Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (6): 608-614.DOI: 10.15541/jim20200509

• RESEARCH ARTICLE • Previous Articles Next Articles

CHEN Lichi1,2( ), WANG Yaogong1,2, WANG Wenjiang1,2, MA Xiaoqin1,2, YANG Jingyuan3(

), WANG Yaogong1,2, WANG Wenjiang1,2, MA Xiaoqin1,2, YANG Jingyuan3( ), ZHANG Xiaoning1,2

), ZHANG Xiaoning1,2

Received:2020-09-01

Revised:2020-10-12

Published:2021-06-20

Online:2020-12-01

Contact:

YANG Jingyuan, engineer. E-mail: yjytonghu@163.com

About author:CHEN Lichi(1995-), male, PhD candidate. E-mail: 734167430@qq.com

Supported by:CLC Number:

CHEN Lichi, WANG Yaogong, WANG Wenjiang, MA Xiaoqin, YANG Jingyuan, ZHANG Xiaoning. Preparation of Silicon Nanowires and Porous Silicon Composite Structure by Electrocatalytic Metal Assisted Chemical Etching[J]. Journal of Inorganic Materials, 2021, 36(6): 608-614.

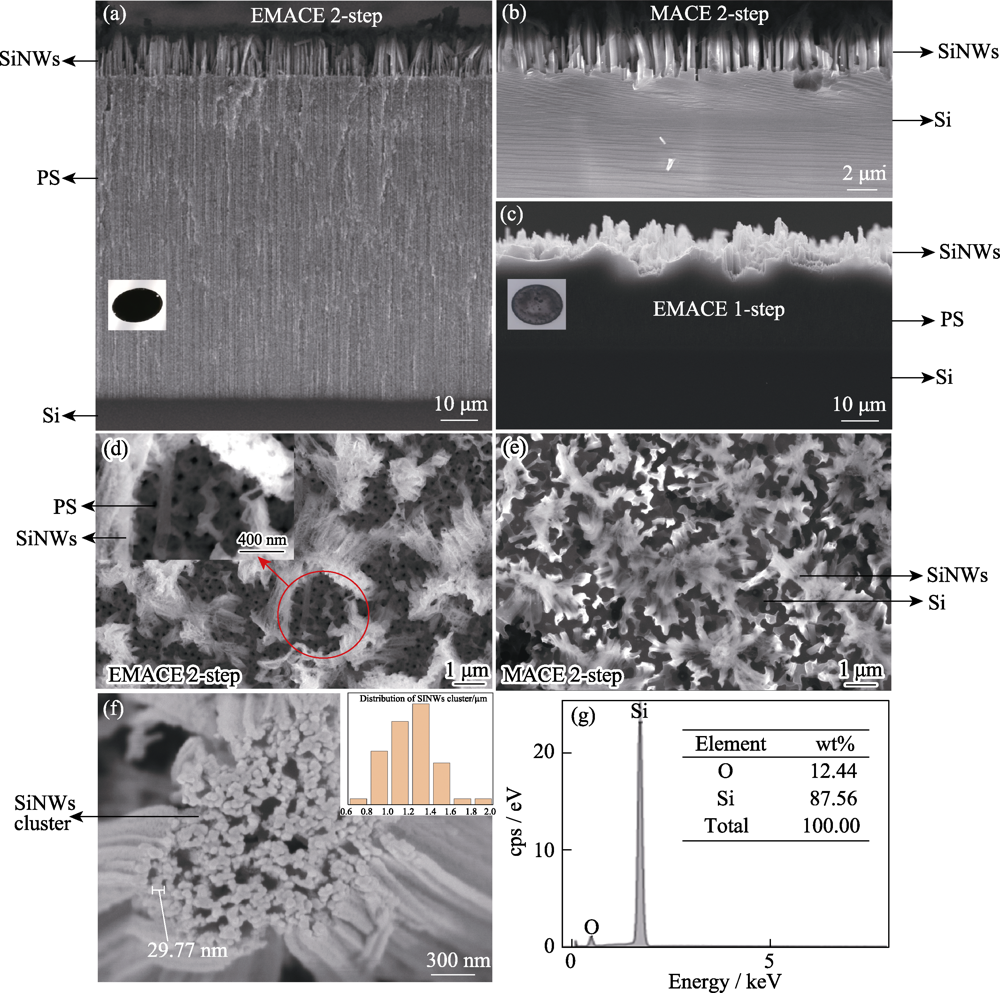

Fig. 2 SEM morphologies of samples prepared by different methods (a,d) EMACE 2-step method; (b,e) MACE 2-step method; (c) EMACE 1-step method; (f) High resolusion FESEM images of SiNWs clusters; (g) EDS of SiNWs clusters

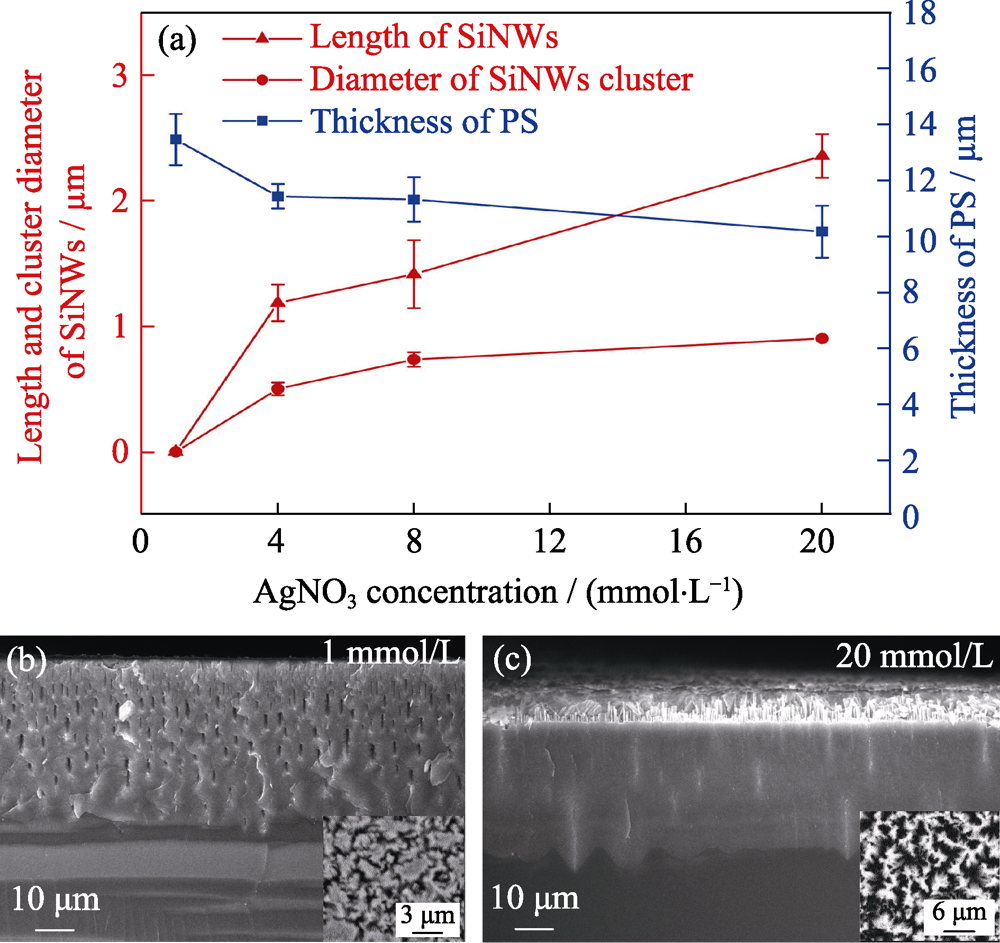

Fig. 3 Effect of AgNO3 concentration on the morphology of SiNWs/PS composites (a) Changes of length of SiNWs, PS and cluster with AgNO3 concentration, and FESEM images of SiNWs/PS composites with AgNO3 concentration of (b) 1 mmol/L and (c) 20 mmol/L

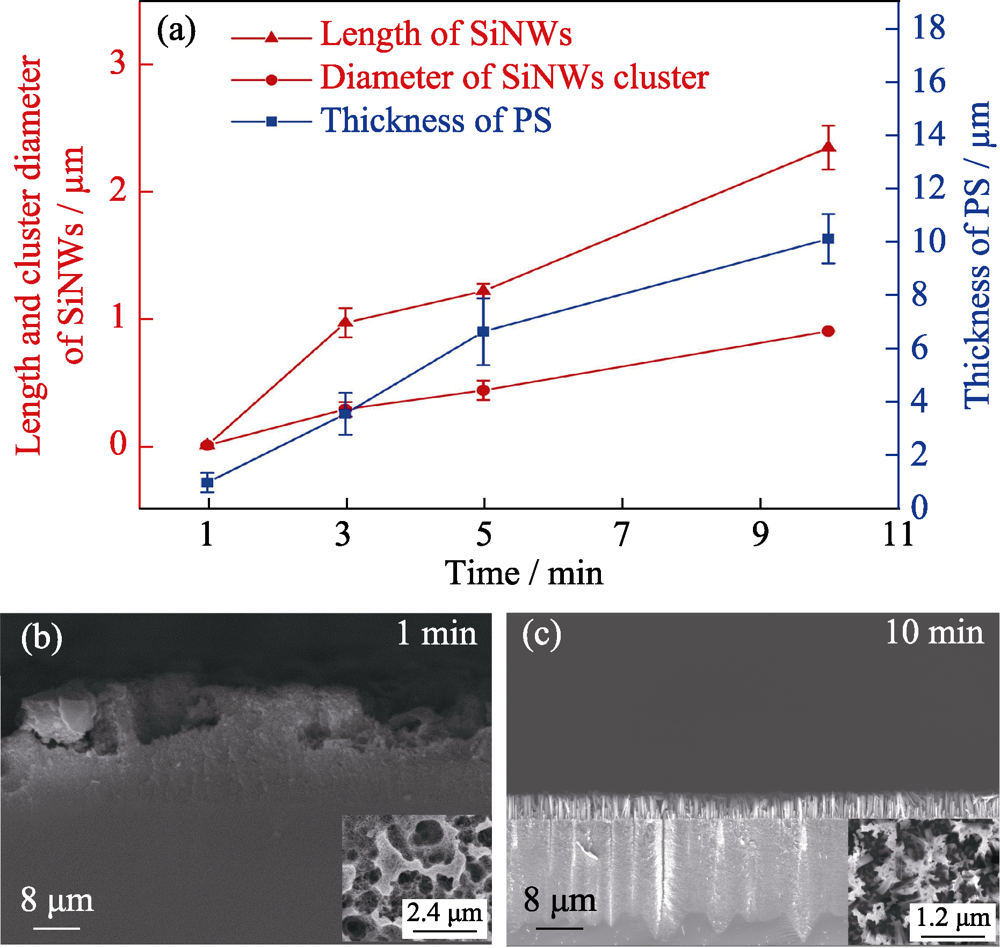

Fig. 4 Effect of etching time on the morphology of SiNWs/PS composites (a) Changes of length of SiNWs, PS and cluster with etching time, and FESEM images of SiNWs/PS composites with etching time of (b) 1 min and (c) 20 min

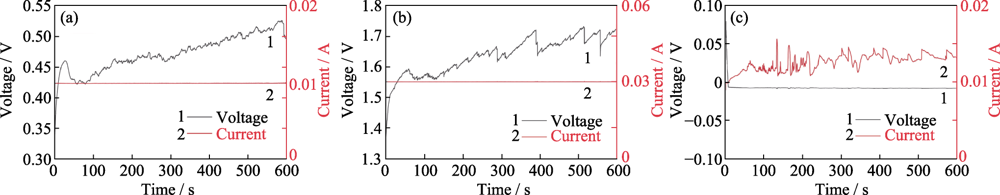

Fig. 8 Variation of voltage/current between anode and cathode with time during the etching (a) EMACE 2-step method at 10 mA; (b) EMACE 2-step method at 30 mA; (c) EMACE 1-step method at 10 mA

| [1] |

PIEDIMONTE P, MAZZETTA I, FUCILE S, et al. Silicon nanowires to detect electric signals from living cells. Materials Research Express, 2019,6(8):084005.

DOI URL |

| [2] |

DIMAGGIO E, PENNELLI G. Potentialities of silicon nanowire forests for thermoelectric generation. Nanotechnology, 2018,29(13):135401.

DOI URL |

| [3] |

PENNELLI G, ELYAMNY S, DIMAGGIO E, et al. Thermal conductivity of silicon nanowire forests. Nanotechnology, 2018,29(50):505402.

DOI URL |

| [4] |

MOKSHIN P V, JUNEJA S, PAVELYEV V S. Synthesis of silicon nanowires using plasma chemical etching process for solar cell applications. Journal of Physics: Conference Series, 2019,1368(2):022060.

DOI URL |

| [5] |

CHEN W H, CABARROCAS P R I. Rational design of nanowire solar cells: from single nanowire to nanowire arrays. Nanotechnology, 2019,30(19):194002.

DOI URL |

| [6] |

KUMAR V, SAXENA S K, KAUSHIK V, et al. Silicon nanowires prepared by metal induced etching (MIE): good field emitters. RSC Advances, 2014,4(101):57799-57803.

DOI URL |

| [7] |

ADAM T, HASHIM U. Silicon nanowire fabrication: silicon trimming via shallow anisotropic etching. Microelectronics International, 2014,31(2):78-85.

DOI URL |

| [8] |

ACHARYA S, KOTTANTHARAYIL A. Poole-Frenkel transport in gold catalyzed VLS grown silicon nanowires. IEEE Transactions on Electron Devices, 2018,65(5):1685-1691.

DOI URL |

| [9] |

LESTER U VINZONS, LEI SHU, SENPO YIP, et al. Unraveling the morphological evolution and etching kinetics of porous silicon nanowires during metal-assisted chemical etching. Nanoscale Research Letters, 2017,12:385.

DOI URL |

| [10] |

CONG L T, NGOC LAM N T, GIANG N T, et al. N-type silicon nanowires prepared by silver metal-assisted chemical etching: fabrication and optical properties. Materials Science in Semiconductor Processing, 2019,90:198-204.

DOI URL |

| [11] |

VIRIDIANA ACA-LÓPEZ, ENRIQUE QUIROGA-GONZÁLEZ, ESTELA GÓMEZ-BAROJAS, et al. Effects of the doping level in the production of silicon nanowalls by metal assisted chemical etching. Materials Science in Semiconductor Processing, 2020,118:105206.

DOI URL |

| [12] |

ZHU Y F, ZHOU L, PAN C J, et al. Fabrication of silicon nanorod arrays via a facile metal-assisted chemical etching method. Journal of Materials Science Materials in Electronics, 2016,27(6):5833-5838.

DOI URL |

| [13] |

HUNG Y J, LEE S L. Manipulating the antireflective properties of vertically-aligned silicon nanowires. Solar Energy Materials & Solar Cells, 2014,130:573-581.

DOI URL |

| [14] |

LI L, FANG Y, XU C, et al. Fabricating vertically aligned sub-20 nm Si nanowire arrays by chemical etching and thermal oxidation. Nanotechnology, 2016,27(16):165303.

DOI URL |

| [15] |

HE LI, WANG WEN-JIANG, ZHANG XIAO-NING. Improvement of electron emission characteristics of porous silicon emitter by using cathode reduction and electrochemical oxidation. Applied Surface Science, 2017,399:592-598.

DOI URL |

| [16] |

KOMODA T, SHENG X, KOSHIDA N. Mechanism of efficient and stable surface-emitting cold cathode based on porous polycrystalline silicon films. Journal of Vacuum Science & Technology B, 1999,17(3):1076-1079.

DOI URL |

| [17] |

FENG W, ARAKI H, OZAKI M, et al. Field emission properties of the nonaligned multiwalled carbon nanotube films with different length. Japanese Journal of Applied Physics, 2005,44(1-7):L253-L255.

DOI URL |

| [18] |

ZHU K, VINZANT T B, NEALE N R, et al. Removing structural disorder from oriented TiO2 nanotube arrays: reducing the dimensionality of transport and recombination in dye-sensitized solar cells. Nano Letters, 2007,7(12):3739.

DOI URL |

| [19] |

HAN H, HUANG Z, LEE W. Metal-assisted chemical etching of silicon and nanotechnology applications. Nano Today, 2014,9(3):271-304.

DOI URL |

| [20] |

ABDULKADIR A, AZIZ A, PAKHURUDDIN M Z. Effects of silver nanoparticles layer thickness towards properties of black silicon fabricated by metal-assisted chemical etching for photovoltaics. SN Applied Sciences, 2020,2(4):515.

DOI URL |

| [21] |

ALHER M A, MOSLEH A, BANIHASHEMIAN S F. Investigation of silicon nanowires produced by metal-assisted chemical etching method. IOP Conference Series: Materials Science and Engineering, 2020,671(1):012028.

DOI URL |

| [22] |

CULLIS A G, CANHAM L T, CALCOTT P J. The structural and luminescence properties of porous silicon. Journal of Applied Physics, 1997,82(3):909-965.

DOI URL |

| [23] | FOWLER R H, NORDHEIM L. Electron emission in intense electric fields. Proceedings of the Royal Society of London, 1928,119(781):173-181. |

| [1] | LI Kunru, HU Xinghui, ZHANG Zhengfu, GUO Yuzhong, HUANG Ruian. Three-dimensional Porous Biogenic Si/C Composite for High Performance Lithium-ion Battery Anode Derived from Equisetum Fluviatile [J]. Journal of Inorganic Materials, 2021, 36(9): 929-935. |

| [2] | DING Sheng, NING Kai, YUAN Binxia, PAN Weiguo, YIN Shibin, LIU Jianfeng. Durability of Fe-N/C Catalysts with Different Nanostructures for Electrochemical Oxygen Reduction in Alkaline Solution [J]. Journal of Inorganic Materials, 2020, 35(8): 953-958. |

| [3] | ZHANG Tong,LI Zi-Juan,GUO Ze-Kun,TIAN Yan,LIN Hao-Jian,XU Ning-Sheng,CHEN Jun,DENG Shao-Zhi,LIU Fei. Single Crystalline SmB6 Nanostructure Arrays: Controllable Synthesis and Field Emission Property [J]. Journal of Inorganic Materials, 2020, 35(2): 199-204. |

| [4] | SHENG Peng, ZHAO Guang-Yao, XU Li, LIU Shuang-Yu, WANG Bo, LIU Hai-Zhen, MA Guang, HAN Yu, CHEN Xin. Reductive Preparation of Blue TiO2 via Deposition of Aluminum [J]. Journal of Inorganic Materials, 2018, 33(9): 942-948. |

| [5] | ZHOU Hui, HAN Man-Gui, TANG Zhong-Kai, WU Yan-Hui. Fabrication and Magnetic Properties of N-type Porous Silicon/Nickel Microtubes Composite [J]. Journal of Inorganic Materials, 2016, 31(8): 855-859. |

| [6] | WANG Ya-Peng, LIU Jia-Jia, LIU Chun-Xiao, CHEN Wei-Wei, LI Ting-Ting, GUO Hong. Morphology-controlled Synthesis of Hollow Core-shell Structural α-MoO3-SnO2 with Superior Lithium Storage [J]. Journal of Inorganic Materials, 2015, 30(9): 919-924. |

| [7] | ZHAO Peng, LI Zhong, CUI Xiao-Li. Facile Preparation Carbon-Doped TiO2 Nanotube Electrodes and Its Enhanced Photoelectrochemical Response [J]. Journal of Inorganic Materials, 2015, 30(6): 599-604. |

| [8] | YE Zuo-Yan, LIU Dao-Xin, LI Chong-Yang, ZHANG Xiao-Hua, ZANG Xiao-Ming, LEI Ming-Xia. Effect of Sealing Treatments on the Corrosion Behavior of Micro-arc Oxidation Coating on Aluminum Alloy in Acid NaCl Solution [J]. Journal of Inorganic Materials, 2015, 30(6): 627-632. |

| [9] | HUANG Yan-Hua, HAN Xiang, CHEN Hui-Xin, CHEN Song-Yan, YANG Yong. Investigation of Porous Silicon/Carbon Composite as Anodes for Lithium Ion Batteries [J]. Journal of Inorganic Materials, 2015, 30(4): 351-356. |

| [10] | LU Yuan, YANG Jian-Feng, LI Jing-Long. Fabrication of Porous Silicon Nitride with High Porosity by Carbothermal Reduction-reaction Bonding [J]. Journal of Inorganic Materials, 2013, 28(5): 469-473. |

| [11] | YE Yun, CHEN Tian-Yuan, CAI Shou-Jin, YAN Min, LIU Yu-Hui, GUO Tai-Liang. Effects of Different Humidity on the Growth and Field Emission Properties of CuO Nanowires [J]. Journal of Inorganic Materials, 2013, 28(12): 1359-1363. |

| [12] | LI Jian-Wen, ZHOU Ai-Jun, LIU Xing-Quan, LI Jing-Ze. Si Nanowire Anode Prepared by Chemical Etching for High Energy Density Lithium-ion Battery [J]. Journal of Inorganic Materials, 2013, 28(11): 1207-1212. |

| [13] | CHEN Yu, LI Wen-Rui, XU Can, SU Jia-Can, LI Ming, LIU Chang-Sheng. Study on Hemostatic Materials of Mesoporous Silicon Dioxide Doped Ca and Ag with Antibacterial Properties [J]. Journal of Inorganic Materials, 2012, 27(5): 513-518. |

| [14] | YAO Dong-Xu,ZENG Yu-Ping. High Flexural Strength Porous Silicon Nitride Prepared via Nitridation of Silicon Powder [J]. Journal of Inorganic Materials, 2011, 26(4): 422-426. |

| [15] | ZHANG Zhi-Yu, SANG Li-Xia, LU Li-Ping, BAI Guang-Mei, DU Chun-Xu, MA Chong-Fang. Preparation of TiO2 Nanotube Arrays and Their Photoelectrochemical Properties [J]. Journal of Inorganic Materials, 2010, 25(11): 1145-1149. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||