Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (7): 817-821.DOI: 10.15541/jim20190450

Special Issue: 结构陶瓷论文精选(2020)

• RESEARCH PAPER • Previous Articles Next Articles

WANG Xi1,2,WANG Kejie1,BAI Hui1,SONG Zhuolin1,2,WANG Bo3,ZHANG Chengyu1,2( )

)

Received:2019-09-02

Revised:2019-10-27

Published:2020-07-20

Online:2019-12-04

Supported by:CLC Number:

WANG Xi,WANG Kejie,BAI Hui,SONG Zhuolin,WANG Bo,ZHANG Chengyu. Creep Properties and Damage Mechanisms of 2D-SiCf/SiC Composites Prepared by CVI[J]. Journal of Inorganic Materials, 2020, 35(7): 817-821.

| Diameter/μm | Density/(g?cm-3) | Tensile strength/GPa | Tensile modulus/GPa |

|---|---|---|---|

| 14 | 2.74 | 2.7 | 270 |

Table 1 Properties of the SiC fiber

| Diameter/μm | Density/(g?cm-3) | Tensile strength/GPa | Tensile modulus/GPa |

|---|---|---|---|

| 14 | 2.74 | 2.7 | 270 |

| Density/(g?cm-3) | Tensile strength/MPa | Tensile modulus/GPa | Porosity/% |

|---|---|---|---|

| 2.5 | 225 | 220 | ~23 |

Table 2 Properties of the SiCf/SiC composite

| Density/(g?cm-3) | Tensile strength/MPa | Tensile modulus/GPa | Porosity/% |

|---|---|---|---|

| 2.5 | 225 | 220 | ~23 |

| Temperature/ ℃ | Stress/ MPa | Rupture time/h | Steady-state creep strain rate/s-1 |

|---|---|---|---|

| 1200 | 100 | 216.0 | 6.1′10-9 |

| 1200 | 120 | 89.0 | 2.2′10-8 |

| 1200 | 140 | 50.0 | 4.5′10-8 |

| 1300 | 100 | 121.0 | 4.4′10-8 |

| 1300 | 120 | 53.0 | 4.9′10-8 |

| 1300 | 140 | 22.0 | 2.0′10-7 |

| 1400 | 100 | 8.6 | 1.5′10-6 |

Table 3 Creep properties of 2D-SiCf/SiC composites

| Temperature/ ℃ | Stress/ MPa | Rupture time/h | Steady-state creep strain rate/s-1 |

|---|---|---|---|

| 1200 | 100 | 216.0 | 6.1′10-9 |

| 1200 | 120 | 89.0 | 2.2′10-8 |

| 1200 | 140 | 50.0 | 4.5′10-8 |

| 1300 | 100 | 121.0 | 4.4′10-8 |

| 1300 | 120 | 53.0 | 4.9′10-8 |

| 1300 | 140 | 22.0 | 2.0′10-7 |

| 1400 | 100 | 8.6 | 1.5′10-6 |

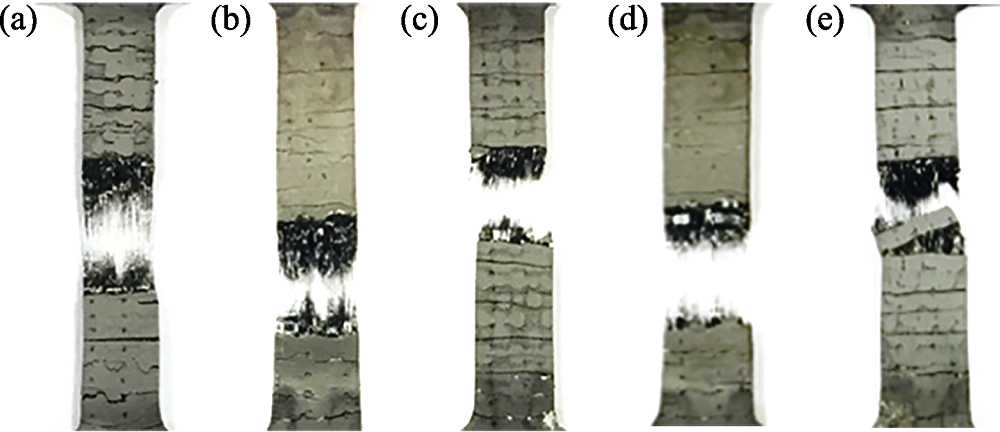

Fig. 3 Fracture morphologies of 2D-SiCf/SiC composites at different creep conditions (a) 1200 ℃/100 MPa; (b) 1200 ℃/120 MPa; (c) 1200 ℃/140 MPa; (d) 1300 ℃/100 MPa;(e) 1400 ℃/100 MPa

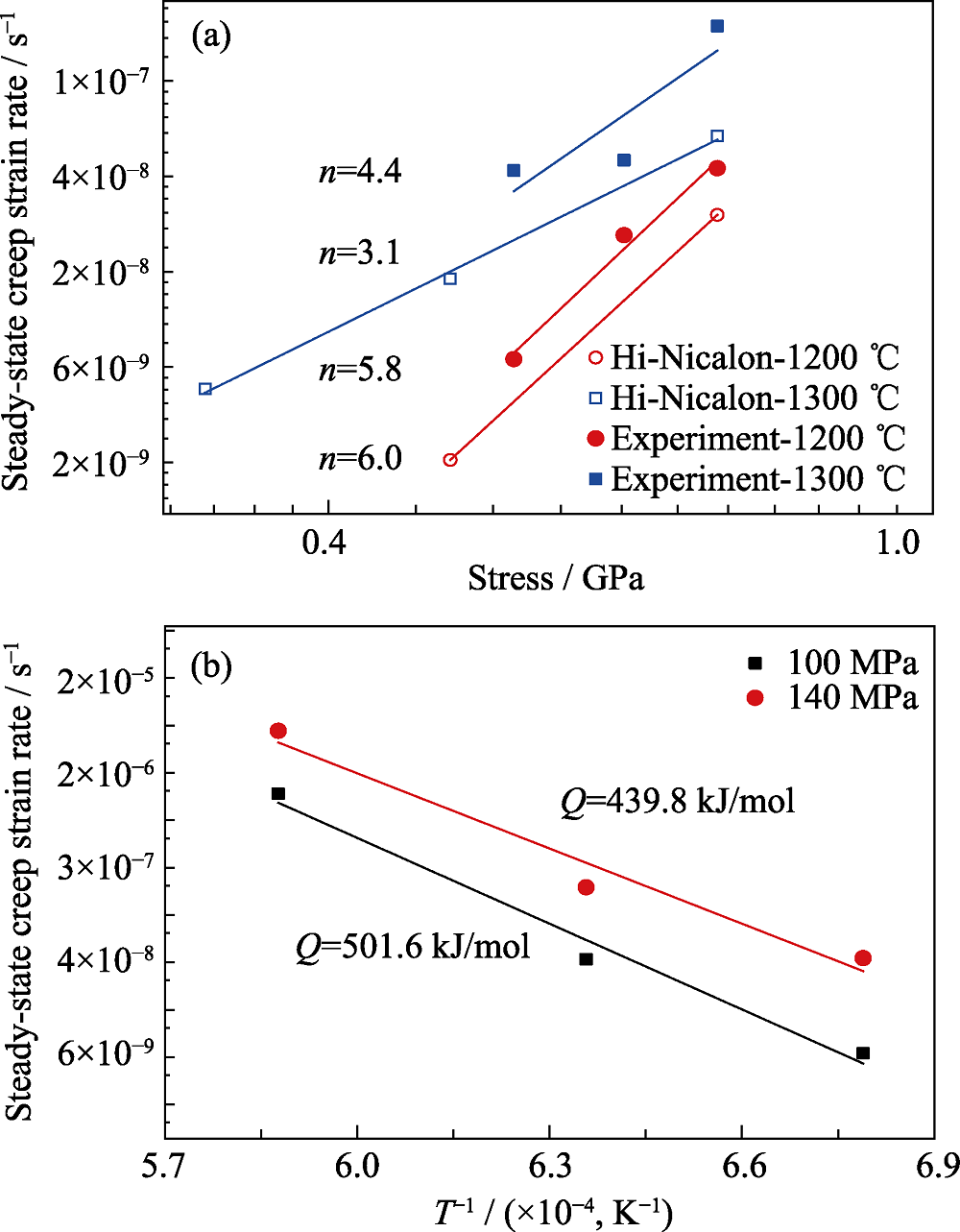

Fig. 5 Relationship between steady state creep strain rate and stress σ, temperature T (a) Steady-state creep strain rate versus stress; (b) Steady-state creep strain rate vs temperature

| [1] |

YUAN QIN, SONG YONG-CAI. Research and development of continuous SiC fibers and SiCf/SiC composites. Journal of Inorganic Materials, 2016,31(11):1157-1165.

DOI URL |

| [2] |

SCHMIDT S, BEYER S, KNABE H, et al. Advanced ceramic matrix composite materials for current and future propulsion technology applications. Acta Astronautica, 2004,55(3):409-420.

DOI URL |

| [3] | MORSCHER G N. Tensile creep and rupture of 2D-woven SiC/SiC composites for high temperature applications. Journal of the European Ceramic Socety, 2010,30(11):2209-2221. |

| [4] |

MORSCHER G N, JOHN R, ZAWADA L, et al. Creep in vacuum of woven sylramic-iBN melt-infiltrated composites. Composites Science and Technology, 2011,71(1):52-59.

DOI URL |

| [5] |

MORSCHER G N. Tensile creep of melt-infiltrated SiC/SiC composites with unbalanced sylramic-iBN fiber architectures. International Journal of Applied Ceramic Technology, 2011,8(2):239-250.

DOI URL |

| [6] |

DICARLO J A, YUN H M, HURST J B. Fracture mechanisms for SiC fibers and SiC/SiC composites under stress-rupture conditions at high temperatures. Applied Mathematics and Computation, 2004,152(2):473-481.

DOI URL |

| [7] |

VICENS J, ROUILLON M H, FOURVEL P, et al. TEM observations of SiC-SiC materials with a carbon interphase after tests at high temperature. Microscopy Microanalysis Microstructures, 1991,2(1):75-85.

DOI URL |

| [8] | SHI YING, ARAKI HIROSHI, YANG WEN, et al. Influence of fiber pre-coating on mechanical properties and interfacial structures of SiC(f)/SiC. Journal of Inorganic Materials, 2001,16(5):883-888. |

| [9] |

FABER K T, EVANS A G. Crack deflection processes—I. Theory. Acta Metallurgica, 1983,31(4):565-576.

DOI URL |

| [10] |

CHERMANT J L, BOITIER G, DARZENS S, et al. The creep mechanism of ceramic matrix composites at low temperature and stress, by a material science approach. Journal of the European Ceramic Society, 2002,22(14):2443-2460.

DOI URL |

| [11] |

DENG S, WARREN R. Creep properties of single crystal oxides evaluated by a Larson-Miller procedure. Journal of the European Ceramic Society, 1995,15(6):513-520.

DOI URL |

| [12] |

BODET R, BOURRAT X, LAMON J, et al. Tensile creep behavior of a silicon carbide-based fiber with a low oxygen content. Journal of Materials Science, 1995,30(3):661-677.

DOI URL |

| [13] |

CHOLLON G, PAILLER R, NASLAIN R, et al. Correlation between microstructure and mechanical behavior at high temperatures of a SiC fiber with a low oxygen content (Hi-Nicalon). Journal of Materials Science, 1997,32(5):1133-1147.

DOI URL |

| [14] | WANG YAN-YAN, ZHANG LI-TONG, TANG XUE-YUAN, et al. Effect of temperature on microstructure and mechanical properties of Hi-Nicalon fibers. Journal of the Chinese Ceramic Society, 2005,33(3):263-267. |

| [15] | HE XIN-BO, QU XUAN-HUI, YE BIN. Preparation and mechanical properties of SiCf/SiC Composites. Journal of Inorganic Materials, 2005,20(3):677-684. |

| [1] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [2] | WANG Yuanjie, PEI Xueliang, LI Haoyi, XU Xin, HE Liu, HUANG Zhengren, HUANG Qing. Crosslinking of Active Polycarbosilane Initiated by Free Radical and Its Application in the Preparation of SiC Fibers [J]. Journal of Inorganic Materials, 2021, 36(9): 967-973. |

| [3] | WANG Pengren, GOU Yanzi, WANG Hao. Third Generation SiC Fibers for Nuclear Applications [J]. Journal of Inorganic Materials, 2020, 35(5): 525-531. |

| [4] | Han-Qing YU, Zhi-Jun DONG, Guan-Ming YUAN, Ye CONG, Xuan-Ke LI, Yong-Ming LUO. Boron-carbon doped Silicon Carbide Fibers: Preparation and Property [J]. Journal of Inorganic Materials, 2019, 34(5): 493-501. |

| [5] | WANG Guo-Dong, SONG Yong-Cai. Enhancing Mechanical Property of SiC Fiber by Decreasing Fiber Diameter through a Modified Melt-spinning Process [J]. Journal of Inorganic Materials, 2018, 33(7): 721-727. |

| [6] | SHI Xu-Guo, LI Ming-Yuan, MA Wei-Gang, ZHOU Xin-Gui, ZHANG Xing. Experimental Study on Thermal Transport Property of KD-II SiC Fiber [J]. Journal of Inorganic Materials, 2018, 33(7): 756-760. |

| [7] | MU Yang, DENG Jia-Xin, LI Hao, ZHOU Wan-Cheng. Comparison of High-temperature Dielectric and Microwave Absorbing Property of Two Continuous SiC Fibers [J]. Journal of Inorganic Materials, 2018, 33(4): 427-433. |

| [8] | ZUO Ya-Zhuo, LI Hong, WANG Shao-Lei, YANG Min, REN Mu-Su, SUN Jin-Liang. Ablation Behavior of (C-SiC)f/C Composites [J]. Journal of Inorganic Materials, 2017, 32(11): 1141-1146. |

| [9] | CAO Shi-Yi, WANG Jun, WANG Hao, WANG Xiao-Zhou. Influence of Free Carbon Elimination on Microstructure and Property of SiC Fibers [J]. Journal of Inorganic Materials, 2016, 31(5): 529-534. |

| [10] | YUAN Qin, SONG Yong-Cai. Research and Development of Continuous SiC Fibers and SiCf/SiC Composities [J]. Journal of Inorganic Materials, 2016, 31(11): 1157-1165. |

| [11] | YUAN Wen-Yu, CHENG Lai-Fei,WU Heng, LIU Yong-Sheng. Effect of Silicon Source on Biomorphic SiC Fibers Converted from Natural Fibers [J]. Journal of Inorganic Materials, 2015, 30(2): 159-164. |

| [12] | ZHANG Rong-Jun, YANG Yan-Qing, SHEN Wen-Tao. Preparation and Tensile Test of SiC Fiber Fabricated by Three-stage Chemical Vapor Deposition [J]. Journal of Inorganic Materials, 2010, 25(8): 840-844. |

| [13] | LIU Xu-Guang,WANG Ying-De,WANG Lei,XUE Jin-Gen,LAN Xin-Yan. Preparation and Microwave Electromagnetic Properties of Cross-shaped SiC Fibers [J]. Journal of Inorganic Materials, 2010, 25(4): 441-444. |

| [14] | ZHANG Rong-Jun, YANG Yan-Qing, WANG Chen, SHEN Wen-Tao, LUO Xian. Microstructure of SiC Fiber Fabricated by Three-stage Chemical Vapor Deposition [J]. Journal of Inorganic Materials, 2010, 25(12): 1281-1285. |

| [15] | ZHAO Da-Fang,WANG Hai-Zhe,LI Xiao-Dong. Development of Polymer-Derived SiC Fiber [J]. Journal of Inorganic Materials, 2009, 24(6): 1097-1104. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||