Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (4): 400-406.DOI: 10.15541/jim20160341

• Orginal Article • Previous Articles Next Articles

XIE Jia-Miao, WANG Feng-Hui

Received:2016-05-25

Revised:2016-07-11

Published:2017-04-20

Online:2017-03-24

Supported by:CLC Number:

XIE Jia-Miao, WANG Feng-Hui. Thermal Stress Analysis of Solid Oxide Fuel Cell with Anode Functional Layer[J]. Journal of Inorganic Materials, 2017, 32(4): 400-406.

| T | NiO-YSZ | YSZ | LSM | NiO | |

|---|---|---|---|---|---|

| E/GPa | 20℃ | 127.3 | 215 | 110 | 110 |

| 800℃ | 105.5 | 185 | 118 | 90 | |

| $\mu $ | 20℃ | 0.33 | 0.308 | 0.36 | 0.34 |

| 800℃ | 0.33 | 0.313 | 0.36 | 0.34 | |

| CTE /×10-6 | 20℃ | 11.77 | 7.6 | 9.8 | 13.0 |

| 800℃ | 12.42 | 10.5 | 11.8 | 13.0 | |

| 1400℃ | 12.50 | 10.5 | 11.8 | 13.1 |

Table 1 Material properties of electrodes and electrolyte[19-21]

| T | NiO-YSZ | YSZ | LSM | NiO | |

|---|---|---|---|---|---|

| E/GPa | 20℃ | 127.3 | 215 | 110 | 110 |

| 800℃ | 105.5 | 185 | 118 | 90 | |

| $\mu $ | 20℃ | 0.33 | 0.308 | 0.36 | 0.34 |

| 800℃ | 0.33 | 0.313 | 0.36 | 0.34 | |

| CTE /×10-6 | 20℃ | 11.77 | 7.6 | 9.8 | 13.0 |

| 800℃ | 12.42 | 10.5 | 11.8 | 13.0 | |

| 1400℃ | 12.50 | 10.5 | 11.8 | 13.1 |

| Layer | AFL | NiO volume fraction | ||

|---|---|---|---|---|

| n=2 | n=1 | n=0.5 | ||

| 1 | AFL1 | 20% | 40% | 56% |

| 2 | AFL1 | 5% | 20% | 40% |

| AFL2 | 45% | 60% | 69% | |

| 3 | AFL1 | 2.5% | 13% | 32% |

| AFL2 | 20% | 40% | 56% | |

| AFL3 | 55% | 66% | 73% | |

| 4 | AFL1 | 1.3% | 10% | 27% |

| AFL2 | 11.3% | 30% | 49% | |

| AFL3 | 31.0% | 50% | 63% | |

| AFL4 | 61.0% | 70% | 75% | |

| 5 | AFL1 | 1% | 8% | 25% |

| AFL2 | 7% | 24% | 43% | |

| AFL3 | 20% | 40% | 56% | |

| AFL4 | 39% | 56% | 66% | |

| AFL5 | 65% | 72% | 76% | |

Table 2 Volume fraction of NiO in AFL sublayers

| Layer | AFL | NiO volume fraction | ||

|---|---|---|---|---|

| n=2 | n=1 | n=0.5 | ||

| 1 | AFL1 | 20% | 40% | 56% |

| 2 | AFL1 | 5% | 20% | 40% |

| AFL2 | 45% | 60% | 69% | |

| 3 | AFL1 | 2.5% | 13% | 32% |

| AFL2 | 20% | 40% | 56% | |

| AFL3 | 55% | 66% | 73% | |

| 4 | AFL1 | 1.3% | 10% | 27% |

| AFL2 | 11.3% | 30% | 49% | |

| AFL3 | 31.0% | 50% | 63% | |

| AFL4 | 61.0% | 70% | 75% | |

| 5 | AFL1 | 1% | 8% | 25% |

| AFL2 | 7% | 24% | 43% | |

| AFL3 | 20% | 40% | 56% | |

| AFL4 | 39% | 56% | 66% | |

| AFL5 | 65% | 72% | 76% | |

| Presented model | Experimental | Numerical analysis | |

|---|---|---|---|

| Max. compressive stresses of YSZ /MPa | 633.3 | 670[ | 608.46[ |

| Error | — | 5.8% | 3.9% |

Table 3 Comparison results of the maximum compressive stresses of YSZ

| Presented model | Experimental | Numerical analysis | |

|---|---|---|---|

| Max. compressive stresses of YSZ /MPa | 633.3 | 670[ | 608.46[ |

| Error | — | 5.8% | 3.9% |

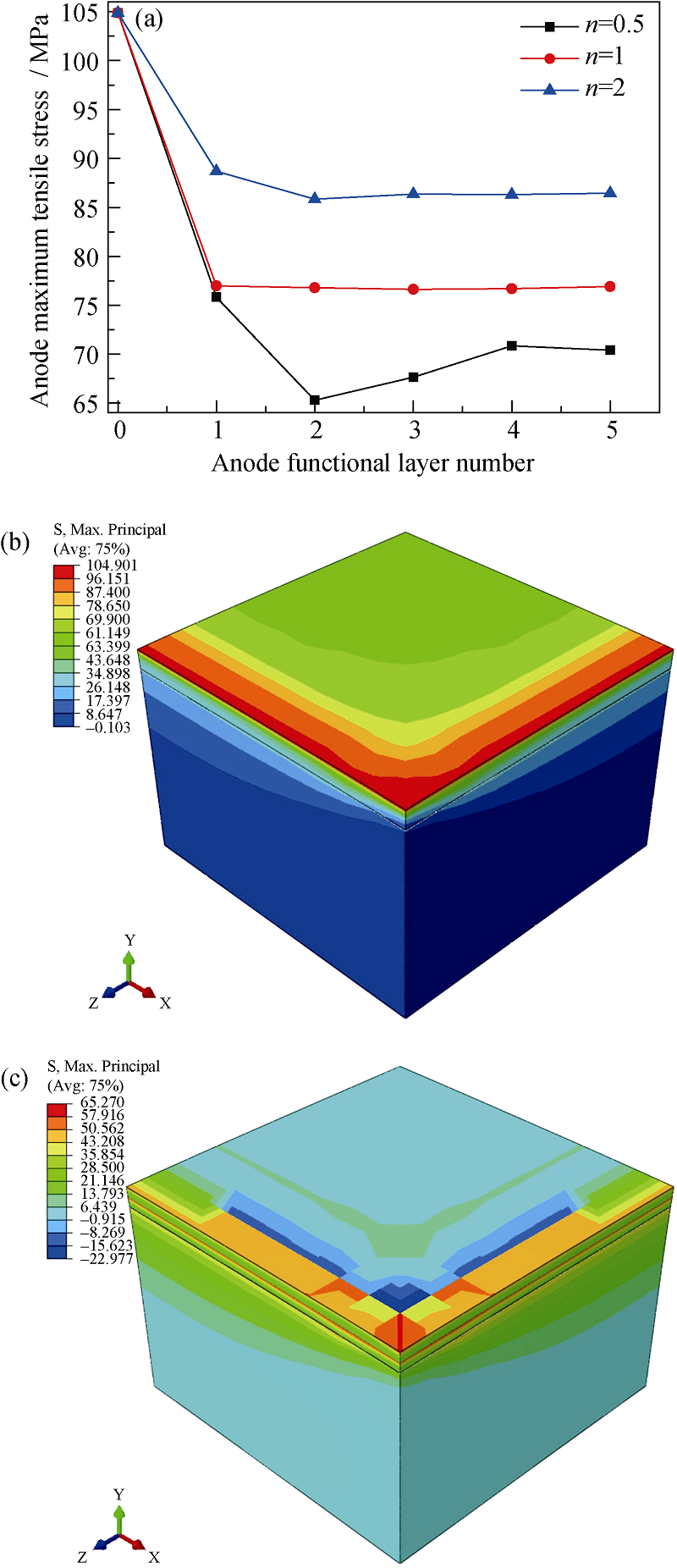

Fig. 6 (a) Maximum tensile stresses of anode with the layers of AFL and the exponent n; (b) contour of anode without AFL; (c) contour of two layers of AFL (n=0.5)

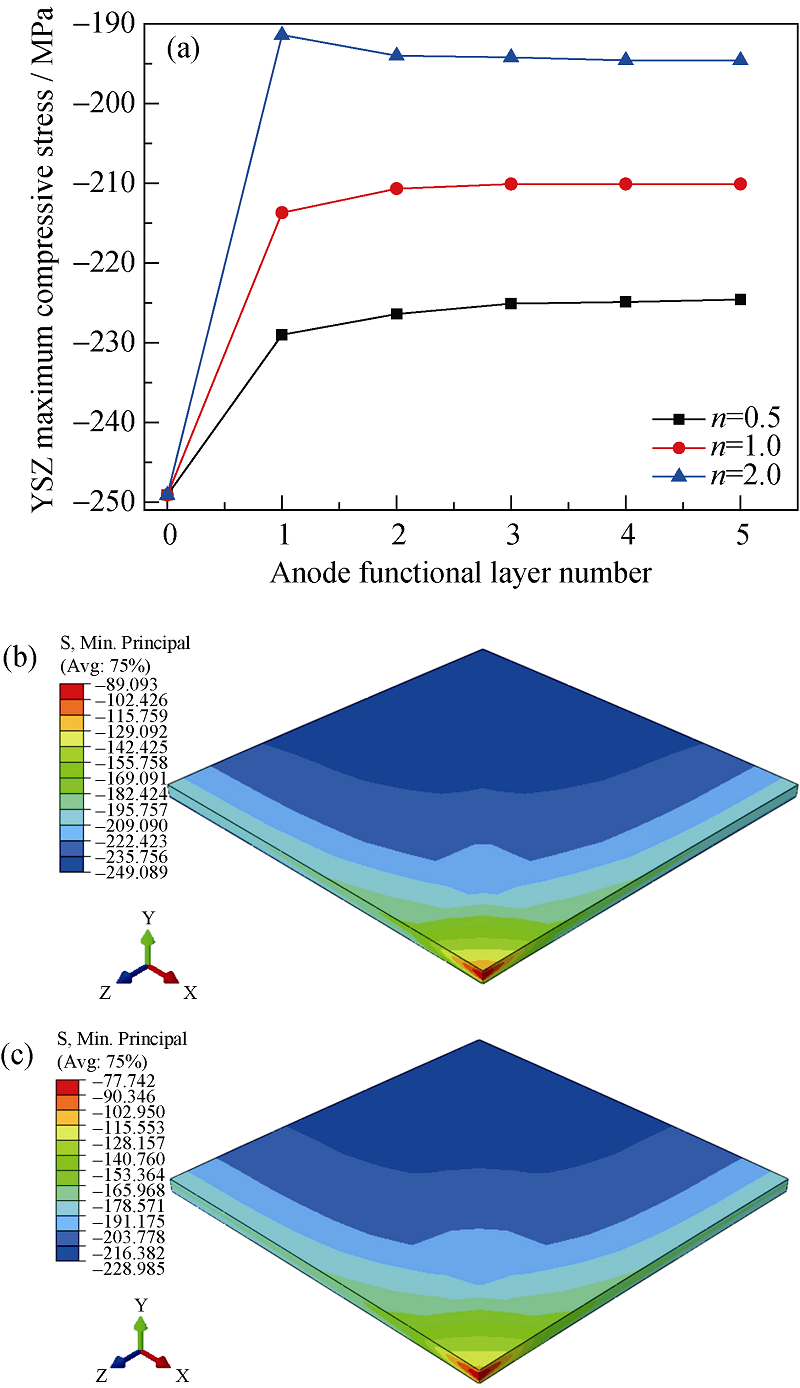

Fig. 7 (a) Maximum compressive stresses of YSZ with the layers of AFL and the exponent n, (b) contour of YSZ without the AFL and (c) contour of YSZ with two layers of the AFL (n=0.5)

| [1] | LAURENCIN J, DELETTE G, LEFEBVRE-JORD F, et al.A numerical tool to estimate SOFC mechanical degradation: case of the planar cell configuration. J. Eur. Ceram. Soc., 2008, 28(9): 1857-1869. |

| [2] | DUAN Z S, YANG M, YAN A Y, et al.Ba0.5Sr0.5Co0.8Fe0.2O3-δ as a cathode for IT-SOFCs with a GDC interlayer. J. Power Sources, 2006, 160(1): 57-64. |

| [3] | CHEN X, LIN Z Z, YIN C, et al.Theoretical prediction of the growth and surface structure of platinum nanoparticles. Acta Phys. Sin., 2012, 61(7): 076801. |

| [4] | SELÇUK A, MERERE G, ATKINSON A. The influence of electrodes on the strength of planar zirconia solid oxide fuel cells. J. Mater. Sci., 2001, 36(5): 1173-1182. |

| [5] | LIANG L J, LI K, YAN D, et al.Mechanical property and deformation behavior of SOFCs. J. Inorg. Mater., 2015, 30(6): 633-638. |

| [6] | CHEN X, YANG J, PU J, et al.Finite element analysis of thermal stresses in planar SOFCs. J. Inorg. Mater., 2007, 22(2): 339-343. |

| [7] | 彭晓领. 组元磁化法制备ZrO2/Ni梯度功能材料研究. 浙江: 浙江大学博士学位论文, 2008. |

| [8] | ERDOGAN F, WU B H.Crack Problems in FGM layers under thermal stresses. J. Therm. Stresses, 1996, 19(3): 237-265. |

| [9] | LEE Y D, ERDOGAN F.Residual/thermal stresses in FGM and laminated thermal barrier coatings. Int. J. Fracture, 1995, 69(2): 145-165. |

| [10] | ZHA S W, ZHANG Y L, LIU M L.Functionally graded cathodes fabricated by Sol-Gel/slurry coating for honeycomb SOFCs. Solid State Ionics, 2005, 176(1/2): 25-31. |

| [11] | JIANG T Z, WANG Z H, REN B Y, et al.Compositionally continuously graded cathode layers of (Ba0.5Sr0.5)(Fe0.91Al0.09)O3-δ-Gd0.1Ce0.9O2 by wet powder spraying technique for solid oxide fuel cells. J. Power Sources, 2014, 247: 858-864. |

| [12] | MCCOPPIN J, BARNEY I, MUKHOPADHYAY S, et al.Compo-sitional control of continuously graded anode functional layer. J. Power Sources, 2012, 215: 160-163. |

| [13] | WANG Y S, GROSS D. Analysis of a crack in a functionally gradient interface layer under static and dynamic loading. Key Eng. Mater., 2000, 183-187: 331-336. |

| [14] | WANG Y S, HUANG G Y, GROSS D.On the mechanical modeling of functionally graded interracial zone with a griffith crack: anti-plane deformation. J. Appl. Mech.-T. ASME, 2003, 70(5): 676-680. |

| [15] | HUANG G Y, WANG Y S, YU S W.A new multi-layered model for in-plane fracture analysis of functionally graded materials (FGMS). Chin. J. Theor. Appl. Mech., 2005, 37(1): 1-8. |

| [16] | MÜLLER A C, HERBSTRITT D, IVERS-TIFFÉE E. Development of a multilayer anode for solid oxide fuel cells. Solid State Ionics, 2002, 152-153: 537-542. |

| [17] | KONG J R, SUN K N, ZHOU D, et al.Ni-YSZ gradient anodes for anode-supported SOFCs. J. Power Sources, 2007, 166(2): 337-342. |

| [18] | ANANDAKUMAR G, Li N, VERMA A, et al.Thermal stress and probability of failure analyses of functionally graded solid oxide fuel cells. J. Power Sources, 2010, 195(19): 6659-6670. |

| [19] | NAKAJO A, WUILLENIN Z, HERLE J V, et al.Simulation of thermal stresses in anode-supported solid oxide fuel cell stacks. Part I: Probability of failure of the cells. J. Power Sources, 2009, 193(1): 203-215. |

| [20] | CLAGUE R, MARQUIS A J, BRANDON N P.Finite element and analytical stress analysis of a solid oxide fuel cell. J. Power Sources, 2012, 210(15): 224-232. |

| [21] | JIANG W C, LUO Y, ZHANG W Y, et al. Effect of temperature fluctuation on creep and failure probability for planar solid oxide fuel cell. J. Fuel Cell Sci. Tech.-T. ASME, 2015, 12(5): 051004- 1-10. |

| [22] | KIN J H, PAULINO G H.Isoparametric graded finite elements for nonhomogeneous isotropic and orthotropic materials. J. Appl. Mech., 2002, 69(4): 502-514. |

| [23] | HIRANO T, WAKASHIMA K.Mathematical modeling and design. MRS Bull., 1995, 20(1): 40-42. |

| [24] | GIANNAKOPOULOS A E, SURESH S, FINOT M, et al.Elastoplastic analysis of thermal cycling: layered materials with compositional gradients. Acta Metal. Mater., 1995, 43(4): 1335-1354. |

| [25] | WILLIAMSON R L, RABIN B H, DRAKE J T.Finite element analysis of thermal residual stresses at graded ceramic-metal interfaces. Part I. Model description and geometrical effects. J. Appl. Phys., 1993, 74(2): 1310. |

| [26] | AMADA S.Hierarchical functionally gradient structures of bamboo, barley, and corn. MRS Bull., 1995, 20(1): 35-36. |

| [27] | TEIXEIRA V. Numerical analysis of the influence of coating porosity and substrate elastic properties on the residual stresses in high temperature graded coatings. Surf. Coat. Tech., 2001, 146-147(2): 79-84. |

| [28] | HSIEH C L, TUAN W H.Elastic and thermal expansion behavior of two-phase composites. Mat. Sci. Eng. A-Struct., 2006, 425(1/2): 349-360. |

| [29] | YAKABE H, BABA Y, SAKURAI T, et al.Evaluation of the residual stress for anode-supported SOFCs. J. Power Sources, 2004, 135(1/2): 9-16. |

| [30] | FAN P F, LI G J, ZENG Y K, et al.Numerical study on thermal stresses of a planar solid oxide fuel cell. Int. J. Therm. Sci., 2014, 77: 1-10. |

| [1] | GUO Tianmin, DONG Jiangbo, CHEN Zhengpeng, RAO Mumin, LI Mingfei, LI Tian, LING Yihan. Enhanced Compatibility and Activity of High-entropy Double Perovskite Cathode Material for IT-SOFC [J]. Journal of Inorganic Materials, 2023, 38(6): 693-700. |

| [2] | FAN Shuai, JIN Tian, ZHANG Shanlin, LUO Xiaotao, LI Chengxin, LI Changjiu. Effect of Li2O Sintering Aid on Sintering Characteristics and Electrical Conductivity of LSGM Electrolyte for Solid Oxide Fuel Cell [J]. Journal of Inorganic Materials, 2022, 37(10): 1087-1092. |

| [3] | CAO Dan,ZHOU Mingyang,LIU Zhijun,YAN Xiaomin,LIU Jiang. Fabrication and Characterization of Anode-supported Solid Oxide Fuel Cell Based on Proton Conductor Electrolyte [J]. Journal of Inorganic Materials, 2020, 35(9): 1047-1052. |

| [4] | XIA Tian, MENG Xie, LUO Ting, ZHAN Zhongliang. La 3+-substituted Sr2Fe1.5Ni0.1Mo0.4O6-δ as Anodes for Solid Oxide Fuel Cells [J]. Journal of Inorganic Materials, 2020, 35(5): 617-622. |

| [5] | Kai LI, Xiao LI, Jian LI, Jia-Miao XIE. Structural Stability of Ni-Fe Supported Solid Oxide Fuel Cells Based on Stress Analysis [J]. Journal of Inorganic Materials, 2019, 34(6): 611-617. |

| [6] | Wei WANG, Li-Li YUAN, Qian-Yuan QIU, Ming-Yang ZHOU, Mei-Lin LIU, Jiang LIU. A Direct Carbon Solid Oxide Fuel Cell Stack Based on a Single Electrolyte Plate Fabricated by Tape Casting Technique [J]. Journal of Inorganic Materials, 2019, 34(5): 509-514. |

| [7] | XIA Tian, MENG Xie, LUO Ting, ZHAN Zhong-Liang. Synthesis and Evaluation of Ca-doped Sr2Fe1.5Mo0.5O6-δ as Symmetrical Electrodes for High Performance Solid Oxide Fuel Cells [J]. Journal of Inorganic Materials, 2019, 34(10): 1109-1114. |

| [8] | WANG Shi-Yang, FU Yu-Dong, CHEN Lei, WANG Yu-Jin. Fabrication and Mechanical Property of W-Y2O3 Composites and Graded material [J]. Journal of Inorganic Materials, 2018, 33(6): 596-602. |

| [9] | XU Hong-Mei, ZHANG Hua, LI Heng, JIAN Yao-Yong, XIE Wu, WANG Yi-Ping, XU Ming-Ze. Preparation and Oxygen-reduction Mechanism Investigation of Nanostructure LSCF-SDC Composite Cathodes [J]. Journal of Inorganic Materials, 2017, 32(4): 379-385. |

| [10] | YANG Yang, TIAN Dong, DING Yan-Zhi, LU Xiao-Yong, LIN Bin, CHEN Yong-Hong. Improved Performance of Symmetrical Solid Oxide Fuel Cells with Redox-reversible Pr0.6Sr0.4Co0.2Fe0.8O3-δ Electrodes [J]. Journal of Inorganic Materials, 2017, 32(3): 235-240. |

| [11] | CHENG Liang, LUO Ling-Hong, SHI Ji-Jun, SUN Liang-Liang, XU Xu, WU Ye-Fan, HU Jia-Xing. Ni/YSZ Anode Impregnated La2O3 on Anti-carbon Deposition of SOFC Cell [J]. Journal of Inorganic Materials, 2017, 32(3): 241-246. |

| [12] | CHANG Xi-Wang, CHEN Ning, WANG Li-Jun, LI Fu-Shen, BIAN Liu-Zhen, CHOU Kuo-Chih. Optimal Principle on Composition of B Site Elements in Perovskite Electrodes with Sr at A Site for Solid Oxide Fuel Cell [J]. Journal of Inorganic Materials, 2017, 32(10): 1055-1062. |

| [13] | LUO Ling-Hong, LIN You-Cheng, SHI Ji-Jun, CHENG Liang, WU Ye-Fan, SUN Liang-Liang. Preparation and Properties of Three-phase Composite Cathode of LSCF-GDC Dipped LSM Sol [J]. Journal of Inorganic Materials, 2016, 31(7): 756-760. |

| [14] | ZHOU Yu-Cun, YE Xiao-Feng, WANG Shao-Rong. All Symmetrical Metal Supported Solid Oxide Fuel Cells [J]. Journal of Inorganic Materials, 2016, 31(7): 769-772. |

| [15] | YANG Zhi-Bin, ZHU Teng-Long, XIANG Wen-Long, YU Li-An, HAN Min-Fang. Sintering Behavior and Electrical Conductivity of Gd0.1Ce0.9O1.95 with Li2O Additives [J]. Journal of Inorganic Materials, 2015, 30(4): 345-350. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||