Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (12): 1333-1339.DOI: 10.15541/jim20200182

Special Issue: 结构陶瓷论文精选(2020)

Previous Articles Next Articles

LIU Jinyun( ),ZHANG Yuting,HONG Zhou,LIU Hua,WANG Shengxian,GU Xuehong(

),ZHANG Yuting,HONG Zhou,LIU Hua,WANG Shengxian,GU Xuehong( )

)

Received:2020-04-07

Revised:2020-06-12

Published:2020-12-20

Online:2020-07-10

About author:LIU Jinyun(1994–), female, Master candidate. E-mail: 1158381254@qq.com

Supported by:CLC Number:

LIU Jinyun, ZHANG Yuting, HONG Zhou, LIU Hua, WANG Shengxian, GU Xuehong. Fabrication of Dual-layer Hollow Fiber Ceramic Composite Membranes by Co-extrusion[J]. Journal of Inorganic Materials, 2020, 35(12): 1333-1339.

| Suspension composition | Inner layer | Outer layer |

|---|---|---|

| Solvent (NMP) | 33.34 | 37.81 |

| Al2O3 (1 μm) | 55.35 | / |

| Al2O3 (300 nm) | / | 49.15 |

| Polymer (PESf) | 9.77 | 11.34 |

| Additive (PVP) | 1.54 | 1.70 |

Table 1 Suspension composition of dual-layer hollow fiber membrane/wt%

| Suspension composition | Inner layer | Outer layer |

|---|---|---|

| Solvent (NMP) | 33.34 | 37.81 |

| Al2O3 (1 μm) | 55.35 | / |

| Al2O3 (300 nm) | / | 49.15 |

| Polymer (PESf) | 9.77 | 11.34 |

| Additive (PVP) | 1.54 | 1.70 |

Fig. 1 SEM images of dual-layer hollow fiber and single-layer hollow fiber Cross-section morphologies of (a, b) dual-layer hollow fiber precursor, (c, d) dual-layer hollow fiber, (e, f) 1 μm single-layer hollow fiber; SEM images of the surface morphology: (g) dual-layer hollow fiber, (h) 1 μm single-layer hollow fiber

| Property | η/% | Fracture load/N | Pure water flux/(m3?m-2?h-1) | Porosity/% | Average pore size/μm | RTOC/% |

|---|---|---|---|---|---|---|

| Single-layer (1 μm) | 13.0 | 9 | 3.52 | 51.57 | 0.70 | 95.4 |

| Single-layer (300 nm) | 16.9 | 19 | 0.86 | 48.20 | 0.13 | 98.4 |

| Dual-layer (1 μm/300 nm) | 14.3 | 12 | 2.30 | 50.89 | 0.24 | 97 |

Table 2 Comparison of properties between single-layer and dual-layer hollow fiber membranes

| Property | η/% | Fracture load/N | Pure water flux/(m3?m-2?h-1) | Porosity/% | Average pore size/μm | RTOC/% |

|---|---|---|---|---|---|---|

| Single-layer (1 μm) | 13.0 | 9 | 3.52 | 51.57 | 0.70 | 95.4 |

| Single-layer (300 nm) | 16.9 | 19 | 0.86 | 48.20 | 0.13 | 98.4 |

| Dual-layer (1 μm/300 nm) | 14.3 | 12 | 2.30 | 50.89 | 0.24 | 97 |

| TiO2 content/wt% | η/% | Fracture load/N | Pure water flux/ (m3?m-2?h-1) | Porosity/% | Average pore size/μm |

|---|---|---|---|---|---|

| 0 | 14.3 | 12 | 2.30 | 50.89 | 0.240 |

| 2 | 14.9 | 24 | 1.65 | 48.05 | 0.152 |

| 5 | 14.9 | 22 | 1.32 | 49.97 | 0.147 |

| 10 | 15.2 | 20 | 1.21 | 46.43 | 0.150 |

| 15 | 15.3 | 19 | 1.12 | 45.68 | 0.145 |

| 20 | 16.3 | 17 | 0.91 | 43.90 | 0.141 |

Table 3 Influence of TiO2 content on properties of dual-layer hollow fiber membranes

| TiO2 content/wt% | η/% | Fracture load/N | Pure water flux/ (m3?m-2?h-1) | Porosity/% | Average pore size/μm |

|---|---|---|---|---|---|

| 0 | 14.3 | 12 | 2.30 | 50.89 | 0.240 |

| 2 | 14.9 | 24 | 1.65 | 48.05 | 0.152 |

| 5 | 14.9 | 22 | 1.32 | 49.97 | 0.147 |

| 10 | 15.2 | 20 | 1.21 | 46.43 | 0.150 |

| 15 | 15.3 | 19 | 1.12 | 45.68 | 0.145 |

| 20 | 16.3 | 17 | 0.91 | 43.90 | 0.141 |

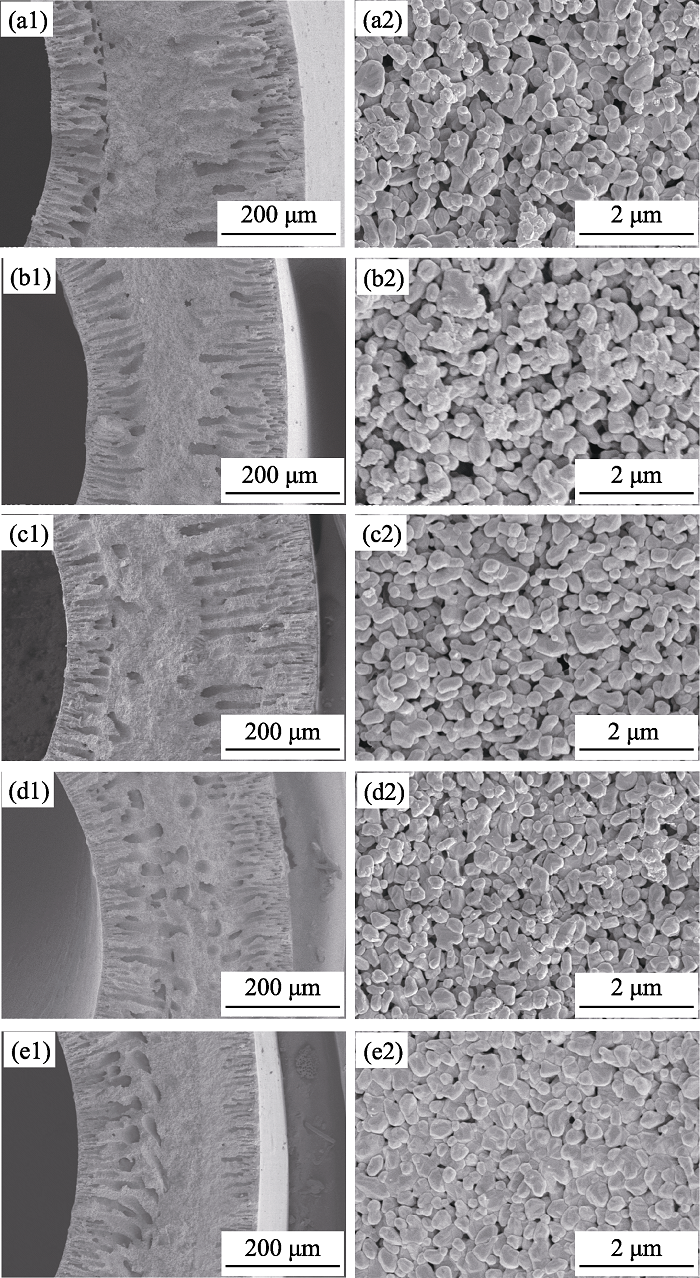

Fig. 3 SEM images of dual-layer hollow fiber membranes with different Al2O3/PESf mass ratios in outer suspension (a) 2.75; (b) 4.33; (c) 5.60; (d) 7.50; (e) 13.3

| Al2O3/PESf | Outer suspension viscosity/cP | Fracture load/N | Pure water flux/ (m3?m-2?h-1) | Porosity/ % | Mean pore size/μm | RTOC/% |

|---|---|---|---|---|---|---|

| 2.75 | 7320 | 21 | 1.99 | 49.90 | 0.180 | 97.3 |

| 4.33 | 8580 | 22 | 1.10 | 52.26 | 0.175 | 97.5 |

| 5.60 | 9720 | 23 | 1.41 | 53.91 | 0.130 | 97.5 |

| 7.50 | 11020 | 25 | 1.08 | 53.31 | 0.125 | 97.6 |

| 13.30 | 58300 | 23 | 0.48 | 52.54 | 0.115 | 97.8 |

Table 4 Influence of Al2O3/PESf mass ratio in outer suspension on properties of dual-layer hollow fiber membranes

| Al2O3/PESf | Outer suspension viscosity/cP | Fracture load/N | Pure water flux/ (m3?m-2?h-1) | Porosity/ % | Mean pore size/μm | RTOC/% |

|---|---|---|---|---|---|---|

| 2.75 | 7320 | 21 | 1.99 | 49.90 | 0.180 | 97.3 |

| 4.33 | 8580 | 22 | 1.10 | 52.26 | 0.175 | 97.5 |

| 5.60 | 9720 | 23 | 1.41 | 53.91 | 0.130 | 97.5 |

| 7.50 | 11020 | 25 | 1.08 | 53.31 | 0.125 | 97.6 |

| 13.30 | 58300 | 23 | 0.48 | 52.54 | 0.115 | 97.8 |

| Temperature/℃ | Fracture load/N | Pure water flux/(m3?m-2?h-1) | Porosity/% | Average pore size/μm | RTOC/% |

|---|---|---|---|---|---|

| 1250 | 11 | 3.23 | 61.97 | 0.235 | 96.7 |

| 1300 | 15 | 2.34 | 55.62 | 0.199 | 97.4 |

| 1350 | 24 | 1.20 | 48.88 | 0.150 | 97.5 |

| 1400 | 37 | 0.26 | 40.33 | 0.126 | 98.3 |

Table 5 Influence of sintering temperature on the properties of dual-layer hollow fiber membranes

| Temperature/℃ | Fracture load/N | Pure water flux/(m3?m-2?h-1) | Porosity/% | Average pore size/μm | RTOC/% |

|---|---|---|---|---|---|

| 1250 | 11 | 3.23 | 61.97 | 0.235 | 96.7 |

| 1300 | 15 | 2.34 | 55.62 | 0.199 | 97.4 |

| 1350 | 24 | 1.20 | 48.88 | 0.150 | 97.5 |

| 1400 | 37 | 0.26 | 40.33 | 0.126 | 98.3 |

| Membranes | Sintering temperature/℃ | Average pore size/μm | Pure water flux/ (m3?m-2?h-1) | Bending strength/MPa | Fracture load/N | Ref. |

|---|---|---|---|---|---|---|

| Single-Channel Al2O3 hollow fiber | 1455 | 0.10 | 0.664 | 88.2 | - | [ |

| Single-Channel Al2O3 hollow fiber | 1500 | 0.75 | 1.280 | 85.8 | - | [ |

| 4-Channel Al2O3 hollow fiber | 1500 | 1.20 | 2.710 | - | 22 | [ |

| 7-Channel Al2O3 hollow fiber | 1350 | 0.183 | 1.070 | - | 14 | [ |

| 7-Channel YSZ/Al2O3 hollow fiber | 1400 | 230.00 | 1.640 | - | 14 | [ |

| 4-Channel 1 μm/300 nm Al2O3 hollow fiber | 1350 | 0.15 | 1.260 | - | 24 | This work |

Table 6 Comparison in properties of different hollow fiber ceramic membranes

| Membranes | Sintering temperature/℃ | Average pore size/μm | Pure water flux/ (m3?m-2?h-1) | Bending strength/MPa | Fracture load/N | Ref. |

|---|---|---|---|---|---|---|

| Single-Channel Al2O3 hollow fiber | 1455 | 0.10 | 0.664 | 88.2 | - | [ |

| Single-Channel Al2O3 hollow fiber | 1500 | 0.75 | 1.280 | 85.8 | - | [ |

| 4-Channel Al2O3 hollow fiber | 1500 | 1.20 | 2.710 | - | 22 | [ |

| 7-Channel Al2O3 hollow fiber | 1350 | 0.183 | 1.070 | - | 14 | [ |

| 7-Channel YSZ/Al2O3 hollow fiber | 1400 | 230.00 | 1.640 | - | 14 | [ |

| 4-Channel 1 μm/300 nm Al2O3 hollow fiber | 1350 | 0.15 | 1.260 | - | 24 | This work |

| [1] | WANG S X, TIAN J Y, WANG Q, et al. Low-temperature sintered high-strength CuO doped ceramic hollow fiber membrane: preparation, characterization and catalytic activity. Journal of Membrane Science, 2019,570-571:333-342. |

| [2] | LEE M, WU Z T, WANG R, et al. Micro-structured alumina hollow fibre membranes- potential applications in wastewater treatment. Journal of Membrane Science, 2014,461:39-48. |

| [3] | HONG J L, MIN K K, JUNG H P. Decompression stripping of carbon dioxide from rich monoethanolamine through porous hydrophobic modified ceramic hollow fiber membrane contactor. Separation and Purification Technology, 2020,236:1-8. |

| [4] | YANG N T, TAN X Y, MA Z F, et al. Fabrication and characterization of Ce0.8Sm0.2O1.9 microtubular dual-structured electrolyte membranes for application in solid oxide fuel cell technology. Journal of the American Ceramic Society, 2009,92(11):2544-2550. |

| [5] | KINGSBURY B F K, LI K. A morphological study of ceramic hollow fibre membranes. Journal of Membrane Science, 2009,328(1/2):134-140. |

| [6] | AZIZ M H A, OTHMAN M H D, HASHIM N A, et al. Fabrication and characterization of mullite ceramic hollow fiber membrane from natural occurring ball clay. Applied Clay Science, 2019,177:51-62. |

| [7] | HUBADILLAH S K, OTHMAN M H D, ISMAIL A F, et al. Fabrication of low cost, green silica based ceramic hollow fibre membrane prepared from waste rice husk for water filtration application. Ceramics International, 2018,44(9):10498-10509. |

| [8] | HENNE W, DUNWEG G, SCHMITZ W, et al. Method of Producing Dialyzing Membrane. US, D01F1/08, US04164437, 1979.08.14. |

| [9] | XIA Q C, LIU M L, CAO X L, et al. Structure design and applications of dual-layer polymeric membranes. Journal of Membrane Science, 2018,562:85-111. |

| [10] | ONG Y K, CHUNG T S. Pushing the limits of high performance dual-layer hollow fiber fabricated via (IPS)-P-2 process in dehydration of ethanol. AIChE Journal, 2013,59(8):3006-3018. |

| [11] | LI D F, CHUNG T S, WANG R. Morphological aspects and structure control of dual-layer asymmetric hollow fiber membranes formed by a simultaneous co-extrusion approach. Journal of Membrane Science, 2004,243(1-2):155-175. |

| [12] | SETIAWAN L, SHI L, KRANTZ W B, et al. Explorations of delamination and irregular structure in poly(amide-imide)-polyethersulfone dual layer hollow fiber membranes. Journal of Membrane Science, 2012,423:73-84. |

| [13] | KHAN I U, OTHMAN M H D, ISMAIL A F, et al. Status and improvement of dual-layer hollow fiber membranes via co-extrusion process for gas separation: a review. Journal of Natural Gas Science and Engineering, 2018,52:215-234. |

| [14] | SHI G M, WANG Y, CHUNG T S. Dual-layer PBI/P84 hollow fibers for pervaporation dehydration of acetone. AIChE Journal, 2012,58(4):1133-1145. |

| [15] | BONYADI S, CHUNG T S. Flux enhancement in membrane distillation by fabrication of dual layer hydrophilic-hydrophobic hollow fiber membranes. Journal of Membrane Science, 2007,306(1/2):134-146. |

| [16] | JONG J D, BENES N E, KOOPS G H, et al. Towards single step production of multi-layer inorganic hollow fibers. Journal of Membrane Science, 2004,239(2):265-269. |

| [17] | DROUSHIOTIS N, OTHMAN M H D, DORASWAMI U, et al. Novel co-extruded electrolyte-anode hollow fibres for solid oxide fuel cells. Electrochemistry Communications, 2009,11(9):1799-1802. |

| [18] | OTHMAN M H D, WU Z T, DROUSHIOTIS N, et al. Single-step fabrication and characterisations of electrolyte/anode dual-layer hollow fibres for micro-tubular solid oxide fuel cells. Journal of Membrane Science, 2010,351(1/2):196-204. |

| [19] | JAMIL S M, OTHMAN M H D, RAHMAN M A, et al. Properties and performance evaluation of dual-layer ceramic hollow fiber with modified electrolyte for MT-SOFC. Renewable Energy, 2019,134:1423-1433. |

| [20] | GONG X, MENG X X, YANG N T, et al. Electrolyte thickness control and its effect on YSZ/Ni-YSZ dual-layer hollow fibres. Journal of Inorganic Materials, 2013,28(10):1108-1114. |

| [21] | WU Z T, WANG B, LI K. A novel dual-layer ceramic hollow fibre membrane reactor for methane conversion. Journal of Membrane Science, 2010,352(1-2):63-70. |

| [22] | CHENG H D, WANG X B, MENG X, et al. Dual-layer BaCe0.8Y0.2O3-δ-Ce0.8Y0.2O2-δ/BaCe0.8Y0.2O3-δ-Ni hollow fiber membranes for H2 separation. Journal of Membrane Science, 2020,:117801-1-9. |

| [23] | CHONG J Y, WANG B, LI K. High performance stainless steel- ceramic composite hollow fibres for microfiltration. Journal of Membrane Science, 2017,541:425-433. |

| [24] | SHI Z Z, ZHANG Y T, CAI C, et al. Preparation and characterization of α-Al2O3 hollow fiber membranes with four-channel configuration. Ceramics International, 2015,41(1):1333-1339. |

| [25] | CAI C, ZHANG Y T, ZHANG C, et al. Microstructure modulation of α-Al2O3 hollow fiber membranes with four-channel geometric configuration. Asia-Pacific Journal of Chemical Engineering, 2016,11(6):949-957. |

| [26] | KALITA S J, SOMANI V. Al2TiO5-Al2O3-TiO2 nanocomposite: Structure, mechanical property and bioactivity studies. Materials Research Bulletin, 2010,45(12):1803-1810. |

| [27] | STANCIU L, GROZA J R, STOICA L, et al. Influence of powder precursors on reaction sintering of Al2TiO5. Scripta Materialia, 2004,50(9):1259-1262. |

| [28] | LEE M, WU Z, WANG R, et al. Micro-structured alumina hollow fibre membranes-potential applications in wastewater treatment. Journal of Membrane Science, 2014,461:39-48. |

| [29] |

ZHU L, JI J, WANG S, et al. Removal of Pb(II) from wastewater using Al2O3-NaA zeolite composite hollow fiber membranes synthesized from solid waste coal fly ash. Chemosphere, 2018,206:278-284.

DOI URL PMID |

| [30] | LEE M, WU Z, WANG B, et al. Micro-structured alumina multi- channel capillary tubes and monoliths. Journal of Membrane Science, 2015,489:64-72. |

| [31] | WANG B, LEE M, LI K. YSZ-reinforced alumina multi-channel capillary membranes for micro-filtration. Membranes, 2016,6:5. |

| [1] | AN Lin, WU Hao, HAN Xin, LI Yaogang, WANG Hongzhi, ZHANG Qinghong. Non-precious Metals Co5.47N/Nitrogen-doped rGO Co-catalyst Enhanced Photocatalytic Hydrogen Evolution Performance of TiO2 [J]. Journal of Inorganic Materials, 2022, 37(5): 534-540. |

| [2] | LÜ Qingyang, ZHANG Yuting, GU Xuehong. Fabrication of Hollow Fiber Supported TiO2 Ultrafiltration Membranes via Ultrasound-assisted Sol-Gel Method [J]. Journal of Inorganic Materials, 2022, 37(10): 1051-1057. |

| [3] | XIAO Xiang, GUO Shaoke, DING Cheng, ZHANG Zhijie, HUANG Hairui, XU Jiayue. CsPbBr3@TiO2 Core-shell Structure Nanocomposite as Water Stable and Efficient Visible-light-driven Photocatalyst [J]. Journal of Inorganic Materials, 2021, 36(5): 507-512. |

| [4] | XI Wen, LI Haibo. Preparation of TiO2/Ti3C2Tx Composite for Hybrid Capacitive Deionization [J]. Journal of Inorganic Materials, 2021, 36(3): 283-291. |

| [5] | LIU Cai, LIU Fang, HUANG Fang, WANG Xiaojuan. Preparation and Photocatalytic Properties of Alga-based CDs-Cu-TiO2 Composite Material [J]. Journal of Inorganic Materials, 2021, 36(11): 1154-1162. |

| [6] | Li Cuixia, SUN Huizhen, JIN Haize, SHI Xiao, LI Wensheng, KONG Wenhui. Construction and Photocatalytic Performance of 3D Hierarchical Pore rGO/TiO2 Composites [J]. Journal of Inorganic Materials, 2021, 36(10): 1039-1046. |

| [7] | WANG Ping,LI Xinyu,SHI Zhanling,LI Haitao. Synergistic Effect of Ag and Ag2O on Photocatalytic H2-evolution Performance of TiO2 [J]. Journal of Inorganic Materials, 2020, 35(7): 781-788. |

| [8] | JI Bang, ZHAO Wenfeng, DUAN Jieli, MA Lizhe, FU Lanhui, YANG Zhou. Synthesis of TiO2/WO3 on Nickel Foam for the Photocatalytic Degradation of Ethylene [J]. Journal of Inorganic Materials, 2020, 35(5): 581-588. |

| [9] | HUANG Xieyi,WANG Peng,YIN Guoheng,ZHANG Shaoning,ZHAO Wei,WANG Dong,BI Qingyuan,HUANG Fuqiang. Removal of Volatile Organic Compounds Driven by Platinum Supported on Amorphous Phosphated Titanium Oxide [J]. Journal of Inorganic Materials, 2020, 35(4): 482-490. |

| [10] | WANG Xucong, DENG Hao, JIANG Zhongyi, YUAN Liyong. Photocatalytic Reduction of Re (VII) on Amorphous TiO2/g-C3N4 Derived from Different N Sources [J]. Journal of Inorganic Materials, 2020, 35(12): 1340-1348. |

| [11] | CHEN Haoyu, ZHANG Yiwen, WU Zhong, QIN Zhenbo, WU Shanshan, HU Wenbin. Room Temperature Magnetoresistance Property of Co-TiO2 Nanocomposite Film Prepared by Strong Magnetic Target Co-sputtering [J]. Journal of Inorganic Materials, 2020, 35(11): 1263-1267. |

| [12] | ZHANG Ya-Ping, DING Wen-Ming, ZHU Hai-Feng, HUANG Cheng-Xing, YU Lian-Qing, WANG Yong-Qiang, LI Zhe, XU Fei. Photoelectrochemical Properties of MoSe2 Modified TiO2 Nanotube Arrays [J]. Journal of Inorganic Materials, 2019, 34(8): 797-802. |

| [13] | Xi-Qing LÜ, Huan-Yu ZHANG, Rui LI, Mei ZHANG, Min GUO. Nb2O5 Coating on the Performance of Flexible Dye Sensitized Solar Cell Based on TiO2 Nanoarrays/Upconversion Luminescence Composite Structure [J]. Journal of Inorganic Materials, 2019, 34(6): 590-598. |

| [14] | Gang JIAN, Mei-Rui LIU, Chen ZHANG, Hui SHAO. Preparation of Fully-coated Ag@TiO2 Particle Fillers for High-k Composites [J]. Journal of Inorganic Materials, 2019, 34(6): 641-645. |

| [15] | LI Yuan-Yang, JIANG Bo. λ/4-λ/2 Double-layer Broadband Antireflective Coatings with Superhydrophilicity and Photocatalysis [J]. Journal of Inorganic Materials, 2019, 34(2): 159-163. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||