Journal of Inorganic Materials ›› 2020, Vol. 35 ›› Issue (1): 35-40.DOI: 10.15541/jim20190184

Special Issue: MAX相和MXene材料; 副主编黄庆研究员专辑; 计算材料论文精选(2020); 【虚拟专辑】层状MAX,MXene及其他二维材料

Previous Articles Next Articles

CHEN Lei-Lei1,DENG Zi-Xuan1,LI Mian1,LI Peng1,CHANG Ke-Ke1,2( ),HUANG Feng1,DU Shi-Yu1,HUANG Qing1

),HUANG Feng1,DU Shi-Yu1,HUANG Qing1

Received:2019-04-29

Revised:2019-07-25

Published:2020-01-20

Online:2019-09-20

About author:CHEN Lei-Lei(1993-), male, Master candidate. E-mail:chenleilei@nimte.ac.cn

Supported by:CLC Number:

CHEN Lei-Lei, DENG Zi-Xuan, LI Mian, LI Peng, CHANG Ke-Ke, HUANG Feng, DU Shi-Yu, HUANG Qing. Phase Diagrams of Novel MAX Phases[J]. Journal of Inorganic Materials, 2020, 35(1): 35-40.

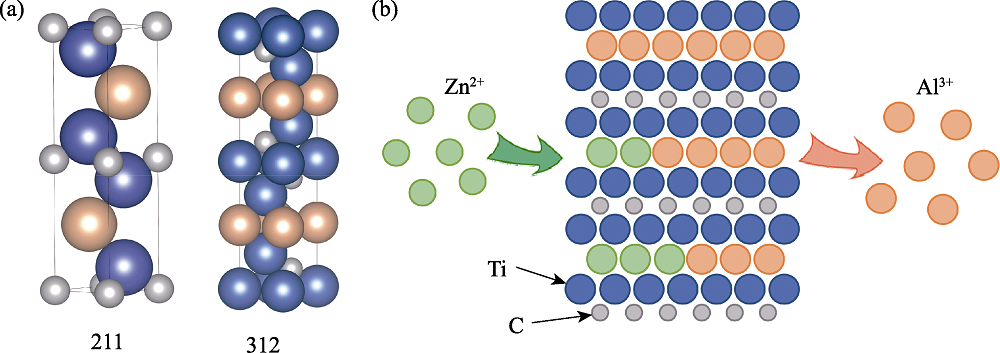

Fig. 1 (a) Crystal structures of MAX phases in 211 and 312 type; (b) Schematic of synthesizing Ti2ZnC via an A-elements substitution reaction in a molten salts bath[6]

| Phase | Lattice parameter/nm | Enthalpy of formation/ (kJ?mol-1?atom-1) | |

|---|---|---|---|

| a | c | ||

| Ti2AuC | 0.3073 | 1.3755 | -66.260 |

| Ti2IrC | 0.2981 | 1.3377 | -75.383 |

| Ti2ZnC | 0.3059 | 1.3726 | -55.925 |

| Ti3AuC2 | 0.3087 | 1.8650 (1.856)* | -76.083 |

| Ti3IrC2 | 0.3025 | 1.8196 | -80.800 |

| Ti3ZnC2 | 0.3078 (0.3094)# | 1.8613 (1.8721)# | -69.105 |

Table 1 Calculated lattice parameters and formation enthalpy of MAX phases

| Phase | Lattice parameter/nm | Enthalpy of formation/ (kJ?mol-1?atom-1) | |

|---|---|---|---|

| a | c | ||

| Ti2AuC | 0.3073 | 1.3755 | -66.260 |

| Ti2IrC | 0.2981 | 1.3377 | -75.383 |

| Ti2ZnC | 0.3059 | 1.3726 | -55.925 |

| Ti3AuC2 | 0.3087 | 1.8650 (1.856)* | -76.083 |

| Ti3IrC2 | 0.3025 | 1.8196 | -80.800 |

| Ti3ZnC2 | 0.3078 (0.3094)# | 1.8613 (1.8721)# | -69.105 |

| [1] |

CHING W Y, MO Y, ARYAL S , et al. Intrinsic mechanical properties of 20 MAX-phase compounds. Journal of the American Ceramic Society, 2013,96(7):2292-2297.

DOI URL |

| [2] |

SUN Z M . Progress in research and development on MAX phases: a family of layered ternary compounds. International Materials Reviews, 2011,56(3):143-166.

DOI URL |

| [3] | BARSOUM M W . The M N+1AXN phases: a new class of solids. Progress in Solid State Chemistry of Materials, 2000,28:201-281. |

| [4] |

FASHANDI H, DAHLQVIST M, LU J , et al. Synthesis of Ti3AuC2, Ti3Au2C2 and Ti3IrC2 by noble metal substitution reaction in Ti3SiC2 for high-temperature-stable Ohmic contacts to SiC. Nature Materials, 2017,16:814.

DOI URL PMID |

| [5] |

LI M, LI Y, LUO K , et al. Synthesis of novel MAX phase Ti3ZnC2 via A-site-element-substitution approach. Journal of Inorganic Materials, 2019,34(1):60-64.

DOI URL |

| [6] |

LI M, LU J, LUO K , et al. Element replacement approach by reaction with Lewis acidic molten salts to synthesize nanolaminated MAX phases and MXenes. Journal of the American Chemical Society, 2019,141(11):4730-4737.

DOI URL PMID |

| [7] |

KRESSE G, FURTHMÜLLER J . Efficient iterative schemes for ab initi total-energy calculations using a plane-wave basis set. Physical Review B, 1996,54(16):11169-11186.

DOI URL PMID |

| [8] |

LIU S, CHANG K, MRÁZ S , et al.Modeling of metastable phase formation for sputtered Ti1-xAlxN thin films. Acta Materialia, 2019,165:615-625.

DOI URL PMID |

| [9] |

CHANG K, TO BABEN M, MUSIC D , et al. Estimation of the activation energy for surface diffusion during metastable phase formation. Acta Materialia, 2015,98:135-140.

DOI URL |

| [10] |

JOUBERT D, KRESSE G . From ultrasoft pseudopotentials to the projector augmented-wave method. Physical Review B, 1999,59(3):1758-1775.

DOI URL PMID |

| [11] |

BURKE K, ERNZERHOF M, PERDEW J P . Generalized gradient approximation made simple. Physical Review Letters, 1996,77(18):3865-3868.

DOI URL PMID |

| [12] |

DINSDALE A T . SGTE data for pure elements. Calphad, 1991,15(4):317-425.

DOI URL PMID |

| [13] |

REDLICH O, KISTER A T . Thermodynamics of nonelectrolyte solutions-xyt relations in a binary system. Industrial & Engineering Chemistry, 1948,40(2):341-345.

DOI URL PMID |

| [14] |

CHANG K, DU Y, SUN W , et al. Thermodynamic assessment of the V-Zn system supported by key experiments and first-principles calculations. Calphad, 2010,34(1):75-80.

DOI URL |

| [15] |

CHEN L, ZHANG Z, HUANG Y ,et al. Thermodynamic description of the Fe-Cu-C system. Calphad, 2019,64:225-235.

DOI URL PMID |

| [16] |

GORBACHEV I I, POPOV V V . Analysis of the solubility of carbides, nitrides, and carbonitrides in steels using methods of computer thermodynamics: III. Solubility of carbides, nitrides, and carbonitrides in the Fe-Ti-C, Fe-Ti-N, and Fe-Ti-C-N systems. Physics of Metals & Metallography, 2009,108(5):484-495.

DOI URL PMID |

| [17] |

LUO W, JIN Z, LIU H ,et al. Thermodynamic assessment of the Au-Ti system. Calphad, 2001,25(1):19-26.

DOI URL |

| [18] |

WANG C, GUO Y, YONG L , et al. Thermodynamic assessment of the Ti-Ir System. Journal of Phase Equilibria & Diffusion, 2014,35(3):269-275.

DOI URL PMID |

| [19] | DENG Z, ZHAO D, HUANG Y , et al. Unpublished research. 2018. |

| [20] |

HÄMÄLÄINEN M, ISOMÄKI I . Thermodynamic evaluation of the C-Co-Zn system. Journal of Alloys and Compounds, 2005,392(1):220-224.

DOI URL PMID |

| [21] |

OKAMOTO H, MASSALSKI T B . The Au-C (Gold-Carbon) system. Bulletin of Alloy Phase Diagrams, 1984,5(4):378-379.

DOI URL PMID |

| [22] |

NADLER M R, KEMPTER C P . Some solidus temperatures in several metal-carbon systems. Journal of Physical Chemistry, 1960,64(10):1468-1471.

DOI URL |

| [23] |

FASHANDI H, LAI C C, DAHLQVIST M , et al. Ti2Au2C and Ti3Au2C2 formed by solid state reaction of gold with Ti2AlC and Ti3AlC2. Chemical Communications, 2017,53(69):9554-9557.

DOI URL PMID |

| [1] | DING Jianxiang, ZHANG Kaige, LIU Dongming, ZHENG Wei, ZHANG Peigen, SUN Zhengming. Ag-based Electrical Contact Material Reinforced by Ti3AlC2 Ceramic and Its Derivative Ti3C2Tx [J]. Journal of Inorganic Materials, 2022, 37(5): 567-573. |

| [2] | LI Youbing, QIN Yanqing, CHEN Ke, CHEN Lu, ZHANG Xiao, DING Haoming, LI Mian, ZHANG Yiming, DU Shiyu, CHAI Zhifang, HUANG Qing. Molten Salt Synthesis of Nanolaminated Sc2SnC MAX Phase [J]. Journal of Inorganic Materials, 2021, 36(7): 773-778. |

| [3] | ZHANG Xiao, LI Youbing, CHEN Ke, DING Haoming, CHEN Lu, LI Mian, SHI Rongrong, CHAI Zhifang, HUANG Qing. Tailoring MAX Phase Magnetic Property Based on M-site and A-site Double Solid Solution [J]. Journal of Inorganic Materials, 2021, 36(12): 1247-1255. |

| [4] | JIN Sen, WANG Zuo-Tong, DU Ya-Qiong, HU Qian-Ku, YU Jian-Gong, ZHOU Ai-Guo. Hot-pressing Sintering of Double-A-layer MAX Phase Mo2Ga2C [J]. Journal of Inorganic Materials, 2020, 35(1): 41-45. |

| [5] | DANG Xiao-Lin, FAN Xiao-Meng, YIN Xiao-Wei, MA Yu-Zhao, MA Xiao-Kang. Research Progress on Multi-functional Integration MAX Phases Modified Continuous Fiber-reinforced Ceramic Matrix Composites [J]. Journal of Inorganic Materials, 2020, 35(1): 29-34. |

| [6] | LI Mian, HUANG Qing. Recent Progress and Prospects of Ternary Layered Carbides/Nitrides MAX Phases and Their Derived Two-dimensional Nanolaminates MXenes [J]. Journal of Inorganic Materials, 2020, 35(1): 1-7. |

| [7] | LI Mian, LI You-Bing, LUO Kan, LU Jun, EKLUND Per, PERSSON Per, ROSEN Johanna, HULTMAN Lars, DU Shi-Yu, HUANG Zheng-Ren, HUANG Qing. Synthesis of Novel MAX Phase Ti3ZnC2 via A-site-element-substitution Approach [J]. Journal of Inorganic Materials, 2019, 34(1): 60-64. |

| [8] | SUN Qing, QI Qi, ZHANG Jian, PAN Fang-Zhen, SHENG Jia-Wei. Structure and Adsorption Property of Magnetic ZnFe2O4-halloysite Composite Material [J]. Journal of Inorganic Materials, 2018, 33(4): 390-396. |

| [9] | PENG Ben, QIU Gui-Bo, YUE Chang-Sheng, ZHANG Mei, GUO Ming. Controllable Synthesis of One-dimensional β-SiAlON Materials [J]. Journal of Inorganic Materials, 2014, 29(7): 706-710. |

| [10] | QIU Rui-Hao, LI Yong-Xiang, ZHANG Wen-Qing. Phase Competition in Bismuth Layered Structure Based on First Principles Thermodynamics [J]. Journal of Inorganic Materials, 2014, 29(11): 1156-1160. |

| [11] | WANG Huan, ZHANG Hua, JIN Hong-Jian, ZHAO Wen-Wen. Effect of Fuel Amount on Synthesis of Gd0.8Sr0.2CoO3-δ Cathode Material by Glycine-nitrate Process [J]. Journal of Inorganic Materials, 2013, 28(8): 818-824. |

| [12] | ZHU Zhi-PING, HUANG Ke-Long, ZHOUYi. Study on Kinetics, Thermodynamics and Mechanism for Carbon Nanotubes Adsorbing Humic Acid [J]. Journal of Inorganic Materials, 2011, 26(2): 170-174. |

| [13] | ZHU Bao-Jun1, TAO Ying2, ZHANG Yang1, ZHENG Rui1, ZOU Xiao-Lin1. Preparation of Li3+xV1-xSixO4 Films by Solvthermal Electrochemical Method [J]. Journal of Inorganic Materials, 2010, 25(6): 631-634. |

| [14] | ZHOU Hong-Ming,LIU Gong-Qi,XIAO Lai-Rong,YI Dan-Qing,ZENG Lin. Low Temperature Oxidation Behavior of MoSi2 Composites Strengthened and Toughened by Si3N4 Particles and SiC Whiskers [J]. Journal of Inorganic Materials, 2009, 24(5): 929-933. |

| [15] | FENG Ji-Wei,ZHANG Wen-Qing,JIANG Wan. Atomistic Thermodynamic Simulation of Ag/Al2O3 Interfaces under O2 Pressure [J]. Journal of Inorganic Materials, 2007, 22(1): 119-122. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||