Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (7): 796-802.DOI: 10.15541/jim20190418

Special Issue: 功能材料论文精选(一):光学材料(2020); 【虚拟专辑】透明陶瓷与光学晶体

• RESEARCH PAPER • Previous Articles Next Articles

HU Zewang1,2,CHEN Xiaopu1,2,LIU Xin1,2,LI Xiaoying1,2,SHI Yun1,KOU Huamin1,XIE Tengfei1,LI Jiang1,2( )

)

Received:2019-08-13

Revised:2019-09-30

Published:2020-07-20

Online:2019-12-04

Supported by:CLC Number:

HU Zewang,CHEN Xiaopu,LIU Xin,LI Xiaoying,SHI Yun,KOU Huamin,XIE Tengfei,LI Jiang. Trace SiO2 Addition on Optical and Scintillation Property of Pr:Lu3Al5O12 Ceramics[J]. Journal of Inorganic Materials, 2020, 35(7): 796-802.

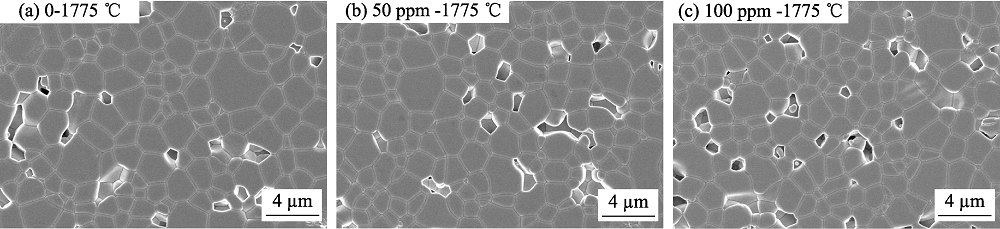

Fig. 3 FESEM images of the thermally etched Pr:LuAG ceramics with different SiO2 additives pre-sintered at 1775 ℃ for 5 h (a) 0; (b) 50 ppm; (c) 100 ppm

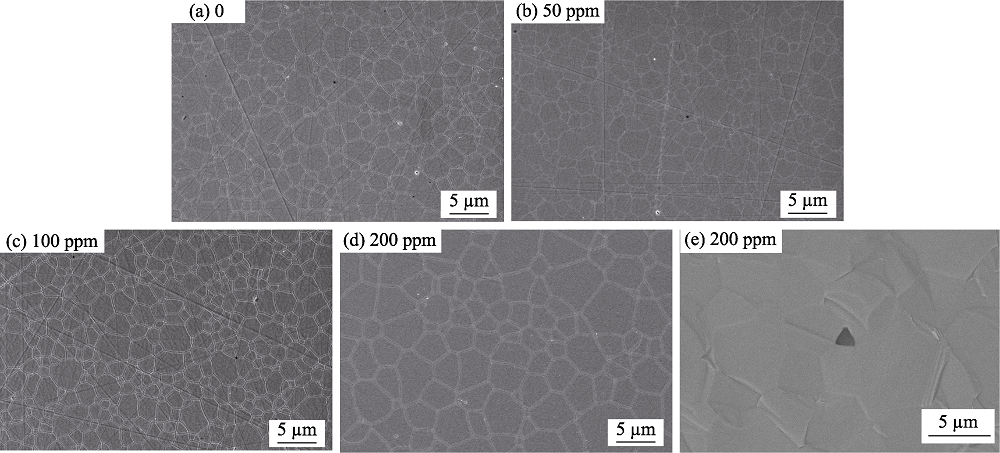

Fig. 5 FESEM images of the thermally etched surface (a-d) and fracture surface (e) of the HIPed Pr:LuAG ceramics with different SiO2 additives pre-sintered at 1775 ℃ for 5 h (a) 0 ppm; (b) 50 ppm; (c) 100 ppm; (d) 200 ppm; (e) 200 ppm

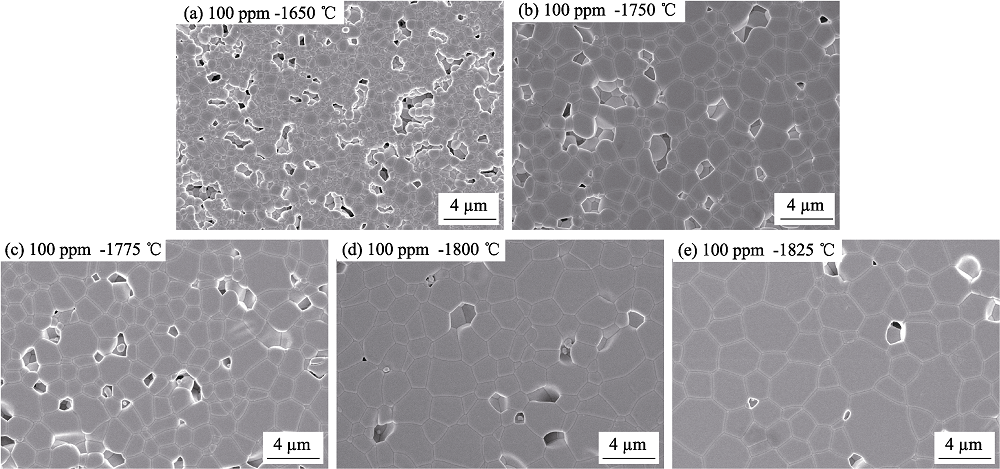

Fig. 6 FESEM images of the thermally etched Pr:LuAG ceramics pre-sintered at different temperatures for 5 h with 100 ppm SiO2 additive (a) 1650 ℃; (b) 1750 ℃; (c) 1775 ℃; (d) 1800 ℃; (e) 1825 ℃

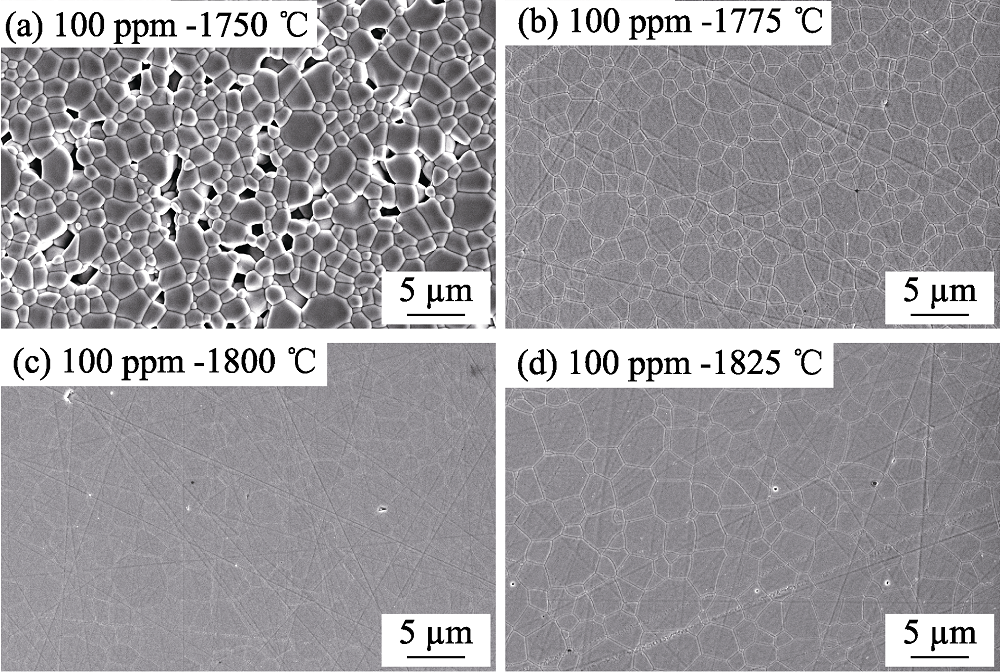

Fig. 8 FESEM images of the thermally etched HIPed Pr:LuAG ceramics pre-sintered at different temperatures for 5 h with 100 ppm SiO2 additive (a) 1750 ℃; (b) 1775 ℃; (c)1800 ℃; (d) 1825 ℃

| SiO2/ ppm | LY, ER @1 μs /(ph·MeV-1, %) | LY, ER @6 μs /(ph·MeV-1, %) | τ1/ns | τ2/ns | Ifast/% |

|---|---|---|---|---|---|

| 0 | 13033, 18.0 | 18091, 17.1 | 23.11 | 1476 | 46.4 |

| 50 | 12560, 16.5 | 15880, 15.3 | 23.75 | 1462 | 57.9 |

| 100 | 10686, 15.4 | 13453, 15.1 | 23.35 | 1343 | 58.2 |

| 150 | 9965, 15.8 | 12574, 15.4 | 21.41 | 1334 | 57.5 |

| 200 | 10104, 14.7 | 12726, 14.3 | 23.27 | 1340 | 58.1 |

Table 1 Light yield, energy resolution, scintillation decay and the intensity of fast component of the Pr:LuAG ceramics with different SiO2 additives

| SiO2/ ppm | LY, ER @1 μs /(ph·MeV-1, %) | LY, ER @6 μs /(ph·MeV-1, %) | τ1/ns | τ2/ns | Ifast/% |

|---|---|---|---|---|---|

| 0 | 13033, 18.0 | 18091, 17.1 | 23.11 | 1476 | 46.4 |

| 50 | 12560, 16.5 | 15880, 15.3 | 23.75 | 1462 | 57.9 |

| 100 | 10686, 15.4 | 13453, 15.1 | 23.35 | 1343 | 58.2 |

| 150 | 9965, 15.8 | 12574, 15.4 | 21.41 | 1334 | 57.5 |

| 200 | 10104, 14.7 | 12726, 14.3 | 23.27 | 1340 | 58.1 |

| [1] |

KAMADA K, YANAGIDA T, ENDO T, et al. Large size single crystal growth of Lu3Al5O12:Pr and their uniformity of scintillation properties. J. Cryst. Growth., 2012,352(1):91-94.

DOI URL |

| [2] |

CONTI M, ERIKSSON L, ROTHFUSS H, et al. Comparison of fast scintillators with TOF-PET potential. IEEE Trans. Nucl. Sci., 2009,56(3):926-933.

DOI URL |

| [3] | LI JIANG, CHEN XIAOPU, KOU HUAMIN, et al. Recent development on garnet single crystal and ceramic scintillators. J. Chin. Ceram. Soc., 2018,46(1):116-127. |

| [4] | LI JIANG, JIANG NAN, GE LIN, et al. Research development and future prospect of optical waveguide laser ceramics. Laser Optoelectron Prog., 2018,55(3):1-21. |

| [5] |

LI JIANG, DAI JIAWEI, PAN YUBAI. Research progress on magneto-optical transparent ceramics. J. Inorg. Mater., 2018,33(1):1-8.

DOI URL |

| [6] |

YANAGIDA T, FUJIMOTO Y, KAMADA K, et al. Scintillation properties of transparent ceramic Pr:LuAG for different Pr concentration. IEEE Trans. Nucl. Sci., 2012,59(5):2146-2151.

DOI URL |

| [7] |

LIU S P, FENG X Q, ZHOU Z W, et al. Effect of Mg2+ co-doping on the scintillation performance of LuAG:Ce ceramics. Phys. Status Solidi RRL., 2014,8(1):105-109.

DOI URL |

| [8] |

SHI Y, NIKL M, FENG X Q, et al. Microstructure, optical, and scintillation characteristics of Pr3+ doped Lu3Al5O12 optical ceramics. J. Appl. Phys., 2011,109(1):013522.

DOI URL |

| [9] |

SHEN Y Q, SHI Y, FENG X Q, et al. The harmful effects of sintering aids in Pr:LuAG optical ceramic scintillator. J. Am. Ceram. Soc., 2012,95(7):2130-2132.

DOI URL |

| [10] |

HU Z W, CAO M Q, CHEN H H, et al. The role of air annealing on the optical and scintillation properties of Mg co-doped Pr:LuAG transparent ceramics. Opt. Mater., 2017,72:201-207.

DOI URL |

| [11] |

MARIYA Z, ANDREY N, EVA M, et al. Crystal growth and scintillating properties of Zr/Si-Codoped YAlO:Pr3+. IEEE Trans. Nucl. Sci., 2008,55(3):1476-1479.

DOI URL |

| [12] |

STEVENSON A J, LI X, MARTINEZ M A, et al. Effect of SiO2 on densification and microstructure development in Nd:YAG transparent ceramics. J. Am. Ceram. Soc., 2011,94(5):1380-1387.

DOI URL |

| [13] |

YANG H, QIN X P, ZHANG J, et al. The effect of MgO and SiO2 codoping on the properties of Nd:YAG transparent ceramic. Opt. Mater., 2012,34(6):940-943.

DOI URL |

| [14] |

LEE S H, KUPP E R, STEVENSON A J, et al. Hot isostatic pressing of transparent Nd:YAG ceramics. J. Am. Ceram. Soc., 2009,92(7):1456-1463.

DOI URL |

| [15] |

SUÁREZ M, FERNÁNDEZ A, MENÉNDEZ J L, et al. Hot isostatic pressing of optically active Nd:YAG powders doped by a colloidal processing route. J. Eur. Ceram. Soc., 2010,30(6):1489-1494.

DOI URL |

| [16] |

SWIDERSKI L, MOSZYNSKI M, NASSALSKI A, et al. Light yield non-proportionality and energy resolution of praseodymium doped LuAG scintillator. IEEE Trans. Nucl. Sci., 2009,56(3):934-938.

DOI URL |

| [1] | YUAN Kang, LIAO Qi-Long, WANG Fu, DAI Yun-Ya, HUANG Jin-Shan. Effects of Sintering Aids (Y3+, La3+ and Mg2+) on the Optical Transmittance of Translucent Alumina Ceramic [J]. Journal of Inorganic Materials, 2017, 32(9): 1004-1008. |

| [2] | YE Le, Shi Jian, Li Huan-Ying, Chen Xiao-Feng, Huang Yue-Feng, XU Jia-Yue, REN Guo-Hao. Growth and Scintillation Properties of GdI3:Ce Crystal [J]. Journal of Inorganic Materials, 2017, 32(4): 346-350. |

| [3] | WANG Qing-Qing, SHI Jian, LI Huan-Ying, CHEN Xiao-Feng, PAN Shang-Ke, BIAN Jian-Jiang, REN Guo-Hao. Optical and Scintillation Properties of Cs2LiYCl6:Ce Crystal [J]. Journal of Inorganic Materials, 2017, 32(2): 175-179. |

| [4] | XU Jia-Yue, WANG Jie, CHEN Wei, XIAO Xue-Feng, YANG Bo-Bo, WANG Zhan-Yong, LI Fei, XIE Hui-Dong. Synthesis, Growth and Scintillation Properties of Large Size Bi4Si3O12 Crystals [J]. Journal of Inorganic Materials, 2016, 31(10): 1147-1150. |

| [5] | SHEN Yi-Qiang, SHI Yun, PAN Yu-Bai, FENG Xi-Qi, WU Le-Xiang, KOU Hua-Min, ZHANG Zhi-Ming, WEI Long. Fabrication and 2D-mapping of Pr: Lu3Al5O12 Scintillator Ceramics with High Light Yield and Fast Decay Time [J]. Journal of Inorganic Materials, 2014, 29(5): 534-538. |

| [6] | LI Mei-Juan, SHEN Qiang, LUO Guo-Qiang, ZHANG Lian-Meng. Effects of Li2O on Densification, Microstructure and Thermal Property of Spark Plasma Sintered AlN Ceramics [J]. Journal of Inorganic Materials, 2011, 26(6): 659-663. |

| [7] | JIANG Jiu-Xin,WANG Pei-Ling,CHENG Yi-Bing,CHEN Wei-Wu,ZHUANG Han-Rui,YAN Dong-Sheng. Sintering of β-Si3N4 Powder Derived by SHS [J]. Journal of Inorganic Materials, 2004, 19(6): 1431-1435. |

| [8] | WANG Yi-Lin,WU Wen-Jun,MAO Wen-Dong,ZHAO Mei-Yu. Fast Sintering Soft Ferrite Materials at Low Temperature [J]. Journal of Inorganic Materials, 2003, 18(3): 601-605. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||