Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (7): 719-725.DOI: 10.15541/jim20150630

• Orginal Article • Previous Articles Next Articles

LI Gen, LI Jiong-Jiong, LI Li-Mei, JIANG Jia-Xing, LI Yu-Bao, LI Ji-Dong

Received:2015-12-14

Revised:2016-01-26

Published:2016-07-20

Online:2016-06-22

About author:LI Gen. E-mail: 1536399719@qq.com

Supported by:CLC Number:

LI Gen, LI Jiong-Jiong, LI Li-Mei, JIANG Jia-Xing, LI Yu-Bao, LI Ji-Dong. Preparation of Calcium Phosphate/Polyurethane Composite Porous Scaffolds for Bone Repair by in situ Self-foaming Method[J]. Journal of Inorganic Materials, 2016, 31(7): 719-725.

| Samples | nHA percentage /wt% | DCPD percentage /wt% | PU percentage /wt% |

|---|---|---|---|

| DCPD/PU | 0 | 30 | 70 |

| nHA-DCPD/PU-1 | 15 | 15 | 70 |

| nHA-DCPD/PU-2 | 20 | 10 | 70 |

Table 1 Abbreviation and composition of fabricated composite scaffolds

| Samples | nHA percentage /wt% | DCPD percentage /wt% | PU percentage /wt% |

|---|---|---|---|

| DCPD/PU | 0 | 30 | 70 |

| nHA-DCPD/PU-1 | 15 | 15 | 70 |

| nHA-DCPD/PU-2 | 20 | 10 | 70 |

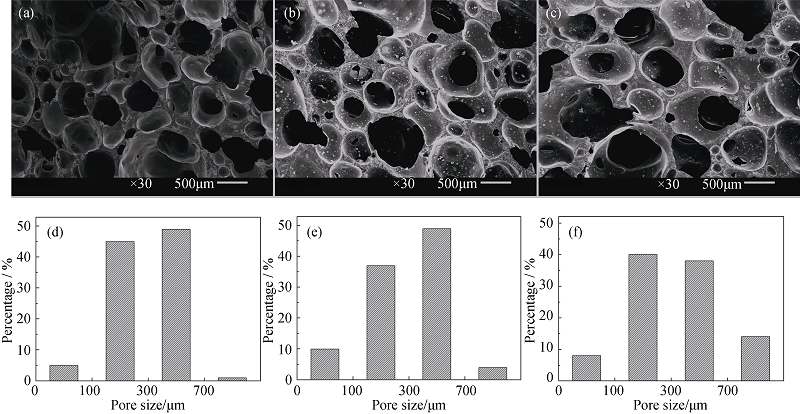

Fig. 3 SEM images (a-c) and pore size distribution (d-f) of CaP/PU porous scaffolds fabricated at 90 ℃ (a, d) DCPD/PU; (b, e) nHA-DCPD/PU-1; (c, f) nHA-DCPD/PU-2

| Composition | Porosity/% | Compressive strength/MPa | Compressive modulus/MPa |

|---|---|---|---|

| DCPD/PU | 92.6±1.1 | 1.1±0.1 | 31.5±1.9 |

| nHA-DCPD/PU-1 | 82.2±2.1 | 1.7±0.2 | 58.6±4.9 |

| nHA-DCPD/PU-2 | 80.3±1.2 | 1.5±0.2 | 43.5±4.2 |

Table 2 Porosity and mechanical properties of DCPD/PU, nHA-DCPD/PU-1 and nHA-DCPD/PU-2 composite scaffolds fabricated at 90 ℃

| Composition | Porosity/% | Compressive strength/MPa | Compressive modulus/MPa |

|---|---|---|---|

| DCPD/PU | 92.6±1.1 | 1.1±0.1 | 31.5±1.9 |

| nHA-DCPD/PU-1 | 82.2±2.1 | 1.7±0.2 | 58.6±4.9 |

| nHA-DCPD/PU-2 | 80.3±1.2 | 1.5±0.2 | 43.5±4.2 |

| Composition | Compressive strength / MPa | Compressive modulus / MPa | Increase of compressive strength after re-curing / % |

|---|---|---|---|

| DCPD/PU | 2±0.3 | 43.8±2.2 | 77 |

| nHA-DCPD/PU-1 | 3.8±0.3 | 74.1±18.6 | 126 |

| nHA-DCPD/PU-2 | 3.6±0.4 | 69.5±10.2 | 137 |

Table 3 Mechanical properties of DCPD/PU, nHA-DCPD/ PU-1 and nHA-DCPD/PU-2 composite scaffolds fabricated at 90 ℃ re-cured at 110 ℃ for 24 h

| Composition | Compressive strength / MPa | Compressive modulus / MPa | Increase of compressive strength after re-curing / % |

|---|---|---|---|

| DCPD/PU | 2±0.3 | 43.8±2.2 | 77 |

| nHA-DCPD/PU-1 | 3.8±0.3 | 74.1±18.6 | 126 |

| nHA-DCPD/PU-2 | 3.6±0.4 | 69.5±10.2 | 137 |

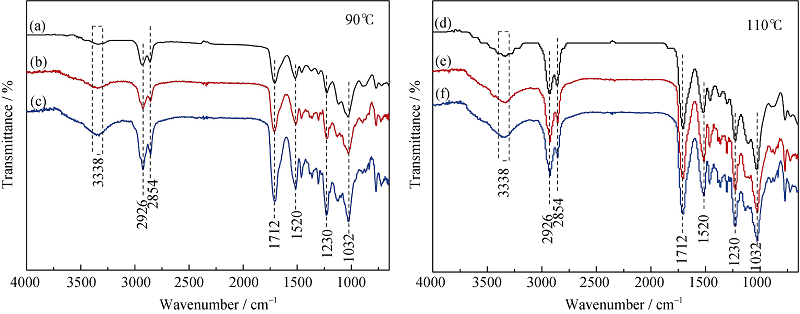

Fig. 5 FT-IR spectra of CaP/PU composite scaffolds cured at 90 ℃ (a-c) and re-cured at 110 ℃ (d-f) (a, d) DCPD/PU; (b, e) nHA-DCPD/PU-1; (c, f) nHA-DCPD/PU-2

| Onset decompositon temperature for samples cured at 90 ℃/℃ | Onset decomposition temperature for samples recured at 110 ℃ for 24 h/℃ | |

|---|---|---|

| DCPD/PU | 309.0 | 316 |

| nHA-DCPD/ PU-1 | 310.0 | 321 |

| nHA-DCPD/ PU-2 | 309.6 | 316 |

Table 4 Results of thermal analysis of CaP/PU composite scaffolds

| Onset decompositon temperature for samples cured at 90 ℃/℃ | Onset decomposition temperature for samples recured at 110 ℃ for 24 h/℃ | |

|---|---|---|

| DCPD/PU | 309.0 | 316 |

| nHA-DCPD/ PU-1 | 310.0 | 321 |

| nHA-DCPD/ PU-2 | 309.6 | 316 |

| [1] | REZWAN K, CHEN Q Z, BLAKER J J, et al.Biodegradable and bioactive porous polymer/inorganic composite scaffolds for bone tissue engineering.Biomaterials, 2006, 27: 3413-3431. |

| [2] | JANIK H, MARZEC M.A review: fabrication of porous polyurethane scaffolds.Materials Science and Engineering C, 2015, 48(1): 586-591. |

| [3] | TIENEN T G, HEIJKANTS R, BUMA P, et al.Tissue ingrowth polymers and degradation of two biodegradable porous with different porosities and pore sizes.Biomaterials, 2002, 23: 1731-1738. |

| [4] | KIRDPONPATTARA S, KHAMKERW A, SANCHAVANAKIT N, et al.Structural modification and characterization of bacterial cellulose-alginate composite scaffolds for tissue engineering.Carbohydrate Polymers, 2015, 132(5): 146-155. |

| [5] | YOU F, LI Y B, ZOU Q, et al.Fabrication and osteogenesis of a Porous nanohydroxyapatite/polyamide scaffold with an anisotropic architecture.ACS Biomaterials Science & Engineering, 2015, 1: 825-833. |

| [6] | TAMIMI F, KUMARASAMI B, DOILLON C, et al.Brushite- collagen composites for bone regeneration.Acta Biomater., 2008, 4: 1315-1321. |

| [7] | MYTHILI J, SUBRAMANIAN M V.Preparation and characterization of two new composites: collagen-brushite and collagen octa-calcium phosphate.Medical Science Monitor: International Medical Journal of Experimental and Clinical Research, 2002, 8(11): 481-487. |

| [8] | GUELCHER S A.Biodegradable polyurethanes: Synthesis and applications in regenerative medicine.Tissue Engineering Part B: Reviews, 2008, 14(1): 3-17. |

| [9] | MCBANE J E, SHAIFPOOR S, CAI K, et al.Biodegradation and in vivo biocompatibility of a degradable, polar/hydrophobic/ionic polyurethane for tisse engineering applications.Biomaterials, 2011, 32(26): 6034-6044. |

| [10] | GIANNITELLI S M, BASOLI F, MOZETIC P, et al.Graded porous polyurethane foam: a potential scaffold for oro-maxillary bone regeneration.Materials Science and Engineering C, 2015, 51: 329-335. |

| [11] | LIU H H, ZHANG L, ZUO Y, et al.Preparation and characterization of aliphatic polyurethane and hydroxyapatite composite scaffold.Journal of Applied Polymer Science, 2009, 112(5): 2968-2975. |

| [12] | YANG W, BOTH S K, ZUO Y, et al.Biological evaluation of porous aliphatic polyurethane/hydroxyapatite composite scaffolds for bone tissue engineering.Journal of Biomedical Materials Reserach Part A, 2015, 103(7): 2251-2259. |

| [13] | APELT D, THEISS F, ELWARRAK A O, et al.In vivo behavior of three different injectable hydraulic calcium phosphate cements.Biomaterials, 2004, 25: 1439-1451. |

| [14] | LI L M, ZUO Y, DU J J, et al.Structural and mechanical properties of composite scaffolds based on nano-hydroxyapatite and polyurethane of alcoholized castor oil.Journal of Inorganic Materials, 2013, 28(8): 811-817. |

| [15] | GABRIELA C, OCTAVIAN C. Mixed-matrix membranes based on polyurethane containingnanohydroxyapatite and its potential applications. Journal of Applied Polymer Science, 2015, (132)17: 41813. |

| [16] | WOODARD J R, HILLDORE A J, LAN S K, et al.The mechanical properties and osteoconductivity of hydroxyapatite bone scaffolds with multi-scale porosity.Biomaterials, 2007, 28: 45-54. |

| [17] | HULBERT S F, YOUNG F A, MATHEWS R S, et al.Potential of ceramic materials as permanently implantable skeletal prostheses.Journal of Biomedical Materials Research, 1970, 4(3): 433-456. |

| [18] | TERAMOTO N, SAITOH Y, TAKAHASHI A, et al.Biodegradable polyurethane elastomers prepared from isocyanate-terminated poly(ethylene adipate), castor oil, and glycero.Journal of Applied Polymer Science, 2010, 115(6): 3199-3204. |

| [19] | MISHRA A K, CHATTOPADHYAY D K, SREEDHAR B.FT-IR and XPS studies of polyurethane-urea-imide coatings.Progress in Organic Coatings, 2006, 55(3): 231-243. |

| [20] | MOTHE C G, ARAUJO C R.Properties of polyurethane elastomers and composites by thermal analysis.Thermochimicaacta, 2000, 357(1): 321-325. |

| [1] | SHI Jixiang, ZHAI Dong, ZHU Min, ZHU Yufang. Preparation and Characterization of Bioactive Glass-Manganese Dioxide Composite Scaffolds [J]. Journal of Inorganic Materials, 2022, 37(4): 427-435. |

| [2] | ZHANG Hang, HAN Kunyuan, DONG Lanlan, LI Xiang. Preparation and Characterization of β-tricalcium Phosphate/Nano Clay Composite Scaffolds via Digital Light Processing Printing [J]. Journal of Inorganic Materials, 2022, 37(10): 1116-1122. |

| [3] | WU Zhongcao, HUAN Zhiguang, ZHU Yufang, WU Chengtie. 3D Printing and Characterization of Microsphere Hydroxyapatite Scaffolds [J]. Journal of Inorganic Materials, 2021, 36(6): 601-607. |

| [4] | DONG Shaojie,WANG Xudong,SHEN Steve Guofang,WANG Xiaohong,LIN Kaili. Research Progress on Functional Modifications and Applications of Bioceramic Scaffolds [J]. Journal of Inorganic Materials, 2020, 35(8): 867-881. |

| [5] | CHEN Xi-Liang, CHEN Qing-Hua, ZHUANG Ying, YAN Ting-Ting. KGM/Gelatin/Nano HAP Scaffolds for Tissue Engineering of Intervertebral Disc Annulus Fibrosus [J]. Journal of Inorganic Materials, 2018, 33(1): 60-66. |

| [6] | XIN Chen, QI Xin, ZHU Min, ZHAO Shi-Chang, ZHU Yu-Fang. Hydroxyapatite Whisker-reinforced Composite Scaffolds Through 3D Printing for Bone Repair [J]. Journal of Inorganic Materials, 2017, 32(8): 837-844. |

| [7] | WANG Quan-Xiang, WU Ying-Yang, DONG Xie-Ping, MA Xu-Hui, WEI Jie. Magnesium Phosphate/PBS/Wheat Protein Biocomposite for Bone Repair [J]. Journal of Inorganic Materials, 2015, 30(9): 957-962. |

| [8] | WEN Hai-Meng, SONG Jun, WANG Chong-Qing, ZHOU Yu, WANG Jun. Directly Synthesis of ZSM-22 Particles by Adding Polyurethane Foam in Ionic Liquid-directed Dry-gel-conversion [J]. Journal of Inorganic Materials, 2015, 30(6): 615-620. |

| [9] | HUANG Ping, LI Peng, ZHAO Jun-Sheng, QU Shu-Xin, FENG Bo, WENG Jie. Mechanical Activation Reinforced Porous Calcium Phosphate Cement [J]. Journal of Inorganic Materials, 2015, 30(4): 432-438. |

| [10] | LUO Pin-Feng, ZHI Wei, ZHANG Jing-Wei, SHI Feng, DUAN Ke, WANG Jian-xin, LU Xiong, WENG Jie. Interconnectivity of Bioceramic Scaffolds with Different Porous Structures and Their Fluid Velocity Distribution Analyzed by Micro-CT Computer Modeling [J]. Journal of Inorganic Materials, 2015, 30(1): 71-76. |

| [11] | GONG Meng-An, Rao Qun-Li, WANG Hong-Lie. A Novel Technique to Prepare Porous 3D Fluoridated Hydroxyapatite Scaffold Using Pore-forming and Foaming Agents [J]. Journal of Inorganic Materials, 2014, 29(3): 289-293. |

| [12] | LI Li-Mei, ZUO Yi, DU Jing-Jing, LI Ji-Dong, SUN Bin, LI Yu-Bao. Structural and Mechanical Properties of Composite Scaffolds Based on Nano-hydroxyapatite and Polyurethane of Alcoholized Castor Oil [J]. Journal of Inorganic Materials, 2013, 28(8): 811-817. |

| [13] | WU Cheng-Tie, CHANG Jiang. Silicate Bioceramics for Bone Tissue Regeneration [J]. Journal of Inorganic Materials, 2013, 28(1): 29-39. |

| [14] | ZHAO Jing, LI Jin-Yu, ZHI Wei, LU Xiong, JIA Zhi-Bin, WENG Jie. Preparation and Optimization of Porous HA Ceramic Scaffolds by Wax Spheres Leaching Method [J]. Journal of Inorganic Materials, 2013, 28(1): 74-78. |

| [15] | ZENG Xiao-Bo, HU Hao, XIE Li-Qin, LAN Fang, WU Yao, GU Zhong-Wei. Preparation and Properties of Supermagnetic Calcium Phosphate Composite Scaffold [J]. Journal of Inorganic Materials, 2013, 28(1): 79-84. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||