Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (4): 433-438.DOI: 10.15541/jim20180289

Previous Articles Next Articles

Zhui WANG1,2,Jian-Jun HAN1,Jian-Qiang LI2( ),Xiao-Yu LI2,Jiang-Tao LI3,Gang HE3,Jun XIE1

),Xiao-Yu LI2,Jiang-Tao LI3,Gang HE3,Jun XIE1

Received:2018-06-29

Revised:2018-10-31

Published:2019-04-20

Online:2019-04-15

Supported by:CLC Number:

Zhui WANG, Jian-Jun HAN, Jian-Qiang LI, Xiao-Yu LI, Jiang-Tao LI, Gang HE, Jun XIE. Plastic Sintering Behavior of Large-sized La2O3-TiO2-ZrO2 Amorphous Bulk[J]. Journal of Inorganic Materials, 2019, 34(4): 433-438.

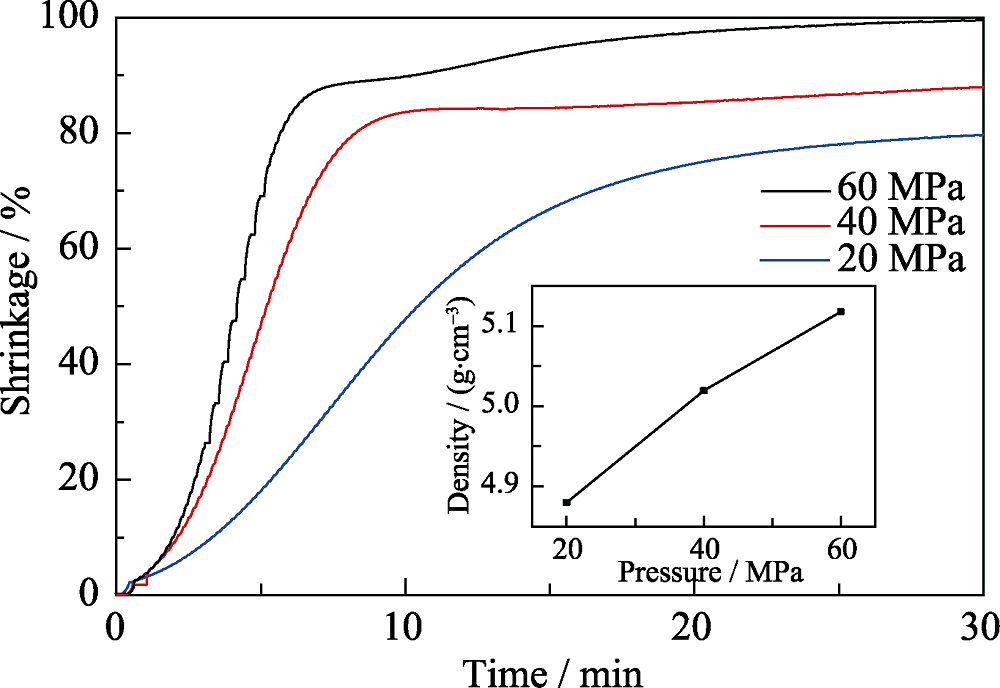

Fig. 5 Shrinkage behaviors of LTZO glass powders sintered at different pressures The inset shows the densities of LTZO samples sintered at different pressures

| [1] | MASUNO A, WATANABE Y, INOUE H , et al. Glass-forming region and high refractive index of TiO2-based glasses prepared by containerless processing. Physica Status Solidi, 2012,9(12):2424-2427. |

| [2] | YODA S, CHO W S, IMAI R . Aerodynamic levitator for large- sized glassy material production. Review of Scientific Instruments, 2015,86(9):21-27. |

| [3] | XIANG H, GUAN L, PENG Z , et al. Preparation of high refractive index La2O3-TiO2 glass by aerodynamic levitation technique and effects of Bi2O3, substitution on its thermal and optical properties. Ceramics International, 2014,40(3):4985-4988. |

| [4] | ZHANG M, WEN H, YU H , et al. Study on upconversion luminescence and thermal properties of Ho3+/Yb3+ co-doped La2O3- TiO2-ZrO2 glasses . Journal of Alloys & Compounds, 2016,672(5):7-12. |

| [5] | WANG C, AI F, WEN H , et al. Effect of Yb3+ on the upconversion luminescence of Tm3+/Yb3+ co-doped La2O3-TiO2-ZrO2 glasses. Optical Materials Express, 2015,5(4):676-683. |

| [6] | INOUE H, WATANABE Y, MASUNO A , et al. Effect of substituting Al2O3 and ZrO2 on thermal and optical properties of high refractive index La2O3-TiO2 glass system prepared by containerless processing. Optical Materials, 2011,33(12):1853-1857. |

| [7] | KANEKO M, KENTEI YU Y, KUMAR V , et al. Glass Forming in La2O3-TiO2-ZrO2 Ternary System by Containerless Processing. 38th COSPAR Scientific Assembly.Bremen, 2010: 8-12. |

| [8] | ZHU MEI-JUAN, YU JIAN-DING, ZHANG MING-HUI , et al. Upconversion luminescence of Er3+/Yb3+ co-doped La2O3-TiO2- ZrO2 glasses prepared by containerless processing . Journal of Inorganic Materials, 2015,30(4):391-396. |

| [9] | PAN X, YU J, LIU Y , et al. Infrared to visible upconversion luminescence in Er3+/Yb3+ doped titanate glass prepared by containerless processing . Journal of Luminescence, 2012,132(4):1025-1029. |

| [10] | ZHANG M, YU J, PAN X , et al. Increase of the blue upconversion emission in Tm3+ /Yb3+, co-doped titanate glass ceramics. Journal of Non-Crystalline Solids, 2013,378(11):106-109. |

| [11] | ROSENFLANZ A, FREY M, ENDRES B , et al. Bulk glasses and ultrahard nanoceramics based on alumina and rare-earth oxides. Nature, 2004,430(7001):761-764. |

| [12] | WANG L, MEI L, HE G , et al. Preparation of Ce:YAG glass- ceramics with low SiO2. Journal of the American Ceramic Society, 2011,94(11):3800-3803. |

| [13] | MEI L, HE G, WANG L L , et al. Fabrication of transparent LaAlO3/t-ZrO2, nanoceramics through controlled amorphous crystallization. Journal of the European Ceramic Society, 2011,31(9):1603-1609. |

| [14] | WANG L L, MEI L, HE G , et al. Preparation of infrared transparent YAG-based glass-ceramics with nano-sized crystallites. Journal of the European Ceramic Society, 2012,32(12):3091-3096. |

| [15] | WANG L L, MEI L, LIU G H , et al. Optical and mechanical properties of amorphous bulk and eutectic ceramics in the HfO2-Al2O3- Y2O3 system. Ceramics International, 2013,39(1):233-238. |

| [16] | MEI L, LIU G H, HE G , et al. Controlled amorphous crystallization: an easy way to make transparent nanoceramics. Optical Materials, 2012,34(6):981-985. |

| [17] | 汪卫华 . 非晶态物质的本质和特性. 物理学进展, 2013,33(5):177-351. |

| [18] | DIMITROV V, SAKKA S . Electronic oxide polarizability and optical basicity of simple oxides. Journal of Applied Physics, 1996,79(3):1736-1740. |

| [19] | MA X, PENG Z, LI J . Effect of Ta2O5 substituting on thermal and optical properties of high refractive index La2O3-Nb2O5 glass system prepared by aerodynamic levitation method. Journal of the American Ceramic Society, 2015,98(3):770-773. |

| [20] | SHI J L, LIN Z X . The flow characteristics of hot-pressing of beta-Al2O3. Ceramics International, 1989,15(2):107-112. |

| [1] | YANG Yong, GUO Xiaotian, TANG Jie, CHANG Haotian, HUANG Zhengren, HU Xiulan. Research Progress and Prospects of Non-oxide Ceramic in Stereolithography Additive Manufacturing [J]. Journal of Inorganic Materials, 2022, 37(3): 267-277. |

| [2] | WANG Ying, ZHANG Wenlong, XING Yanfeng, CAO suqun, DAI Xinyi, LI Jingze. Performance of Amorphous Lithium Phosphate Coated Lithium Titanate Electrodes in Extended Working Range of 0.01-3.00 V [J]. Journal of Inorganic Materials, 2021, 36(9): 999-1005. |

| [3] | ZHU Yunna, CHEN Biqing, CHENG Tianshu, DU Chan, ZHANG Shimin, ZHAO Jing. Amorphous Nd-Ni-B/NF Rare Earth Composites: Preparation and HER Electrocatalytic Performance [J]. Journal of Inorganic Materials, 2021, 36(6): 637-644. |

| [4] | HUANG Xieyi,WANG Peng,YIN Guoheng,ZHANG Shaoning,ZHAO Wei,WANG Dong,BI Qingyuan,HUANG Fuqiang. Removal of Volatile Organic Compounds Driven by Platinum Supported on Amorphous Phosphated Titanium Oxide [J]. Journal of Inorganic Materials, 2020, 35(4): 482-490. |

| [5] | WANG Xucong, DENG Hao, JIANG Zhongyi, YUAN Liyong. Photocatalytic Reduction of Re (VII) on Amorphous TiO2/g-C3N4 Derived from Different N Sources [J]. Journal of Inorganic Materials, 2020, 35(12): 1340-1348. |

| [6] | WANG Jing, CUI Chunyue, TIAN Xia, ZHANG Xue, WANG Ying, XIN Yanjun. Amorphous Pd-P/Polypyrrole/Foam Ni Electrode: Electrocatalytic Hydrodechlorination of Pentachlorophenol [J]. Journal of Inorganic Materials, 2020, 35(10): 1157-1162. |

| [7] | Ren-De CHEN, Peng GUO, Xiao ZUO, Shi-Peng XU, Pei-Ling KE, Ai-Ying WANG. Ag Doped Amorphous Carbon Films: Structure, Mechanical and Electrical Behaviors [J]. Journal of Inorganic Materials, 2019, 34(4): 387-393. |

| [8] | NIE Lan-Jian, GU Zhen-An, WANG Yu-Fen, XIANG Zai-Kui, ZHANG Chen-Yang, RAO Chuan-Dong. SiO2 Soot Body at Vacuum Sintering Process: Densification and Transparency Mechanism [J]. Journal of Inorganic Materials, 2019, 34(10): 1060-1066. |

| [9] | GUO Sheng-Qiang, WANG Hao, TU Bing-Tian, WANG Bin, XU Peng-Yu, WANG Wei-Min, FU Zheng-Yi. Fabrication and Property of Fine-grained MgO·1.44Al2O3 Spinel Transparent Ceramic [J]. Journal of Inorganic Materials, 2019, 34(10): 1067-1071. |

| [10] | LI Han-Chao, LIU Pan-Pan, SUN Li-Li, KE Pei-Ling, CUI Ping, WANG Ai-Ying. Recent Development of the Transformation from Amorphous Carbon to Graphene Method via Metal Catalyst [J]. Journal of Inorganic Materials, 2018, 33(6): 587-595. |

| [11] | WEI Jing, LI Han-Chao, KE Pei-Ling, WANG Ai-Ying. Characterization of Tetrahedral Amorphous Carbon Film with Various Thickness by High Through-put Method [J]. Journal of Inorganic Materials, 2018, 33(11): 1173-1178. |

| [12] | LI Ren-Yi, LI Xiao-Yu, LI Jian-Qiang, ZHAO Jian-Ling, MA Xiao-Guang, HE Gang, LI Jiang-Tao. Large-sized La2O3-TiO2-SiO2 Amorphous Oxide Fabricated by Hot Press Sintering [J]. Journal of Inorganic Materials, 2017, 32(8): 851-856. |

| [13] | GAO Jiao-Jiao, JIANG Long-Kai, SONG Jin-Peng, LIANG Guo-Xing, AN Jing, XIE Jun-Cai, CAO Lei, LV Ming. Effects of TiC Content on Microstructure and Mechanical Property of WC-TiC-TaC Cemented Carbides [J]. Journal of Inorganic Materials, 2017, 32(8): 891-896. |

| [14] | SONG Jia, XU Ying, MO Yan-Ping, LI Yong-An. Enhanced Photocatalytic Activity of Bi2WO6 by the Synergistic Action of Ti(IV) and Graphene Bi-cocatalysts [J]. Journal of Inorganic Materials, 2017, 32(3): 269-274. |

| [15] | YUAN Qin, SONG Yong-Cai. Effects of Al and O Content on Transformation from SiAlCO to Si(Al)C Fibers after High Temperature Treatment [J]. Journal of Inorganic Materials, 2016, 31(4): 393-400. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||