Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (7): 756-760.DOI: 10.15541/jim20150617

• Orginal Article • Previous Articles Next Articles

LUO Ling-Hong, LIN You-Cheng, SHI Ji-Jun, CHENG Liang, WU Ye-Fan, SUN Liang-Liang

Received:2015-12-07

Revised:2016-02-27

Published:2016-07-20

Online:2016-06-22

Supported by:CLC Number:

LUO Ling-Hong, LIN You-Cheng, SHI Ji-Jun, CHENG Liang, WU Ye-Fan, SUN Liang-Liang. Preparation and Properties of Three-phase Composite Cathode of LSCF-GDC Dipped LSM Sol[J]. Journal of Inorganic Materials, 2016, 31(7): 756-760.

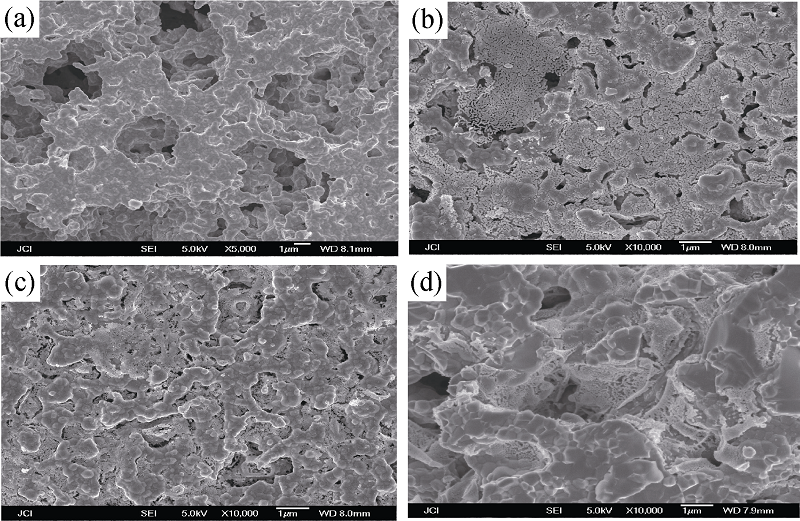

Fig. 2 SEM images for the different pH value on the impregnation of LSM to LSCF-GDC cathode (a) Porous skeleton of LSCF-GDC cathode; sample dipped by LSM sol with pH of (b) 6.0, (c) 7.0 and (d) 8.0

| [1] | MINH N Q.Ceramic fuel-cells.J. Am. Ceram. Soc., 1993, 76: 563-588. |

| [2] | WACHSMAN E D, LEE K T.Lowering the temperature of solid oxide fuel cells.Science, 2011, 334: 935-939. |

| [3] | DING D, LI X, LAI S Y, et al.Enhancing SOFC cathode performance by surface modification through infiltration.Energy & Environmental Science, 2014, 7: 552-575. |

| [4] | HøJBERG J, SøGAARD M. Impregnation of LSM based cathodes for solid oxide fuel cells.Electrochemical and Solid-state Letters, 2011, 14: B77-B79. |

| [5] | JIANG Z, LEI Z, DING B, et al.Electrochemical characteristics of solid oxide fuel cell cathodes prepared by infiltrating (La, Sr)MnO3 nanoparticles into yttria-stabillized bismuth oxide backbones.International Journal of Hydrogen Energy, 2010, 35: 8322-8330. |

| [6] | KIEBACH R, KNöFEL C, BOZZA F, et al. Infiltration of ionic-, electronic- and mixed-conducting nano particles into La0.75Sr0.25MnO3- Y0.16Zr0.84O2 cathodes-a comparative study of performance enhancement and stability at different temperature.Journal of Powder Sources, 2013, 228: 170-177. |

| [7] | CHEN K, AI N, JIANG S P.Performance and structural stability of Gd0.2Ce0.8O1.9 infiltrated La0.8Sr0.2MnO3 nano-structured oxygen electrodes of solid oxide electrolysis cells.International Journal of Hydrogen Energy, 2014, 39: 10349-10358. |

| [8] | JIANG S P.A review of wet impregnationd-An alternative method for the fabrication of high performance and nanostructured electrodes of solid oxide fuel cells.Mater. Sci. Eng. A, 2006, 418: 199-210. |

| [9] | VOHS J M, GORTE R J.High-performance SOFC cathodes prepared by infiltration.Adv. Mater., 2009, 21: 943-956. |

| [10] | JIANG S P.Nanoscale and nano-structured electrodes of solid oxide fuel cells by infiltration: advances and challenges.Int. J. Hydrogen Energy, 2012, 37: 449-470. |

| [11] | WANG A, PU J, YAN D, et al.Promoted electrochemical performance of intermediate temperature solid oxide fuel cells with Pd0.95Mn0.05O-infiltrated (La0.8Sr0.2)0.95MnO3-δY0.16Zr0.84O2 composite cathodes.Journal of Power Sources, 2016, 303: 37-141. |

| [12] | THEODORE E.B, JASON D N. Precursor solution additives improve desiccated La0.6Sr0.4Co0.8Fe0.2O3-x infiltrated solid oxide fuel cell cathode performance.Journal of Power Sources, 2016, 301: 287-298. |

| [13] | ZHAO E Q, JIA Z, ZHAO L.One dimensional La0.8Sr0.2 Co0.2Fe0.8O3-δ/Ce0.8Gd0.2O1.9 nano composite cathodes for intermediate temperature solid oxide fuel cells,J. Power Sources, 2012, 219: 133-139. |

| [14] | LU K, SHEN F.Long term behaviors of La0.8Sr0.2MnO3 and La0.6Sr0.4-Co0.2Fe0.8O3 as cathodes for solid oxide fuel cells.Int. J. Hydrog. Energy, 2014, 39(15): 7963-7971. |

| [1] | TUERHONG Munire, ZHAO Honggang, MA Yuhua, QI Xianhui, LI Yuchen, YAN Chenxiang, LI Jiawen, CHEN Ping. Construction and Photocatalytic Activity of Monoclinic Tungsten Oxide/Red Phosphorus Step-scheme Heterojunction [J]. Journal of Inorganic Materials, 2023, 38(6): 701-707. |

| [2] | KONG Guoqiang, LENG Mingzhe, ZHOU Zhanrong, XIA Chi, SHEN Xiaofang. Sb Doped O3 Type Na0.9Ni0.5Mn0.3Ti0.2O2 Cathode Material for Na-ion Battery [J]. Journal of Inorganic Materials, 2023, 38(6): 656-662. |

| [3] | GUO Tianmin, DONG Jiangbo, CHEN Zhengpeng, RAO Mumin, LI Mingfei, LI Tian, LING Yihan. Enhanced Compatibility and Activity of High-entropy Double Perovskite Cathode Material for IT-SOFC [J]. Journal of Inorganic Materials, 2023, 38(6): 693-700. |

| [4] | WU Rui, ZHANG Minhui, JIN Chenyun, LIN Jian, WANG Deping. Photothermal Core-Shell TiN@Borosilicate Bioglass Nanoparticles: Degradation and Mineralization [J]. Journal of Inorganic Materials, 2023, 38(6): 708-716. |

| [5] | WU Lin, HU Minglei, WANG Liping, HUANG Shaomeng, ZHOU Xiangyuan. Preparation of TiHAP@g-C3N4 Heterojunction and Photocatalytic Degradation of Methyl Orange [J]. Journal of Inorganic Materials, 2023, 38(5): 503-510. |

| [6] | MA Xiaosen, ZHANG Lichen, LIU Yanchao, WANG Quanhua, ZHENG Jiajun, LI Ruifeng. 13X@SiO2: Synthesis and Toluene Adsorption [J]. Journal of Inorganic Materials, 2023, 38(5): 537-543. |

| [7] | DU Jianyu, GE Chen. Recent Progress in Optoelectronic Artificial Synapse Devices [J]. Journal of Inorganic Materials, 2023, 38(4): 378-386. |

| [8] | YANG Yang, CUI Hangyuan, ZHU Ying, WAN Changjin, WAN Qing. Research Progress of Flexible Neuromorphic Transistors [J]. Journal of Inorganic Materials, 2023, 38(4): 367-377. |

| [9] | TIAN Yu, ZHU Xiaojian, SUN Cui, YE Xiaoyu, LIU Huiyuan, LI Runwei. Intrinsically Stretchable Threshold Switching Memristor for Artificial Neuron Implementations [J]. Journal of Inorganic Materials, 2023, 38(4): 413-420. |

| [10] | CHEN Xinli, LI Yan, WANG Weisheng, SHI Zhiwen, ZHU Liqiang. Gelatin/Carboxylated Chitosan Gated Oxide Neuromorphic Transistor [J]. Journal of Inorganic Materials, 2023, 38(4): 421-428. |

| [11] | YOU Junqi, LI Ce, YANG Dongliang, SUN Linfeng. Double Dielectric Layer Metal-oxide Memristor: Design and Applications [J]. Journal of Inorganic Materials, 2023, 38(4): 387-398. |

| [12] | WANG Jingyu, WAN Changjin, WAN Qing. Dual-gate IGZO-based Neuromorphic Transistors with Stacked Al2O3/Chitosan Gate Dielectrics [J]. Journal of Inorganic Materials, 2023, 38(4): 445-451. |

| [13] | LIN Siqi, LI Airan, FU Chenguang, LI Rongbing, JIN Min. Crystal Growth and Thermoelectric Properties of Zintl Phase Mg3X2 (X=Sb, Bi) Based Materials: a Review [J]. Journal of Inorganic Materials, 2023, 38(3): 270-279. |

| [14] | WANG Donghai, LI Dongzhen, XU Jun. An Important Breakthrough in the Technology of Sapphire Plate with Large Size Grown by the Edge-defined Film-fed Growth Method [J]. Journal of Inorganic Materials, 2023, 38(3): 363-364. |

| [15] | QI Zhanguo, LIU Lei, WANG Shouzhi, WANG Guogong, YU Jiaoxian, WANG Zhongxin, DUAN Xiulan, XU Xiangang, ZHANG Lei. Progress in GaN Single Crystals: HVPE Growth and Doping [J]. Journal of Inorganic Materials, 2023, 38(3): 243-255. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||