Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (6): 660-666.DOI: 10.15541/jim20180395

Previous Articles Next Articles

Shu-Guang ZHOU1,2,Yi-Jun GUO2( ),Xiao LIU2

),Xiao LIU2

Received:2018-08-28

Revised:2018-11-23

Published:2019-06-20

Online:2019-05-23

Supported by:CLC Number:

Shu-Guang ZHOU, Yi-Jun GUO, Xiao LIU. Simulation of ZrB2 Oxidation Behavior at Constant Temperature Ambient[J]. Journal of Inorganic Materials, 2019, 34(6): 660-666.

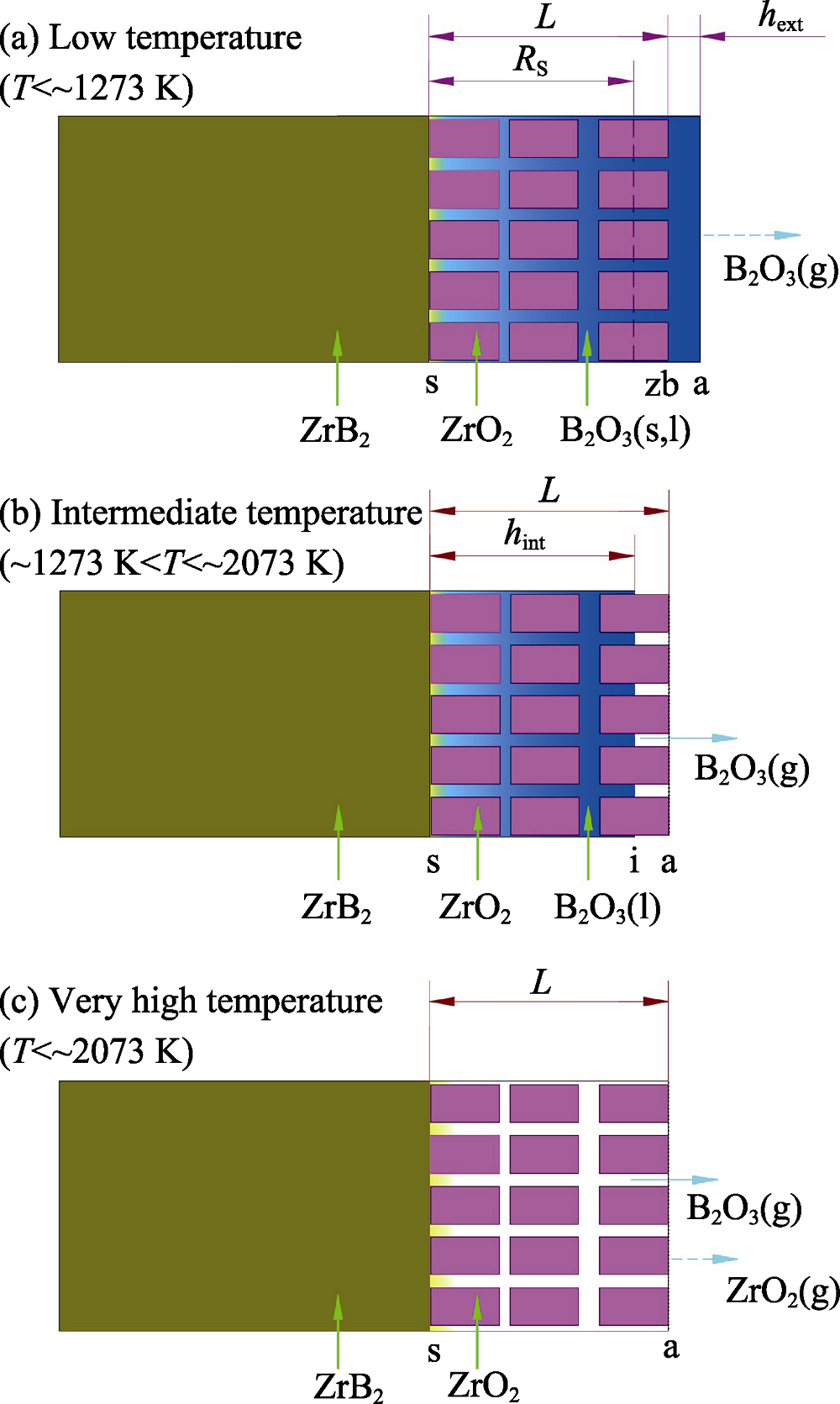

Fig. 1 Schematic sketch of the oxidation products of ZrB2 and morphology assumed in the model L: scale thickness; Rs: recession of substrate; hext: outside layer thickness of B2O3; hint: inside layer thickness of B2O3; a: interface between ambient and oxide; zb: interface between liquid and inside solid; s: interface between oxides and substrate; i: interface between inside liquid and solid

| T/K | 1098 | 1163 | 1263 | 1365 | 1478 | 1573 | 1673 |

|---|---|---|---|---|---|---|---|

| Ratio | 1.05 | 1.04 | 1.03 | 0.99 | 0.96 | 0.87 | 0.70 |

Table 1 Ratio of thickness of B2O3 to that of ZrO2 at different temperatures

| T/K | 1098 | 1163 | 1263 | 1365 | 1478 | 1573 | 1673 |

|---|---|---|---|---|---|---|---|

| Ratio | 1.05 | 1.04 | 1.03 | 0.99 | 0.96 | 0.87 | 0.70 |

| [1] | CLOUGHERTY E V, KALISH D, PETER E T . esearch and development of refractory oxidation resistant diborides. RAFML-TR-68-190, 1968. |

| [2] |

ZHANG GUO-JUN, LIU HAI-TAO, ZOU JI , et al. Chemical reactions in the life cycle of ZrB2 ceramics. Chinese Science Bulletin, 2015,60(3):276-286.

DOI URL |

| [3] | LI GANG, HAN WEN-BO, JIANG JIU-XING . Mechanicalproperties and thermal shock resistance of ZrB2-SiC-AN ultrahigh temperature ceramics. Journal of Synthetic Crystals, 2009, 38, Special Edition: 36-39. |

| [4] | SONG JIAN-RONG, LI JUN-GUO, SHEN QIANG , et al. Thermal shock and oxidation resistances of ZrB2-ZrO2 ceramics. Journal of the Chinese Ceramic Society, 2008,36(5):663-667. |

| [5] | SONG JIE-GUANG, DU DA-MING, XU MING-HAN , et al. Oxidation behavior of ZrB2-matrix composite materials at high-temperature conditions. Powder Metallurgy Technology, 2015,33(5):336-340, 364. |

| [6] |

ZHOU HAI-JUN, ZHANG XIANG-YU, GAO LE , et al. Ablation properties of ZrB2-SiC ultra-high temperature ceramic coatings. Journal of Inorganic Materials, 2013,28(3):256-260.

DOI URL |

| [7] | ZHAO HAI-LEI, WANG JIAN, LI WEN-CHAO . Study on oxidation kinetics of ZrB2-corundum-mullite composite. Naihuo Cailiao, 1998,32(6):322-325. |

| [8] |

PARTHASARATHY T A, RAPP R A, OPEKA M , et al. A model for the oxidation of ZrB2, HfB2 and TiB2. Acta Materialia, 2007,55(17):5999-6010.

DOI URL |

| [9] |

PARTHASARATHY T A, RAPP R A, OPEKA M , et al. A model for transitions in oxidation regimes of ZrB2. Materials Science Forum, 2008. 595-598:823-832.

DOI URL |

| [10] |

PARTHASARATHY T A, RAPP R A, OPEKA M , et al. Effects of phase change and oxygen permeability in oxide scales on oxidation kinetics of ZrB2 and HfB2. Journal of the American Ceramic Society, 2009,92(5):1079-1086.

DOI URL |

| [11] |

BERKOWITZ-MATTUCK J B . High-temperature oxidation III. zirconium and hafnium diborides. Journal of the Electrochemical Society, 1966,113(9):908-914.

DOI URL |

| [12] | HU PING, WANG GUO-LIN, WANG ZHI . Oxidation mechanism and resistance of ZrB2-SiC composites. Corrosion Science, 2009,51(11):2747-2732. |

| [13] | ANDREEVA A F . Zirconium diboride low resistance layers. MAM’97-Materials for Advanced Metallization, Poster Session I, 1997. |

| [14] | PAGE R J, SHORT R A, HALBACH C R . Evaluation of zirconia, thoria and zirconium diboride for advanced resistojet use. NASA CR-112075, 1972. |

| [15] | MCCLAINE L A . Thermodynamic and kinetic studies for a refractory materials program, Part III. ASD-TDR-62-204Part III, 1964. |

| [16] |

LUTHRA K L . Oxidation of carbon/carbon composites—a theoretical analysis. Carbon, 1988,26(2):217-224.

DOI URL |

| [17] | . CHASE JR M W. , NIST-JANAF Thermochemical Tables 4 th Ed. Physical and Chemical Reference Data Monograph No.9, 1998: 286-291, 1756, 1780. |

| [18] |

TRIPP W C, GRAHAM H C . Thermogravimetric study of the oxidation of ZrB2 in the temperature range of 800 to 1500 ℃. Journal of the Electrochemical Society, 1971,118(7):1195-1199.

DOI URL |

| [19] | PERRY R H, GREEN D W, MALONEY J O . Perry’s Chemical Engineers’ Handbook 7 th Ed. New York:McGraw-Hill, 1997: 570. |

| [20] | BARIN I . Thermochemical data of pure substances. New York: VCH Verlags-gesellschaft, 1995: 122-124. |

| [21] |

JACOBSON N S, CURRY D M . Oxidation microstructure studies of reinforced carbon/carbon. Carbon, 2006,44(7):1142-1150.

DOI URL |

| [22] | WELTY J R, RORRER G L, FOSTER D G . Fundamentals of momentum, heat and mass transfer 6th Ed. New York: WILEY, 2013,P448. |

| [23] | BIRD R B, STEWART W E, LIGHTFOOT E N . Transport phenomena. New York: John Wiley, 2002: 526, 866. |

| [24] | J. SZEKELY J, EVANS J, SOHN W H Y . Gas Solid Reactions. New York: Academic Press, 1976: 25. |

| [25] | DUFFA G. Ablative thermal protection system modeling . Reston: AIAA, Inc. Press, 2012: 109. |

| [26] | LI JIAN-FENG, ZHOU XIA-MING, DING CHUAN-XIAN . Statistical analysis of porosity variations in plasma sprayed Cr3C2- NiCr coatings. Journal of Aeronautical Materials, 2000,20(1):33-38. |

| [27] | ZHANG HONG-SONG, WANG FU-CHI, MA ZHUANG , et al. Quantitative analysis of pores in plasma-sprayed ZrO2 coatings. Journal of Materials Engineering, 2006, Supplement 1: 407-425. |

| [28] |

PRATTEN N A . The precise measurement of the density in small samples. Materials Science, 1981,16(7):1737-1747.

DOI URL |

| [29] | ZHAO YANG, LIN LI, MA ZHI-YUAN , et al. Establishing TBC random pore model based on random media theory. China Surface Engineering, 2010,23(2):78-81. |

| [30] |

FOX A C, CLYNE T W . Oxygen transport by gas permeation through the zirconia layer in plasma sprayed thermal barrier coating. Surface and Coatings Technology, 2004,184(2/3):311-321.

DOI URL |

| [1] | MU Honghe, WANG Pengfei, SHI Yufeng, ZHANG Zhonghan, WU Anhua, SU Liangbi. Large-size CeF3 Crystal Growth by Heat Exchanger-Bridgman Method: Thermal Field Design and Optimization [J]. Journal of Inorganic Materials, 2023, 38(3): 288-295. |

| [2] | LI Yicun, LIU Xuedong, HAO Xiaobin, DAI Bing, LYU Jilei, ZHU Jiaqi. Rapid Growth of Single Crystal Diamond at High Energy Density by Plasma Focusing [J]. Journal of Inorganic Materials, 2023, 38(3): 303-309. |

| [3] | WANG Donghai, LI Dongzhen, XU Jun. An Important Breakthrough in the Technology of Sapphire Plate with Large Size Grown by the Edge-defined Film-fed Growth Method [J]. Journal of Inorganic Materials, 2023, 38(3): 363-364. |

| [4] | SHI Yanlei, SUN Niefeng, XU Chengyan, WANG Shujie, LIN Peng, MA Chunlei, XU Senfeng, WANG Wei, CHEN Chunmei, FU Lijie, SHAO Huimin, LI Xiaolan, WANG Yang, QIN Jingkai. Thermal Field of 6-inch Indium Phosphide Single Crystal Growth by Semi-sealed Czochralski Method [J]. Journal of Inorganic Materials, 2023, 38(3): 335-342. |

| [5] | CHEN Kunfeng, HU Qianyu, LIU Feng, XUE Dongfeng. Multi-scale Crystallization Materials: Advances in in-situ Characterization Techniques and Computational Simulations [J]. Journal of Inorganic Materials, 2023, 38(3): 256-269. |

| [6] | CHEN Mingyue, YAN Zhichao, CHEN Jing, LI Minjuan, LIU Zhiyong, CAI Chuanbing. YBa2Cu3O7-δ Thin Film: Preparation by BaCl2/BaF2-MOD Method and Superconducting Property [J]. Journal of Inorganic Materials, 2023, 38(2): 199-204. |

| [7] | XIE Bing, CAI Jinxia, WANG Tongtong, LIU Zhiyong, JIANG Shenglin, ZHANG Haibo. Research Progress of Polymer-based Multilayer Composite Dielectrics with High Energy Storage Density [J]. Journal of Inorganic Materials, 2023, 38(2): 137-147. |

| [8] | ZHANG Xiaoyu, LIU Yongsheng, LI Ran, LI Yaogang, ZHANG Qinghong, HOU Chengyi, LI Kerui, WANG Hongzhi. Cu3(HHTP)2 Film-based Ionic-liquid Electrochromic Electrode [J]. Journal of Inorganic Materials, 2022, 37(8): 883-890. |

| [9] | DENG Taoli, CHEN Hexin, HEI Lingli, LI Shuxing, XIE Rongjun. Achieving High Light Uniformity Laser-driven White Lighting Source by Introducing Secondary Phases in Phosphor Converters [J]. Journal of Inorganic Materials, 2022, 37(8): 891-896. |

| [10] | CHENG Weijie, WANG Minglei, LIN Guoqiang. Composition, Structure and Properties of CrAlN-DLC Hard Composite Films Deposited by Arc Ion Plating [J]. Journal of Inorganic Materials, 2022, 37(7): 764-772. |

| [11] | ZHAO Yuyao, OUYANG Jun. Columnar Nanograined BaTiO3 Ferroelectric Thin Films Integrated on Si with a Sizable Dielectric Tunability [J]. Journal of Inorganic Materials, 2022, 37(6): 596-602. |

| [12] | YANG Zhu, GUO Shaobo, CAI Henghui, DONG Xianlin, WANG Genshui. Preparation of Epitaxial Metallic LaNiO3 Thin Film by Polymer Assisted Deposition [J]. Journal of Inorganic Materials, 2022, 37(5): 561-566. |

| [13] | WANG Wanhai, ZHOU Jie, TANG Weihua. Passivation Strategies of Perovskite Film Defects for Solar Cells [J]. Journal of Inorganic Materials, 2022, 37(2): 129-139. |

| [14] | XIA Qiuying, SUN Shuo, ZAN Feng, XU Jing, XIA Hui. Amorphous LiSiON Thin Film Electrolyte for All-solid-state Thin Film Lithium Battery [J]. Journal of Inorganic Materials, 2022, 37(2): 230-236. |

| [15] | LIU Dan, ZHAO Yaxin, GUO Rui, LIU Yantao, ZHANG Zhidong, ZHANG Zengxing, XUE Chenyang. Effect of Annealing Conditions on Thermoelectric Properties of Magnetron Sputtered MgO-Ag3Sb-Sb2O4 Flexible Films [J]. Journal of Inorganic Materials, 2022, 37(12): 1302-1310. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||