Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (7): 749-755.DOI: 10.15541/jim20170461

• Orginal Article • Previous Articles Next Articles

FAN Guang-Xin1, LIU Ze-Ping1, WEN Yin1, LIU Bao-Zhong2

Received:2017-09-28

Revised:2018-01-31

Published:2018-07-10

Online:2018-06-19

About author:FAN Guang-Xin. E-mail: fangx@hpu.edu.cn

Supported by:CLC Number:

FAN Guang-Xin, LIU Ze-Ping, WEN Yin, LIU Bao-Zhong. Surface Treatment on Structure and Property of LiNi0.8Co0.15Al0.05O2 by Silane Coupling Agent[J]. Journal of Inorganic Materials, 2018, 33(7): 749-755.

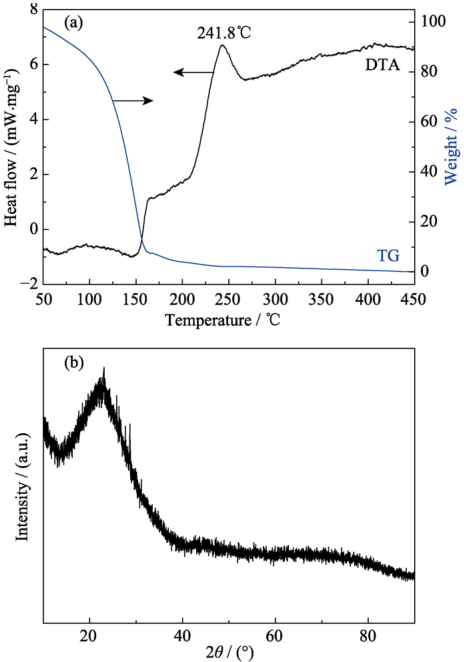

Fig. 1 (a) TG-DTA curves of the KH550 silane coupling agent in air and (b) XRD pattern for thermal decomposition product of the silane coupling agent after heating at 450℃ for 5 h

| Sample | a/nm | c/nm | c/a | FWHM/(°) | |

|---|---|---|---|---|---|

| (003) | (104) | ||||

| NCA | 0.2869 | 1.4193 | 4.948 | 0.130 | 0.225 |

| a-NCA | 0.2869 | 1.4200 | 4.949 | 0.131 | 0.228 |

Table 1 Structural parameters of NCA and a-NCA

| Sample | a/nm | c/nm | c/a | FWHM/(°) | |

|---|---|---|---|---|---|

| (003) | (104) | ||||

| NCA | 0.2869 | 1.4193 | 4.948 | 0.130 | 0.225 |

| a-NCA | 0.2869 | 1.4200 | 4.949 | 0.131 | 0.228 |

| Sample | 0.1C/(mAh·g-1) | 0.2C/(mAh·g-1) | 1C/(mAh·g-1) | Difference values of (Ni2+/Ni4+)/V | Capacity retention |

|---|---|---|---|---|---|

| NCA-RT | 171.5 | 164.7 | 146.0 | 0.11 | 94.7% |

| a-NCA-RT | 164.6 | 153.8 | 140.2 | 0.10 | 96.0% |

| NCA-HT | 184.9 | 174.2 | 153.8 | 0.05 | 86.5% |

| a-NCA-HT | 183.2 | 176.4 | 158.9 | 0.01 | 91.4% |

Table 2 Electrochemical performances of NCA and a-NCA

| Sample | 0.1C/(mAh·g-1) | 0.2C/(mAh·g-1) | 1C/(mAh·g-1) | Difference values of (Ni2+/Ni4+)/V | Capacity retention |

|---|---|---|---|---|---|

| NCA-RT | 171.5 | 164.7 | 146.0 | 0.11 | 94.7% |

| a-NCA-RT | 164.6 | 153.8 | 140.2 | 0.10 | 96.0% |

| NCA-HT | 184.9 | 174.2 | 153.8 | 0.05 | 86.5% |

| a-NCA-HT | 183.2 | 176.4 | 158.9 | 0.01 | 91.4% |

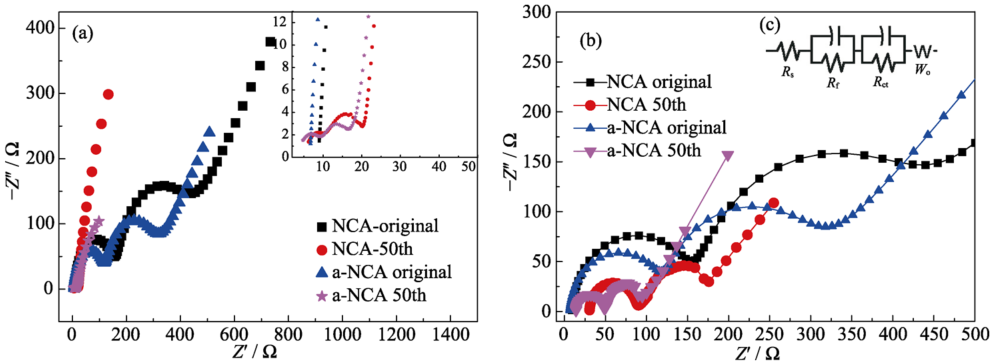

Fig. 9 EIS plots of NCA and a-NCA at (a) room temperature and (b) high temperature with inset in (b) showing the corresponding equivalent circuit diagram

| Sample | Condition | Rs/Ω | Rf/Ω | Rct/Ω | Wo/(×10-3, Ω) |

|---|---|---|---|---|---|

| NCA | Original | 8.6 | 136.4 | 211.9 | 2.0 |

| RT-50th | 7.5 | 8.3 | 126.1 | 2.8 | |

| HT-50th | 7.9 | 55.7 | 114.2 | 7.5 | |

| a-NCA | Original | 6.5 | 106.0 | 156.6 | 3.1 |

| RT-50th | 4.5 | 7.4 | 92.1 | 4.9 | |

| HT-50th | 6.2 | 21.4 | 75.5 | 8.6 |

Table 3 Electrochemical AC impedance values of NCA and a-NCA

| Sample | Condition | Rs/Ω | Rf/Ω | Rct/Ω | Wo/(×10-3, Ω) |

|---|---|---|---|---|---|

| NCA | Original | 8.6 | 136.4 | 211.9 | 2.0 |

| RT-50th | 7.5 | 8.3 | 126.1 | 2.8 | |

| HT-50th | 7.9 | 55.7 | 114.2 | 7.5 | |

| a-NCA | Original | 6.5 | 106.0 | 156.6 | 3.1 |

| RT-50th | 4.5 | 7.4 | 92.1 | 4.9 | |

| HT-50th | 6.2 | 21.4 | 75.5 | 8.6 |

| Condition | a/nm | Δa/a | c/nm | V/(×10-3, nm3) | |

|---|---|---|---|---|---|

| NCA | Original | 0.2869 | 1.4193 | 0.1011 | |

| RT-50th | 0.2858 | 0.39% | 1.4246 | 0.1007 | |

| HT-50th | 0.2841 | 0.96% | 1.4299 | 0.995 | |

| a-NCA | Original | 0.2869 | 1.4199 | 0.1012 | |

| RT-50th | 0.2862 | 0.26% | 1.4224 | 0.1008 | |

| HT-50th | 0.2857 | 0.43% | 1.4242 | 0.1001 |

Table 4 Structural parameters of NCA and a-NCA before and after cycling at room temperature and high temperature

| Condition | a/nm | Δa/a | c/nm | V/(×10-3, nm3) | |

|---|---|---|---|---|---|

| NCA | Original | 0.2869 | 1.4193 | 0.1011 | |

| RT-50th | 0.2858 | 0.39% | 1.4246 | 0.1007 | |

| HT-50th | 0.2841 | 0.96% | 1.4299 | 0.995 | |

| a-NCA | Original | 0.2869 | 1.4199 | 0.1012 | |

| RT-50th | 0.2862 | 0.26% | 1.4224 | 0.1008 | |

| HT-50th | 0.2857 | 0.43% | 1.4242 | 0.1001 |

| [1] | NITTA N, WU F, LEE J T,et al.Li-ion battery materials: present and future. Mater. Today, 2015, 18(5): 252-264. |

| [2] | TRAN H Y, TÄUBERT C, WOHLFAHRT-MEHRENS M. Influence of the technical process parameters on structural mechanical and electrochemical properties of LiNi0.8Co0.15Al0.05O2 based electrodes - a review.Prog. Solid State Ch., 2014, 42(4): 118-127. |

| [3] | WANG H, LAI C, XIAO Y,et al.A new lithium-ion battery with LiNi0.8Co0.15Al0.05O2 cathode and lithium pre-doping hard carbon anode.Mater. Lett., 2015, 160: 250-254. |

| [4] | ZUO D, TIAN G, LI X,et al.Recent progress in surface coating of cathode materials for lithium ion secondary batteries.J. Alloys Comp., 2017, 706: 24-40. |

| [5] | XU Y, LI X, WANG Z,et al.Structure and electrochemical performance of TiO2-coated LiNi0.8Co0.15Al0.05O2 cathode materials.Mater. Lett., 2015, 143: 151-154. |

| [6] | LIU W, HU G, DU K,et al.Surface coating of LiNi0.8Co0.15Al0.05O2 with LiCoO2 by a molten salt method.Surf. Coat. Tech., 2013, 216: 267-272. |

| [7] | HUANG B, LI X, WANG Z,et al.A facile process for coating amorphous FePO4 onto LiNi0.8Co0.15Al0.05O2 and the effects on its electrochemical properties.Mater. Lett., 2014, 131: 210-213. |

| [8] | LEE D J, SCROSATI B, SUN Y K.Ni3(PO4)2-coated LiNi0.8Co0.15Al0.05O2 lithium battery electrode with improved cycling performance at 55℃.J. Power Sources, 2011, 196(18): 7742-7746. |

| [9] | HE X, DU C, SHEN B,et al.Electronically conductive Sb-doped SnO2 nanoparticles coated LiNi0.8Co0.15Al0.05O2 cathode material with enhanced electrochemical properties for Li-ion batteries.Electrochim. Acta, 2017, 236: 273-279. |

| [10] | CHEN C, TAO T, WANG Q,et al.High-performance lithium ion batteries using SiO2-coated LiNi0.5Co0.2Mn0.3O2 microspheres as cathodes.J. Alloys Comp., 2017, 709: 708-716. |

| [11] | FAN Y, WANG J, TANG Z,et al.Effects of the nanostructured SiO2 coating on the performance of LiNi0.5Mn1.5O4 cathode materials for high voltage Li-ion batteries.Electrochim. Acta, 2007, 52(11): 3870-3875. |

| [12] | LIANG L, HU G, JIANG F,et al.Electrochemical behaviours of SiO2-coated LiNi0.8Co0.1Mn0.1O2 cathode materials by a novel modification method.J. Alloys Comp., 2016, 657: 570-581. |

| [13] | ZHOU P, ZHANG Z, MENG H,et al.SiO2-coated LiNi0.915Co0.075Al0.01O2 cathode material for rechargeable Li-ion batteries.Nanoscale, 2016, 8(46): 19263-19269. |

| [14] | CHO W, KIM S M, SONG J H,et al.Improved electrochemical and thermal properties of nickel rich LiNi0.6Co0.2Mn0.2O2 cathode materials by SiO2 coating.J. Power Sources, 2015, 282: 45-50. |

| [15] | LI Y, ZHAO S.Electrochemical performance of SiO2-coated LiFePO4 cathode materials for lithium ion battery.J. Alloys Comp., 2011, 509(3): 957-960. |

| [16] | MALLAKPOUR S, MADANI M.A review of current coupling agents for modification of metal oxide nanoparticles.Prog. Org. Coat., 2015, 86: 194-207. |

| [17] | LIU HUAN-MIN, HUANG KE-LONG, XUE JIAN-JUN,et al.Study on the performance of LiCrxMn2-xO4 by surface treatment with silane coupling agent.Battery Bimonthly, 2004, 34(6): 403-405. |

| [18] | 王雪明. 硅烷偶联剂在金属预处理及有机涂层中的应用研究. 济南:山东大学硕士学位论文, 2005. |

| [19] | HUANG WEI, CAO XUE-JUAN, ZHU HONG-ZHOU,et al.Research on physic adsorption and photocatalytic activity of TiO2/SiO2 with different molar content of SiO2.J. Wuhan Univ. Technol., 2015, 37(9): 25-31. |

| [20] | CHO Y, CHO J.Significant improvement of LiNi0.8Co0.15Al0.05O2 cathodes at 60℃ by SiO2 dry coating for Li-ion batteries.J. Electrochem. Soc., 2010, 157(6): A625-A629. |

| [21] | SHI Y, ZHANG M, QIAN D,et al.Ultrathin Al2O3 coatings for improved cycling performance and thermal stability of LiNi0.5Co0.2Mn0.3O2 cathode material.Electrochim. Acta, 2016, 203: 154-161. |

| [22] | YIN S C, RHO Y H, SWAINSON I,et al.X-ray/neutron diffraction and electrochemical studies of lithium de/re-intercalation in Li1-xCo1/3Ni1/3Mn1/3O2 (x=0→1).Chem. Mater., 2006, 18(7): 1901-1910. |

| [23] | LIN C K, REN Y, AMINE K,et al.In situ high-energy X-ray diffraction to study overcharge abuse of 18650-size lithium-ion battery.J. Power Sources, 2013, 230: 32-37. |

| [1] | FAN Dong, ZHONG Xin, WANG Yawen, ZHANG Zhenzhong, NIU Yaran, LI Qilian, ZHANG Le, ZHENG Xuebin. Corrosion Behavior and Mechanism of Aluminum-rich CMAS on Rare-earth Silicate Environmental Barrier Coatings: [J]. Journal of Inorganic Materials, 2023, 38(5): 544-552. |

| [2] | LI Yue, ZHANG Xuliang, JING Fangli, HU Zhanggui, WU Yicheng. Growth and Property of Ce3+-doped La2CaB10O19 Crystal [J]. Journal of Inorganic Materials, 2023, 38(5): 583-588. |

| [3] | ZHANG Wanwen, LUO Jianqiang, LIU Shujuan, MA Jianguo, ZHANG Xiaoping, YANG Songwang. Zirconia Spacer: Preparation by Low Temperature Spray-coating and Application in Triple-layer Perovskite Solar Cells [J]. Journal of Inorganic Materials, 2023, 38(2): 213-218. |

| [4] | PAN Yangyang, LIANG Bo, HONG Du, QI Zhixiang, NIU Yaran, ZHENG Xuebin. High Temperature Long-term Service Performance of TiAlCrY/YSZ Coating on TiAl Alloy [J]. Journal of Inorganic Materials, 2023, 38(1): 105-112. |

| [5] | AN Wenran, HUANG Jingqi, LU Xiangrong, JIANG Jianing, DENG Longhui, CAO Xueqiang. Effect of Heat-treatment Temperature on Thermal and Mechanical Properties of LaMgAl11O19 Coating [J]. Journal of Inorganic Materials, 2022, 37(9): 925-932. |

| [6] | ZHU Hezhen, WANG Xuanpeng, HAN Kang, YANG Chen, WAN Ruizhe, WU Liming, MAI Liqiang. Enhanced Lithium Storage Stability Mechanism of Ultra-high Nickel LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2 Cathode Materials [J]. Journal of Inorganic Materials, 2022, 37(9): 1030-1036. |

| [7] | FENG Kun, ZHU Yong, ZHANG Kaiqiang, CHEN Zhang, LIU Yu, GAO Yanfeng. Boehmite Nanosheets-coated Separator with Enhanced Performance for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(9): 1009-1015. |

| [8] | HONG Du, NIU Yaran, LI Hong, ZHONG Xin, ZHENG Xuebin. Tribological Properties of Plasma Sprayed TiC-Graphite Composite Coatings [J]. Journal of Inorganic Materials, 2022, 37(6): 643-650. |

| [9] | LIU Pingping, ZHONG Xin, ZHANG Le, LI Hong, NIU Yaran, ZHANG Xiangyu, LI Qilian, ZHENG Xuebin. Molten Salt Corrosion Behaviors and Mechanisms of Ytterbium Silicate Environmental Barrier Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1267-1274. |

| [10] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [11] | MENG Qing, LI Jiangtao. Hydrophobic BN Powders by Combustion Synthesis and Its Super-hydrophobic Coatings: Preparation and Property [J]. Journal of Inorganic Materials, 2022, 37(10): 1037-1042. |

| [12] | LIU Fangfang, CHUAN Xiuyun, YANG Yang, LI Aijun. Influence of N/S Co-doping on Electrochemical Property of Brucite Template Carbon Nanotubes [J]. Journal of Inorganic Materials, 2021, 36(7): 711-717. |

| [13] | YE Wenhao, WEI Qiang, LIANG Jiamin, ZHOU Jie, MENG Fanping, EKLUND Per, HUANG Qing. Zr2Al3C4 Coatings on Zirconium-alloy Substrates with Enhanced Adhesion and Diffusion Barriers by Al/Mo-C Interlayers [J]. Journal of Inorganic Materials, 2021, 36(5): 541-546. |

| [14] | ZHU Jiatong, LOU Zhihao, ZHANG Ping, ZHAO Jia, MENG Xuanyu, XU Jie, GAO Feng. Preparation and Thermal Properties of Rare Earth Tantalates (RETaO4) High-Entropy Ceramics [J]. Journal of Inorganic Materials, 2021, 36(4): 411-417. |

| [15] | SANG Weiwei, ZHANG Hongsong, CHEN Huahui, WEN Bin, LI Xinchun. Preparation and Thermophysical Properties of (Sm0.2Gd0.2Dy0.2Y0.2Yb0.2)3TaO7 High-entropy Ceramic [J]. Journal of Inorganic Materials, 2021, 36(4): 405-410. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||