Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (1): 8-18.DOI: 10.15541/jim20190282

Special Issue: MAX相和MXene材料; 二维材料; 功能陶瓷论文精选(二); MXene材料专辑(2020~2021); 【虚拟专辑】层状MAX,MXene及其他二维材料; 【虚拟专辑】柔性材料(2020~2021)

Previous Articles Next Articles

YANG Yi-Na1,2,WANG Ran-Ran1,SUN Jing1( )

)

Received:2019-06-11

Revised:2019-07-05

Published:2020-01-20

Online:2019-10-23

About author:YANG Yi-Na (1992-), female, PhD candidate. E-mail:yangyina@student.sic.ac.cn

Supported by:CLC Number:

YANG Yi-Na, WANG Ran-Ran, SUN Jing. MXenes in Flexible Force Sensitive Sensors: a Review[J]. Journal of Inorganic Materials, 2020, 35(1): 8-18.

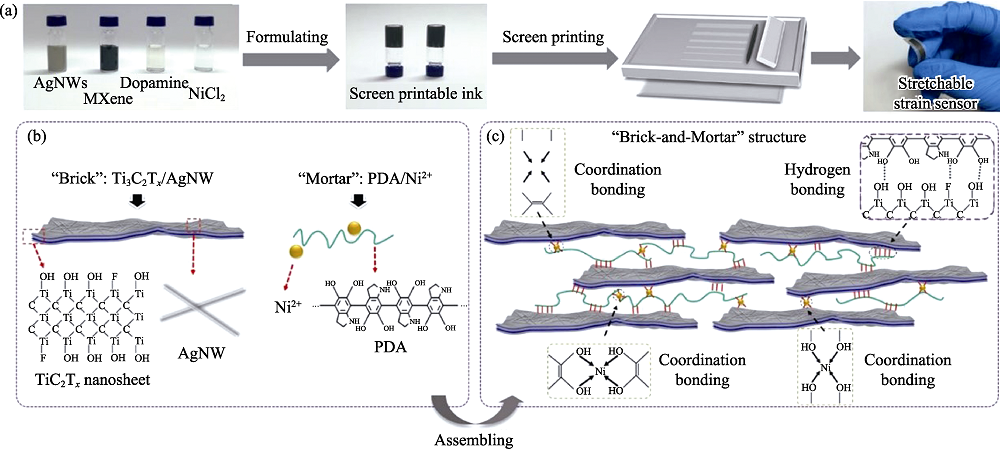

Fig. 3 (a) Schematic of the fabrication process for the bioinspired Ti3C2Tx-AgNW-PDA/Ni2+ sensor fabricated through the screen-printing method; (b) Schematic illustration of the structures for the “brick” materials (Ti3C2Tx and AgNWs) and “mortar” material (PDA/Ni2+); (c) Schematic illustration of the Ti3C2Tx-AgNW-PDA/Ni2+ sensor based on the “brick-and-mortar” architecture[56]

Fig. 4 Electromechanical properties of M-hydrogel composite and mechanisms Electrical response of M-hydrogel to (a) tensile strain and (b) compressive strain, with insets showing the corresponding GFs; Scanning electron microscopy (SEM) images of M-hydrogel surface (c) before and (d) after stretching; (e-f) Schematic illustration for the mechanism of the electromechanical responses from M-hydrogel[58]

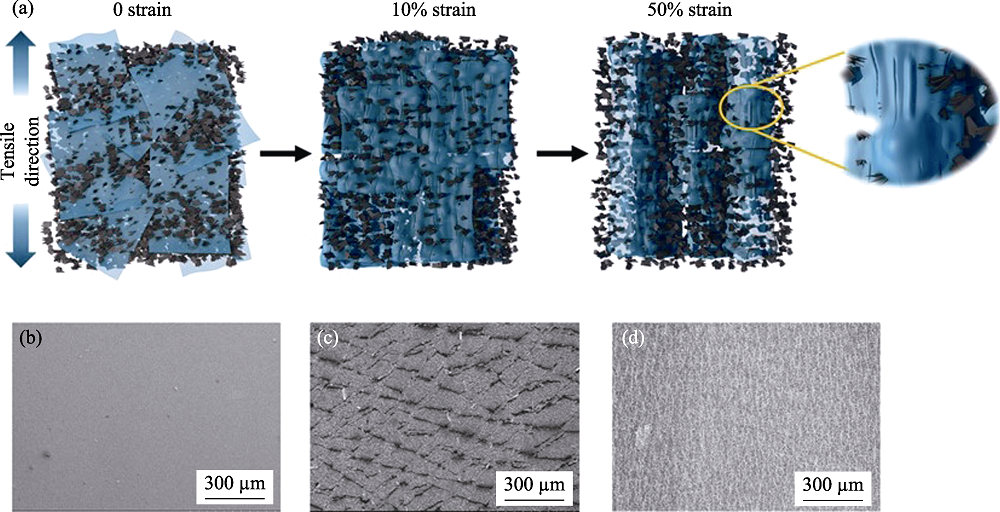

Fig. 5 (a) Schematic diagram of the HF18 h-d20 min-Ti3C2Tx conductive film at various stretching states during the first stretching-releasing cycle. Top-view SEM images of (b) HF6 h-d3 h-Ti3C2Tx-, (c) TMA-Ti3C2Tx-, and (d) HF18 h-d20 min-Ti3C2Tx-based strain sensors in the maximum tensile state[15]

| [1] |

BARLION A A, PARK W T, MALLON J R , et al. Review: semiconductor piezoresistance for microsystems. Proc. IEEE Inst. Electr. Electron. Eng., 2009,97(3):513-552.

DOI URL PMID |

| [2] |

CHORTOS A, LIU J, BAO Z . Pursuing prosthetic electronic skin. Nat. Mater., 2016,15(9):937-950.

DOI URL PMID |

| [3] |

AMJADI M, KYUNG K U, PARK I , et al. Stretchable, skin- mountable, and wearable strain sensors and their potential applications: a review. Adv. Funct. Mater., 2016,26(11):1678-1698.

DOI URL |

| [4] |

NIE P, WANG R, XU X , et al. High-performance piezoresistive electronic skin with bionic hierarchical microstructure and microcracks. ACS Appl. Mater. Interfaces, 2017,9(17):14911-14919.

DOI URL PMID |

| [5] |

XU X, WANG R, NIE P , et al. Copper nanowire-based aerogel with tunable pore structure and its application as flexible pressure sensor. ACS Appl. Mater. Interfaces, 2017,9(16):14273-14280.

DOI URL PMID |

| [6] |

BAE G Y, PARK S, KIM D , et al. Linearly and highly pressure- sensitive electronic skin based on a bioinspired hierarchical structural array. Adv. Mater., 2016,28(26):5300-5306.

DOI URL PMID |

| [7] |

PAN L, CHORTOS A, YU G , et al. An ultra-sensitive resistive pressure sensor based on hollow-sphere microstructure induced elasticity in conducting polymer film. Nat. Commun., 2014,5:3002.

DOI URL PMID |

| [8] |

TRUNG T Q, LEE N E . Flexible and stretchable physical sensor integrated platforms for wearable human-activity monitoringand personal healthcare. Adv. Mater., 2016,28(22):4338-4372.

DOI URL PMID |

| [9] |

GONG S, SCHWALB W, WANG Y , et al. A wearable and highly sensitive pressure sensor with ultrathin gold nanowires. Nat. Commun., 2014,5:3132.

DOI URL PMID |

| [10] |

JIAN M, XIA K, WANG Q , et al. Flexible and highly sensitive pressure sensors based on bionic hierarchical structures. Adv. Funct. Mater., 2017,27(9):1606066.

DOI URL |

| [11] |

KIM D H, XIAO J, SONG J , et al. Stretchable, curvilinear electronics based on inorganic materials. Adv. Mater., 2010,22(19):2108-2124.

DOI URL PMID |

| [12] |

SHENG L, LIANG Y, JIANG L , et al . Bubble-decorated honeycomb-like graphene film as ultrahigh sensitivity pressure sensors. Adv. Funct. Mater., 2015,25(41):6545-6551.

DOI URL |

| [13] |

KIM J, LEE S W, KIM M H , et al. Zigzag-shaped silver nanoplates: synthesis via ostwald ripening and their application in highly sensitive strain sensors. ACS Appl. Mater. Interfaces, 2018,10(45):39134-39143.

DOI URL PMID |

| [14] |

BOLAND CONOR S, KHAN UMAR, BACKES CLAUDAI , et al. Sensitive, high-strain, high-rate bodily motion sensors based on graphene rubber composites. ACS Nano, 2014,8(9):8819-8830.

DOI URL PMID |

| [15] |

YANG Y, SHI L, CAO Z , et al. Strain sensors with a high sensitivity and a wide sensing range based on a Ti3C2Tx( MXene) nanoparticle- nanosheet hybrid network. Adv Funct. Mater., 2019,29(14):1807882.

DOI URL |

| [16] |

SHI X, LIU S, SUN Y , et al. Lowering internal friction of 0D-1D-2D ternary nanocomposite-based strain sensor by fullerene to boost the sensing performance. Adv. Funct. Mater., 2018,28(22):1800850.

DOI URL |

| [17] |

PARK J, LEE Y, HONG J , et al. Tactile-direction-sensitive and stretchable electronic skins based on human-skin-inspired interlocked microstructures. ACS Nano, 2014,8(12):12020-12029.

DOI URL PMID |

| [18] |

BOLAND C, KHAN U, RYAN G , et al. Sensitive electromechanical sensors using viscoelastic graphene-polymer nanocomposites. Science, 2016,354(6317):1257-1260.

DOI URL PMID |

| [19] |

PARK J, LEE Y, HONG J , et al. Giant tunneling piezoresistance of composite elastomers with interlocked microdome arrays for ultrasensitive and multimodal electronic skins. ACS Nano, 2014,8(5):4689-4697.

DOI URL PMID |

| [20] |

COHEN D J, MITRA D, PETERSON K , et al. A highly elastic, capacitive strain gauge based on percolating nanotube networks. Nano Lett., 2012,12(4):1821-1825.

DOI URL PMID |

| [21] |

PANG C, LEE G Y, KIM T I , et al. A flexible and highly sensitive strain-gauge sensor using reversible interlocking of nanofibres. Nat. Mater., 2012,11(9):795-801.

DOI URL PMID |

| [22] |

CHENG Y, WANG R, SUN J , et al. A stretchable and highly sensitive graphene-based fiber for sensing tensile strain, bending, and torsion. Adv. Mater., 2015,27(45):7365-7371.

DOI URL PMID |

| [23] |

MANNSFELD S C, TEE B C, STOLTENBERG R , et al. Highly sensitive flexible pressure sensors with microstructured rubber dielectric layers. Nat. Mater., 2010,9(10):859-864.

DOI URL PMID |

| [24] |

WANG X, GU Y, XIONG Z , et al. Silk-molded flexible, ultrasensitive, and highly stable electronic skin for monitoring human physiological signals. Adv. Mater., 2014,26(9):1336-1342.

DOI URL |

| [25] |

CAO Z, WANG R, HE T , et al. Interface-controlled conductive fibers for wearable strain sensors and stretchable conducting wires. ACS Appl. Mater. Interfaces, 2018,10(16):14087-14096.

DOI URL PMID |

| [26] |

LEE J, KIM S, LEE J , et al. A stretchable strain sensor based on a metal nanoparticle thin film for human motion detection. Nanoscale, 2014,6(20):11932-11939.

DOI URL |

| [27] |

BOLAND C S, KHAN U, BENAMUR H , et al. Surface coatings of silver nanowires lead to effective, high conductivity, high-strain, ultrathin sensors. Nanoscale, 2017,9(46):18507-18515.

DOI URL PMID |

| [28] |

NUR R, MATSUHISA N, JIANG Z , et al. A highly sensitive capacitive-type strain sensor using wrinkled ultrathin gold films. Nano Lett., 2018,18(9):5610-5617.

DOI URL PMID |

| [29] |

WANG Y, WANG Y, YANG Y . Graphene-polymer nanocomposite-based redox-induced electricity for flexible self-powered strain sensors. Adv. Energy Mater., 2018,8(22):1800961.

DOI URL |

| [30] |

LEE J, PYO S, KWON D S , et al. Ultrasensitive strain sensor based on separation of overlapped carbon nanotubes. Small, 2019,15(12):1805120.

DOI URL PMID |

| [31] |

ZHOU J, XU X, XIN Y , et al. Coaxial thermoplastic elastomer- wrapped carbon nanotube fibers for deformable and wearable strain sensors. Adv. Funct. Mater., 2018,28(16):1705591.

DOI URL PMID |

| [32] |

KIM KH, JANG NS, HA SH , et al. Highly sensitive and stretchable resistive strain sensors based on microstructured metal nanowire/elastomer composite films. Small, 2018,14(14):1704232.

DOI URL PMID |

| [33] |

OH J, YANG J, KIM J , et al. Pressure insensitive strain sensor with facile solution-based process for tactile sensing applications. ACS Nano, 2018,12(8):7546-7553.

DOI URL PMID |

| [34] |

LI X, ZHANG R, YU W , et al. Stretchable and highly sensitive graphene-on-polymer strain sensors. Sci. Rep., 2012,2:870.

DOI URL PMID |

| [35] |

NAGUIB M, KURTOGLU M, PRESSER V , et al. Two-dimensional nanocrystals produced by exfoliation of Ti3AlC2. Adv. Mater., 2011,23(37):4248-4253.

DOI URL PMID |

| [36] |

NAGUIB M, JOSHUA C, PRESSER V , et al. Two-dimensional transition metal carbides. ACS Nano, 2012,6(2):1322-1331.

DOI URL PMID |

| [37] |

NAGUIB M, MOCHALIN V N, BARSOUM M W , et al. 25th anniversary article: MXenes: a new family of two-dimensional materials. Adv Mater, 2014,26(7):992-1005.

DOI URL |

| [38] |

LEI J, ZHANG X, ZHOU Z . Recent advances in MXene: preparation, properties, and applications. Frontiers of Physics, 2015,10(3):276-286.

DOI URL PMID |

| [39] |

WANG H, CAO H, ZHANG J . Research progress of novel two-dimensional material MXene. Journal of Inorganic Materials, 2017,32(6):561-570.

DOI URL |

| [40] |

XIU L, WANG Z, YU M , et al. Aggregation-resistant 3D MXene-based architecture as efficient bifunctional electrocatalyst for overall water splitting. ACS Nano, 2018,12(8):8017-8028.

DOI URL PMID |

| [41] |

NAGUIB M, GOGOTSI Y . Synthesis of two-dimensional materials by selective extraction. ACC Chem. Res., 2015,48(1):128-135.

DOI URL PMID |

| [42] |

NAGUIB M, UNOCIC R R, ARMSTRONG B L , et al. Large-scale delamination of multi-layers transition metal carbides and carbonitrides "MXenes". Dalton Trans., 2015,44(20):9353-9358.

DOI URL PMID |

| [43] |

GHIDIU M, LUKATSKAYA M R, ZHAO M Q , et al. Conductive two-dimensional titanium carbide 'clay' with high volumetric capacitance. Nature, 2014,516(7529):78-81.

DOI URL |

| [44] |

MASHTALIR O, NAGUIB M, DYATKIN B , et al. Kinetics of aluminum extraction from Ti3AlC2 in hydrofluoric acid. Mater. Chem. Phys., 2013,139(1):147-152.

DOI URL |

| [45] |

ENYASHIN A N, IVANOVSKII A L . Atomic structure, comparative stability and electronic properties of hydroxylated Ti2C and Ti3C2 nanotubes. Comput. Theor. Chem., 2012,989:27-32.

DOI URL |

| [46] |

ANASARI B, XIE Y, BEDAGHI M , et al. Two-dimensional, ordered, double transition metals carbides (MXenes). ACS Nano, 2015,9(10):9507-9516.

DOI URL PMID |

| [47] |

KHAZAEI M, ARAI M, SASAKI T , et al. Novel electronic and magnetic properties of two-dimensional transition metal carbides and nitrides. Adv. Funct. Mater., 2013,23(17):2185-2192.

DOI URL |

| [48] |

WU F, JIANG Y, YE Z , et al. A 3D flower-like VO2/MXene hybrid architecture with superior anode performance for sodium ion batteries. J. Mater. Chem. A, 2019,7(3):1315-1322.

DOI URL |

| [49] |

XIAO Z, YANG Z, LI Z , et al. Synchronous gains of areal and volumetric capacities in lithium-sulfur batteries promised by flower-like porous Ti3C2Tx matrix. ACS Nano, 2019,13(3):3404-3412.

DOI URL PMID |

| [50] |

LUO J, WANG C, WANG H , et al. Pillared MXene with ultralarge iInterlayer spacing as a stable matrix for high performance sodium metal anodes. Adv. Funct. Mater., 2019,29:1805946.

DOI URL |

| [51] |

PENG Y, AKUZUM B, KURRA N , et al. All-MXene (2D titanium carbide) solid-state microsupercapacitors for on-chip energy storage. Energy Environ. Sci., 2016,9(9):2847-2854.

DOI URL |

| [52] |

PERSSON I, HALIM J, LIND H , et al. 2D Transition metal carbides (MXenes) for carbon capture. Adv. Mater., 2019,31(2):1805472.

DOI URL PMID |

| [53] |

LIU J, ZHANG H, SUN R , et al. Hydrophobic, flexible, and lightweight MXene foams for high-performance electromagnetic- interference shielding. Adv Mater, 2017,29(38):1702367.

DOI URL PMID |

| [54] |

FAISAL S, CHRISTINE B, ANASORI B , et al. Electromagnetic interference shielding with 2D transition metal carbides (MXenes). Science, 2016,353(6304):1137-1140.

DOI URL PMID |

| [55] |

CAI Y, SHEN J, GE G , et al. Stretchable Ti3C2Tx MXene/carbon nanotube composite based strain sensor with ultrahigh sensitivity and tunable sensing range. ACS Nano, 2018,12(1):56-62.

DOI URL PMID |

| [56] |

SHI X, WANG H, XIE X , et al. Bioinspired ultrasensitive and stretchable MXene-based strain sensor via nacre-mimetic microscale "brick-and-mortar" architecture. ACS Nano, 2019,13(1):649-659.

DOI URL PMID |

| [57] |

HYOSUNG AN, TOUSEEF HABIB, SMIT SHAH , et al. Surface- agnostic highly stretchable Surface- agnostic highly stretchable and bendable conductive MXene multilayers. Sci. Adv. 2018, 4(3): eaaq0118

DOI URL PMID |

| [58] |

ZHANG Y, LEE K, ANJUM D , et al. MXenes stretch hydrogel sensor performance to new limits. Sci. Adv., 2018, 4(6): eaat0098.

DOI URL PMID |

| [59] |

MA Y, LIU N, LI L , et al. A highly flexible and sensitive piezoresistive sensor based on MXene with greatly changed interlayer distances. Nat. Commun., 2017,8:1207.

DOI URL PMID |

| [60] |

MA Y, YUE Y, ZHANG H , et al. 3D Synergistical MXene/reduced graphene oxide aerogel for a piezoresistive sensor. ACS Nano, 2018,12(4):3209-3216.

DOI URL PMID |

| [61] |

LIU J, ZHANG H, XIE X , et al. Multifunctional, superelastic, and lightweight MXene/polyimide aerogels. Small, 2018,14(45):1802479.

DOI URL PMID |

| [62] |

ZHUO H, HU Y, CHEN Z , et al. A carbon aerogel with super mechanical and sensing performances for wearable piezoresistive sensors. J. Mater. Chem. A, 2019,7(14):8092-8100.

DOI URL |

| [63] |

CHEN Z, HU Y, ZHUO H , et al. Compressible, elastic, and pressure- sensitive carbon aerogels derived from 2D titanium carbide nanosheets and bacterial cellulose for wearable sensors. Chem. Mater., 2019,31(9):3301-3312.

DOI URL |

| [64] |

YUE Y, LIU N, LIU W , et al. 3D hybrid porous MXene-sponge network and its application in piezoresistive sensor. Nano Energy, 2018,50:79-87.

DOI URL |

| [65] |

LI X, LI Y, LI X , et al. Highly sensitive, reliable and flexible piezoresistive pressure sensors featuring polyurethane sponge coated with MXene sheets. J. Colloid Interface Sci., 2019,542:54-62.

DOI URL PMID |

| [66] |

GUO Y, ZHONG M, FANG Z , et al. A wearable transient pressure sensor made with MXene nanosheets for sensitive broad-range human-machine interfacing. Nano Lett., 2019,19(2):1143-1150.

DOI URL PMID |

| [1] | DING Ling, JIANG Rui, TANG Zilong, YANG Yunqiong. MXene: Nanoengineering and Application as Electrode Materials for Supercapacitors [J]. Journal of Inorganic Materials, 2023, 38(6): 619-633. |

| [2] | YANG Zhuo, LU Yong, ZHAO Qing, CHEN Jun. X-ray Diffraction Rietveld Refinement and Its Application in Cathode Materials for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2023, 38(6): 589-605. |

| [3] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [4] | LIN Junliang, WANG Zhanjie. Research Progress on Ferroelectric Superlattices [J]. Journal of Inorganic Materials, 2023, 38(6): 606-618. |

| [5] | NIU Jiaxue, SUN Si, LIU Pengfei, ZHANG Xiaodong, MU Xiaoyu. Copper-based Nanozymes: Properties and Applications in Biomedicine [J]. Journal of Inorganic Materials, 2023, 38(5): 489-502. |

| [6] | YUAN Jingkun, XIONG Shufeng, CHEN Zhangwei. Research Trends and Challenges of Additive Manufacturing of Polymer-derived Ceramics [J]. Journal of Inorganic Materials, 2023, 38(5): 477-488. |

| [7] | DU Jianyu, GE Chen. Recent Progress in Optoelectronic Artificial Synapse Devices [J]. Journal of Inorganic Materials, 2023, 38(4): 378-386. |

| [8] | YANG Yang, CUI Hangyuan, ZHU Ying, WAN Changjin, WAN Qing. Research Progress of Flexible Neuromorphic Transistors [J]. Journal of Inorganic Materials, 2023, 38(4): 367-377. |

| [9] | YOU Junqi, LI Ce, YANG Dongliang, SUN Linfeng. Double Dielectric Layer Metal-oxide Memristor: Design and Applications [J]. Journal of Inorganic Materials, 2023, 38(4): 387-398. |

| [10] | LIN Siqi, LI Airan, FU Chenguang, LI Rongbing, JIN Min. Crystal Growth and Thermoelectric Properties of Zintl Phase Mg3X2 (X=Sb, Bi) Based Materials: a Review [J]. Journal of Inorganic Materials, 2023, 38(3): 270-279. |

| [11] | QI Zhanguo, LIU Lei, WANG Shouzhi, WANG Guogong, YU Jiaoxian, WANG Zhongxin, DUAN Xiulan, XU Xiangang, ZHANG Lei. Progress in GaN Single Crystals: HVPE Growth and Doping [J]. Journal of Inorganic Materials, 2023, 38(3): 243-255. |

| [12] | ZHANG Chaoyi, TANG Huili, LI Xianke, WANG Qingguo, LUO Ping, WU Feng, ZHANG Chenbo, XUE Yanyan, XU Jun, HAN Jianfeng, LU Zhanwen. Research Progress of ScAlMgO4 Crystal: a Novel GaN and ZnO Substrate [J]. Journal of Inorganic Materials, 2023, 38(3): 228-242. |

| [13] | CHEN Kunfeng, HU Qianyu, LIU Feng, XUE Dongfeng. Multi-scale Crystallization Materials: Advances in in-situ Characterization Techniques and Computational Simulations [J]. Journal of Inorganic Materials, 2023, 38(3): 256-269. |

| [14] | XIE Bing, CAI Jinxia, WANG Tongtong, LIU Zhiyong, JIANG Shenglin, ZHANG Haibo. Research Progress of Polymer-based Multilayer Composite Dielectrics with High Energy Storage Density [J]. Journal of Inorganic Materials, 2023, 38(2): 137-147. |

| [15] | FENG Jingjing, ZHANG Youran, MA Mingsheng, LU Yiqing, LIU Zhifu. Current Status and Development Trend of Cold Sintering Process [J]. Journal of Inorganic Materials, 2023, 38(2): 125-136. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||