Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (1): 63-68.DOI: 10.15541/jim20160206

• Orginal Article • Previous Articles Next Articles

GONG Wei1,2, LI Hua3, ZHOU Li-Ming1, BAI Cao-Zhong1, WANG En-Ze4

Received:2016-03-29

Revised:2016-07-05

Published:2017-01-20

Online:2016-12-15

Supported by:CLC Number:

GONG Wei, LI Hua, ZHOU Li-Ming, BAI Cao-Zhong, WANG En-Ze. Microstructure and Properties of 3Y-TZP/LZAS Glass-ceramic Functionally Gradient Coatings[J]. Journal of Inorganic Materials, 2017, 32(1): 63-68.

| Layer | Micro-hardness Hv/GPa | Fracture toughness KIC/(MPa•m1/2) |

|---|---|---|

| Transition layer | 2.43 | 0.62 |

| 1st toughening layer | 3.24 | 1.32 |

| 2nd toughening layer | 3.78 | 1.94 |

| 3rd toughening layer | 4.53 | 2.12 |

| 4th toughening layer | 5.11 | 2.83 |

Table 1 Micro-hardness and fracture toughness of different layer for the 3Y-TZP/LZAS gradient coatings

| Layer | Micro-hardness Hv/GPa | Fracture toughness KIC/(MPa•m1/2) |

|---|---|---|

| Transition layer | 2.43 | 0.62 |

| 1st toughening layer | 3.24 | 1.32 |

| 2nd toughening layer | 3.78 | 1.94 |

| 3rd toughening layer | 4.53 | 2.12 |

| 4th toughening layer | 5.11 | 2.83 |

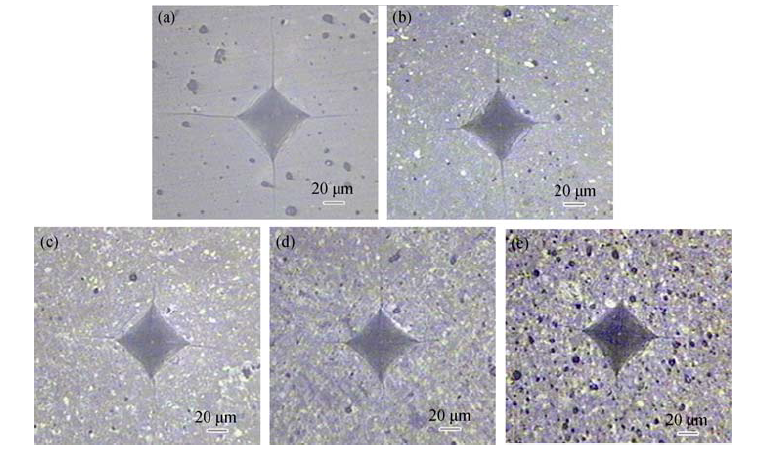

Fig. 9 Optical images of Vickers indentation on the section of coatings(a) Transition layer; (b) The 1st toughening layer; (c) The 2nd toughening layer; (d) The 3rd toughening layer; (e) The 4th toughening layer

| [1] | LU YU-FENG, LOU MIAO, DENG LI-RONG,et al.Research of dielectric coatings for 0Cr18Ni9 stainless steel substrate prepared by BaO-Al2O3-SiO2 glass-ceramics.Journal of Functional Materials, 2010, 41(12): 2216-2219. |

| [2] | ZHOU HONG-MING, JIA YANG, LI JIAN,et al.Microstructure, phase composition and oxidation resistance of glass-ceramic coating prepared by slurry spraying technique.Journal of Central South University, 2014, 45(1): 45-50. |

| [3] | SHEN M L, ZHU S L, WANG F H.Cyclic oxidation behavior of glass-ceramic composite coatings on superalloy K38G at 1100℃.Thin Solid Films, 2011, 519: 484-488. |

| [4] | HUANG KAI, CAI SHU, REN MONG-GUO,et al.Preparation of mesoporous 45S5 bioactive glass-ceramic coating on magnesium alloy and its in vitro biodegradation.Journal of the Chinese Ceramic Society, 2014, 42(7): 846-850. |

| [5] | ERCENK E, SEN U, YILMAZ S.Tribological properties of SiC-reinforced basalt-based coatings.Tribol. Lett., 2014, 56(2): 337-354. |

| [6] | YILMAZ S, BAYRAK G, SEN S,et al.Structural characterization of basalt-based glass-ceramic coatings.Mater. Design, 2006, 27(10): 1092-1096. |

| [7] | ROTHER B, MUCHA A.Transparent glass-ceramic coatings: property distribution on 3D parts.Surf.Coat. Tech., 2000, 124: 128-134. |

| [8] | HU X L, CUI L, LIU T Y,et al.Crystallization and properties of B2O3 doped LZAS vitrified bond for diamond grinding tools.J. Non-cryst. Solids, 2015, 427: 69-75. |

| [9] | CUI L, HAO X J, HU X L, et al.Effects of Y2O3 addition on structure and properties of LZAS vitrified bond for CBN grinding tools application.Ceram. Int., 2015, 41: 9916-9922. |

| [10] | GONG WEI, ZHOU LI-MING, WANG EN-ZE.Analysis on the residual stresses in Y-TZP/LZAS glass-ceramic gradient coatings.Journal of Functional Materials, 2014, 45(17): 17140-17144. |

| [11] | YAMADA K, IMAMURA K, ITOH H,et al.Bone bonding behavior of the hydroxyapatite containing glass-titanium composite prepared by the cullet method.Biomaterials, 2001, 22: 2207-2214. |

| [12] | EVANS A G, CHARLES E A.Fracture toughness determination by indentation. J. Am. Ceram. Soc., 1976, 59: 371-372. |

| [13] | GAO CHAO, LU AAN-XIAN, WANG KE-QIANG,et al.Investigation of high-temperature thermal staility of a novel solid oxide fuel cell seal glass.Journal of wuhan University of Techrology, 2011, 33(10): 1-6. |

| [14] | HRMA P.Glass viscosity as a function of temperature and composition: a model based on Adam-Gibbs equation. J.Non-Cryst. Solids, 2008, 354: 3389-3399. |

| [15] | XIAO ZI-FAN, CHENG JIN-SHU, WU HAO.Effect of Al2O3/SiO2 ratio on the viscosity and workability of high-alumina soda-lime-silicate glasses.Journal of the Chinese Ceramic Society, 2012, 40(7): 1000-1005. |

| [16] | GONG WEI, ZHONG LI-MING, LIU CHUAN-HUI,et al.Effect of heat treatment on crystallization behaviors of LZAS system glass-ceramics.Journal of Synthetic Crystals, 2015, 44(11): 3140-3146. |

| [17] | WANG JUN.Study on the sealing properties of Bi2O3-ZnO-B2O3 low-melting glass.Wuhan University of Technology, 2011. |

| [18] | YANG DAN, SHEN ZHUO-SHEN.Study on the Li2O-Al2O3- ZnO-SiO2 glass-ceramics used for the sealing of Kovar.Electronic components and materials, 2010, 29(4): 57-60. |

| [19] | WU MAO, QU XUAN-HUI, HE XIN-BO,et al.Wettability of Kovar with glass-ceramics of ZnO-Al2O3-B2O3-SiO2 system.Transactions of Materials and Heat Treatment, 2009, 30(6): 25-30. |

| [20] | OMAR A A, EI-SHENNAWI A W A, EI-GHANNAM A R. Thermal expansion of Li2O-ZnO-Al2O3-SiO2 glasses and corresponding glass-ceramics.J. Mater. Sci., 1991(26): 6049-6056. |

| [21] | CHEN JIAN-FENG, CAO PING-ZHOU.Experimental investigation into mechanical properties of steel post high temperatures. Journal of PLA University of Science and Technology, 2010, 11(3): 328-332. |

| [22] | KARIMI E, KHALIL-ALLAFI J, KHALILI V.Electrophoretic deposition of double-layer HA/Al composite coating on NiTi.Mat.Sci. Eng C-Mater.,2016, 58: 882-890. |

| [1] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [2] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [3] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [4] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [5] | HONG Du, NIU Yaran, LI Hong, ZHONG Xin, ZHENG Xuebin. Tribological Properties of Plasma Sprayed TiC-Graphite Composite Coatings [J]. Journal of Inorganic Materials, 2022, 37(6): 643-650. |

| [6] | XU Puhao, ZHANG Xiangzhao, LIU Guiwu, ZHANG Mingfen, GUI Xinyi, QIAO Guanjun. Microstructure and Mechanical Properties of SiC Joint Brazed by Al-Ti Alloys as Filler Metal [J]. Journal of Inorganic Materials, 2022, 37(6): 683-690. |

| [7] | LI Qi, HUANG Yi, QIAN Bin, XU Beibei, CHEN Liying, XIAO Wenge, QIU Jianrong. Photo Curing and Pressureless Sintering of Orange-emitting Glass-ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 289-296. |

| [8] | HUANG Longzhi, YIN Jie, CHEN Xiao, WANG Xinguang, LIU Xuejian, HUANG Zhengren. Selective Laser Sintering of SiC Green Body with Low Binder Content [J]. Journal of Inorganic Materials, 2022, 37(3): 347-352. |

| [9] | WU Xishi, ZHU Yunzhou, HUANG Qing, HUANG Zhengren. Effect of Pore Structure of Organic Resin-based Porous Carbon on Joining Properties of Cf/SiC Composites [J]. Journal of Inorganic Materials, 2022, 37(12): 1275-1280. |

| [10] | SUN Yangshan, YANG Zhihua, CAI Delong, ZHANG Zhengyi, LIU Qi, FANG Shuqing, FENG Liang, SHI Lifen, WANG Youle, JIA Dechang. Crystallization Kinetics, Properties of α-cordierite Based Glass-ceramics Prepared by Glass Powder Sintering [J]. Journal of Inorganic Materials, 2022, 37(12): 1351-1357. |

| [11] | CHEN Cheng, DING Jingxin, WANG Hui, WANG Deping. Nd-doped Mesoporous Borosilicate Bioactive Glass-ceramic Bone Cement [J]. Journal of Inorganic Materials, 2022, 37(11): 1245-1258. |

| [12] | SUN Luchao, ZHOU Cui, DU Tiefeng, WU Zhen, LEI Yiming, LI Jialin, SU Haijun, WANG Jingyang. Directionally Solidified Al2O3/Er3Al5O12 and Al2O3/Yb3Al5O12 Eutectic Ceramics Prepared by Optical Floating Zone Melting [J]. Journal of Inorganic Materials, 2021, 36(6): 652-658. |

| [13] | HUANG Xinyou, LIU Yumin, LIU Yang, LI Xiaoying, FENG Yagang, CHEN Xiaopu, CHEN Penghui, LIU Xin, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Yb:YAG Transparent Ceramics Using Alcohol-water Co-precipitation Method [J]. Journal of Inorganic Materials, 2021, 36(2): 217-224. |

| [14] | ZHANG Junmin, CHEN Xiaowu, LIAO Chunjin, GUO Feiyu, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Optimizing Microstructure and Properties of SiCf/SiC Composites Prepared by Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2021, 36(10): 1103-1110. |

| [15] | ZHU Danyang, QIAN Kang, CHEN Xiaopu, HU Zewang, LIU Xin, LI Xiaoying, PAN Yubai, MIHÓKOVÁ Eva, NIKL Martin, LI Jiang. Fine-grained Ce,Y:SrHfO3 Scintillation Ceramics Fabricated by Hot Isostatic Pressing [J]. Journal of Inorganic Materials, 2021, 36(10): 1118-1124. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||