Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (4): 394-400.DOI: 10.15541/jim20180276

Previous Articles Next Articles

Bo-Le MA1,2,Wen MA1,2( ),Wei HUANG1,2,Yu BAI1,2,Rui-Ling JIA1,2,Hong-Ying DONG2,3

),Wei HUANG1,2,Yu BAI1,2,Rui-Ling JIA1,2,Hong-Ying DONG2,3

Received:2018-06-22

Revised:2018-08-29

Published:2019-04-20

Online:2019-04-15

Supported by:CLC Number:

Bo-Le MA, Wen MA, Wei HUANG, Yu BAI, Rui-Ling JIA, Hong-Ying DONG. Thermophysical Property of Single-phase Strontium Zirconate Co-doped with Double Rare-earth Oxides as a Thermal Barrier Coating Material[J]. Journal of Inorganic Materials, 2019, 34(4): 394-400.

| Current/A | Ar/(L?min-1) | H2/(L?min-1) | Spray distance/mm | Power/kW |

|---|---|---|---|---|

| 500 | 40 | 10 | 100 | 35.8 |

Table 1 Parameters of spraying

| Current/A | Ar/(L?min-1) | H2/(L?min-1) | Spray distance/mm | Power/kW |

|---|---|---|---|---|

| 500 | 40 | 10 | 100 | 35.8 |

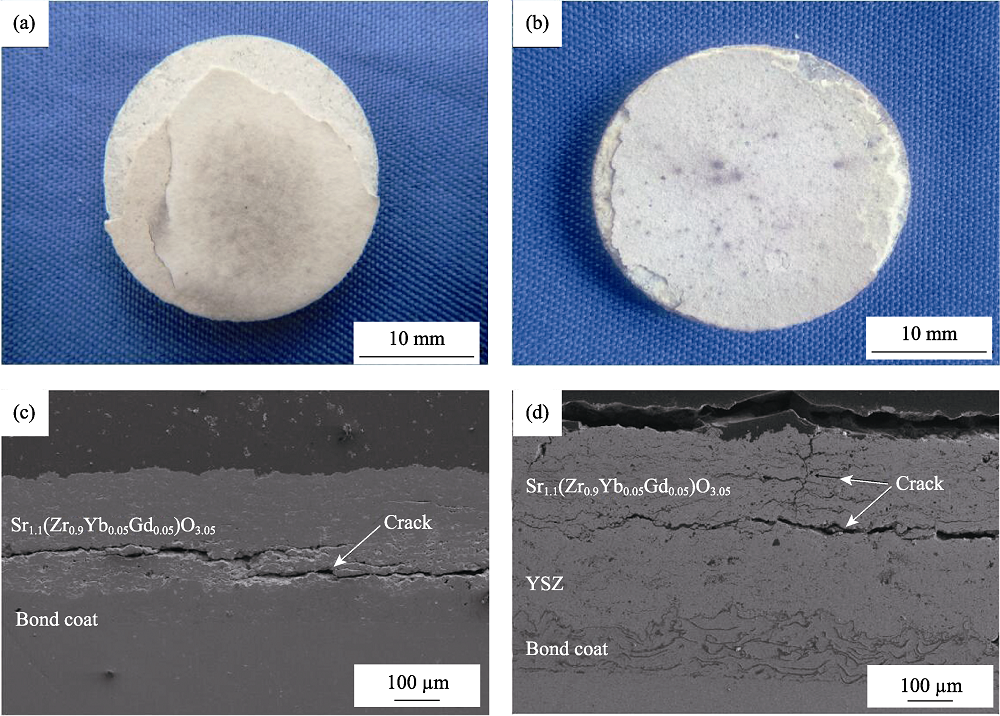

Fig. 8 Photographs (a-b) and SEM microstructures (c-d) of coatings after burner rig tests (a, c) Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05; (b, d) Sr1.1(Zr0.9Yb0.05Gd0.05)O3.05/YSZ

| [1] | 曹学强 . 热障涂层新材料和新结构. 北京: 科学出版社, 2016 |

| [2] | KUMAR V, BALASUBRAMANIAN K . Progress update on failure mechanisms of advanced thermal barrier coatings: a review. Progress in Organic Coatings, 2016,90:54-82. |

| [3] | MAUER G, MACK D E, VAβEN R. Plasma-sprayed thermal barrier coatings: new materials, processing issues, and solutions. Journal of Thermal Spray Technology, 2013,22(5):646-658. |

| [4] | GUPTA M. Design of Thermal Barrier Coatings. Berlin: Springer International Publishing, 2015. |

| [5] | 郭敏海 . 超声辅助激光熔覆YSZ陶瓷涂层实验研究. 大连: 大连理工大学博士学位论文, 2015. |

| [6] | SHEN JIE, ZHAO XIAO-DONG, GAO FENG , et al. Study on oxidation resistance of NiCoCrAlY bonded coating. Thermal Spray Technology, 2010,2(4):24-29. |

| [7] | WANG HAO, WANG QUQN-SHENG . Research progress on modification in compositions of MCrAIY coatings. Surface Technology, 2014,43(3):152-174. |

| [8] | KRAUSE A R, GARCES H F, DWIVEDI G , et al. Calcia- magnesia-alumino-silicate (CMAS)-induced degradation and failure of air plasma sprayed yttria-stabilized zirconia thermal barrier coatings. Acta Materialia, 2016,105:355-366. |

| [9] | 凌锡祥 . 8YSZ热障涂层隔热性能及热冲击性能的数值研究. 上海: 上海交通大学博士学位论文, 2015. |

| [10] | CHRISTOPHER J HOWARD, KEVIN S KNIGHT, BRENDAN J KENNEDY , et al. The structural phase transitions in strontium zirconate revisited. Journal of Physics Condensed Matter, 2000,12(12):L677-L683. |

| [11] | MA W, MACK D, MALZBENDER J , et al. Yb2O3 and Gd2O3 doped strontium zirconate for thermal barrier coatings. Journal of the European Ceramic Society, 2008,28(16):3071-3081. |

| [12] | MA WEN, SONG FENG-YU, DONG HONG-YING , et al. Thermophysical properties of Y2O3 and Gd2O3 co-doped SrZrO3 thermal barrier coating material. Journal of Inorganic Materials, 2012,27(2):209-213. |

| [13] | MA W, WANG D, DONG H , et al. Double rare-earth oxides co-doped strontium zirconate as a new thermal barrier coating material. Journal of Thermal Spray Technology, 2013,22(2/3):104-109. |

| [14] | MA WEN, GUO HONG-BO, GONG SHENG-KAI , et al. Lanthanum- cerium oxide thermal barrier coatings prepared by atmospheric plasma spray. Journal of Inorganic Materials, 2009,24(5):983-988. |

| [15] | OU YANG-JING, LI XIAO-YU, JIN JIAO , et al. Research progress in the structural, mechanical properties of ZrO2 and their applications. Materials Review, 2013,27(15):13-18. |

| [16] | LI ZHENG, ZHANG XIN, ZHANG DE-MING , et al. Study on effects of amount of doping rare earth oxide for modified YSZ thermal barrier coatings. Thermal Spray Technology, 2015,7(1):44-49. |

| [17] | SPEIGHT J G . Lange’s Handbook of Chemistry. 16th Edition, New York: McGraw-Hill,Inc., 2014. |

| [18] | ZHANG ER-GENG, CHEN QIANG, HUANG BIAO , et al. Research progress and performance of thermal barrier coatings. Journal of Ceramics, 2016,37(1):5-10. |

| [19] | TRAEGER F, AHRENS M, VAβEN R , et al. A life time model for ceramic thermal barrier coatings. Materials Science & Engineering A, 2003,358(1/2):255-265. |

| [20] | RAGHAVAN S, WANG H, DINWIDDIE R B , et al. The effect of grain size, porosity and yttria content on the thermal conductivity of nanocrystalline zirconia. Scripta Materialia, 1998,39(8):1119-1125. |

| [1] | CHEN Qiang, BAI Shuxin, YE Yicong. Highly Thermal Conductive Silicon Carbide Ceramics Matrix Composites for Thermal Management: a Review [J]. Journal of Inorganic Materials, 2023, 38(6): 634-646. |

| [2] | ZHANG Shuo, FU Qiangang, ZHANG Pei, FEI Jie, LI Wei. Influence of High Temperature Treatment of C/C Porous Preform on Friction and Wear Behavior of C/C-SiC Composites [J]. Journal of Inorganic Materials, 2023, 38(5): 561-568. |

| [3] | AN Wenran, HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang. Effect of Heat-treatment Temperature on Thermal and Mechanical Properties of LaMgAl11O19 Coating [J]. Journal of Inorganic Materials, 2022, 37(9): 925-932. |

| [4] | FU Shi, YANG Zengchao, LI Honghua, WANG Liang, LI Jiangtao. Mechanical Properties and Thermal Conductivity of Si3N4 Ceramics with Composite Sintering Additives [J]. Journal of Inorganic Materials, 2022, 37(9): 947-953. |

| [5] | HU Jiajun, WANG Kai, HOU Xinguang, YANG Ting, XIA Hongyan. Boron Phosphide with High Thermal Conductivity: Synthesis by Molten Salt Method and Thermal Management Performance [J]. Journal of Inorganic Materials, 2022, 37(9): 933-940. |

| [6] | WANG Pengjiang, KANG Huijun, YANG Xiong, LIU Ying, CHENG Cheng, WANG Tongmin. Inhibition of Lattice Thermal Conductivity of ZrNiSn-based Half-Heusler Thermoelectric Materials by Entropy Adjustment [J]. Journal of Inorganic Materials, 2022, 37(7): 717-723. |

| [7] | RUAN Jing, YANG Jinshan, YAN Jingyi, YOU Xiao, WANG Mengmeng, HU Jianbao, ZHANG Xiangyu, DING Yusheng, DONG Shaoming. Porous SiC Ceramic Matrix Composite Reinforced by SiC Nanowires with High Strength and Low Thermal Conductivity [J]. Journal of Inorganic Materials, 2022, 37(4): 459-466. |

| [8] | LOU Xunuo, DENG Houquan, LI Shuang, ZHANG Qingtang, XIONG Wenjie, TANG Guodong. Thermal and Electrcial Transport Properities of Ge Doped MnTe Thermoelectrics [J]. Journal of Inorganic Materials, 2022, 37(2): 209-214. |

| [9] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [10] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [11] | WANG Weide, CHEN Huanbei, LI Shishuai, YAO Dongxu, ZUO Kaihui, ZENG Yuping. Preparation of Silicon Nitride with High Thermal Conductivity and High Flexural Strength Using YbH2-MgO as Sintering Additive [J]. Journal of Inorganic Materials, 2021, 36(9): 959-966. |

| [12] | WANG Haoxuan, LIU Qiaomu, WANG Yiguang. Research Progress of High Entropy Transition Metal Carbide Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 355-364. |

| [13] | ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie, GAO Feng. Preparation and Thermal Properties of Rare Earth Tantalates (RETaO4) High-Entropy Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 411-417. |

| [14] | SANG Weiwei, ZHANG Hongsong, CHEN Huahui, WEN Bin, LI Xinchun. Preparation and Thermophysical Properties of (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7 High-entropy Ceramic [J]. Journal of Inorganic Materials, 2021, 36(4): 405-410. |

| [15] | MU Tinghai, XU Wentao, LING Junrong, DONG Tianwen, QIN Zixuan, ZHOU Youfu. Microstructure and Properties of ZrO2-AlN Composite Ceramics by Microwave Sintering [J]. Journal of Inorganic Materials, 2021, 36(11): 1231-1236. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||