Journal of Inorganic Materials ›› 2021, Vol. 36 ›› Issue (3): 306-312.DOI: 10.15541/jim20200364

Special Issue: 【虚拟专辑】吸波材料(2020~2021); 【结构材料】陶瓷基复合材料

• RESEARCH PAPER • Previous Articles Next Articles

WU Zhihong1( ), DENG Yue1, MENG Zhenzhen1, ZHANG Guoli1, ZHANG Luping1,2, WANG Yubin3

), DENG Yue1, MENG Zhenzhen1, ZHANG Guoli1, ZHANG Luping1,2, WANG Yubin3

Received:2020-07-01

Revised:2020-08-01

Published:2021-03-20

Online:2020-09-09

About author:WU Zhihong(1974-), male, PhD, associate professor. E-mail: zhihong@xauat.edu.cn

Supported by:CLC Number:

WU Zhihong, DENG Yue, MENG Zhenzhen, ZHANG Guoli, ZHANG Luping, WANG Yubin. Microwave Absorbing Properties of Novel SiC/Cf Composites Containing SiC Array Modified Coating[J]. Journal of Inorganic Materials, 2021, 36(3): 306-312.

| Composition | NaH2PO2/ ( mol·L-1) | C6H5Na3O7·2H2O/ ( mol·L-1) | NiSO4/ ( mol·L-1) | NH4Cl/ ( mol·L-1) | H2O/mL | Temperature/℃ | pH |

|---|---|---|---|---|---|---|---|

| Process conditions | 0.38 | 0.26 | 0.15 | 1.87 | 200 | (90±2) | 8-9 |

Table 1 Basic composition and process conditions of plating solution

| Composition | NaH2PO2/ ( mol·L-1) | C6H5Na3O7·2H2O/ ( mol·L-1) | NiSO4/ ( mol·L-1) | NH4Cl/ ( mol·L-1) | H2O/mL | Temperature/℃ | pH |

|---|---|---|---|---|---|---|---|

| Process conditions | 0.38 | 0.26 | 0.15 | 1.87 | 200 | (90±2) | 8-9 |

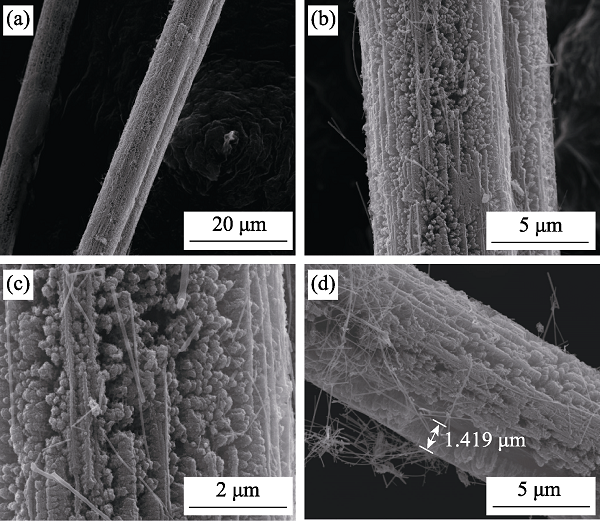

Fig. 2 SEM images of SiC/Cf composite (a) SiC tightly wrapped on the Cf; (b) SiC uniformly distributed; (c) SiC orderly arranged and insulated; (d) A few SiC nanowires distributed

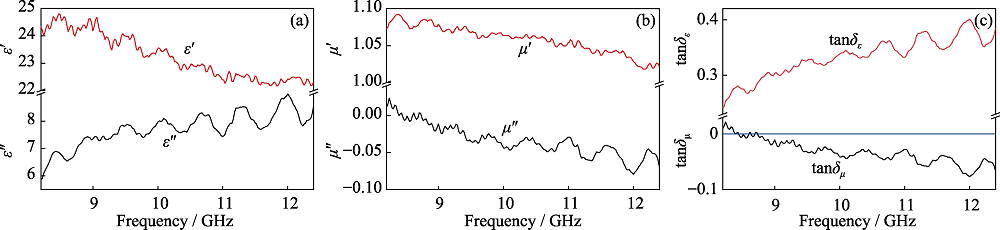

Fig. 3 Electromagnetic parameters of SiC/Cf composite (a) Real part (ε′) and imaginary part (ε″) of relative permittivity; (b) Real part (μ′) and imaginary part (μ″) of relative permeability; (c) Dielectric loss tangent (tanδε) and magnetic loss tangent (tanδμ)

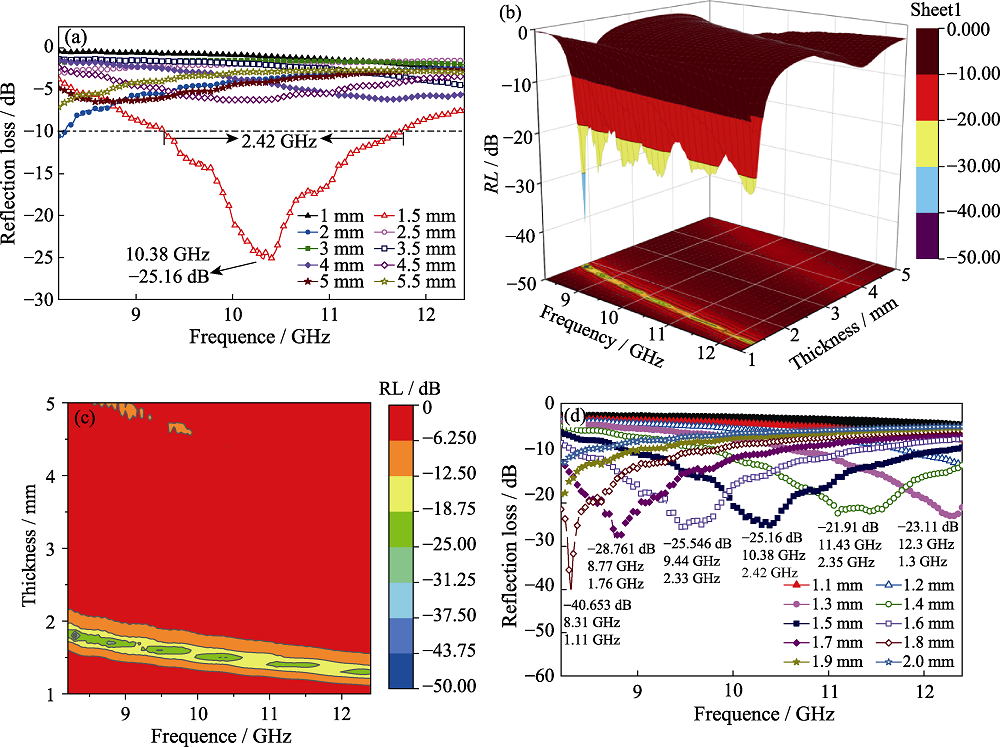

Fig. 5 RL diagrams of SiC/Cf composite material RL value (a), 3D display RL value (b) and 3D RL value projection (c) with a thickness of 1-5.5 mm; RL value with thickness of 1.1-2.0 mm (d)

| Absorbent material | Thickness/mm | RLmin/dB | Frequency/GHz | Effective absorption bandwidth/GHz | Ref. |

|---|---|---|---|---|---|

| SiCNW | 3.00 | -17.40 | 11.20 | 2.50 | [29] |

| SiCNW/Cf | 2.00 | -21.50 | 7.70 | 2.40 | [30] |

| SiCNW-Cf/LAS | 3.00 | -37.80 | 7.20 | <2.00 | [31] |

| ZnO/Cf | 4.35 | -33.00 | - | 5.10 | [32] |

| NiZn ferrite/BC | 2.00 | -11.00 | - | - | [33] |

| HPC/Fe3O4 | 5.50 | -20.10 | 11.76 | ~2.00 | [34] |

| SiC/Cf | 1.50 | -25.16 | 10.38 | 2.42 | This work |

| 1.80 | -40.66 | 8.31 | 1.11 | This work |

Table 2 Comparison between SiC/Cf composite and other similar structural materials

| Absorbent material | Thickness/mm | RLmin/dB | Frequency/GHz | Effective absorption bandwidth/GHz | Ref. |

|---|---|---|---|---|---|

| SiCNW | 3.00 | -17.40 | 11.20 | 2.50 | [29] |

| SiCNW/Cf | 2.00 | -21.50 | 7.70 | 2.40 | [30] |

| SiCNW-Cf/LAS | 3.00 | -37.80 | 7.20 | <2.00 | [31] |

| ZnO/Cf | 4.35 | -33.00 | - | 5.10 | [32] |

| NiZn ferrite/BC | 2.00 | -11.00 | - | - | [33] |

| HPC/Fe3O4 | 5.50 | -20.10 | 11.76 | ~2.00 | [34] |

| SiC/Cf | 1.50 | -25.16 | 10.38 | 2.42 | This work |

| 1.80 | -40.66 | 8.31 | 1.11 | This work |

| [1] | YE X L, CHEN Z F, AI S F, et al. Novel three-dimensional SiC/ melamine-derived carbon foam-reinforced SiO2 aerogel composite with low dielectric loss and high impedance matching ratio. ACS Sustainable Chemistry & Engineering, 2019,7(2):2774-2783. |

| [2] | 赵灵智, 胡社军, 李伟善 , 等. 吸波材料的吸波原理及其研究进展. 现代防御技术, 2007(1):27-31. |

| [3] | LIANG X H, ZHANG X M, LIU W, et al. A simple hydrothermal process to grow MoS2 nanosheets with excellent dielectric loss and microwave absorption performance. Journal of Materials Chemistry C, 2016,4(28):6816-6821. |

| [4] | JIANG Y, CHEN Y, LIU Y J, et al. Lightweight spongy bone-like graphene@SiC aerogel composites for high-performance microwave absorption. Chemical Engineering Journal, 2018,337:522-531. |

| [5] | QIU J, WU X Y, QIU T T. High electromagnetic wave absorbing performance of activated hollow carbon fibers decorated with CNTs and Ni nanoparticles. Ceramics International, 2016,42(4):5278-5285. |

| [6] | 武志红, 李妤婕, 张聪 , 等. 竹炭/SiC复合材料结构及其吸波性能. 硅酸盐学报, 2018,46(1):150-155. |

| [7] | 刘丹莉, 刘平安, 杨青松 , 等. 吸波材料的研究现状及其发展趋势. 材料导报, 2013(17):77-81. |

| [8] | LI W W, CHEN M J, ZENG Z H, et al. Broadband composite radar absorbing structures with resistive frequency selective surface: optimal design, manufacturing and characterization. Composites Science and Technology, 2017,145:10-14. |

| [9] | CHOI W, KIM C. Broadband microwave-absorbing honeycomb structure with novel design concept. Composites Part B-Engineering, 2015,83:14-20. |

| [10] | LI W C, LI C S, LIN L H, et al. All-dielectric radar absorbing array metamaterial based on silicon carbide/carbon foam material. Journal of Alloys and Compounds, 2019 ( 781):883-891. |

| [11] |

YE W, SUN Q L, ZHANG G Y. Effect of heat treatment conditions on properties of carbon-fiber-based electromagnetic-wave-absorbing composites. Ceramics International, 2019,45(4):5093-5099.

DOI URL |

| [12] | ADEBAYO L L, SOLEIMANI H, YAHYA N, et al. Recent advances in the development of Fe3O4-BASED microwave absorbing materials. Ceramics International, 2020,46(2):1249-1268. |

| [13] | LIU Y, ZHANG Z Q, XIAO S T, et al. Preparation and properties of cobalt oxides coated carbon fibers as microwave-absorbing materials. Applied Surface Science, 2011,257(17):7678-7683. |

| [14] | SONG Z M, LIU X F, SUN X, et al. Alginate-templated synthesis of CoFe/carbon fiber composite and the effect of hierarchically porous structure on electromagnetic wave absorption performance. Carbon, 2019,151:36-45. |

| [15] | CHEN X G, YE Y, CHENG J P. Recent progress in electromagnetic wave absorbers, Journal of Inorganic Materials, 2011,26(5):449-457. |

| [16] | 吕晓艳, 田玉平, 魏云 , 等. 镍/碳纳米纤维复合物的制备及其吸波性能. 化学研究, 2016,27(6):756-759. |

| [17] | WU R B, YANG Z H, FU M S, et al. In-situ growth of SiC nanowire arrays on carbon fibers and their microwave absorption properties. Journal of Alloys & Compounds, 2016,687:833-838. |

| [18] | ZHOU W, LONG L, XIAO P, et al. Silicon carbide nano-fibers in-situ grown on carbon fibers for enhanced microwave absorption properties. Ceramics International, 2017,43(7):5628-5634. |

| [19] | WU Z H, ZHENG H K, ZHANG G L, et al. Synthesis of diameter- fluctuating silicon carbide nanowires for excellent microwave absorption. Materials Chemistry and Physics, 2020,244:122648. |

| [20] | FU M, ZHU Z, ZHOU Y, et al. Multifunctional pompon flower- like nickel ferrites as novel pseudocapacitive electrode materials and advanced absorbing materials. Ceramics International, 2020,46(1):850-856. |

| [21] | LIANG C Y, WANG Z J. Eggplant-derived SiC aerogels with high- performance electromagnetic wave absorption and thermal insulation properties. Chemical Engineering Journal, 2019,373:598-605. |

| [22] | DUAN Y, LIU Z, JING H, et al. Novel microwave dielectric response of Ni/Co-doped manganese dioxides and their microwave absorbing properties. Journal of Materials Chemistry, 2012,22(35):18291-18299. |

| [23] | DONG S, ZHANG X H, HU P T, et al. Biomass-derived carbon and polypyrrole addition on SiC whiskers for enhancement of electromagnetic wave absorption. Chemical Engineering Journal, 2019,359:882-893. |

| [24] | HU P, DONG S, LI X, et al. A low-cost strategy to synthesize MnO nanorods anchored on 3D biomass-derived carbon with superior microwave absorption properties. Journal of Materials Chemistry C, 2019,7(30):9219-9228. |

| [25] | ZHANG X J, LI S, WANG S W, et al. Self-supported construction of three-dimensional MoS2 hierarchical nanospheres with tunable high-performance microwave absorption in broadband. Journal of Physical Chemistry C, 2016,120(38):22019-22027. |

| [26] | LIANG H S, LIU J L, ZHANG Y, et al. Ultra-thin broccoli-like SCFs@TiO2 one-dimensional electromagnetic wave absorbing material. Composites Part B Engineering, 2019,178:107507. |

| [27] |

NING M Q, LU M M, LI J B, et al. Two-dimensional nanosheets of MoS2: a promising material with high dielectric properties and microwave absorption performance. Nanoscale, 2015,7(38):15734-15740.

DOI URL PMID |

| [28] | ZHOU X F, JIA Z R, FENG A L, et al. Synthesis of fish skin- derived 3D carbon foams with broadened bandwidth and excellent electromagnetic wave absorption performance. Carbon, 2019,152:827-836. |

| [29] | WU R B, ZHOU K, YANG Z H, et al. Molten-salt-mediated synthesis of SiC nanowires for microwave absorption applications. CrystEngComm, 2013,15(3):570-576. |

| [30] | ZHANG W D, ZHANG X, WU H J, et al. Impact of morphology and dielectric property on the microwave absorbing performance of MoS2-based materials. Journal of Alloys and Compounds, 2018,751:34-42. |

| [31] | XIA L, ZHANG X Y, YANG Y N, et al. Enhanced electromagnetic wave absorption properties of laminated SiCNW-Cf/lithium-aluminum- silicate (LAS) composites. Journal of Alloys and Compounds, 2018,748:154-162. |

| [32] | WANG X X, YU M X, ZHANG W, et al. Synthesis and microwave absorption properties of graphene/nickel composite materials. Applied Physics A, 2015,118(3):1053-1058. |

| [33] | WU K H, TING T H, LIU C I, et al. Electromagnetic and microwave absorbing properties of Ni0.5Zn0.5Fe2O4/bamboo charcoal core-shell nanocomposites. Composites Science and Technology, 2008,68(1):132-139. |

| [34] | LIU Z, LV Y X, FANG J Y, et al. A new method for an efficient porous carbon/Fe3O4 composite based electromagnetic wave absorber derived from a specially designed polyimide. Composites Part B-engineering, 2018,155:148-155. |

| [35] |

LIU L L, ZHANG S, YAN F, et al. Three-dimensional hierarchical MoS2 nanosheets/ultralong N-doped carbon nanotubes as high- performance electromagnetic wave absorbing material. ACS Applied Materials & Interfaces, 2018,10(16):14108-14115.

DOI URL PMID |

| [36] | ZHAO H, CHENG Y, LV H, et al. Achieving sustainable ultralight electromagnetic absorber from flour by turning surface morphology of nanoporous carbon. ACS Sustainable Chemistry & Engineering, 2018,6(11):15850-15857. |

| [37] |

QIU X, WANG L X, ZHU H L, et al. Lightweight and efficient microwave absorbing materials based on walnut shell-derived nano-porous carbon. Nanoscale, 2017,9(22):7408-7418.

DOI URL PMID |

| [1] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [2] | ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(5): 561-568. |

| [3] | LI Yanran, XIE Dingdong, JIANG Jie. Bionic Research on Multistage Pain Sensitization Based on Ionic Oxide Transistor Array [J]. Journal of Inorganic Materials, 2023, 38(4): 429-436. |

| [4] | JING Kaikai, GUAN Haoyang, ZHU Siyu, ZHANG Chao, LIU Yongsheng, WANG Bo, WANG Jing, LI Mei, ZHANG Chengyu. Tensile Creep Behavior of Cansas-II SiCf/SiC Composites at High Temperatures [J]. Journal of Inorganic Materials, 2023, 38(2): 177-183. |

| [5] | SHENG Lili, CHANG Jiang. Photo/Magnetic Thermal Fe2SiO4/Fe3O4 Biphasic Bioceramic and Its Composite Electrospun Membrane: Preparation and Antibacterial [J]. Journal of Inorganic Materials, 2022, 37(9): 983-990. |

| [6] | HE Huikai, YANG Rui, XIA Jian, WANG Tingze, DONG Dequan, MIAO Xiangshui. High-uniformity Memristor Arrays Based on Two-dimensional MoTe2 for Neuromorphic Computing [J]. Journal of Inorganic Materials, 2022, 37(7): 795-801. |

| [7] | XU Puhao, ZHANG Xiangzhao, LIU Guiwu, ZHANG Mingfen, GUI Xinyi, QIAO Guanjun. Microstructure and Mechanical Properties of SiC Joint Brazed by Al-Ti Alloys as Filler Metal [J]. Journal of Inorganic Materials, 2022, 37(6): 683-690. |

| [8] | ZHANG Ye, YAO Dongxu, ZUO Kaihui, XIA Yongfeng, YIN Jinwei, ZENG Yuping. Combustion Synthesis of Si3N4-BN-SiC Composites by in-situ Introduction of BN and SiC [J]. Journal of Inorganic Materials, 2022, 37(5): 574-578. |

| [9] | RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Electromagnetic Interference Shielding Properties of SiC Ceramic Matrix Composite Reinforced by Three-dimensional Silicon Carbide Nanowire Network [J]. Journal of Inorganic Materials, 2022, 37(5): 579-584. |

| [10] | WANG Hongda, FENG Qian, YOU Xiao, ZHOU Haijun, HU Jianbao, KAN Yanmei, CHEN Xiaowu, DONG Shaoming. Microstructure and Corrosion Behavior of Brazed Joints of SiC/SiC Composites and Hastelloy N Alloy Using Cu-Ni Alloy [J]. Journal of Inorganic Materials, 2022, 37(4): 452-458. |

| [11] | RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Porous SiC Ceramic Matrix Composite Reinforced by SiC Nanowires with High Strength and Low Thermal Conductivity [J]. Journal of Inorganic Materials, 2022, 37(4): 459-466. |

| [12] | HUANG Longzhi, YIN Jie, CHEN Xiao, WANG Xinguang, LIU Xuejian, HUANG Zhengren. Selective Laser Sintering of SiC Green Body with Low Binder Content [J]. Journal of Inorganic Materials, 2022, 37(3): 347-352. |

| [13] | WU Xishi, ZHU Yunzhou, HUANG Qing, HUANG Zhengren. Effect of Pore Structure of Organic Resin-based Porous Carbon on Joining Properties of Cf/SiC Composites [J]. Journal of Inorganic Materials, 2022, 37(12): 1275-1280. |

| [14] | XU Xiaoke, DENG Mingxue, LIU Qian, YU Jianding, ZHOU Zhenzhen, ZHANG Xiang, HE Huan. Advanced Multi-laser-beam Parallel Heating System for Rapid High Temperature Treatment [J]. Journal of Inorganic Materials, 2022, 37(1): 107-112. |

| [15] | LI Bangxin, ZHANG Qian, XIAO Jie, XIAO Wenyan, ZHOU Ying. Iron-doping Enhanced Basic Nickel Carbonate for Moisture Resistance and Catalytic Performance of Ozone Decomposition [J]. Journal of Inorganic Materials, 2022, 37(1): 45-50. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||