Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (3): 345-351.DOI: 10.15541/jim20170205

• Orginal Article • Previous Articles Next Articles

HUANG Pan1, ZHOU Liang1, LI Hua-Zheng1, LI Hong-Jian1, YANG Jian-hua2, WANG Jin-Qu1, 2

Received:2017-04-28

Revised:2017-06-08

Published:2018-03-20

Online:2018-03-12

About author:HUANG Pan. E-mail: huangpanchem@sina.com

Supported by:CLC Number:

HUANG Pan, ZHOU Liang, LI Hua-Zheng, LI Hong-Jian, YANG Jian-hua, WANG Jin-Qu. Preparation and Characterization of High Performance MFI Zeolite Membrane in Ultradilute Solution[J]. Journal of Inorganic Materials, 2018, 33(3): 345-351.

| Sample | Precursor | Temp./℃ | Average size/μm | Conc./wt% |

|---|---|---|---|---|

| A | 1 | 96 | 0.4 | 0.35 |

| B | 2 | 100 | 0.8 | 0.35 |

| C | 2 | 150 | 1.3 | 2.5&0.35 |

Table 1 Preparation of Silicalite-1 seeds with different sizes

| Sample | Precursor | Temp./℃ | Average size/μm | Conc./wt% |

|---|---|---|---|---|

| A | 1 | 96 | 0.4 | 0.35 |

| B | 2 | 100 | 0.8 | 0.35 |

| C | 2 | 150 | 1.3 | 2.5&0.35 |

Fig. 1 Surface and cross-sectional SEM images of the α-Al2O3 support(a)-(b), the support modified by large seeds(c, d) and the seed layers prepared with differently sized seeds (0.4 μm (e, f); 0.8 μm (g, h) and 1.3 μm (i, j))

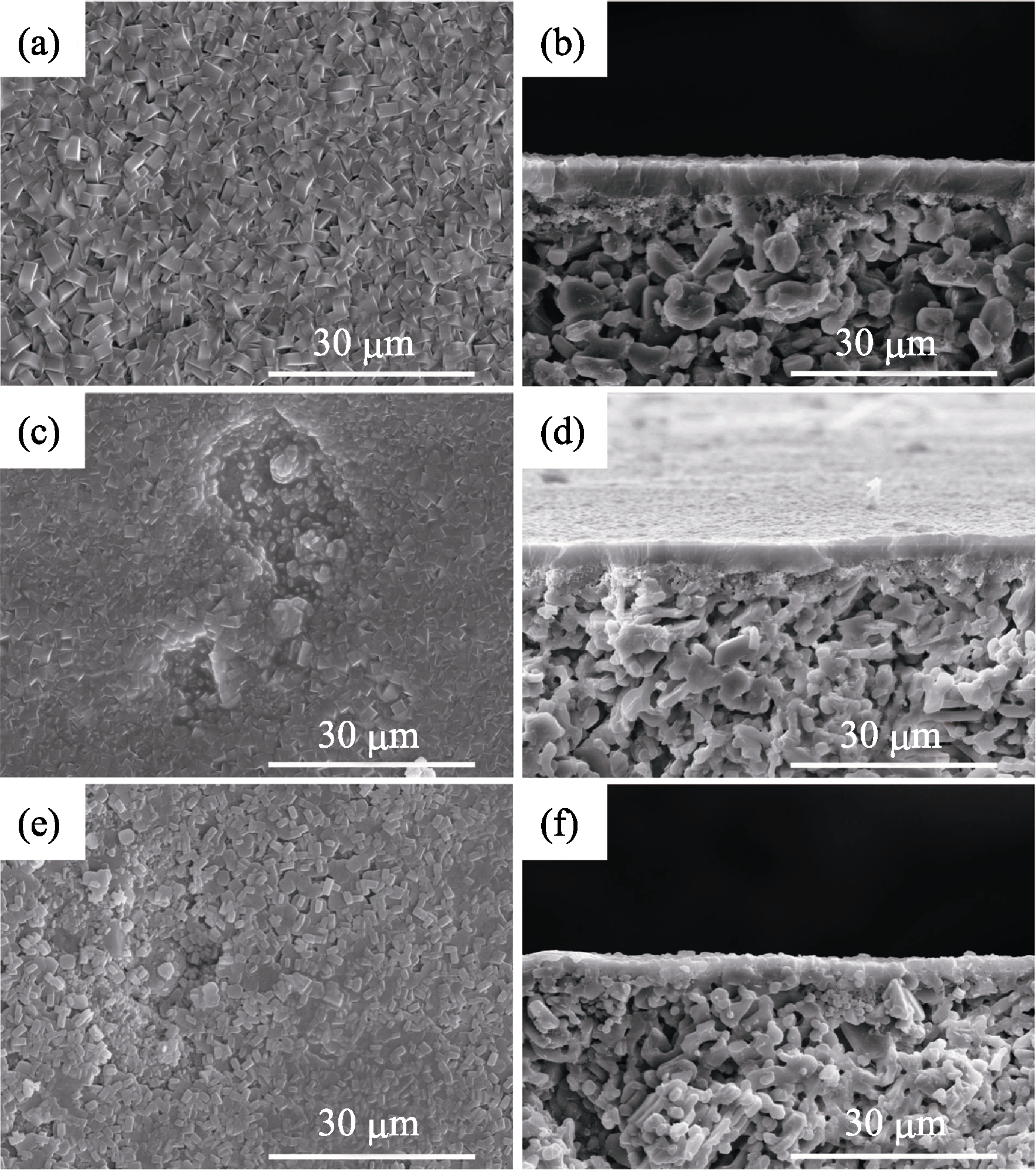

Fig. 2 SEM images of MFI zeolite membranes prepared with different-size seeds in H2O/SiO2=1000 synthetic solution (a, b)-M1 0.4 μm; (c, d)-M2 0.8 μm; (e, f)-M3 1.3 μm

| No | Seed size/μm | H2O/SiO2 | Time/h | J/(kg·m-2·h-1) | α |

|---|---|---|---|---|---|

| M1 | 0.4 | 1000 | 24 | 4.09 | 47 |

| M2 | 0.8 | 1000 | 24 | 4.22 | 39 |

| M3 | 1.3 | 1000 | 24 | 4.30 | 35 |

| M4 | 0.4 | 1800 | 32 | 4.36 | 19 |

| M5 | 0.8 | 1800 | 32 | - | - |

| M6 | 1.3 | 1800 | 32 | - | - |

Table 2 Pervaporation performance of MFI zeolite membranes prepared with seeds of different size

| No | Seed size/μm | H2O/SiO2 | Time/h | J/(kg·m-2·h-1) | α |

|---|---|---|---|---|---|

| M1 | 0.4 | 1000 | 24 | 4.09 | 47 |

| M2 | 0.8 | 1000 | 24 | 4.22 | 39 |

| M3 | 1.3 | 1000 | 24 | 4.30 | 35 |

| M4 | 0.4 | 1800 | 32 | 4.36 | 19 |

| M5 | 0.8 | 1800 | 32 | - | - |

| M6 | 1.3 | 1800 | 32 | - | - |

Fig. 3 SEM images of MFI zeolite membranes prepared with different-size seeds in H2O/SiO2=1800 synthetic solution (a, b)-M4 0.4 μm; (c, d)-M5 0.8 μm; (e, f)-M6 1.3 μm

| Sample | H2O/SiO2 | Time /h | J/(kg·m-2·h-1) | α |

|---|---|---|---|---|

| M7 | 200 | 24 | 2.94 | 22 |

| M8 | 650 | 24 | 3.60 | 32 |

| M1 | 1000 | 24 | 4.09 | 47 |

| M9 | 1400 | 24 | 4.40 | 43 |

| M10 | 1800 | 24 | 4.90 | 11 |

| M4 | 1800 | 32 | 4.36 | 19 |

Table 3 Pervaporation performances of MFI-type zeolite membranes prepared from synthesis solutions with different H2O/SiO2

| Sample | H2O/SiO2 | Time /h | J/(kg·m-2·h-1) | α |

|---|---|---|---|---|

| M7 | 200 | 24 | 2.94 | 22 |

| M8 | 650 | 24 | 3.60 | 32 |

| M1 | 1000 | 24 | 4.09 | 47 |

| M9 | 1400 | 24 | 4.40 | 43 |

| M10 | 1800 | 24 | 4.90 | 11 |

| M4 | 1800 | 32 | 4.36 | 19 |

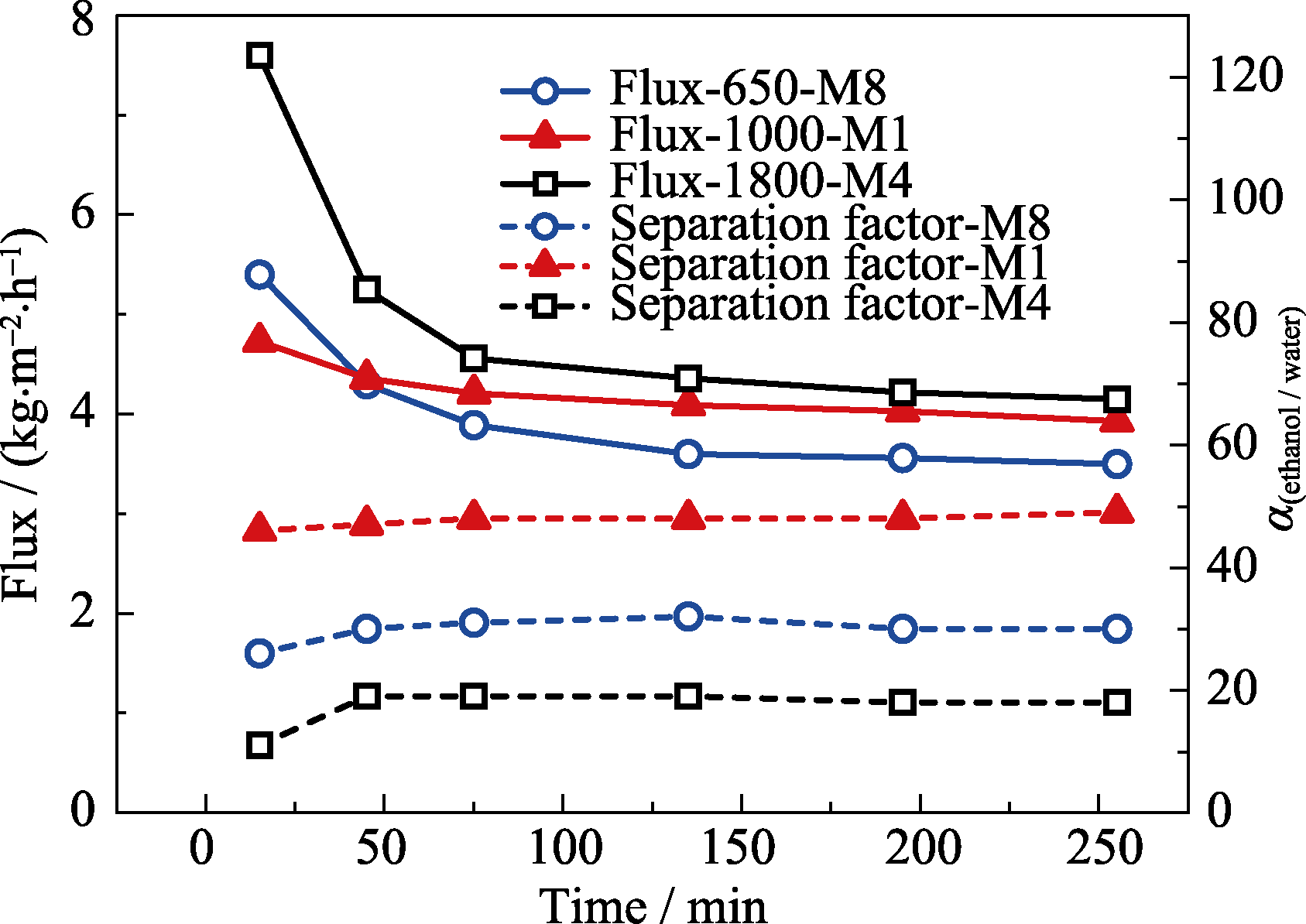

Fig. 7 Pervaporation performance of MFI zeolite membrane prepared in synthetic solution with different H2O/SiO2 ratios for separation of 5wt% ethanol/water mixtures at 60℃

| Membrane/Support | Pore size/μm | H2O/SiO2 | Feed conc./wt% | Feed temp./℃ | J/(kg·m-2·h-1) | α(ethanol/water) | Ref. |

|---|---|---|---|---|---|---|---|

| Si-1/Ml-t | 1.0 | 800 | 5 | 60 | 1.91 | 66 | [22] |

| MFI/α-d | 0.1+3.0 | 58 | 10 | 60 | 9.00 | 5 | [14] |

| Si-1/α-t | 2.0 | 120 | 5 | 60 | 1.81 | 89 | [15] |

| Si-1/Ml-t | 1.0 | 120 | 5 | 60 | 2.23 | 62 | [15] |

| MFI/α-hf | 0.1-0.2 | 165 | 3 | 60 | 2.90 | 66 | [17] |

| MFI/α-t | 1.0-3.0 | 165 | 5 | 60 | 1.36 | 85 | [26] |

| MFI/α-t | 3.0-4.0 | 1000 | 5 | 60 | 4.09 | 47 | This work |

| MFI/α-t | 3.0-4.0 | 1400 | 5 | 60 | 4.40 | 43 | This work |

Table 4 Pervaporation performance of MFI membranes for ethanol/water mixtures

| Membrane/Support | Pore size/μm | H2O/SiO2 | Feed conc./wt% | Feed temp./℃ | J/(kg·m-2·h-1) | α(ethanol/water) | Ref. |

|---|---|---|---|---|---|---|---|

| Si-1/Ml-t | 1.0 | 800 | 5 | 60 | 1.91 | 66 | [22] |

| MFI/α-d | 0.1+3.0 | 58 | 10 | 60 | 9.00 | 5 | [14] |

| Si-1/α-t | 2.0 | 120 | 5 | 60 | 1.81 | 89 | [15] |

| Si-1/Ml-t | 1.0 | 120 | 5 | 60 | 2.23 | 62 | [15] |

| MFI/α-hf | 0.1-0.2 | 165 | 3 | 60 | 2.90 | 66 | [17] |

| MFI/α-t | 1.0-3.0 | 165 | 5 | 60 | 1.36 | 85 | [26] |

| MFI/α-t | 3.0-4.0 | 1000 | 5 | 60 | 4.09 | 47 | This work |

| MFI/α-t | 3.0-4.0 | 1400 | 5 | 60 | 4.40 | 43 | This work |

| [1] | LEE I, JEONG H K.Synthesis and gas permeation properties of highly b-oriented MFI silicalite-1 thin membranes with controlled microstructure. Micropor. Mesopor. Mater., 2011, 141(1): 175-183. |

| [2] | WANG H, LIN Y S.Synthesis and modification of ZSM-5/silicalite bilayer membrane with improved hydrogen separation performance .[J]. Membr. Sci., 2012, 396: 128-137. |

| [3] | HONG Z, ZHANG C, GU X, et al.A simple method for healing nonzeolitic pores of MFI membranes by hydrolysis of silanes .[J]. Membr. Sci., 2011, 366(1): 427-435. |

| [4] | YUAN W, LIN Y S, YANG W.Molecular sieving MFI-type zeolite membranes for pervaporation separation of xylene isomers .[J]. Am. Chem. Soc., 2004, 126(15): 4776-4777. |

| [5] | YAN Y, JIANG S, ZHANG H, et al.Preparation of novel Fe-ZSM-5 zeolite membrane catalysts for catalytic wet peroxide oxidation of phenol in a membrane reactor. Chemical Engineering Journal, 2015, 259: 243-251. |

| [6] | SATO T, KUMAGAI A, ITOH N.A catalytic ZSM-5 membrane sandwiched with silicalite-1 layers for highly selective toluene disproportionation. Sep. Purif. Technol., 2010, 73(1): 32-37. |

| [7] | LI L, ZHANG W, YANG J, et al.Preparation and characterization of water perm-selectivity ZSM-5 zeolite membrane using fluoride route. Journal of Inorganic Materials, 2015, 30(11): 1167-1171. |

| [8] | ZHU M, KUMAKIRI I, TANAKA K, et al.Dehydration of acetic acid and esterification product by acid-stable ZSM-5 membrane. Micropor. Mesopor. Mater., 2013, 181: 47-53. |

| [9] | BOWEN T C, NOBLE R D, FALCONER J L.Fundamentals and applications of pervaporation through zeolite membranes .[J]. Membr. Sci., 2004, 245(1): 1-33. |

| [10] | WEE S L, TYE C T, BHATIA S.Membrane separation process- pervaporation through zeolite membrane. Sep. Purif. Technol., 2008, 63(3): 500-516. |

| [11] | ZHAO C, LIU X, ZHANG B.Submicrometer-thick b-oriented Fe-silicalite-1 membranes: microwave-assisted fabrication and pervaporation performances. RSC Advances, 2016, 6(110): 108265-108269. |

| [12] | YU L, KORELSKIY D, GRAHN M, et al.Very high flux MFI membranes for alcohol recovery via pervaporation at high temperature and pressure. Sep. Purif. Technol., 2015, 153: 138-145. |

| [13] | UENO K, NEGISHI H, MIYAMOTO M, et al.Effect of deposition seed crystal amount on the α-Al2O3 support and separation performance of silicalite-1 membranes for acetic acid/water mixtures. Sep. Purif. Technol., 2017, 174: 57-65. |

| [14] | KORELSKIY D, ZHOU H, GRAHN M, et al.High flux MFI membranes for pervaporation .[J]. Membr. Sci., 2013, 427: 381-389. |

| [15] | LIN X, KITA H, OKAMOTO K.Silicalite membrane preparation, characterization, and separation performance. Ind. Eng. Chem. Res., 2001, 40(19): 4069-4078. |

| [16] | WANG X W, YANG J H, LU J M, et al.Synthesis of Sn-substituted ZSM-5/carbon zeolite membrane and application in separation of acetic acid/water mixture by pervaporation. Journal of Inorganic Materials, 2008, 23(6): 1225-1230. |

| [17] | SHAN L, SHAO J, WANG Z, et al.Preparation of zeolite MFI membranes on alumina hollow fibers with high flux for pervaporation .[J]. Membr. Sci., 2011, 378(1): 319-329. |

| [18] | SHU X, WANG X, GU X, et al.High-flux MFI zeolite membrane supported on YSZ hollow fiber for separation of ethanol/water. Ind. Eng. Chem. Res., 2012, 51(37): 12073-12080. |

| [19] | XIA S, PENG Y, WANG Z.Microstructure manipulation of MFI-type zeolite membranes on hollow fibers for ethanol-water separation .[J]. Membr. Sci., 2016, 498: 324-335. |

| [20] | ZHOU R, ZHU M, CHEN X, et al.Inexpensive synthesis of silicalite-1 membranes with high pervaporation performance. Chem. Lett., 2010, 39(4): 388-389. |

| [21] | ZHANG X L, ZHU M H, ZHOU R F, et al.Synthesis of silicalite-1 membranes with high ethanol permeation in ultradilute solution containing fluoride. Sep. Purif. Technol., 2011, 81(3): 480-484. |

| [22] | ZHANG X L, ZHU M H, ZHOU R F, et al.Synthesis of a silicalite zeolite membrane in ultradilute solution and its highly selective separation of organic/water mixtures. Ind. Eng. Chem. Res., 2012, 51(35): 11499-11508. |

| [23] | ELYASSI B, JEON M Y, TSAPATSIS M, et al.Ethanol/water mixture pervaporation performance of b-oriented silicalite-1 membranes made by gel-free secondary growth. AIChE. J., 2016, 62(2): 556-563. |

| [24] | CHE X, WANG J, YIN D, et al.High-performance zeolite T membrane for dehydration of organics by a new varying temperature hot-dip coating method. AIChE. J., 2013, 59(3): 936-947. |

| [25] | LV Y, LI H, YANG J, et al.Preparation and characterization of high performance zeolite T membranes from clear solutions. Journal of Inorganic Materials, 2016, 31(7): 705-710. |

| [26] | PENG Y, LU H, WANG Z, et al.Microstructural optimization of MFI-type zeolite membranes for ethanol-water separation. J. Mater. Chem. A, 2014, 2(38): 16093-16100. |

| [27] | TOKAY B, FALCONER J L, Noble R D.Alcohol and water adsorption and capillary condensation in MFI zeolite membranes .[J]. Membr. Sci., 2009, 334(1): 23-29. |

| [1] | DONG Shurui, ZHAO Di, ZHAO Jing, JIN Wanqin. Effect of Ionized Amino Acid on the Water-selective Permeation through Graphene Oxide Membrane in Pervaporation Process [J]. Journal of Inorganic Materials, 2022, 37(4): 387-394. |

| [2] | ZHANG Bo,ZHANG Ning,YANG Jianhua,LAN Jiancheng,WANG Jinqu. High Performance a&b Oriented T Zeolite Membrane by a Two-stage Crystallization Synthesis [J]. Journal of Inorganic Materials, 2020, 35(8): 939-946. |

| [3] | ZHU Chunhui, XU Rong, REN Xiuxiu, ZUO Shixiang, GONG Genghao, ZHONG Jing. Fabrication of ZIF-8-NH2/Organosilica Hybrid Membranes for Pervaporation Desalination [J]. Journal of Inorganic Materials, 2020, 35(11): 1239-1246. |

| [4] | WANG Xiao-Lei, ZHANG Yu-Ting, GAO Bing, ZHANG Chun, GU Xue-Hong. Preparation and Characterization of NaA Zeolite Membranes on Inner-surface of Four-channel Ceramic Hollow Fibers [J]. Journal of Inorganic Materials, 2018, 33(3): 339-344. |

| [5] | LV You-Jia, LI Hua-Zheng, YANG Jian-Hua, WANG Jin-Qu, YIN De-Hong, LU Jin-Ming. Preparation and Characterization of High Performance Zeolite T Membranes from Clear Solutions [J]. Journal of Inorganic Materials, 2016, 31(7): 705-710. |

| [6] | ZHOU Liang, YANG Jian-Hua, WANG Jin-Qu, LU Jin-Ming, ZHANG Yan, YIN De-Hong. Synthesis of SAPO-34 Molecular Sieve Membranes by Steam-assisted Conversion Seeding and Their Characterization [J]. Journal of Inorganic Materials, 2015, 30(3): 294-298. |

| [7] | LI Liang-Qing, ZHANG Wen-Xu, YANG Jian-Hua, LU Jin-Ming, YIN De-Hong, WANG Jin-Qu. Preparation and Characterization of Water Perm-selectivity ZSM-5 Zeolite Membrane Using Fluoride Route [J]. Journal of Inorganic Materials, 2015, 30(11): 1167-1171. |

| [8] | WANG Xian-Wu,YANG Jian-Hua,LU Jin-Ming,WANG Tong-Hua,WANG Jin-Qu. Synthesis of Sn-Substituted ZSM-5/Carbon Zeolite Membrane and Application in Separation of Acetic Acid/water Mixtures by Pervaporation [J]. Journal of Inorganic Materials, 2008, 23(6): 1225-1230. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||