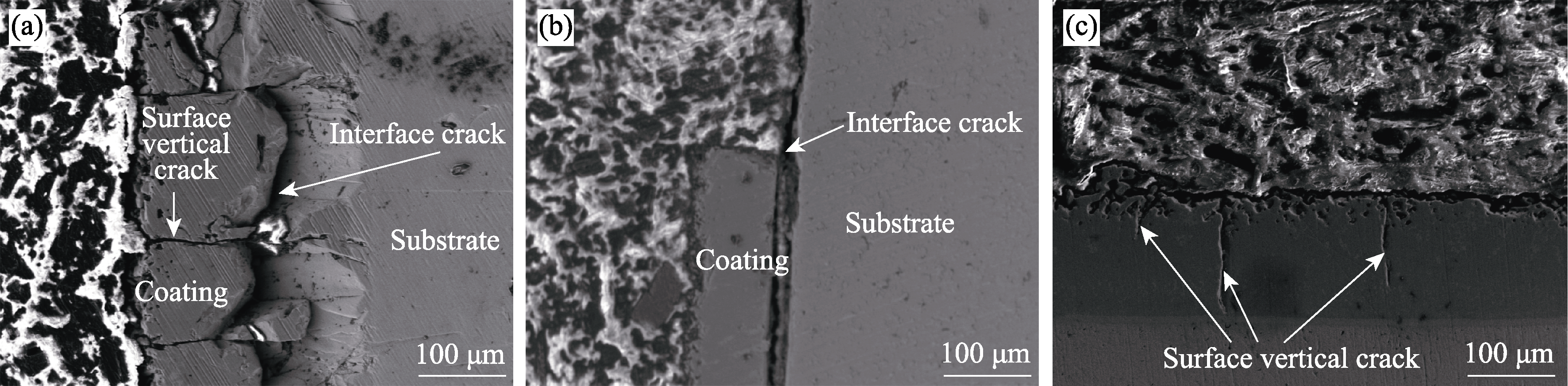

Fig. 6 SEM images of specimen (a) Surface vertical cracks and interface cracks of the coating under tension; (b) Interface cracks of the coating under compression; (c) Surface vertical cracks of the coating under tension

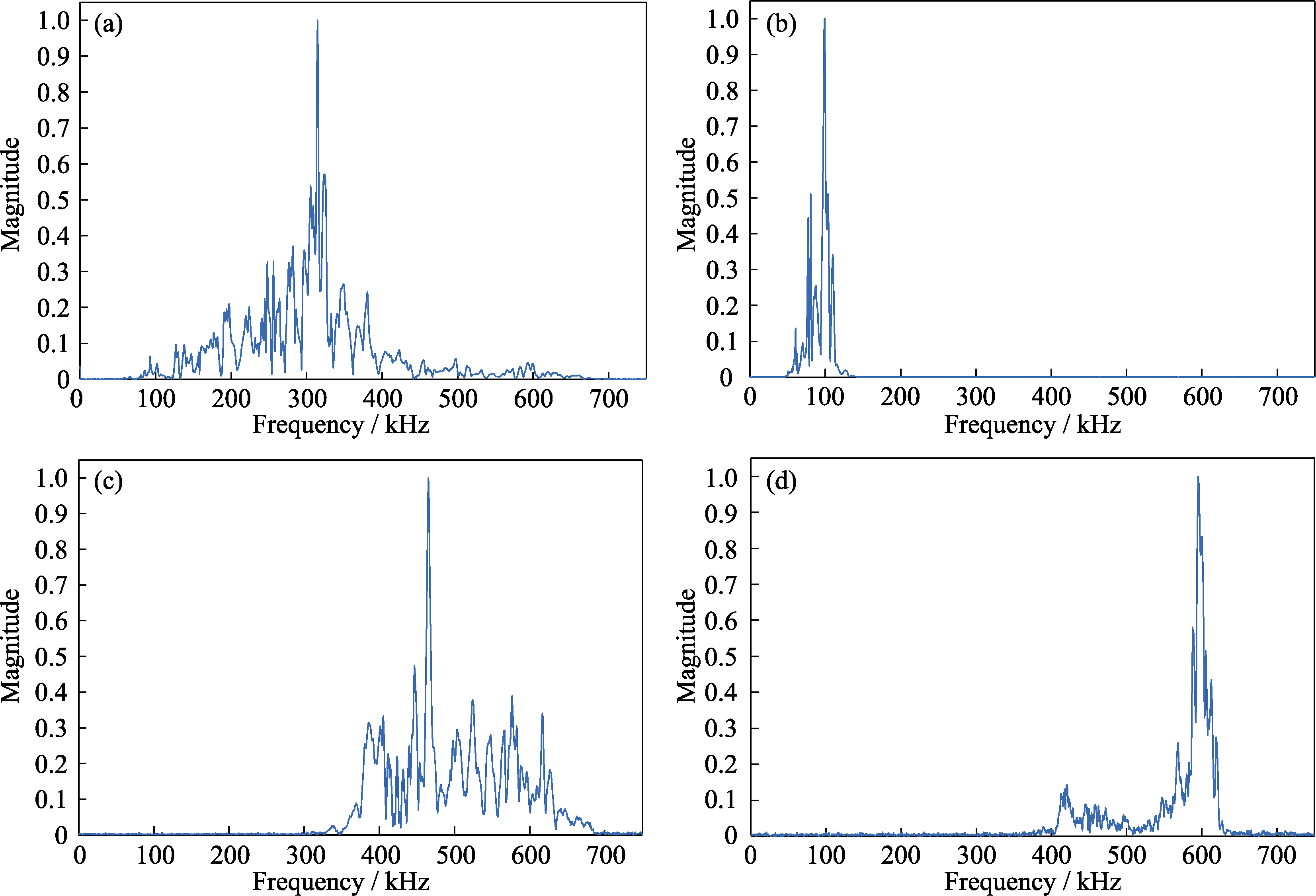

Fig. 7 Frequency spectra of the AE signal from (a) surface vertical cracks, (b) substrate deformation, (c) opening interface cracks, and (d) sliding interface cracks

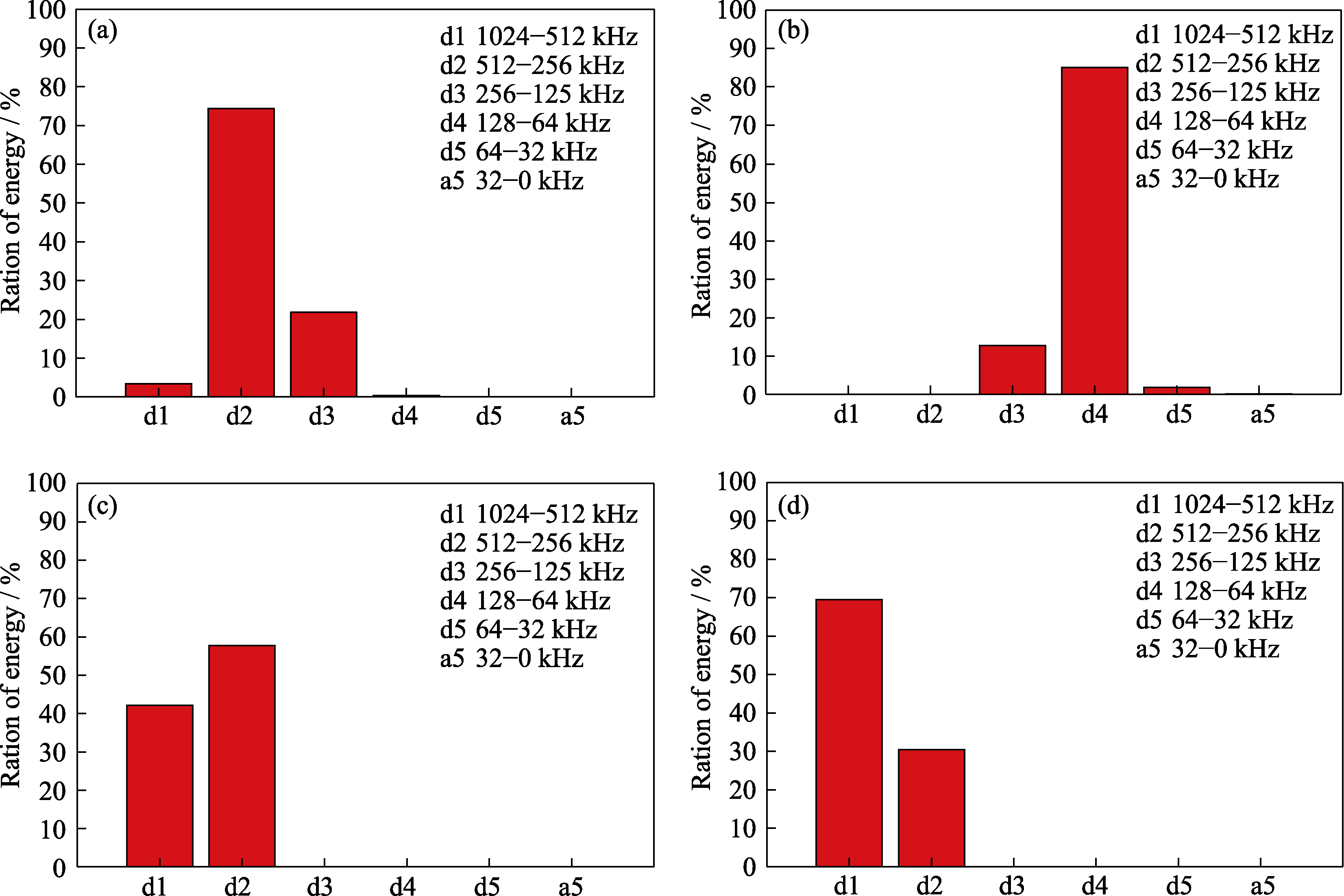

Fig. 8 Wavelet energy spectra of the AE signal from (a) surface vertical cracks, (b) substrate deformation, (c) opening interface cracks, and (d) sliding interface cracks

| [1] |

NARITA T, THOSIN K Z, FENGQUN L, et al. Development of Re-based diffusion barrier coatings on nickel-based superalloys. Materials and Corrosion-Werkstoffe und Korrosion, 2005, 56(12):923-929.

DOI URL |

| [2] | RODHAMMER P, KNABL W, SEMPRIMOSCHNIG C, et al. Protection of Nb-based and Ta-based alloys against high- temperature oxidation. International Journal of Refractory Metals & Hard Materials, 1994, 12(5):283-293. |

| [3] | 郑欣, 白润, 王东辉, 等. 航天航空用难熔金属材料的研究进展. 稀有金属材料与工程, 2011, 40(10):1871-1875. |

| [4] | BOUILLET C, CIOSMAK D, LALLEMANT M, et al. Oxidation of niobium sheets at high temperature. Solid State Ionics, 1997, 101:819-824. |

| [5] |

HELLWIG O AND ZABEL H. Oxidation of Nb(110) thin films on a-plane sapphire substrates: an X-ray study. Physica B, 2000, 283(1/2/3):228-231.

DOI URL |

| [6] | 李丹, 贾中华, 许谅亮. 新型多元铌合金的高温氧化行为. 宇航材料工艺, 2008, 038(6):73-76. |

| [7] | TANAKA R, KASAMA A, FUJIKURA M, et al. Newly Developed Niobium-based Superalloys for Elevated Temperature Application. Warrendale: Minerals, Metals & Materials Soc, Swiss: TMS. 2004: 89-98. |

| [8] | WANG YU, GAO JIAPING, LI YUNPENG, et al. Microstructure and oxidation-resistance of silicide coatings on C-103 niobium alloys. Journal of Inorganic Materials, 2000, 15(1):143-149. |

| [9] | 唐勇, 杜继红, 李争显, 等. 铌及铌合金高温抗氧化防护涂层研究. 表面技术, 2009, 38(5):42. |

| [10] | LORIA E A. Niobium-base superallloys via powder-metallurgy technology. Journal of Metals, 1987, 39(7):22-26. |

| [11] | PERKINS R A, MEIER G H. The oxidation behavior and protection of niobium. JOM-Journal of the Minerals Metals & Materials Society, 1990, 42(8):17-21. |

| [12] | 王禹, 陈日文, 郜嘉平, 等. Ti-Cr-Si硅化物涂层结构及裂纹扩展. 稀有金属材料与工程, 2000, 10(05):315-320. |

| [13] | 张绪虎, 徐方涛, 贾中华, 等. 难熔金属表面高温抗氧化涂层技术现状. 中国材料进展, 2013, 32(4):21-30. |

| [14] | 田进鹏, 周小军, 赵刚, 等. 铌钨合金抗高温氧化硅化物涂层的性能. 材料保护, 2016, 49(5):8-11. |

| [15] | 唐新阳, 沈统, 肖来荣, 等. Nb521表面改性Si-Cr-Ti涂层的高温氧化行为. 腐蚀与防护, 2016, 37(5):392-397. |

| [16] | 潘兆义, 蔡刚, 马双民, 等. 硅化物涂层对铌钨合金的热防护行为研究. 火箭推进, 2015, 41(3):59-65. |

| [17] |

MA X Q, CHO S, TAKEMOTO M. Acoustic emission source analysis of plasma sprayed thermal barrier coatings during four-point bend tests. Surface & Coatings Technology, 2001, 139(1):55-62.

DOI URL |

| [18] |

WANG L, MING C, ZHONG X H, et al. Prediction of critical rupture of plasma-sprayed yttria stabilized zirconia thermal barrier coatings under burner rig test via finite element simulation and in-situ acoustic emission technique. Surface & Coatings Technology, 2019, 367:58-74.

DOI URL |

| [19] |

YANG L, ZHONG Z C, YOU J, et al. Acoustic emission evaluation of fracture characteristics in thermal barrier coatings under bending. Surface & Coatings Technology, 2013, 232:710-718.

DOI URL |

| [20] |

YANG L, ZHONG Z C, ZHOU Y C, et al. Acoustic emission assessment of interface cracking in thermal barrier coatings. Acta Mechanica Sinica, 2016, 32(2):342-348.

DOI URL |

| [21] |

YAO W B, DAI C Y, MAO W G, et al. Acoustic emission analysis on tensile failure of air plasma-sprayed thermal barrier coatings. Surface & Coatings Technology, 2012, 206(18):3803-3807.

DOI URL |

| [22] | MAO W G, WU D J, YAO W B, et al. Multiscale monitoring of interface failure of brittle coating/ductile substrate systems: a non-destructive evaluation method combined digital image correlation with acoustic emission. Journal of Applied Physics, 2011, 110(8):5. |

| [23] |

WANG L, NI J X, SHAO F, et al. Failure behavior of plasma-sprayed yttria-stabilized zirconia thermal barrier coatings under three-point bending test via acoustic emission technique. Journal of Thermal Spray Technology, 2017, 26(1/2):116-131.

DOI URL |

| [24] |

WANG L, WANG H D, DI Y L, et al. Research on strain distribution and damage behavior of thermal barrier coatings based on digital image correlation. International Journal of Applied Ceramic Technology, 2020, 17(5):2156-2161.

DOI URL |

| [25] |

ZHU W, WU Q, YANG L, et al. In situ characterization of high temperature elastic modulus and fracture toughness in air plasma sprayed thermal barrier coatings under bending by using digital image correlation. Ceramics International, 2020, 46(11):18526-18533.

DOI URL |

| [26] |

MAJEWSKI M S, KELLEY C, HASSAN W, et al. Laser induced breakdown spectroscopy for contamination removal on engine-run thermal barrier coatings. Surface & Coatings Technology, 2011, 205(19):4614-4619.

DOI URL |

| [27] |

MANERO A, SELIMOV A, FOULIARD Q, et al. Piezospectroscopic evaluation and damage identification for thermal barrier coatings subjected to simulated engine environments. Surface & Coatings Technology, 2017, 323:30-38.

DOI URL |

| [28] | RINALDI C, DE MARIA L, MANDELLI M. Assessment of the spent life fraction of gas turbine blades by coating life modeling and photostimulated luminescence piezospectroscopy. Journal of Engineering for Gas Turbines and Power-Transactions of the Asme, 2010, 132(11):4. |

| [29] |

WANG X, ATKINSON A, CHIRIVI L, et al. Evolution of stress and morphology in thermal barrier coatings. Surface & Coatings Technology, 2010, 204(23):3851-3857.

DOI URL |

| [30] |

WANG X, LEE G, ATKINSON A. Investigation of TBCs on turbine blades by photoluminescence piezospectroscopy. Acta Materialia, 2009, 57(1):182-195.

DOI URL |

| [31] | JAYARAJ B, VISHWESWARAIAH S, DESAI V H, et al. Electrochemical impedance spectroscopy of thermal barrier coatings as a function of isothermal and cyclic thermal exposure. Surface & Coatings Technology, 2004, 177:140-151. |

| [32] | THORNTON J, COOKSON D, PESCOTT E. The measurement of strains within the bulk of aged and as-sprayed thermal barrier coatings using synchrotron radiation. Surface & Coatings Technology, 1999, 120:96-102. |

| [33] | YU F L, BENNETT T D. Phase of thermal emission spectroscopy for properties measurements of delaminating thermal barrier coatings. Journal of Applied Physics, 2005, 98(10):8. |

| [34] | DAVIES D L, DON BOULDIN. A cluster separation measure. IEEE Trans. Pattern Anal. Mach. Intell., 1979, PAMI-1(2):224-227. |

| [35] |

BENSON P M, VINCIGUERRA S, MEREDITH P G, et al. Laboratory simulation of volcano seismicity. Science, 2008, 322(5899):249-252.

DOI URL |

| [36] |

YANG L, ZHOU Y C, LU C. Damage evolution and rupture time prediction in thermal barrier coatings subjected to cyclic heating and cooling: an acoustic emission method. Acta Materialia, 2011, 59(17):6519-6529.

DOI URL |

| [37] | YANG L, ZHOU Y C, MAO W G, et al. Real-time acoustic emission testing based on wavelet transform for the failure process of thermal barrier coatings. Applied Physics Letters, 2008, 93(23):299. |

| [38] | 李巧莲, 张坤, 张凯, 等. 热喷涂涂层界面断裂韧性的反向三点弯曲法试验. 金属热处理, 2010, 35(1):114-116. |

| [39] | 朱旺. 屈曲法表征薄膜/韧性基底材料体系的界面结合性能. 湘潭: 湘潭大学博士学位论文, 2014. |

| [40] |

GUTENBERG B, RICHTER C F. Frequency of earthquakes in Califonia. Bulletin of the Seismological Society of America, 1944, 34(4):185-188.

DOI URL |

| [41] |

COLOMBO S, MAIN I G, FORDE M C. Assessing damage of reinforced concrete beam using “ b-value” analysis of acoustic emission signals. Journal of Materials in Civil Engineering, 2003, 15(3):280-286.

DOI URL |

| [42] | COX S J D, MEREDITH P G. Microcrack formation and material softening in rock measured by monitoring acoustic emissions. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts., 1993, 30(1):11-24. |

| [43] | 吴多锦. 热障涂层界面破坏实时测试分析及实验模拟系统的研制. 湘潭: 湘潭大学硕士学位论文, 2011. |

| [1] | LI Longbin, XUE Yudong, HU Jianbao, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Influence of SiC Nanowires on the Damage Evolution of SiCf/SiC Composites [J]. Journal of Inorganic Materials, 2021, 36(10): 1111-1117. |

| [2] | ZHANG Yongzhen, TONG Xiaoyan, YAO Leijiang, LI Bin, BAI Guodong. Acoustic Emission Pattern Recognition on Tensile Damage Process of C/SiC Composites Using an Improved Genetic Algorithm [J]. Journal of Inorganic Materials, 2020, 35(5): 593-600. |

| [3] | LI Xuqin, TAN Zhiyong, CHENG Laifei, ZHOU Lingke, GAO Jian. Tensile Behaviors and Matrix Cracking Mechanism of C/SiCN Composite Prepared by Precursor Infiltration Pyrolysis Method [J]. Journal of Inorganic Materials, 2020, 35(11): 1227-1233. |

| [4] | WANG Yanan, LI Hua, WANG Zhengkun, LI Qingfeng, LIAN Chen, HE Xin. Progress on Failure Mechanism of Lithium Ion Battery Caused by Diffusion Induced Stress [J]. Journal of Inorganic Materials, 2020, 35(10): 1071-1087. |

| [5] | ZHANG Qi-Hao, BAI Sheng-Qiang, CHEN Li-Dong. Technologies and Applications of Thermoelectric Devices: Current Status, Challenges and Prospects [J]. Journal of Inorganic Materials, 2019, 34(3): 279-293. |

| [6] | HUANG Xi-Peng, WANG Bo, YANG Cheng-Peng, PAN Wen-Ge, LIU Xiao-Ying. Evaluating Damage Evolution of Three-dimension Needled C/SiC Composite Based on Acoustic Emission Signal Analysis [J]. Journal of Inorganic Materials, 2018, 33(6): 609-616. |

| [7] | ZHANG Xiao-Feng, ZHOU Ke-Song, ZHANG Ji-Fu, ZHANG Yong, LIU Min, DENG Chun-Ming. Structure Evolution of 7YSZ Thermal Barrier Coating During Thermal Shock Testing [J]. Journal of Inorganic Materials, 2015, 30(12): 1261-1266. |

| [8] | DENG Qi-Huang, WANG Lian-Jun, XU Hong-Jie, WANG Hong-Zhi, JIANG Wan. Fatigue Life Investigation of PZT Ceramics by MSP Method [J]. Journal of Inorganic Materials, 2012, 27(10): 1047-1052. |

| [9] | PAN Wen-Ge,JIAO Gui-Qiong,WANG Bo,GUAN Guo-Yang. Characterizing Damage Evolution of Three-dimensional Braided C/SiC Composite with AE Technology [J]. Journal of Inorganic Materials, 2004, 19(4): 871-875. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||