Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (10): 1067-1071.DOI: 10.15541/jim20180589

Previous Articles Next Articles

GUO Sheng-Qiang,WANG Hao( ),TU Bing-Tian,WANG Bin,XU Peng-Yu,WANG Wei-Min,FU Zheng-Yi

),TU Bing-Tian,WANG Bin,XU Peng-Yu,WANG Wei-Min,FU Zheng-Yi

Received:2018-12-17

Revised:2019-02-02

Published:2019-09-23

Online:2019-05-29

Supported by:CLC Number:

GUO Sheng-Qiang, WANG Hao, TU Bing-Tian, WANG Bin, XU Peng-Yu, WANG Wei-Min, FU Zheng-Yi. Fabrication and Property of Fine-grained MgO·1.44Al2O3 Spinel Transparent Ceramic[J]. Journal of Inorganic Materials, 2019, 34(10): 1067-1071.

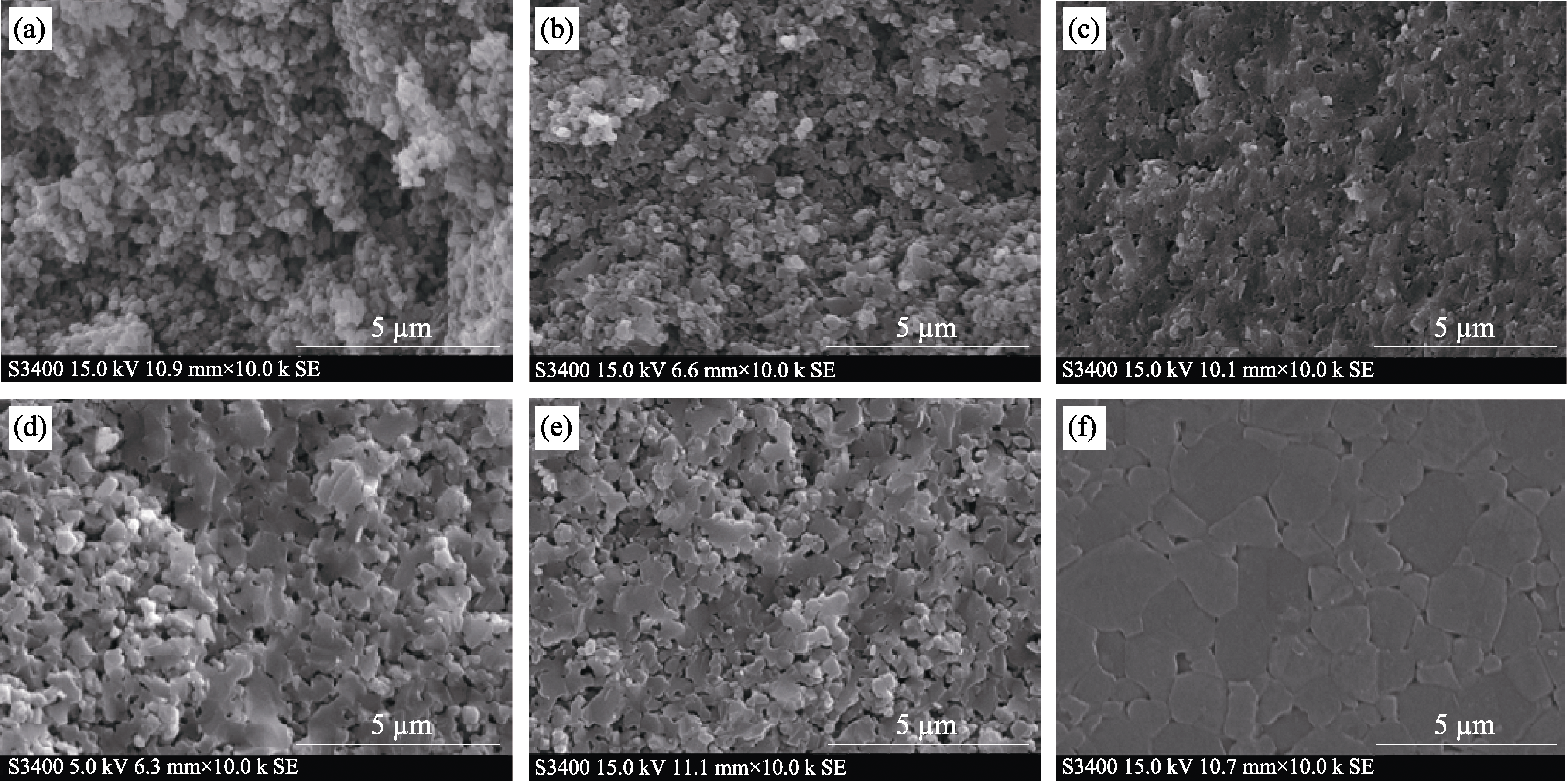

Fig. 5 SEM images of samples CIP-50, SPS-73 and SPS-85 before and after pressureless sintering (a-c): Fractured surface of samples CIP-50, SPS-73 and SPS-85; (d-e) Fractured surface of the samples CIP-50, SPS-73 pressureless sintered for 15 and 6 h; (f): Chemical etched surface of the sample SPS-85 pressureless sintered for 6 h

| n | Grain size/μm | Vickers hardness (9.8 N)/GPa | Young's modulus/GPa |

|---|---|---|---|

| 1.5 | >200 | (12.75±0.12)[ | 288.7[ |

| 1.44 | 1.9 | (13.94±0.20) | 289 |

| 1.3[ | 23 | (12.8±0.3) | - |

Table 1 Grain size and mechanical properties of MgO·nAl2O3 transparent ceramics

| n | Grain size/μm | Vickers hardness (9.8 N)/GPa | Young's modulus/GPa |

|---|---|---|---|

| 1.5 | >200 | (12.75±0.12)[ | 288.7[ |

| 1.44 | 1.9 | (13.94±0.20) | 289 |

| 1.3[ | 23 | (12.8±0.3) | - |

| [1] | MARC R D M, KLEEBE H J, MÜLLER M M ,et al. Fifty years of research and development coming to fruition; unraveling the complex interactions during processing of transparent magnesium aluminate (MgAl2O4) spinel. Journal of the American Ceramic Society, 2013,96(11):3341-3365. |

| [2] | TU B T, WANG H, LIU X ,et al. Theoretical predictions of composition- dependent structure and properties of alumina-rich spinel. Journal of the European Ceramic Society, 2016,36(4):1073-1079. |

| [3] | WAETZIG K, KRELL A . The effect of composition on the optical properties and hardness of transparent Al-rich MgO·nAl2O3 spinel ceramics. Journal of the American Ceramic Society, 2016,99(3):946-953. |

| [4] |

KRELL A, BALES A . Grain size-dependent hardness of transparent magnesium aluminate spinel. International Journal of Applied Ceramic Technology, 2011,8(5):1108-1114.

DOI |

| [5] | TOKARIEV O, SCHNETTER L, BECK T ,et al. Grain size effect on the mechanical properties of transparent spinel ceramics. Journal of the European Ceramic Society, 2013,33(4):749-757. |

| [6] | HAN D, ZHANG J, LIU P ,et al. Densification and microstructure evolution of reactively sintered transparent spinel ceramics. Ceramics International, 2018,44(10):11101-11108. |

| [7] | ESPOSITO L, PIANCASTELLI A, MARTELLI S . Production and characterization of transparent MgAl2O4 prepared by hot pressing. Journal of the European Ceramic Society, 2013,33(4):737-747. |

| [8] | SHIMADA M, ENDO T, SAITO T ,et al. Fabrication of transparent spinel polycrystalline materials. Materials Letters, 1996,28(4/6):413-415. |

| [9] | SUTORIK A C, COOPER C, GILDE G . Visible light transparency for polycrystalline ceramics of MgO·2Al2O3 and MgO·2.5Al2O3 spinel solid solutions. Journal of the American Ceramic Society, 2013,96(12):3704-3707. |

| [10] | SUTORIK A C, GILDE G, COOPER C ,et al. The effect of varied amounts of LiF sintering aid on the transparency of alumina rich spinel ceramic with the composition MgO·1.5Al2O3. Journal of the American Ceramic Society, 2012,95(6):1807-1810. |

| [11] | SUTORIK A C, GILDE G, SWAB J J ,et al. Transparent solid solution magnesium aluminate spinel polycrystalline ceramic with the alumina-rich composition MgO·1.2Al2O3. Journal of the American Ceramic Society, 2012,95(2):636-643. |

| [12] | YUAN Z, WANG H, TU B T ,et al. Preparation of MgO·1.5Al2O3 transparent ceramic by pressureless sintering and hot isostatic pressing. Journal of Inorganic Materials, 2015,30(8):843-847. |

| [13] | TING C J, LU H Y . Defect reactions and the controlling mechanism in the sintering of magnesium aluminate spinel. Journal of the American Ceramic Society, 1999,82(4):841-848. |

| [14] | KRELL A, HUTZLER T, KLIMKE J ,et al. Fine-grained transparent spinel windows by the processing of different nanopowders. Journal of the American Ceramic Society, 2010,93(9):2656-2666. |

| [15] | TRUNEC M, MACA K . Compaction and pressureless sintering of zirconia nanoparticles. Journal of the American Ceramic Society, 2010,90(9):2735-2740. |

| [16] | BARRINGER E A, BOWEN H K . Effects of particle packing on the sintered microstructure. Applied Physics A, 1988,45(4):271-275. |

| [17] | KRELL A, KLIMKE J . Effects of the homogeneity of particle coordination on solid-state sintering of transparent alumina. Journal of the American Ceramic Society, 2006,89(6):1985-1992. |

| [18] | KIM J M, KIM H N, PARK Y J ,et al. Fabrication of transparent MgAl2O4 spinel through homogenous green compaction by microfluidization and slip casting. Ceramics International, 2015,41(10):13354-13360. |

| [19] | 袁泽 . MgO·nAl2O3 (n=1~2)透明陶瓷的制备研究探索. 武汉: 武汉理工大学硕士学位论文, 2015. |

| [20] | SWEENEY S M, MAYO M J . Relation of pore size to green density: the Kozeny equation. Journal of the American Ceramic Society, 2010,82(7):1931-1933. |

| [21] | LU G Q . Evolution of the pore structure of a ceramic powder compact during sintering. Journal of Materials Processing Technology, 1996,59(4):297-302. |

| [22] | SHIAU F S, FANG T T, LEU T H . Effect of particle-size distribution on the microstructural evolution in the intermediate stage of sintering. Journal of the American Ceramic Society, 2010,80(2):286-290. |

| [23] |

CHAIM R, KALINA M, SHEN J Z . Transparent yttrium aluminum garnet (YAG) ceramics by spark plasma sintering. Journal of the European Ceramic Society, 2007,27(11):3331-3337.

DOI |

| [24] | IKESUE A, YOSHIDA K . Influence of pore volume on laser performance of Nd: YAG ceramics. Journal of Materials Science, 1999,34(6):1189-1195. |

| [25] |

MULLER A M, GREEN D J . Elastic-plastic indentation response of two transparent fine-grained polycrystalline spinels. Journal of the American Ceramic Society, 2011,94(11):3967-3975.

DOI |

| [1] | CHENG Weijie, WANG Minglei, LIN Guoqiang. Composition, Structure and Properties of CrAlN-DLC Hard Composite Films Deposited by Arc Ion Plating [J]. Journal of Inorganic Materials, 2022, 37(7): 764-772. |

| [2] | YANG Yong, GUO Xiaotian, TANG Jie, CHANG Haotian, HUANG Zhengren, HU Xiulan. Research Progress and Prospects of Non-oxide Ceramic in Stereolithography Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 267-277. |

| [3] | PENG Junhui, TIKHONOV Evgenii. Vacancy on Structures, Mechanical and Electronic Properties of Ternary Hf-Ta-C System: a First-principles Study [J]. Journal of Inorganic Materials, 2022, 37(1): 51-57. |

| [4] | Zhui WANG, Jian-Jun HAN, Jian-Qiang LI, Xiao-Yu LI, Jiang-Tao LI, Gang HE, Jun XIE. Plastic Sintering Behavior of Large-sized La2O3-TiO2-ZrO2 Amorphous Bulk [J]. Journal of Inorganic Materials, 2019, 34(4): 433-438. |

| [5] | NIE Lan-Jian, GU Zhen-An, WANG Yu-Fen, XIANG Zai-Kui, ZHANG Chen-Yang, RAO Chuan-Dong. SiO2 Soot Body at Vacuum Sintering Process: Densification and Transparency Mechanism [J]. Journal of Inorganic Materials, 2019, 34(10): 1060-1066. |

| [6] | CUI Feng-Dan, MA Tian, LI Wei-Ping, WU Guo-Qing. Damage Characteristics of SiC and B4C Ballistic Insert Plates Subjected to Multi-hi [J]. Journal of Inorganic Materials, 2017, 32(9): 967-972. |

| [7] | LI Ren-Yi, LI Xiao-Yu, LI Jian-Qiang, ZHAO Jian-Ling, MA Xiao-Guang, HE Gang, LI Jiang-Tao. Large-sized La2O3-TiO2-SiO2 Amorphous Oxide Fabricated by Hot Press Sintering [J]. Journal of Inorganic Materials, 2017, 32(8): 851-856. |

| [8] | YUAN Qin, SONG Yong-Cai. Effects of Al and O Content on Transformation from SiAlCO to Si(Al)C Fibers after High Temperature Treatment [J]. Journal of Inorganic Materials, 2016, 31(4): 393-400. |

| [9] | YUAN Qin, SONG Yong-Cai. Effect of SiCxOy Decomposition on Densification of SiCO(Al) Fibers during Sintering Process [J]. Journal of Inorganic Materials, 2016, 31(12): 1320-1326. |

| [10] | LI Hai-Tao, LI Qian, YAN Yan-Fu, XU Rong-Hui. Effect of ZnO-doping on Sinterability and Microwave Dielectric Property of Ca0.25(Li0.43Sm0.57)0.75TiO3 Ceramics [J]. Journal of Inorganic Materials, 2015, 30(4): 369-373. |

| [11] | LI Yan, CUI Hong, ZHANG Hua-Kun, JI A-Lin, JIE Yu-Jie. Densification Behavior of Thermal Gradient CVI of Large-scale C/C Composites [J]. Journal of Inorganic Materials, 2015, 30(2): 153-158. |

| [12] | WU Zhi-Li, LI Yu-Ge, WU Bi, LEI Ming-Kai. Microstructure Controlling and Properties of TiAlSiN Nanocomposite Coatings Deposited by Modulated Pulsed Power Magnetron Sputtering [J]. Journal of Inorganic Materials, 2015, 30(12): 1254-1260. |

| [13] | LI Ge-Yang. Comment on Experiment Fundament of Veprek’s nc-TiN/a-Si3N4 Model and Its “Exceed Diamond Hardness” [J]. Journal of Inorganic Materials, 2015, 30(1): 1-8. |

| [14] | MENG Jia, ZHAO Li-Li, SONG Li-Xin. Photostimulated Luminescence and Radiation Hardness Properties of CsBr:(Eu2+,KOH) [J]. Journal of Inorganic Materials, 2013, 28(5): 551-556. |

| [15] | JIANG Da-Dong, ZHENG Xue-Jun, GONG Yue-Qiu, ZHU-Zhe, PENG Jin-Feng. Effect of Annealing Temperature on the Mechanical Properties of Bi3.15(Eu0.7Nd0.15)Ti3O12 Ferroelectric Thin Films [J]. Journal of Inorganic Materials, 2013, 28(2): 131-135. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||