Journal of Inorganic Materials ›› 2018, Vol. 33 ›› Issue (3): 313-319.DOI: 10.15541/jim20170145

Special Issue: 离子电池材料

• Orginal Article • Previous Articles Next Articles

WANG Jing1, CHENG Zhi-Ning1, GUO Yu-Zhong1, HUANG Rui-An2, WANG Jian-Hua1

Received:2017-03-30

Revised:2017-06-14

Published:2018-03-20

Online:2018-03-12

About author:WANG Jing. E-mail: 1456429099@qq.com

Supported by:CLC Number:

WANG Jing, CHENG Zhi-Ning, GUO Yu-Zhong, HUANG Rui-An, WANG Jian-Hua. Preparation and Electrochemical Performance of Ordered Mesoporous Si/C Composite for Anode Material[J]. Journal of Inorganic Materials, 2018, 33(3): 313-319.

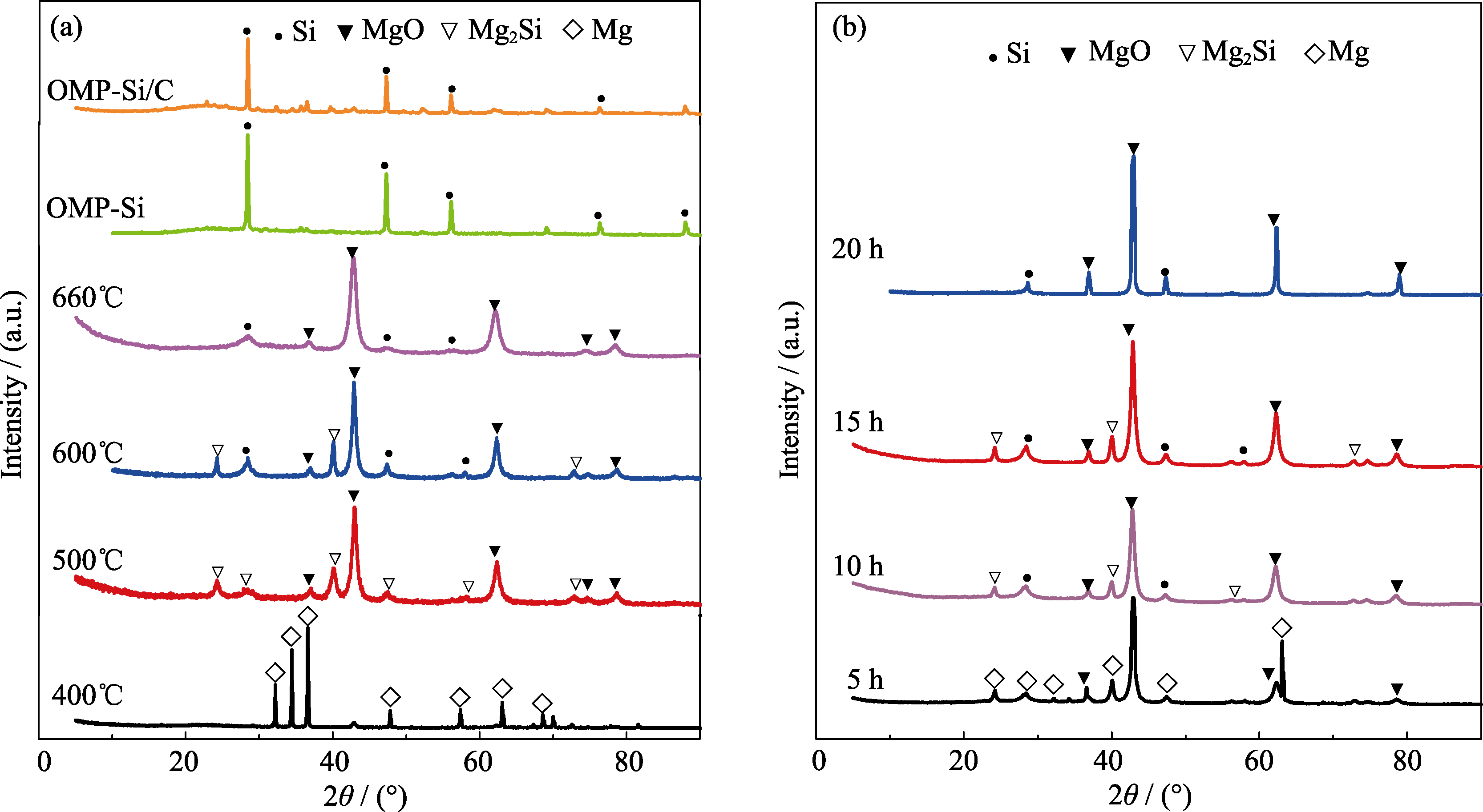

Fig. 1 XRD patterns of the samples prepared by magnesiothermic reduction routes(a) Reaction at 400, 500, 600 and 660℃for 5 h, OMP-Si and OMP-Si/C; (b) Reaction at 560℃for 5, 10, 15 and 20 h

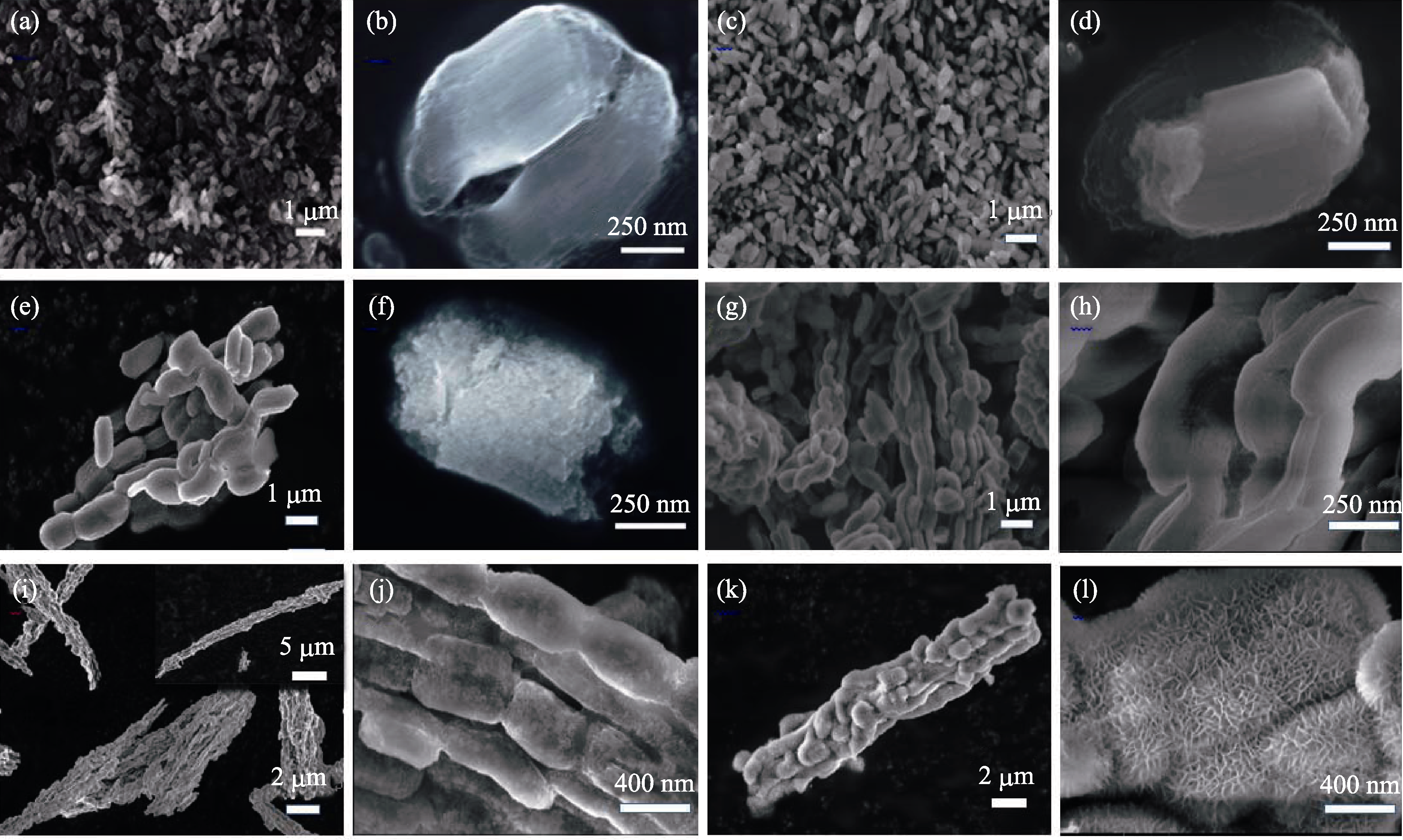

Fig. 3 FESEM images of porous Si synthesized under different conditions(a, b) SBA-15; (c, d) Without acid etching, 400℃, 20 h; (e, f) Without acid etching, 500℃, 20 h; (g, h) Without acid etching, 600℃, 5 h; (i, j) Without acid etching, 660℃, 5 h; (k, l) Hydrochloric acid treatment OMP-Si, 660℃, 5 h

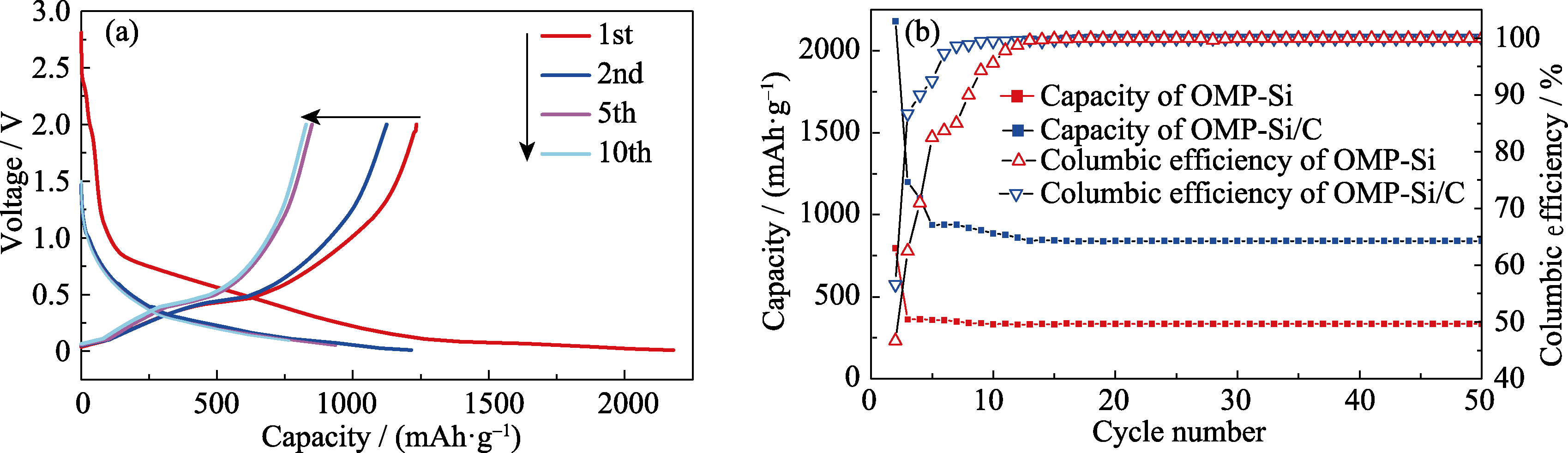

Fig. 7 (a) Charge/discharge curves of OMP-Si/C sample and (b) the specific capacity and columbic efficiency versus cycle number for as-prepared samples

| [1] | ARMAND M, TARASCON J M.Building better batteries. Nature, 2002, 452(7179): 652-657. |

| [2] | TERADA N, YANAGI T, ARAI S, et al.Development of lithium batteries for energy storage and EV applications. Journal of Power Sources, 2001, 100: 80-92. |

| [3] | SCROSATI B.Technology: charging towards the superbattery. Nature, 2011, 473: 448-449. |

| [4] | WINTER M, BESENHARD J O, SPAHR M E, et al.Insertion electrode materials for rechargeable lithium batteries. Adv. Mater., 1998, 10(10): 725-763. |

| [5] | BOUKAMP B A, LEASH G C, HUGGINS R A J. All solid lithium electrodes with mixed conductor matrix. Electrochem. Soc., 1981, 128: 725-729. |

| [6] | WU H, CUI Y.Designing nanostructured Si anodes for high energy lithium ion batteries. Nano Today, 2012, 7: 414-429. |

| [7] | CUI L F, RUFFO R, CHAN C K, et al.Crystalline-amorphous core-shell silicon nanowires for high capacity and high current battery electrodes. Nano Lett., 2009, 9(1): 491-495. |

| [8] | ZHOU Y L, JIANG X L, CHEN L, et al.Novel mesoporous silicon nanorod as an anode material for lithium ion batteries. Electrochim. Acta, 2014, 127: 252-258. |

| [9] | YAO Y, MCDOWELL M T, RYU I, et al.Interconnected silicon hollow nanospheres for lithium-ion battery anodes with long cycle life. Nano Lett., 2011, 11(7): 2949-2954. |

| [10] | DATTA M K, MARANCHI J, CHUNG S J, et al . Amorphous silicon-carbon based nano-scale thin film anode materials for lithium ion batteries. Electrochim. Acta, 2011, 56: 4717-4723. |

| [11] | TANG Y Y, XIA X H, YU Y X, et al.Cobalt nanomountain array supported silicon film anode for high-performance lithium ion batteries. Electrochim. Acta , 2013, 88: 664-670. |

| [12] | HUANG Y, DUAN X F, WEI Q Q, et al.Directed assembly of one-dimensional nanostructures into functional networks. Science, 2001, 291(5504): 630-633. |

| [13] | ZHONG H, ZHAN H, ZHOU Y H.Synthesis of nanosized mesoporous silicon by magnesium-thermal method used as anode material for lithium ion battery. Journal of Power Sources, 2014, 262: 10-14. |

| [14] | BANG B M, LEE J I, KIM H, et al.High-performance macroporous bulk silicon anodes synthesized by template-free chemical etching. Advanced Energy Materials, 2012, 2: 878-883. |

| [15] | LIANG J W, LI X N, HOU Z G, et al.A deep reduction and partial oxidation strategy for fabrication of mesoporous Si anode for lithium ion batteries. ACS Nano, 2016, 10(2): 2295-2304. |

| [16] | SUN C F, ZHU H, OKADA M, et al.Interfacial oxygen stabilizes composite silicon anodes. Nano Lett., 2015, 15(1): 703-708. |

| [17] | ZHANG R Y, DU Y J, SHEN D, et al.Highly reversible and large lithium storage in mesoporous Si/C nanocomposite anodes with silicon nanoparticles embedded in a carbon framework. Adv. Mater., 2014, 26: 6749-6755. |

| [18] | TARASCON J M.Key challenges in future Li-battery research. Phil. Trans. R. Soc. A, 2010, 368: 3227-3241. |

| [19] | GAO P C, SIMON P, FAVIER F.Silicon carbide with tunable ordered mesoporosity. Microporous and Mesoporous Materials, 2013, 180: 172-177. |

| [20] | HONG I, CROSATI B, CROCE F.Mesoporous, Si/C composite anode for Li battery obtained by ‘magnesium-thermal’ reduction process. Solid State Ionics, 2013, 232: 24-28. |

| [21] | BAO Z H, WEATHERSPOON M R, SHIAN S, et al.Chemical reduction of three-dimensional silica micro-assemblies into microporous silicon replicas. Nature, 2007, 446: 172-175. |

| [22] | JIA H P, GAO P F, YANG J, et al.Novel three-dimensional mesoporous silicon for high power lithium-ion battery anode material. Advanced Energy Materials, 2011, 1: 1036-1039. |

| [23] | LIU N A, HUO K F, MCDOWELL M T, et al. Rice husks as a sustainable source of nanostructured silicon for high performance Li-ion battery anodes. Scientfic Reports, 2013, 3: 1919-1-7. |

| [24] | TANG Y P, YUAN S, GUO Y Z, et al.Highly ordered mesoporous Si/C nanocomposite as high performance anode material for Li-ion batteries. Electrochim. Acta, 2016, 200: 182-188. |

| [25] | XIAO C M, DU N, SHI X X, et al.Large-scale synthesis of Si@C three-dimensional porous structures as high-performance anode materials for lithium-ion batteries. Journal of Materials Chemistry, 2014, 2: 20494-20499. |

| [26] | KIM W S, HUA Y, SHIN J H, et al.Scalable synthesis of silicon nanosheets from sand as an anode for Li-ion batteries. Nanoscale, 2014, 6: 4297-4302. |

| [27] | AHN JIHON, KIM HEE SOO, PYO JUNG, et al.Variation in crystalline phases: controlling the selectivity between silicon and silicon carbide via magnesiothermic reduction using silica/carbon composites. Chemistry of Materials, 2016, 28: 1526-1536. |

| [28] | TAO H C, FAN L Z, QU X H.Facile synthesis of ordered porous Si@C nanorods as anode materials for Li-ion batteries. Electrochim. Acta, 2012, 71: 194-200. |

| [29] | WANG L L, MUNIR Z A, MAXIMOV Y M.Thermite reactions: their utilization in the synthesis and processing of materials .[J]. Mater. Sci., 1993, 28: 3693-3708. |

| [30] | HUGGINS R A. Lithium alloy negative electrodes. Power Sources, 1999, 81-82: 13-19. |

| [31] | YU X L, YANG J, FENG X J, et al.Preparation and electrochemical properties of porous silicon/carbon composite as negative electrode materials. Journal of Inorganic Materials, 2013, 28(9): 937-942. |

| [32] | WADA T, ICHITSUBO T, YUBUTA K, et al.Buk-nanoporou- silicon negative electrode with extremely high cyclability for lithium-ion batteries prepared using a top-down process. Nano Lett., 2014, 14: 4505-4510. |

| [33] | KIM H, CHOU C Y, EKERDT J G, et al.Structure and properties of Li-Si alloys: a first-principles study. Journal of Physical Chemistry, 2011, 115(5): 2514-2521. |

| [1] | XIAO Meixia, LI Miaomiao, SONG Erhong, SONG Haiyang, LI Zhao, BI Jiaying. Halogenated Ti3C2 MXene as High Capacity Electrode Material for Li-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(6): 660-668. |

| [2] | LI Jian, YAO Shu-Heng, ZHOU Hong-Ming, GENG Wen-Jun. Preparation of LiMn0.4Fe0.6PO4/C Composite by A New Route Combining Solid-state Reaction with Hydrothermal Synthesis [J]. Journal of Inorganic Materials, 2014, 29(4): 443-448. |

| [3] | QIU Cai-Xia, YUAN Zhong-Zhi, LIU Ling, CHENG Si-Jie, LIU Jin-Cheng. Preparation and Characterization of Ge4+-doping Li4Ti5O12 Anode Material for Li-ion Battery and Its Electrochemical Properties [J]. Journal of Inorganic Materials, 2013, 28(7): 727-732. |

| [4] | ZHANG Qian, LIU Wei-Wei, FANG Guo-Qing, XIA Bing-Bo, SUN Hong-Dan, KANEKO Shingo, YANG Yu-Sheng, ZHENG Jun-Wei, LI De-Cheng. Structural and Electrochemical Performances of Li1+2xMn0.3+xNi0.3-3xCr0.4O2 Synthesized by Spray-dry Method [J]. Journal of Inorganic Materials, 2013, 28(06): 616-622. |

| [5] | SHAO Jin, REN Yu-Rong, LI Guo-Qiang, HUANG Xiao-Bing, ZHOU Gu-Min, QU Mei-zhen. Carbon Coated Helical Carbon Nanotubes used as Anode Materials of Li-ion Battery [J]. Journal of Inorganic Materials, 2011, 26(6): 631-637. |

| [6] | ZHANG Xi-Gui,ZHANG Jian,YANG Chuan-Zheng,LI Jia. Simulation and Experimental Study on Mixed Arrange of Li/Ni Atoms in LiMeO2 Materials [J]. Journal of Inorganic Materials, 2010, 25(1): 8-12. |

| [7] | ZHU Yong-Jun,LI Xin-Hai,WANG Zhi-Xing,YANG Zhi,HU Qi-Yang. Synthesis and Electrochemical Performance of Spherical LiNi0.5-xCo2xMn0.5-x O2 [J]. Journal of Inorganic Materials, 2007, 22(5): 873-878. |

| [8] | YAO Yao-Chun,DAI Yong-Nian,YANG Bin,CUI Meng-Jia,LI Wei-Hong. Synthesis and Performance of LiCrxMn2-xO4 Cathode Materials for Li-ion Battery [J]. Journal of Inorganic Materials, 2005, 20(5): 1127-1131. |

| [9] | CHEN Fang,LIANG Hai-Chao,LI Ren-Gui,LIU Li,DENG Zheng-Hua. Progress in Research on Li4Ti5O12 as Anode for Electrochemical Devices [J]. Journal of Inorganic Materials, 2005, 20(3): 537-544. |

| [10] | XIA Jun-Lei,ZHAO Shi-Xi,LIU Han-Xing,OUYANG Shi-Xi,. Synthesis and Performance of S-Co Co-doped LiMn2O4 [J]. Journal of Inorganic Materials, 2003, 18(4): 942-946. |

| [11] | KANG Kai,DAI Shou-Hui,WAN Yu-Hua. Progress in Synthetic Methods of Cathode Material LiMxMn2-xO4 for Lithium Ion Batteries [J]. Journal of Inorganic Materials, 2001, 16(4): 586-594. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||