Journal of Inorganic Materials ›› 2019, Vol. 34 ›› Issue (4): 387-393.DOI: 10.15541/jim20180263

Previous Articles Next Articles

Ren-De CHEN1,Peng GUO1,Xiao ZUO1,Shi-Peng XU2,Pei-Ling KE1,3,Ai-Ying WANG1,3( )

)

Received:2018-06-19

Revised:2018-09-25

Published:2019-04-20

Online:2019-04-15

Supported by:CLC Number:

Ren-De CHEN, Peng GUO, Xiao ZUO, Shi-Peng XU, Pei-Ling KE, Ai-Ying WANG. Ag Doped Amorphous Carbon Films: Structure, Mechanical and Electrical Behaviors[J]. Journal of Inorganic Materials, 2019, 34(4): 387-393.

| Sputtering current /A | Sputtering power /W | Ag concentration /at% | O concentration /at% | Thickness /nm | Deposition rate /(nm?min-1) |

|---|---|---|---|---|---|

| 1.3 | 582 | 0.7 | 30.2 | 364.5 | 18.2 |

| 1.4 | 602 | 0.8 | 26.5 | 358.3 | 17.9 |

| 1.5 | 647 | 1.2 | 27.2 | 508.5 | 25.4 |

| 1.6 | 859 | 13.0 | 45.2 | 725.4 | 36.3 |

| 1.8 | 788 | 37.8 | 32.9 | 1409.1 | 70.5 |

| 2.0 | 856 | 41.4 | 32.2 | 1720.4 | 86.0 |

Table 1 Ag concentration, O concentration, film thickness and average deposition rate varied with sputtering current and power

| Sputtering current /A | Sputtering power /W | Ag concentration /at% | O concentration /at% | Thickness /nm | Deposition rate /(nm?min-1) |

|---|---|---|---|---|---|

| 1.3 | 582 | 0.7 | 30.2 | 364.5 | 18.2 |

| 1.4 | 602 | 0.8 | 26.5 | 358.3 | 17.9 |

| 1.5 | 647 | 1.2 | 27.2 | 508.5 | 25.4 |

| 1.6 | 859 | 13.0 | 45.2 | 725.4 | 36.3 |

| 1.8 | 788 | 37.8 | 32.9 | 1409.1 | 70.5 |

| 2.0 | 856 | 41.4 | 32.2 | 1720.4 | 86.0 |

| Ag concentration /at% | G-peak position/cm-1 | ID/IG | FWHM of G-peak/cm-1 |

|---|---|---|---|

| 0.7 | 1533.0 | 0.75 | 159.4 |

| 0.8 | 1535.9 | 0.79 | 151.6 |

| 1.2 | 1539.8 | 0.85 | 151.4 |

| 13.0 | 1582.5 | 1.94 | 122.5 |

| 37.8 | 1566.4 | 2.15 | 123.6 |

| 41.4 | 1580.7 | 2.68 | 110.0 |

Table 2 The fitted G-peak position, ID/IG and FWHM of G-peak varied with different Ag concentrations

| Ag concentration /at% | G-peak position/cm-1 | ID/IG | FWHM of G-peak/cm-1 |

|---|---|---|---|

| 0.7 | 1533.0 | 0.75 | 159.4 |

| 0.8 | 1535.9 | 0.79 | 151.6 |

| 1.2 | 1539.8 | 0.85 | 151.4 |

| 13.0 | 1582.5 | 1.94 | 122.5 |

| 37.8 | 1566.4 | 2.15 | 123.6 |

| 41.4 | 1580.7 | 2.68 | 110.0 |

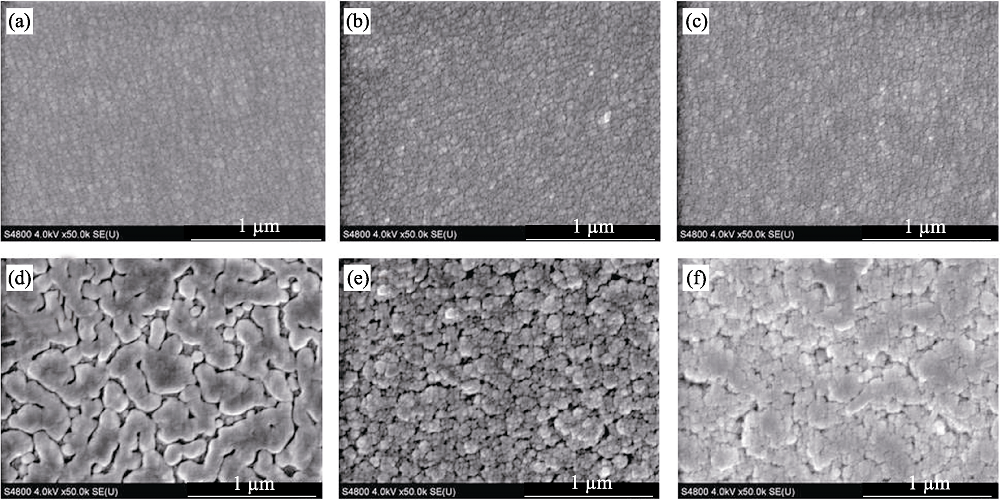

Fig. 5 Surface topographies of a-C:Ag films with different Ag concentrations (a) 0.7at%; (b) 0.8at%; (c) 1.2at%; (d) 13.0at%; (e) 37.8at%; (f) 41.4at%

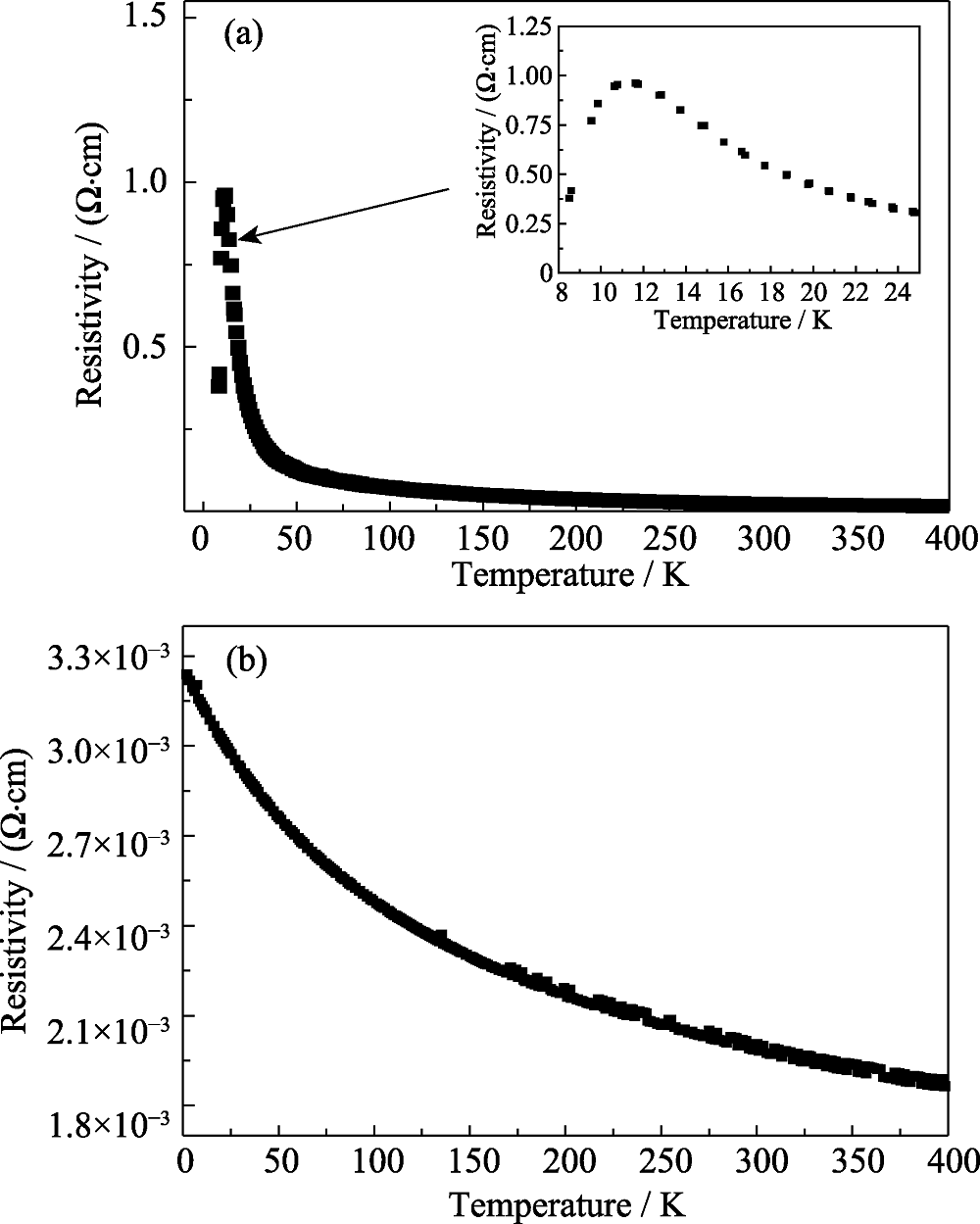

Fig. 8 Temperature dependence of resistivity in a-C:Ag film with 37.8at% Ag in the range of 8~400 K (a) and the a-C:Ag with 41.4at% Ag in the range of 2~400 K (b)

| [1] | 薛群基, 王立平 . 类金刚石碳基薄膜材料. 北京: 科学出版社, 2012. |

| [2] | ROBERTSON J . Diamond-like amorphous carbon. Mater. Sci. Eng.B, 2002,37(4/5/6):129-281. |

| [3] | DAI W . Research on the synthesis, structure and properties of metal doped diamond-like carbon nanocomposite films. New Technology & New Process, 2015,7:128-131. |

| [4] | ZHANG S, WU Y, ZHU L , et al. Research progress of metal doped diamond-like carbon films. Aeronautical Manufacturing Technology, 2017,13:77-82. |

| [5] | TAMULEVICIUS S, MESKINIS S, TAMULEVICIUS T , et al. Diamond like carbon nanocomposites with embedded metallic nanoparticles. Rep. Prog. Phys., 2018, 81(2): 024501-1-31. |

| [6] | PU J, WANG L, XUE Q . Progress in strengthening and toughening carbon-based films. China Surface Engineering, 2014,27(6):4-27. |

| [7] | WU Y, CHEN J, LI H , et al. Preparation and properties of Ag/DLC nanocomposite films fabricated by unbalanced magnetron sputtering. Appl. Surf.Sci, 2013,284:165-170. |

| [8] | MAZARE A, ANGHEL A, SURDU-BOB C , et al. Silver doped diamond-like carbon antibacterial and corrosion resistance coatings on titanium. Thin Solid Films, 2018,657:16-23. |

| [9] | CONSTANTINOU M, PERVOLARAKI M, NIKOLAOU P , et al. Microstructure and nanomechanical properties of pulsed excimer laser deposited DLC:Ag films: enhanced nanotribological response. Surf. Coat. Technol, 2017,309:320-330. |

| [10] | DWIVEDI N, KUMAR S, CAREY J D , et al. Influence of silver incorporation on the structural and electrical properties of diamond-like carbon thin films. ACS Appl Mater Interfaces, 2013,5:2725-2732. |

| [11] | MEŠKINIS Š, VASILIAUSKAS A, ŠLAPIKAS K , et al. Bias effects on structure and piezoresistive properties of DLC:Ag thin films. Surf. Coat. Technol., 2014,255:84-89. |

| [12] | PEINER E, TIBREWALA A, BANDORF R , et al. Diamond-like carbon for MEMS.[J]. Micromech. Microeng., 2007,17(7):S83-S90. |

| [13] | CHUA D H C, MILNE W I, SHEEJA D , et al. Fabrication of diamond- like amorphous carbon cantilever resonators. J. Vac. Sci. Technol. B, 2004,22(6):2680-2684. |

| [14] | SARSEMBINOV S S, PRIKHODKO O Y, RYAGUZOV A P , et al. Electronic properties of diamond-like carbon films modified by silver nanoclusters. Phys. Status Solidi C, 2009,7:805-807. |

| [15] | ABDOLGHADERI S, ASTINCHAP B, SHAFIEKHANI A . Electrical percolation threshold in Ag-DLC nanocomposite films prepared by RF-sputtering and RF-PECVD in acetylene plasma. J Mater Sci: Mater Electron, 2016,27(7):6713-6720. |

| [16] | MUSIL J, LOUDA M, SOUKUP Z , et al. Relationship between mechanical properties and coefficient of friction of sputtered a-C/Cu composite thin films. Diamond Relat. Mater., 2008,17(11):1905-1911. |

| [17] | MATSUNAMI N, YAMAMURA Y, ITIKAWA Y , et al. Energy dependence of the ion-induced sputtering yields of monatomic solids. At. Data Nucl.Data Tables, 1984,31:1-80. |

| [18] | SMENTKOWSKI V S . Trends in sputtering. Prog. Surf. Sci., 2000,64:1-58. |

| [19] | TAKI T, TAKAI O . XPS structural characterization of hydrogenated amorphous carbon thin films prepared by shielded arc ion plating. Thin Solid Films, 1998,316:45-50. |

| [20] | KIM H W, LEE N E . Conformal electroless filling of Cu into patterned amorphous carbon layer modified by oxygen plasma and aminosilane treatments. J. Vac. Sci. Technol.B, 2010,28(4):715-719. |

| [21] | WARREN B E . X-ray diffraction, New edition, US: Dover Publications, 1990. |

| [22] | FERRARI A C, ROBERTSON J . Interpretation of Raman spectra of disordered and amorphous carbon. Phys. Rev.B, 2000,61(20):14095-14107. |

| [23] | FERRARI A C, ROBERTSON J . Resonant Raman spectroscopy of disordered,amorphous,diamondlike carbon. Phys. Rev. B, 2001, 64(7): 075414-1-13. |

| [24] | CASIRAGHI C, FERRARI A C, ROBERTSON J. Raman spectroscopy of hydrogenated amorphous carbon. Phys. Rev. B, 2005, 72: 085401-1-14. |

| [25] | ZOU C W, WANG H J, FENG L , et al. Effects of Cr concentrations on the microstructure, hardness, and temperature-dependent tribological properties of Cr-DLC coatings. Appl. Surf. Sci., 2013,286:137-141. |

| [26] | DAI W, KE P, MOON M W , et al. Investigation of the microstructure, mechanical properties and tribological behaviors of Ti- containing diamond-like carbon films fabricated by a hybrid ion beam method. Thin Solid Films, 2012,520(19):6057-6063. |

| [27] | QUAN J, ZHANG J, QI X , et al. A study on the correlation between the dewetting temperature of Ag film and SERS intensity. Sci. Rep., 2017,7(1):14771-14782. |

| [28] | GUO P, SUN L, LI X , et al. Structural properties and surface wettability of Cu-containing diamond-like carbon films prepared by a hybrid linear ion beam deposition technique. Thin Solid Films, 2015,584:289-293. |

| [29] | SINGH V, JIANG J C, MELETIS E I . Cr-diamondlike carbon nanocomposite films: synthesis, characterization and properties. Thin Solid Films, 2005,489(1/2):150-158. |

| [30] | SONODA T, NAKAO S, IKEYAMA M . Deposition of Ti/C nano-composite DLC films by magnetron DC sputtering with dual targets. Vacuum, 2009,84(5):666-668. |

| [31] | WANG A Y, LEE K R, AHN J P , et al. Structure and mechanical properties of W incorporated diamond-like carbon films prepared by a hybrid ion beam deposition technique. Carbon, 2006,44(9):1826-1832. |

| [32] | GUO P, LI X, SUN L , et al. Stress reduction mechanism of diamond- like carbon films incorporated with different Cu contents. Thin Solid Films, 2017,640:45-51. |

| [33] | DONNET C, ERDEMIR A . Tribology of Diamond-like Carbon Films. US: Springer, 2008. |

| [34] | WAN C, ZHANG X, VANACKEN J , et al. Electro- and magneto- transport properties of amorphous carbon films doped with iron. Diamond Relat. Mater., 2011,20(1):26-30. |

| [35] | TAKENO T, MIKI H, TAKAGI T , et al. Electrically conductive properties of tungsten-containing diamond-like carbon films. Diamond Relat. Mater., 2006,15(11/12):1902-1905. |

| [36] | HUANG Q F, YOON S F, RUS LI , et al. Conduction mechanism in molybdenum-containing diamond-like carbon deposited using electron cyclotron resonance chemical vapor deposition.[J]. Appl. Phys., 2000,88(7):4191-4195. |

| [1] | AN Wenran, HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang. Effect of Heat-treatment Temperature on Thermal and Mechanical Properties of LaMgAl11O19 Coating [J]. Journal of Inorganic Materials, 2022, 37(9): 925-932. |

| [2] | LI Wenjun, WANG Hao, TU Bingtian, CHEN Qiangguo, ZHENG Kaiping, WANG Weiming, FU Zhengyi. Preparation and Property of Mg0.9Al2.08O3.97N0.03 Transparent Ceramic with Broad Optical Transmission Range [J]. Journal of Inorganic Materials, 2022, 37(9): 969-975. |

| [3] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [4] | HONG Du, NIU Yaran, LI Hong, ZHONG Xin, ZHENG Xuebin. Tribological Properties of Plasma Sprayed TiC-Graphite Composite Coatings [J]. Journal of Inorganic Materials, 2022, 37(6): 643-650. |

| [5] | XU Puhao, ZHANG Xiangzhao, LIU Guiwu, ZHANG Mingfen, GUI Xinyi, QIAO Guanjun. Microstructure and Mechanical Properties of SiC Joint Brazed by Al-Ti Alloys as Filler Metal [J]. Journal of Inorganic Materials, 2022, 37(6): 683-690. |

| [6] | DING Jianxiang, ZHANG Kaige, LIU Dongming, ZHENG Wei, ZHANG Peigen, SUN Zhengming. Ag-based Electrical Contact Material Reinforced by Ti3AlC2 Ceramic and Its Derivative Ti3C2Tx [J]. Journal of Inorganic Materials, 2022, 37(5): 567-573. |

| [7] | WEI Tingting, GAO Xiguang, SONG Yingdong. Response of 2D SiC/SiC Composites Resistivity to Service Environments [J]. Journal of Inorganic Materials, 2022, 37(4): 420-426. |

| [8] | SUN Yangshan, YANG Zhihua, CAI Delong, ZHANG Zhengyi, LIU Qi, FANG Shuqing, FENG Liang, SHI Lifen, WANG Youle, JIA Dechang. Crystallization Kinetics, Properties of α-cordierite Based Glass-ceramics Prepared by Glass Powder Sintering [J]. Journal of Inorganic Materials, 2022, 37(12): 1351-1357. |

| [9] | LIU Yunpeng, SHENG Weifan, WU Zhonghua. Synchrotron Radiation and Its Applications Progress in Inorganic Materials [J]. Journal of Inorganic Materials, 2021, 36(9): 901-918. |

| [10] | DONG Kangjia, JIANG Chen, REN Shaobin, LANG Xiaohu, GAO Rui, YE Hui. Anisotropic Calculation of Mechanical Property of GaAs Crystal [J]. Journal of Inorganic Materials, 2021, 36(6): 645-651. |

| [11] | SUN Luchao, ZHOU Cui, DU Tiefeng, WU Zhen, LEI Yiming, LI Jialin, SU Haijun, WANG Jingyang. Directionally Solidified Al2O3/Er3Al5O12 and Al2O3/Yb3Al5O12 Eutectic Ceramics Prepared by Optical Floating Zone Melting [J]. Journal of Inorganic Materials, 2021, 36(6): 652-658. |

| [12] | LÜ Shasha, ZU Yufei, CHEN Guoqing, ZHAO Bojun, FU Xuesong, ZHOU Wenlong. Preparation and Mechanical Property of the Ceramic-reinforced Cr0.5MoNbWTi Refractory High-entropy Alloy Matrix Composites [J]. Journal of Inorganic Materials, 2021, 36(4): 386-392. |

| [13] | WANG Haoxuan, LIU Qiaomu, WANG Yiguang. Research Progress of High Entropy Transition Metal Carbide Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 355-364. |

| [14] | JIN Min, BAI Xudong, ZHAO Su, ZHANG Rulin, CHEN Yuqi, ZHOU Lina. Mechanical Property of SnSe Single Crystal Prepared via Vertical Bridgman Method [J]. Journal of Inorganic Materials, 2021, 36(3): 313-318. |

| [15] | FENG Mingxing, WANG Bin, XU Pengyu, TU Bingtian, WANG Hao. Predicting Thermomechanical Properties of MgAl2O4 Transparent Ceramic Based on Bond Valence Models [J]. Journal of Inorganic Materials, 2021, 36(10): 1067-1073. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||