Journal of Inorganic Materials ›› 2017, Vol. 32 ›› Issue (1): 33-38.DOI: 10.15541/jim20160220

• Orginal Article • Previous Articles Next Articles

ZONG Peng-An1,2, CHEN Li-Dong1

Received:2016-04-01

Revised:2016-05-31

Published:2017-01-20

Online:2016-12-15

About author:ZONG Peng-An. E-mail: zongpengan@student.sic.ac.cn

Supported by:CLC Number:

ZONG Peng-An, CHEN Li-Dong. Preparation and Mechanical Properties of Ce0.85Fe3CoSb12/rGO Thermoelectric Nanocomposite[J]. Journal of Inorganic Materials, 2017, 32(1): 33-38.

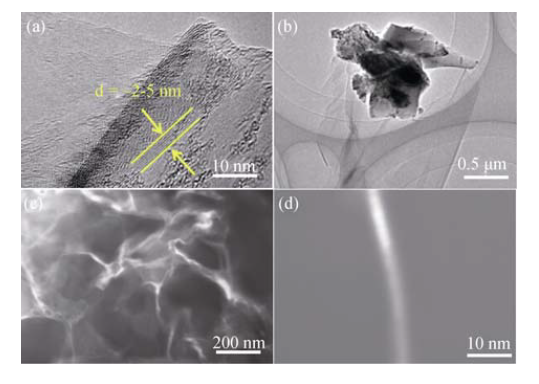

Fig. 4 (a) High resolution TEM image of fold GO sheet edge, (b) TEM image of Ce0.85Fe3CoSb12/1.4vol% GO mixed powder, (c) HADDF-STEM image of the SPSed Ce0.85Fe3CoSb12/ 1.4vol% rGO bulk surface and (d) Local high resolution HADDF-STEM image of the Ce0.85Fe3CoSb12/1.4vol% rGO bulk interface

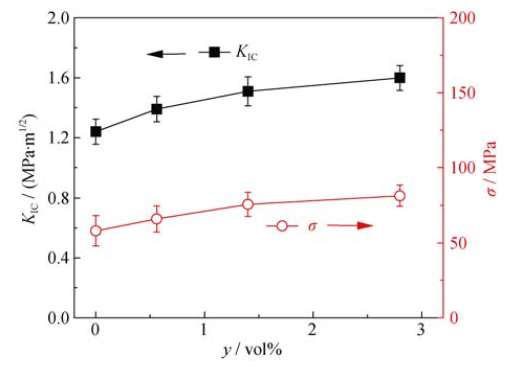

Fig. 6 Three-point flexural strength (σ) and fracture toughness (KIC) of the Ce0.85Fe3CoSb12/yvol% rGO (y = 0, 0.56, 1.4, 2.8) composites as a function of rGO content

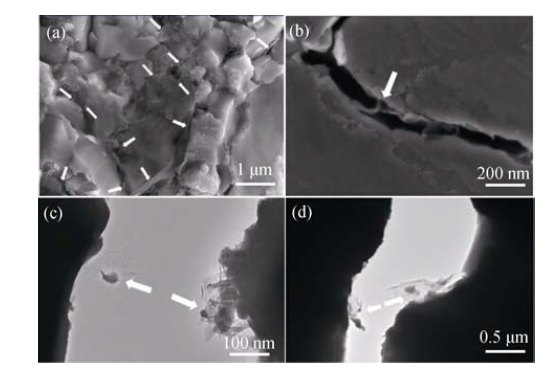

Fig. 7 (a) Fracture SEM image of the Ce0.85Fe3CoSb12/ 1.4vol% rGO bulk nanocomposite; (b) SEM image of the expanded crack of the Ce0.85Fe3CoSb12/1.4vol% rGO bulk nanocomposite and (c,d) TEM images of failed crack with breaked rGO (example I, II)

| [1] | CHEN L D, XIONG Z, BAI S Q.Recent progress of thermoelectric nano-composites.Journal of Inorganic Materials, 2010, 25(6): 561-568. |

| [2] | TANG Y S, BAI S Q, REN D D.Interface structure and electrical property of Yb0.3Co4Sb12/Mo-Cu element prepared by welding using Ag-Cu-Zn solder.Journal of Inorganic Materials, 2015, 3(30): 256-260. |

| [3] | ROGL G, ROGL P.Mechanical properties of skutterudites.Science of Advanced Materials, 2011, 3(4): 517-538. |

| [4] | RAVI V, FIRDOSY S, CAILLAT T, et al. Mechanical Properties of Thermoelectric Skutterudites. AIP Conference Proceedings, 2008, 969: 656-662. |

| [5] | SLACK G A, ROWE D M, ed. CRC Handbook of Thermoelectrics. Boca Raton: CRC Press, 1995. |

| [6] | CHEN L D, KAWAHARA T, TANG X F,et al.Anomalous barium filling fraction and n-type thermoelectric performance of BayCo4Sb12.Journal of Applied Physics, 2001, 90(4): 1864-1868. |

| [7] | SHI X, YANG J, SALVADOR R J,et al.Multiple-filled skutterudites: high thermoelectric figure of merit through separately optimizing electrical and thermal transports.Journal of the American Chemical Society, 2011, 133(20): 7837-7846. |

| [8] | DING J, LIU R H, GU H,et al.Study on the high temperature stability of YbyCo4Sb12/Yb2O3 composite thermoelctric material.Journal of Inorganic Materials, 2014, 29(2): 209-214. |

| [9] | ROGL G, GRYTSIV A, ROGL P,et al.N-type skutterudites (R,Ba,Yb)yCo4Sb12(R = Sr, La, Mm, DD, SrMm, SrDD) approaching ZT ≈ 2.0.Acta Materialia, 2014, 63: 30-43. |

| [10] | ROGL G, GRYTSIV A, ROGL P,et al.Nanostructuring of p- and n-type skutterudites reaching figures of merit of approximately 1.3 and 1.6, respectively.Acta Materialia, 2014, 76: 434-448. |

| [11] | ZHANG Q H, HUANG X Y, BAI S Q,et al.Thermoelectric devices for power generation: recent progress and future challenges.Advanced Engineering Materials, 2016, 18(2): 194-213. |

| [12] | GEIM A K.Graphene: status and prospects.Science, 2009, 324(5934): 1530-1534. |

| [13] | LI J L, CHEN B B, ZHANG W,et al.Recent progress in ceramic/graphene bulk composites.Journal of Inorganic Materials, 2014, 29(3): 225-236. |

| [14] | WALKER L S, MAROTTO V R, RAFIEE M A, et al.Toughening in graphene ceramic composites.ACS Nano, 2011, 5(4): 3182-3190. |

| [15] | RAMIREZA C, MIRANZO P, BELMONTE M,et al.Extraordinary toughening enhancement and flexural strength in Si3N4 composites using graphene sheets.Journal of the European Ceramic Society, 2014, 34(2): 161-169. |

| [16] | LIU J, YAN H X, JIANG K.Mechanical properties of graphene platelet-reinforced alumina ceramic composites.Ceramic International, 2013, 39(6): 6215-6221. |

| [17] | FAN Y C, IGARASHI G, JIANG W,et al.Highly strain tolerant and tough ceramic composite by incorporation of graphene.Carbon, 2015, 90: 274-283. |

| [18] | ZONG P A, CHEN X H, ZHU Y W,et al.Construction of a 3D-rGO network-wrapping architecture in a YbyCo4Sb12/rGO composite for enhancing the thermoelectric performance.Journal of Material Chemistry A, 2015, 3(16): 8643-8649. |

| [19] | STANKOVICH S, DIKIN D A, PINER R D,et al.Synthesis of graphene-based nanosheets via chemical reduction of exfoliated graphite oxide.Carbon, 2007, 45(7): 1558-1565. |

| [20] | MARCANO D C, KOSYNKIN D V, BERLIN J M,et al.Improved synthesis of graphene oxide.ACS Nano, 2010, 4(8): 4806-4814. |

| [21] | RAMÍREZ C, VEGA-DIAZ S M, MORELOS-GÓMEZ A,et al.Synthesis of conducting graphene/Si3N4 composites by spark plasma sintering.Carbon, 2013, 57: 425-432. |

| [1] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [2] | CHEN Saisai, PANG Yali, WANG Jiaona, GONG Yan, WANG Rui, LUAN Xiaowan, LI Xin. Preparation and Properties of Green-yellow Reversible Electro-thermochromic Fabric [J]. Journal of Inorganic Materials, 2022, 37(9): 954-960. |

| [3] | CHENG Cheng, LI Jianbo, TIAN Zhen, WANG Pengjiang, KANG Huijun, WANG Tongmin. Thermoelectric Property of In2O3/InNbO4 Composites [J]. Journal of Inorganic Materials, 2022, 37(7): 724-730. |

| [4] | SUN Ming, SHAO Puzhen, SUN Kai, HUANG Jianhua, ZHANG Qiang, XIU Ziyang, XIAO Haiying, WU Gaohui. First-principles Study on Interface of Reduced Graphene Oxide Reinforced Aluminum Matrix Composites [J]. Journal of Inorganic Materials, 2022, 37(6): 651-659. |

| [5] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [6] | AN Lin, WU Hao, HAN Xin, LI Yaogang, WANG Hongzhi, ZHANG Qinghong. Non-precious Metals Co5.47N/Nitrogen-doped rGO Co-catalyst Enhanced Photocatalytic Hydrogen Evolution Performance of TiO2 [J]. Journal of Inorganic Materials, 2022, 37(5): 534-540. |

| [7] | WANG Hongli, WANG Nan, WANG Liying, SONG Erhong, ZHAO Zhankui. Hydrogen Generation from Formic Acid Boosted by Functionalized Graphene Supported AuPd Nanocatalysts [J]. Journal of Inorganic Materials, 2022, 37(5): 547-553. |

| [8] | DONG Shurui, ZHAO Di, ZHAO Jing, JIN Wanqin. Effect of Ionized Amino Acid on the Water-selective Permeation through Graphene Oxide Membrane in Pervaporation Process [J]. Journal of Inorganic Materials, 2022, 37(4): 387-394. |

| [9] | JIANG Lili, XU Shuaishuai, XIA Baokai, CHEN Sheng, ZHU Junwu. Defect Engineering of Graphene Hybrid Catalysts for Oxygen Reduction Reactions [J]. Journal of Inorganic Materials, 2022, 37(2): 215-222. |

| [10] | WU Jing, YU Libing, LIU Shuaishuai, HUANG Qiuyan, JIANG Shanshan, ANTON Matveev, WANG Lianli, SONG Erhong, XIAO Beibei. NiN4/Cr Embedded Graphene for Electrochemical Nitrogen Fixation [J]. Journal of Inorganic Materials, 2022, 37(10): 1141-1148. |

| [11] | LI Tie, LI Yue, WANG Yingyi, ZHANG Ting. Preparation and Catalytic Properties of Graphene-Bismuth Ferrite Nanocrystal Nanocomposite [J]. Journal of Inorganic Materials, 2021, 36(7): 725-732. |

| [12] | XIAO Xiang, GUO Shaoke, DING Cheng, ZHANG Zhijie, HUANG Hairui, XU Jiayue. CsPbBr3@TiO2 Core-shell Structure Nanocomposite as Water Stable and Efficient Visible-light-driven Photocatalyst [J]. Journal of Inorganic Materials, 2021, 36(5): 507-512. |

| [13] | XIANG Hui, QUAN Hui, HU Yiyuan, ZHAO Weiqian, XU Bo, YIN Jiang. Piezoelectricity of Graphene-like Monolayer ZnO and GaN [J]. Journal of Inorganic Materials, 2021, 36(5): 492-496. |

| [14] | XIONG Jinyan, LUO Qiang, ZHAO Kai, ZHANG Mengmeng, HAN Chao, CHENG Gang. Facilely Anchoring Cu nanoparticles on WO3 Nanocubes for Enhanced Photocatalysis through Efficient Interface Charge Transfer [J]. Journal of Inorganic Materials, 2021, 36(3): 325-331. |

| [15] | LI Hao, TANG Zhihong, ZHUO Shangjun, QIAN Rong. High Performance of Room-temperature NO2 Gas Sensor Based on ZIF8/rGO [J]. Journal of Inorganic Materials, 2021, 36(12): 1277-1282. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||