Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (1): 29-34.DOI: 10.15541/jim20190400

Special Issue: MAX相和MXene材料; 陶瓷基复合材料; 结构陶瓷论文精选(2020); 【虚拟专辑】吸波材料(2020~2021); 【虚拟专辑】层状MAX,MXene及其他二维材料

Previous Articles Next Articles

DANG Xiao-Lin,FAN Xiao-Meng( ),YIN Xiao-Wei(

),YIN Xiao-Wei( ),MA Yu-Zhao,MA Xiao-Kang

),MA Yu-Zhao,MA Xiao-Kang

Received:2019-08-08

Revised:2019-09-26

Published:2020-01-20

Online:2019-10-25

About author:DANG Xiao-Lin (1996-), female, PhD candidate. E-mail:dangxl@mail.nwpu.edu.cn

Supported by:CLC Number:

DANG Xiao-Lin, FAN Xiao-Meng, YIN Xiao-Wei, MA Yu-Zhao, MA Xiao-Kang. Research Progress on Multi-functional Integration MAX Phases Modified Continuous Fiber-reinforced Ceramic Matrix Composites[J]. Journal of Inorganic Materials, 2020, 35(1): 29-34.

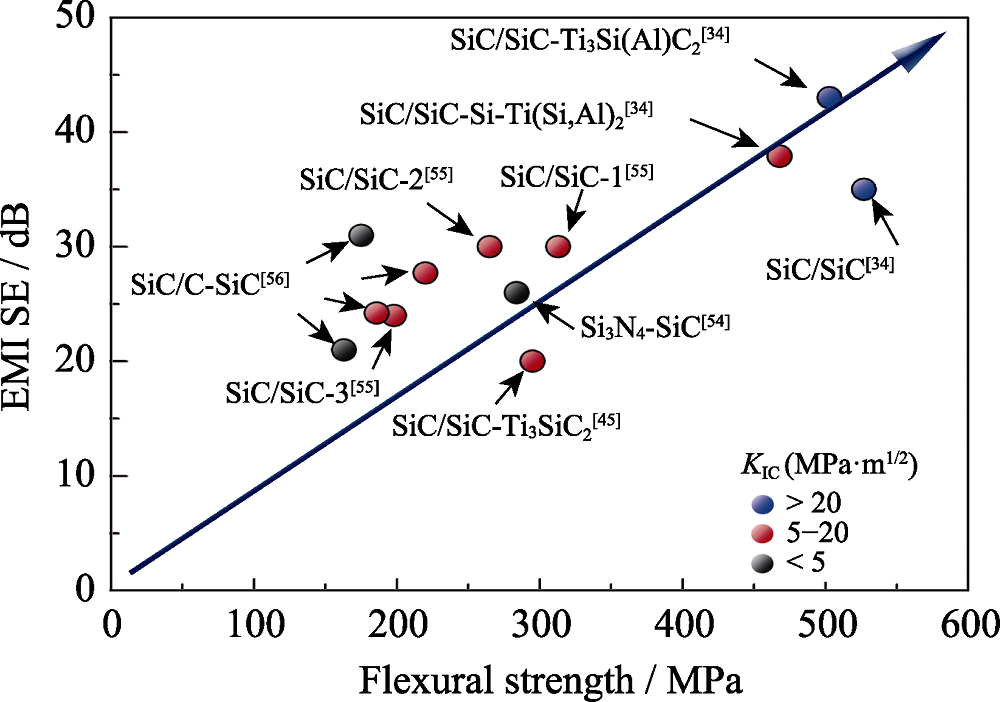

Fig. 5 The flexural strength, fracture toughness and electromagnetic interference (EMI) shielding effectiveness of SiC/ SiC-based composites[34,45,54-56]

| [1] |

YIN X W, CHENG L F, ZHANG L T , et al. Fibre-reinforced multifunctional SiC matrix composite materials. Int. Mater. Rev., 2017,62(3):117-172.

DOI URL |

| [2] |

NASLAIN R . Design, preparation and properties of non-oxide CMCs for application in engines and nuclear reactors: an overview. Compos. Sci. Technol., 2004,64(2):155-170.

DOI URL |

| [3] |

KRENKEL W, BERNDT F . C/C-SiC composites for space applications and advanced friction systems. Materials Science & Engineering A (Structural Materials: Properties, Microstructure and Processing), 2005,412(1):177-181.

DOI URL PMID |

| [4] |

MA Q S, LIU H T, PAN Y , et al. Research progress on the application of C/SiC composites in scramjet. J. Inorg. Mater., 2013,28(3):247-255.

DOI URL |

| [5] | 张立同 . 纤维增韧碳化硅陶瓷复合材料—模拟、表征与设计. 北京: 化学工业出版社, 2009. |

| [6] |

NOWOTNY V . Strukturchemie einiger verbindungen der übergangsmetalle mit den elementen C, Si, Ge, Sn. Prog. Solid State Chem., 1971,5(71):27-70.

DOI URL |

| [7] |

BARSOUM M W, EI-RAGHY T . Synthesis and characterization of a remarkable ceramic: Ti3SiC2. J. Am. Ceram. Soc., 1996,79(7):1953-1956.

DOI URL |

| [8] |

LI M, LI Y B, LUO K , et al. Synthesis of novel MAX phase Ti3ZnC2 via A-site-element-substitution approach J. Inorg. Mater., 2019,34(1):60-64.

DOI URL PMID |

| [9] |

ZHANG J, LIU B, WANG J Y , et al. Low-temperature instability of Ti2SnC: a combined transmission electron microscopy, differential scanning calorimetry, and x-ray diffraction investigations. J. Mater. Res., 2009,24(1):39-49.

DOI URL |

| [10] |

SUN Z M . Progress in research and development on MAX phases: a family of layered ternary compounds. Int. Mater. Rev., 2013,56(3):143-166.

DOI URL |

| [11] |

BARSOUM M W, RADOVIC M . Elastic and mechanical properties of the MAX phases. Ann. Rev. Mater. Res., 2011,41(1):195-227.

DOI URL PMID |

| [12] |

BARSOUM M W, EI-RAGHY T . The MAX phases: unique new carbide and nitride materials. Am. Sci., 2001,89(4):334-343.

DOI URL |

| [13] |

YANG C P, JIAO G Q, WANG B . Effects of interface properties on tensile strength of ceramic matrix composites. J. Inorg. Mater., 2009,24(5):919-923.

DOI URL PMID |

| [14] |

SNEAD L L, BURCHELL T D, KATOH Y . Swelling of nuclear graphite and high quality carbon fiber composite under very high irradiation temperature. J. Nucl. Mater., 2008,381(1/2):55-61.

DOI URL |

| [15] |

KATOH Y, OZAWA K, SHIH C , et al. Continuous SiC fiber, CVI SiC matrix composites for nuclear applications: properties and irradiation effects. J. Nucl. Mater., 2014,448(1/2/3):448-476.

DOI URL |

| [16] |

LI M, ZHOU X B, YANG H , et al. The critical issues of SiC materials for future nuclear systems. Scripta Mater., 2018,143:149-153.

DOI URL |

| [17] |

MA Y Z, YIN X W, FAN X M , et al. Modification and toughening of 3D needled C/SiC composite by deformable MAX phase-based matrix. Mat. Sci. Eng. A, 2018,712:397-405.

DOI URL |

| [18] |

WHITTLE K R, BLACKFORD M G, AUGHTERSON R D , et al. Radiation tolerance of Mn+1AXn phases, Ti3AlC2 and Ti3SiC2. Acta Mater., 2010,58(13):4362-4368.

DOI URL |

| [19] |

WANG C X, YANG T F, TRACY C L , et al. Role of the X and n factors in ion-irradiation induced phase transformations of Mn+1AXn phases. Acta Mater., 2018,144:432-446.

DOI URL |

| [20] |

WANG C X, YANG T F, TRACY C L , et al. Disorder in Mn+1AXn phases at the atomic scale. Nat. Commun., 2019,10(1):622.

DOI URL PMID |

| [21] |

WANG C X, YANG T F, XIAO J R , et al. Irradiation-induced structural transitions in Ti2AlC. Acta Mater., 2015,98:197-205.

DOI URL |

| [22] |

WANG X H, ZHOU Y C . Layered machinable and electrically conductive Ti2AlC and Ti3AlC2 ceramics: a review. J. Mater. Sci. Technol., 2010,26(5):385-416.

DOI URL |

| [23] |

FAKIH H, JACQUES S, DEZELLUS O , et al. Phase equilibria and reactive chemical vapor deposition (RCVD) of Ti3SiC2. Journal of Phase Equilibria and Diffusion, 2008,29(3):239-246.

DOI URL |

| [24] |

JACQUES S, FAKIH H, VIALA J C . Reactive chemical vapor deposition of Ti3SiC2 with and without pressure pulses: effect on the ternary carbide texture. Thin Solid Films, 2010,518(18):5071-5077.

DOI URL |

| [25] |

FILBERT-DEMUT I, TRAVITZKY N, MOTZ G , et al. Polymer derived ceramics reinforced with Ti3SiC2 coated SiC fibers: a feasibility study. Mater. Lett., 2015,145:229-231.

DOI URL |

| [26] |

FILBERT-DEMUT I, BEI G, HÖSCHEN T , et al. Influence of Ti3SiC2 fiber coating on interface and matrix cracking in an SiC fiber-reinforced polymer-derived ceramic. Adv. Eng. Mater., 2015,17(8):1142-1148.

DOI URL |

| [27] |

LEE H G, KIM D, JEONG Y S , et al. Formation of Ti3SiC2 interphase of SiC fiber by electrophoretic deposition method. Journal of the Korean Ceramic Society, 2016,53(1):87-92.

DOI URL |

| [28] |

LEE H G, KIM D, PARK J Y , et al. Formation of Ti3SiC2 interphase coating on SiCf/SiC composite by electrophoretic deposition. Inter. J. Appl. Ceram. Tec., 2017,15(3):602-610.

DOI URL |

| [29] |

LI M, WANG K, WANG J , et al. Preparation of TiC/Ti2AlC coating on carbon fiber and investigation of the oxidation resistance properties. J. Am. Ceram. Soc., 2018,101(11):5269-5280.

DOI URL |

| [30] |

GILBERT C J, BLOYER D R, BARSOUM M W , et al. Fatigue- crack growth and fracture properties of coarse and fine-grained Ti3SiC2. Scripta Mater., 2000,42(8):761-767.

DOI URL |

| [31] |

YIN X W, HE S S, ZHANG L T , et al. Fabrication and characterization of a carbon fibre reinforced carbon-silicon carbide- titanium silicon carbide hybrid matrix composite. Mat. Sci. Eng. A-Struct., 2010,527(3):835-841.

DOI URL |

| [32] |

LU C Y, YIN X W, LI X M . A novel in-situ synthesis route of Ti3SiC2-SiC composite by liquid silicon infiltration. J. Inorg. Mater., 2010,25(9):1003-1008.

DOI URL |

| [33] |

FAN X M, YIN X W, WANG L , et al. Processing, microstructure and ablation behavior of C/SiC-Ti3SiC2 composites fabricated by liquid silicon infiltration. Corros. Sci., 2013,74:98-105.

DOI URL |

| [34] |

MA X K, YIN X W, FAN X M , et al. Microstructure and properties of dense Tyranno-ZMI SiC/SiC containing Ti3Si(Al)C2 with plastic deformation toughening mechanism. J. Eur. Ceram. Soc., 2018,38(4):1069-1078.

DOI URL |

| [35] |

DONG N, CHEN L Q, YIN X W , et al. Fabrication and electromagnetic interference shielding effectiveness of Ti3Si(Al)C2 modified Al2O3/SiC composites. Ceram. Int., 2016,42(8):9448-9454.

DOI URL |

| [36] |

FAN X M, YIN X W, CHEN L Q , et al. Mechanical behavior and electromagnetic interference shielding properties of C/SiC-Ti3Si(Al)C2. J. Am. Ceram. Soc., 2016,99(5):1717-1724.

DOI URL |

| [37] |

LENZ F, KRENKEL W . Fabrication of fiber composites with a MAX phase matrix by reactive melt infiltration. IOP Conference Series: Materials Science and Engineering, 2011,18(20):202030.

DOI URL |

| [38] |

LENZ F, KRENKEL W . Carbon fiber reinforced ceramics based on reactive melt infiltration processes. Journal of the Korean Ceramic Society, 2012,49(4):287-294.

DOI URL |

| [39] |

SPENCER C B, CÓRDOBA J M, OBANDO N H , et al. The reactivity of Ti2AlC and Ti3SiC2 with SiC fibers and powders up to temperatures of 1550 ℃. J. Am. Ceram. Soc., 2011,94(6):1737-1743.

DOI URL |

| [40] |

ZHANG J W, HU C F, WANG Y G , et al. Interfacial reactions between polymer derived SiC fiber and Ti3Si(Al)C2. Key Eng. Mater., 2013,544:238-244.

DOI URL |

| [41] |

GUO S Q, HU C F, GAO H , et al. SiC(SCS-6) fiber-reinforced Ti3AlC2 matrix composites: interfacial characterization and mechanical behavior. J. Eur. Ceram. Soc., 2015,35(5):1375-1384.

DOI URL |

| [42] |

GUO S Q . Improvement of mechanical properties of SiC(SCS-6) fibre-reinforced Ti3AlC2 matrix composites with Ti barrier layer. J. Eur. Ceram. Soc., 2016,36(6):1349-1358.

DOI URL |

| [43] |

YANG J S, DONG S M, XU C Y . Mechanical response and microstructure of 2D carbon fiber reinforced ceramic matrix composites with SiC and Ti3SiC2 fillers. Ceram. Int., 2016,42(2):3019-3027.

DOI URL |

| [44] | YANG J S, DONG S M, HE P , et al. Fabrication Fabrication and properties of Cf/Ti3SiC2-SiC composites using Ti3SiC2 as inert filler. Key Eng. Mater., 2012,512-515:681-684. |

| [45] |

MU Y, ZHOU W C, WAN F , et al. High-temperature dielectric and electromagnetic interference shielding properties of SiCf/SiC composites using Ti3SiC2 as inert filler. Composites Part A: Applied Science and Manufacturing, 2015,77:195-203.

DOI URL |

| [46] |

SONG G M, LI S B, ZHAO C X , et al. Ultra-high temperature ablation behavior of Ti2AlC ceramics under an oxyacetylene flame. J. Eur. Ceram. Soc., 2011,31(5):855-862.

DOI URL |

| [47] |

SHEN X T, LI K Z, LI H J , et al. Microstructure and ablation properties of zirconium carbide doped carbon/carbon composites. Carbon, 2010,48(2):344-351.

DOI URL |

| [48] |

SONG G M, WANG Y J, ZHOU Y . Elevated temperature ablation resistance and thermophysical properties of tungsten matrix composites reinforced with ZrC particles. J. Mater. Sci., 2001,36(19):4625-4631.

DOI URL |

| [49] |

HU S J, LI S B, LI H L , et al. Oxyacetylene torch testing and microstructural characterization of a Cr2AlC ceramic. J. Alloys Compd., 2018,740:77-81.

DOI URL |

| [50] |

LI H L, LI S B, ZHANG L Q , et al. Synthesis and ultra-high temperature ablation behavior of a ZrC/Cr2AlC composite. Ceram. Int., 2016,42(5):5686-5692.

DOI URL |

| [51] |

ZHOU Y C, HE L F, LIN Z J , et al. Synthesis and structure- property relationships of a new family of layered carbides in Zr-Al(Si)-C and Hf-Al(Si)-C systems. J. Eur. Ceram. Soc., 2013,33(15/16):2831-2865.

DOI URL |

| [52] |

MA Y Z, YIN X W, FAN X M , et al. Ablation behavior of Zr-Al(Si)-C layered carbides modified 3D needled C/SiC composites. Adv. Eng. Mater., 2019,21(6):1800936.

DOI URL |

| [53] |

FAN X M, YIN X W, CAI Y Z , et al. Mechanical and electromagnetic interference shielding behavior of C/SiC composite containing Ti3SiC2. Adv. Eng. Mater., 2018,20(2):1700590.

DOI URL |

| [54] |

LI X M, ZHANG L T, YIN X W , et al. Effect of chemical vapor infiltration of SiC on the mechanical and electromagnetic properties of Si3N4-SiC ceramic. Scripta Mater., 2010,63(6):657-660.

DOI URL |

| [55] |

MU Y, ZHOU W C, WANG C , et al. Mechanical and electromagnetic shielding properties of SiCf/SiC composites fabricated by combined CVI and PIP process. Ceram. Int., 2014,40(7):10037-10041.

DOI URL |

| [56] |

WANG H Y, ZHU D M, MU Y , et al. Effect of SiC/C preform densities on the mechanical and electromagnetic interference shielding properties of dual matrix SiC/C-SiC composites. Ceram. Int., 2015,41(10):14094-14100.

DOI URL |

| [1] | DING Ling, JIANG Rui, TANG Zilong, YANG Yunqiong. MXene: Nanoengineering and Application as Electrode Materials for Supercapacitors [J]. Journal of Inorganic Materials, 2023, 38(6): 619-633. |

| [2] | YANG Zhuo, LU Yong, ZHAO Qing, CHEN Jun. X-ray Diffraction Rietveld Refinement and Its Application in Cathode Materials for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2023, 38(6): 589-605. |

| [3] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [4] | LIN Junliang, WANG Zhanjie. Research Progress on Ferroelectric Superlattices [J]. Journal of Inorganic Materials, 2023, 38(6): 606-618. |

| [5] | NIU Jiaxue, SUN Si, LIU Pengfei, ZHANG Xiaodong, MU Xiaoyu. Copper-based Nanozymes: Properties and Applications in Biomedicine [J]. Journal of Inorganic Materials, 2023, 38(5): 489-502. |

| [6] | YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(5): 477-488. |

| [7] | DU Jianyu, GE Chen. Recent Progress in Optoelectronic Artificial Synapse Devices [J]. Journal of Inorganic Materials, 2023, 38(4): 378-386. |

| [8] | YANG Yang, CUI Hangyuan, ZHU Ying, WAN Changjin, WAN Qing. Research Progress of Flexible Neuromorphic Transistors [J]. Journal of Inorganic Materials, 2023, 38(4): 367-377. |

| [9] | YOU Junqi, LI Ce, YANG Dongliang, SUN Linfeng. Double Dielectric Layer Metal-oxide Memristor: Design and Applications [J]. Journal of Inorganic Materials, 2023, 38(4): 387-398. |

| [10] | LIN Siqi, LI Airan, FU Chenguang, LI Rongbing, JIN Min. Crystal Growth and Thermoelectric Properties of Zintl Phase Mg3X2 (X=Sb, Bi) Based Materials: a Review [J]. Journal of Inorganic Materials, 2023, 38(3): 270-279. |

| [11] | CHEN Kunfeng, HU Qianyu, LIU Feng, XUE Dongfeng. Multi-scale Crystallization Materials: Advances in in-situ Characterization Techniques and Computational Simulations [J]. Journal of Inorganic Materials, 2023, 38(3): 256-269. |

| [12] | ZHANG Chaoyi, TANG Huili, LI Xianke, WANG Qingguo, LUO Ping, WU Feng, ZHANG Chenbo, XUE Yanyan, XU Jun, HAN Jianfeng, LU Zhanwen. Research Progress of ScAlMgO4 Crystal: a Novel GaN and ZnO Substrate [J]. Journal of Inorganic Materials, 2023, 38(3): 228-242. |

| [13] | QI Zhanguo, LIU Lei, WANG Shouzhi, WANG Guogong, YU Jiaoxian, WANG Zhongxin, DUAN Xiulan, XU Xiangang, ZHANG Lei. Progress in GaN Single Crystals: HVPE Growth and Doping [J]. Journal of Inorganic Materials, 2023, 38(3): 243-255. |

| [14] | XIE Bing, CAI Jinxia, WANG Tongtong, LIU Zhiyong, JIANG Shenglin, ZHANG Haibo. Research Progress of Polymer-based Multilayer Composite Dielectrics with High Energy Storage Density [J]. Journal of Inorganic Materials, 2023, 38(2): 137-147. |

| [15] | LIU Yan, ZHANG Keying, LI Tianyu, ZHOU Bo, LIU Xuejian, HUANG Zhengren. Electric-field Assisted Joining Technology for the Ceramics Materials: Current Status and Development Trend [J]. Journal of Inorganic Materials, 2023, 38(2): 113-124. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||