Journal of Inorganic Materials ›› 2016, Vol. 31 ›› Issue (7): 687-693.DOI: 10.15541/jim20150566

• Orginal Article • Previous Articles Next Articles

YU Fang-Li1, BAI Yu2, WU Xiu-Ying3, Wang Hai-Jun4, WU Jiu-Hui1

Received:2015-11-16

Revised:2016-01-03

Published:2016-07-20

Online:2016-06-22

Supported by:CLC Number:

YU Fang-Li, BAI Yu, WU Xiu-Ying, Wang Hai-Jun, WU Jiu-Hui. Corrosion Resistance and Anti-wear Property of Nickel Based Abradable Sealing Coating Deposited by Plasma Spraying[J]. Journal of Inorganic Materials, 2016, 31(7): 687-693.

| Material | Product mark | Composition/wt% | Density/ (g·cm-3) |

|---|---|---|---|

| Ni-C | M 307 | Ni75-C25 | 3.2 |

| NiCrAl-BN | M 301 | Ni60Cr14Al-BN5.5 | 4.4 |

Table 1 Materials for abradable seal coating[12]

| Material | Product mark | Composition/wt% | Density/ (g·cm-3) |

|---|---|---|---|

| Ni-C | M 307 | Ni75-C25 | 3.2 |

| NiCrAl-BN | M 301 | Ni60Cr14Al-BN5.5 | 4.4 |

| Parameters | Ni-C | NiCrAl-BN |

|---|---|---|

| Current /A | 200 | 320 |

| Voltage /V | 90 | 90 |

| Primary gas, Ar /(m3·h-1) | 2.8 | 2.8 |

| Carrier gas flow rate /(L·min-1) | 10 | 10 |

| Carrier gas pressure / MPa | 0.8 | 0.8 |

| Powder feed rate /(g·min-1) | 40 | 48 |

Table 2 Spray parameters

| Parameters | Ni-C | NiCrAl-BN |

|---|---|---|

| Current /A | 200 | 320 |

| Voltage /V | 90 | 90 |

| Primary gas, Ar /(m3·h-1) | 2.8 | 2.8 |

| Carrier gas flow rate /(L·min-1) | 10 | 10 |

| Carrier gas pressure / MPa | 0.8 | 0.8 |

| Powder feed rate /(g·min-1) | 40 | 48 |

| Parameters | Value |

|---|---|

| Distance /mm | 100 |

| Pressure /MPa | 0.3 |

| Compressed air flow rate /(m3·h-1) | 3 |

| Inner diameter of nozzle / mm | 3.6 |

| Length of nozzle /mm | 22 |

| Particle size of abrasive particles-Brown alumina | 100# |

Table 3 Parameters for erosive wear test

| Parameters | Value |

|---|---|

| Distance /mm | 100 |

| Pressure /MPa | 0.3 |

| Compressed air flow rate /(m3·h-1) | 3 |

| Inner diameter of nozzle / mm | 3.6 |

| Length of nozzle /mm | 22 |

| Particle size of abrasive particles-Brown alumina | 100# |

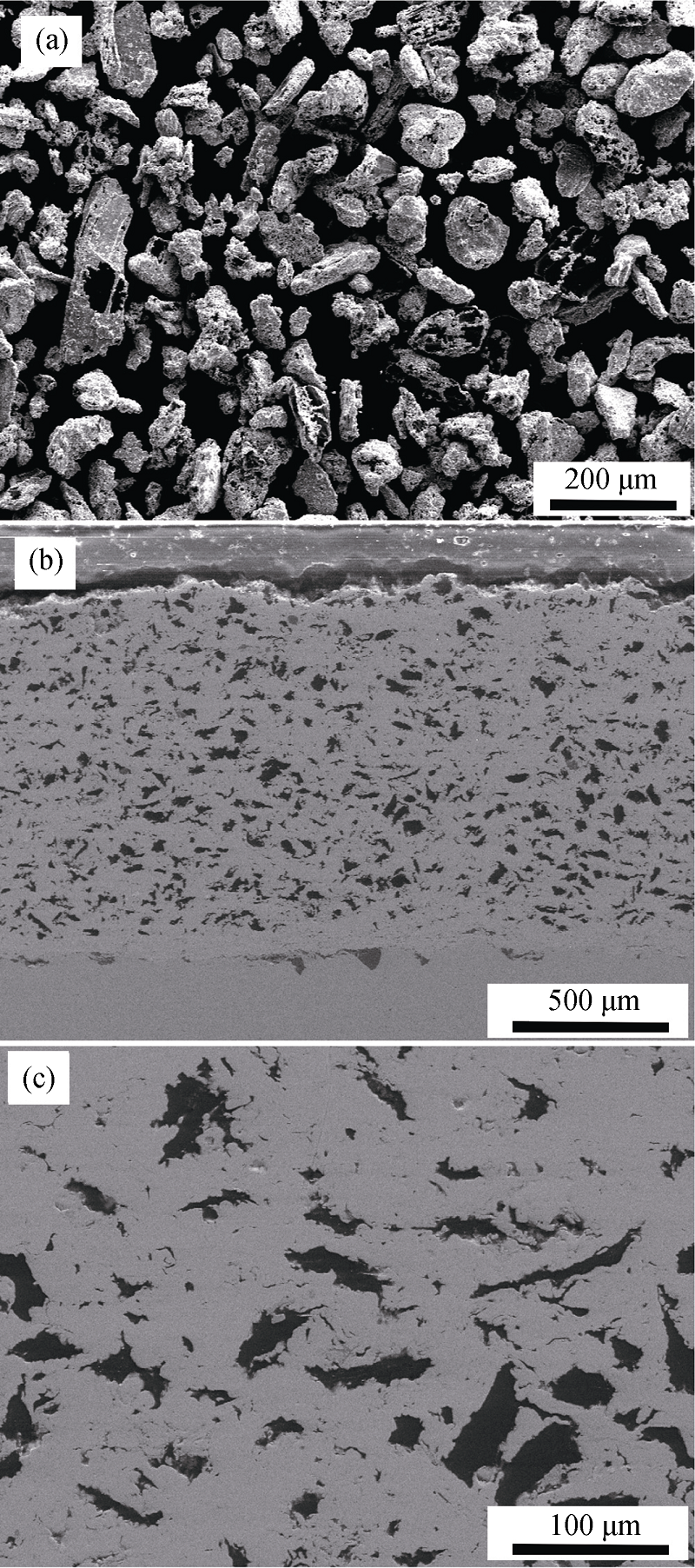

Fig. 3 Ni-C feedstock powder and cross-sectional images of Ni-C as-sprayed coating(a) Feedstock powder; (b) Whole image of coating;; (c) Detailed image of coating

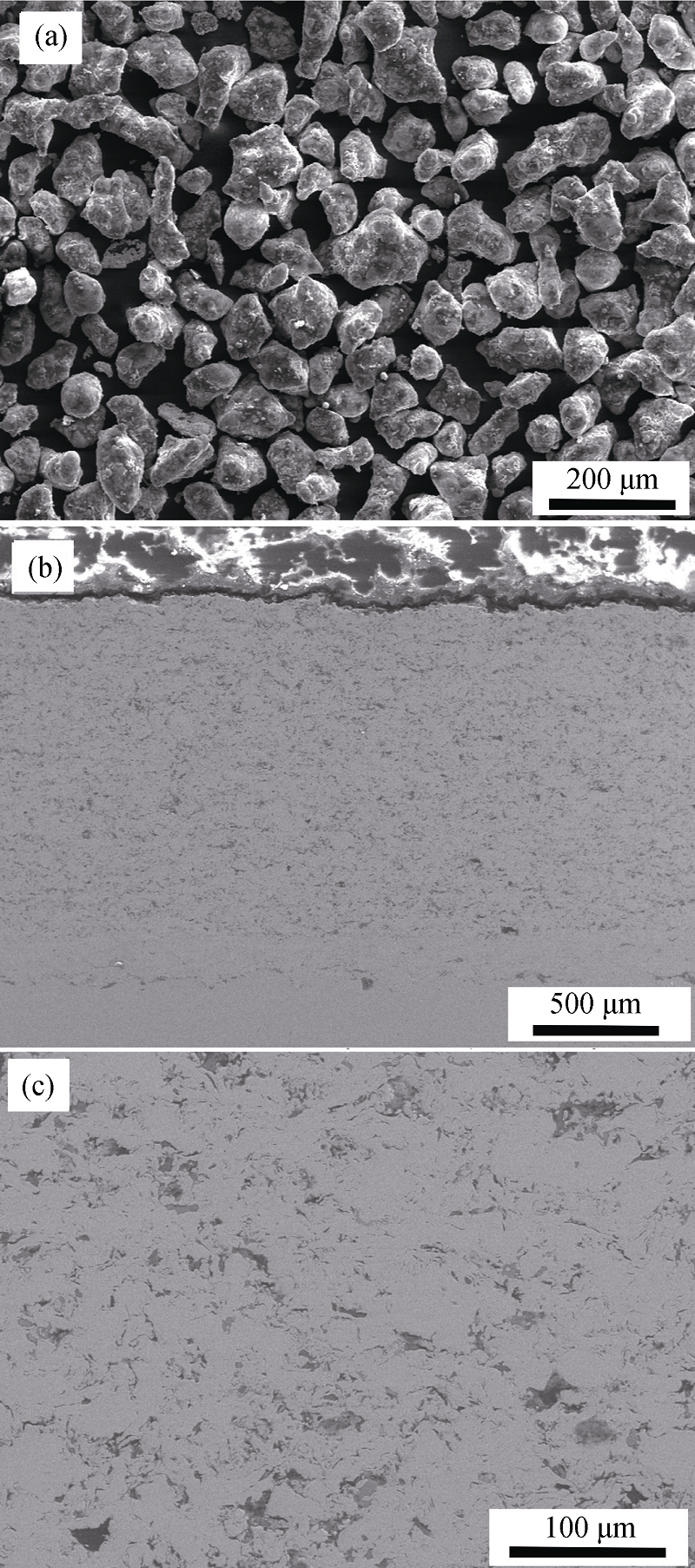

Fig. 4 NiCrAl-BN feedstock powder and cross-sectional images of NiCrAl-BN coating(a) Feedstock powder; (b) Whole image of coating; (c) Detailed image of coating

| [1] | DELEBARRE C, WAGNER V, PARIS J Y, et al.An experimental study of the high speed interaction between a labyrinth seal and an abradable coating in a turbo-engine application.Wear, 2014, 316: 109-118. |

| [2] | MA XIAO, MATTHEWS A.Evaluation of abradable seal coating mechanical properties.Wear, 2009, 267: 1501-1510. |

| [3] | MA XIAO, MATTHEWS A.Investigation of abradable seal coating performance using scratch testing. Surface & Coatings Technology, 2007, 202: 1214-1220. |

| [4] | CAO YU-XIA, LIU WEI, DU LING-ZHONG, et al.Preparation and property of Al/hBN plasma sprayed abradable sealing coating.Rare Metal Materials and Engineering, 2012, 41(S2): 813-816. |

| [5] | XU CUN-GUAN, DU LING-ZHONG, ZHANG WEI-GANG, et al.Salt spray corrosion of Ni/Graphite abradable sealing coatings,Journal of Aeronautical Materials, 2010, 30(4):53-58. |

| [6] | XU CUN-GUAN, DU LING-ZHONG, YANG BIN, et al.Study on salt spray corrosion of Ni-graphite abradable coating with 80Ni20Al and 96NiCr-4Al as bonding layers.Surface & Coatings Technology, 2011, 205: 4154-4161. |

| [7] | LEI BING, LI MAN, ZHAO ZHONG-XING, et al.Corrosion mechanism of an Al-BN abradable seal coating system in chloride solution.Corrosion Science, 2014, 79: 198-205. |

| [8] | XU CUN-GUAN, DU LING-ZHONG, YANG BIN, et al.The effect of Al content on the galvanic corrosion behaviour of coupled Ni/graphite and Ni-Al coatings.Corrosion Science, 2011, 53: 2066-2074. |

| [9] | WANG HAI-JUN, XIE ZHAO-QIAN, GUO YONG-MING, et al.Characteristic of high efficiency supersonic plasma spraying particles and coatings.China Surface Engineering, 2010, 23(3):84-88. |

| [10] | BAI Y, HAN Z H, LI H Q, et al.Structure-property differences between supersonic and conventional atmospheric plasma sprayed zirconia thermal barrier coatings,Surface & Coatings Technology, 2011, 205: 3833-3839. |

| [11] | WANG GANG, TENG BAI-QIU, WANG ZHI-HONG, et al.The development of abradable coatings for aero engine.Thermal Spray Technology, 2012, 4(1): 20-23. |

| [12] | YI MAO-ZHONG, ZHANG XIAN-LONG, ZHENG JI-HONG, et al.Development of abradable seal coatings and their performance evaluation.Aeronautical Manufacturing Technology, 1998, 3: 3-5. |

| [13] | WANG HAI-JUN, CAI JIANG, HAN ZHI-HAI.Study on erosion wear of WC-Co coatings prepared by supersonic plasma spray and HVOF spray.Journal of Materials Engineering, 2005, 4: 50-54. |

| [14] | MATTHEWS S, JAMES B, HYLAND M.The role of microstructure in the mechanism of high velocity erosion of Cr3C2-NiCr thermal spray coatings: Part 1-As-sprayed coatings.Surface and Coatings Technology, 2009, 203: 1086-1093. |

| [15] | MATTHEWS S, JAMES B, HYLAND M.The role of microstructure in the mechanism of high velocity erosion of Cr3C2-NiCr thermal spray coatings: Part 2 - Heat treated coatings.Surface and Coatings Technology, 2009, 203: 1094-1100. |

| [16] | YI MAO-ZHONG, ZHANG XIAN-LONG, HE JIA-WEN.Relationship between erosion wear resistance of abradable seal coating & experimental parameters.Aviation Engineering and Mainienance, 1999, 2: 16-18. |

| [17] | YI MAO-ZHONG, HUANG BAI-YUN, HE JIA-WEN.Erosion wear behaviour and model of abradable seal coating.Wear, 2002, 252: 9-15. |

| [18] | LIU WEI, ZHOU KUI, DU LING-ZHONG, et al.Frictional wear resistance and erosion resistance of abradable seal coating.Thermal Spray. Technology, 2012, 4(4):34-41. |

| [19] | CHEN BAI-MING, BI QIN-LING, YANG JUN, et al.Tribological properties of solid lubricants (graphite, h-BN) for Cu-based P/M friction composites.Tribology International, 2008, 41: 1145-1152. |

| [20] | LI JIAN-LIANG, XIONG DANG-SHENG, Tribological behavior of graphite-containing nickel-based composite as function of temperature, load and counterface.Wear, 2009, 266: 360-367. |

| [1] | FAN Dong, ZHONG Xin, WANG Yawen, ZHANG Zhenzhong, NIU Yaran, LI Qilian, ZHANG Le, ZHENG Xuebin. Corrosion Behavior and Mechanism of Aluminum-rich CMAS on Rare-earth Silicate Environmental Barrier Coatings: [J]. Journal of Inorganic Materials, 2023, 38(5): 544-552. |

| [2] | LUO Shuwen, MA Mingsheng, LIU Feng, LIU Zhifu. Corrosion Behavior and Mechanism of LTCC Materials in Ca-B-Si System [J]. Journal of Inorganic Materials, 2023, 38(5): 553-560. |

| [3] | DING Jianxiang, ZHANG Kaige, LIU Dongming, ZHENG Wei, ZHANG Peigen, SUN Zhengming. Ag-based Electrical Contact Material Reinforced by Ti3AlC2 Ceramic and Its Derivative Ti3C2Tx [J]. Journal of Inorganic Materials, 2022, 37(5): 567-573. |

| [4] | WANG Hongda, FENG Qian, YOU Xiao, ZHOU Haijun, HU Jianbao, KAN Yanmei, CHEN Xiaowu, DONG Shaoming. Microstructure and Corrosion Behavior of Brazed Joints of SiC/SiC Composites and Hastelloy N Alloy Using Cu-Ni Alloy [J]. Journal of Inorganic Materials, 2022, 37(4): 452-458. |

| [5] | LIU Pingping, ZHONG Xin, ZHANG Le, LI Hong, NIU Yaran, ZHANG Xiangyu, LI Qilian, ZHENG Xuebin. Molten Salt Corrosion Behaviors and Mechanisms of Ytterbium Silicate Environmental Barrier Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1267-1274. |

| [6] | ZHANG Zhigang,LU Xiaotong,LIU Jinli. NiFe2O4 Ceramic U-shaped Sleeve Prepared by Slip Casting and Pressureless Sintering [J]. Journal of Inorganic Materials, 2020, 35(6): 661-668. |

| [7] | DING Jianxiang,HUANG Peiyan,ZHA Yuhui,WANG Dandan,ZHANG Peigen,TIAN Wubian,SUN Zhengming. High-purity Ti2AlC Powder: Preparation and Application in Ag-based Electrical Contact Materials [J]. Journal of Inorganic Materials, 2020, 35(6): 729-734. |

| [8] | WANG Zhihu,ZHANG Jumei,BAI Lijing,ZHANG Guojun. Mg(OH)2 Film on Micro-arc Oxidation Ceramic Coating of AZ31 Magnesium Alloy: Preparation and Corrosion Resistance [J]. Journal of Inorganic Materials, 2020, 35(6): 709-716. |

| [9] | TANG Shuai,ZHANG Wentai,QIAN Junyu,XIAN Peng,MO Xiaoshan,HUANG Nan,WAN Guojiang. Long-term in Vitro Corrosion Behavior of Zinc in Ringer’s Solution [J]. Journal of Inorganic Materials, 2020, 35(4): 461-468. |

| [10] | FAN Jia-Feng,ZHANG Xiao-Feng,ZHOU Ke-Song,LIU Min,DENG Chang-Guang,DENG Chun-Ming,NIU Shao-Peng,DENG Zi-Qian. Influence of Al-modification on CMAS Corrosion Resistance of PS-PVD 7YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2019, 34(9): 938-946. |

| [11] | TONG Wei, XIONG Dang-Sheng. Bioinspired Superhydrophobic Materials: Progress and Functional Application [J]. Journal of Inorganic Materials, 2019, 34(11): 1133-1144. |

| [12] | SI Xiao-Yang, CHEN Fan-Yan, DENG Qi-Huang, DU Shi-Yu, HUANG Qing. Preparation and Property of MXene/Copper Alloy Composites [J]. Journal of Inorganic Materials, 2018, 33(6): 603-608. |

| [13] | XIA Wei, WANG Tao, SONG Li, GONG Hao, GUO Hu, FAN Xiao-Li, GAO Bin, ZHAO Jun, HE Jian-Ping. Graphene/Epoxy Composite Coating Damage under γ-ray Irradiation and Corrosion Protection [J]. Journal of Inorganic Materials, 2018, 33(1): 35-40. |

| [14] | YANG Tao, WANG Hai-Bin, SONG Xiao-Yan, LIU Xue-Mei, HOU Chao, WANG Xue-Zheng. Corrosion Resistance of HVOF-sprayed Nano- and Micon-structured WC-η Coatings against Molten Zinc [J]. Journal of Inorganic Materials, 2017, 32(8): 806-812. |

| [15] | WANG Xue-Zheng, WANG Hai-Bin, LIU Xue-Mei, YANG Tao, SONG Xiao-Yan. Grain Growth Inhibitor on the WC-Co Cemented Carbide Coating [J]. Journal of Inorganic Materials, 2017, 32(8): 813-818. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||