Journal of Inorganic Materials ›› 2015, Vol. 30 ›› Issue (9): 906-912.DOI: 10.15541/jim20150051

• Orginal Article • Previous Articles Next Articles

HE Shao-Yang1, 2, ZENG Jian-Bang1, JIANG Fang-Ming1

Received:2015-01-26

Revised:2015-04-15

Published:2015-09-20

Online:2015-08-19

About author:HE Shao-Yang. E-mail: hesy@ms.giec.ac.cn

Supported by:CLC Number:

HE Shao-Yang, ZENG Jian-Bang, JIANG Fang-Ming. Numerical Reconstruction and Characterization Analysis of Microstructure of Lithium-ion Battery Graphite Anode[J]. Journal of Inorganic Materials, 2015, 30(9): 906-912.

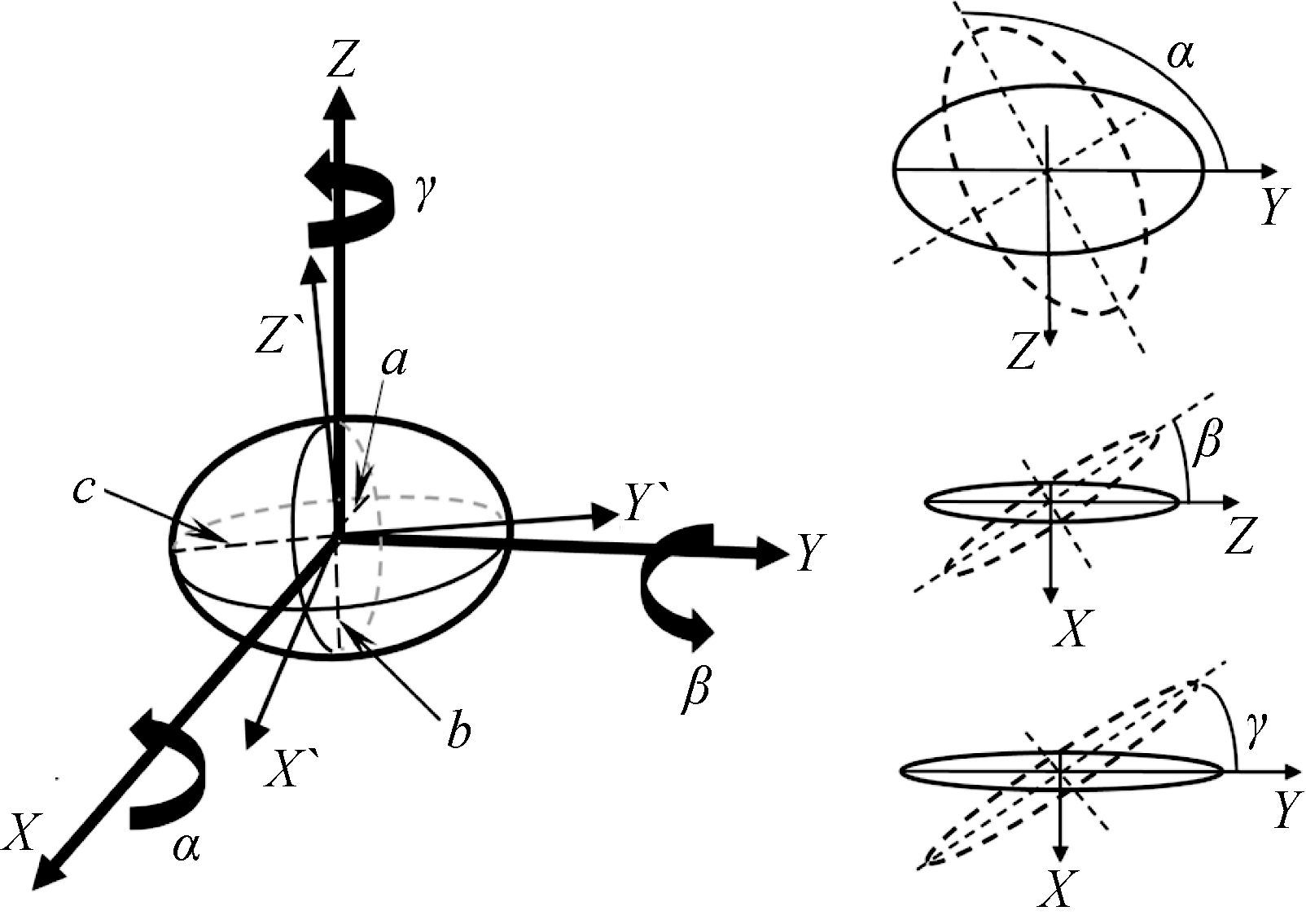

Fig. 2 Ellipsoid particle The a, b and c are the three semi axial lengths of ellipsoid. The α, β and γ are the three rotation angles for the X’-Y’-Z’ coordinates relative to the X-Y-Z coordinates

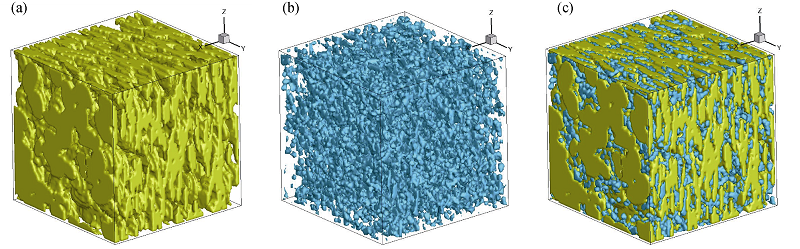

Fig. 3 3D microstructure of reconstructed graphite anode (a) Spatial distribution of graphite; (b) Spatial distribution of solid additive; (c) Spatial distribution and topological relation of graphite anode microstructureconsisting of 3 components. Yellow denotes graphite, blue solid additive and transparent pore or electrolyte

| Particle size (2a/ 2b/ 2c) /μm | Average pore diameter /μm | Specific surface area /m-1 | Connectivity /% | |

|---|---|---|---|---|

| Solid | Pore | |||

| 4/8/16 | 3.88 | 539430 | 99.62 | 98.68 |

| 4/8/24 | 3.98 | 479619 | 99.73 | 98.42 |

| 4/16/24 | 4.45 | 456897 | 99.60 | 98.00 |

| 4/16/32 | 4.80 | 437198 | 99.04 | 98.35 |

| 4/24/32 | 4.87 | 418739 | 99.62 | 97.66 |

| 2/16/24 | 3.26 | 563154 | 99.86 | 95.86 |

Table 1 Effects of particle size on microstructural characteristics of the reconstructed anode

| Particle size (2a/ 2b/ 2c) /μm | Average pore diameter /μm | Specific surface area /m-1 | Connectivity /% | |

|---|---|---|---|---|

| Solid | Pore | |||

| 4/8/16 | 3.88 | 539430 | 99.62 | 98.68 |

| 4/8/24 | 3.98 | 479619 | 99.73 | 98.42 |

| 4/16/24 | 4.45 | 456897 | 99.60 | 98.00 |

| 4/16/32 | 4.80 | 437198 | 99.04 | 98.35 |

| 4/24/32 | 4.87 | 418739 | 99.62 | 97.66 |

| 2/16/24 | 3.26 | 563154 | 99.86 | 95.86 |

| [1] | WEN J W, YU Y, CHEN C H.A review on lithium-ion batteries safety issues: existing problems and possible solutions.Mater. Express, 2012, 2(3): 197-212. |

| [2] | LI Z, HUANG J, LIAW BY, METZLER V, et al.A review of lithium deposition in lithium-ion and lithium metal secondary batteries.J. Power Sources, 2014, 254: 168-182. |

| [3] | YANG L J, CHENG X Q, GAO Y Z, et al.Lithium compound deposition on mesocarbon microbead anode of lithium ion batteries after long-term cycling.ACS Appl. Mater. Interfaces, 2014, 6(15): 12962-12970. |

| [4] | GUY D, LESTRIEZ B, BOUCHET R, et al.Improvement of lithium battery performance through composite electrode microstructure optimization.Ionics, 2004, 10(5/6): 443-449. |

| [5] | FATTAKHOVA D, KAVAN L, KRTIL P.Lithium insertion into titanium dioxide (anatase) electrodes: microstructure and electrolyte effects.J. Solid State Electrochem., 2001, 5(3): 196-204. |

| [6] | JIANG F M, ZENG J B, WU W.Design and optimization for lithium- ion battery electrode: mesoscale numerical model.Advanced Materials Industry, 2011, 12: 2-6. |

| [7] | ZENG J B, JIANG F M.A mesoscale smoothed particle hydrodynamics model for lithium-ion batteries.Acta Phys. -Chim. Sin. , 2013, 29(11): 2371-2384. |

| [8] | ZENG J B, WU W, JIANG F M.Smoothed particle hydrodynamics prediction of effective transport coefficients of lithium-ion battery electrodes.Solid State Ionics, 2014, 260(1): 76-85. |

| [9] | QUIBLIER J A.A new three-dimensional modeling technique for studying porous media.J. Colloid Interface Sci., 1984, 98(1): 84-102. |

| [10] | YEONG C L Y, TORQUATO S. Reconstructing random media.Phys. Rev., 1998, 57(1): 495-506. |

| [11] | ČAPEK P, HEJTMÁNEK V, BRABEC L, et al. 3D stochastic replicas of porous solids: a way to improve predicted diffusivity.Diffusion-Fundamentals, 2009, 91: 1-4. |

| [12] | KIM S H, PITSCH H.Reconstruction and effective transport properties of the catalyst layer in PEM fuel cells.J. Electrochem. Soc., 2009, 156(6): 673-681. |

| [13] | WU W, JIANG F M.Simulated annealing reconstruction and characterization of a LiCoO2 lithium-ion battery cathode.Chin. Sci. Bull., 2013, 58(36): 4692-4695. |

| [14] | WU W, JIANG F M.Microstructure reconstruction and characterization of PEMFC electrodes.Int. J. Hydrogen Energy, 2014, 39(28): 15894-15906. |

| [15] | SIDDIQUE N A, LIU F.Process based reconstruction and simulation of a three-dimensional fuel cell catalyst layer.Electrochimica Acta, 2010, 55(19): 5357-5366. |

| [16] | WU W, JIANG F M, CHEN Y, et al.3D monte carlo reconstruction and characterization of LiCoO2 cathode.Journal of Inorganic Materials, 2013, 28(11): 1243-1247. |

| [17] | STEPHENSON D E, HARTMAN E M, HARB J N, et al.Modeling of particle-particle interactions in porous cathodes for lithium-ion batteries.J. Electrochem. Soc., 2007, 154(12): A1146-A1155. |

| [18] | MARKERVICH E, SALITRA G, LEVI M D, et al.Capacity fading of lithiated graphite electrodes studied by a combination of electroanalytical methods, Raman spectroscopy and SEM.J. Power Sources, 2005, 146(1/2): 146-150. |

| [19] | 吴其修, 安秀梅, 刘正荣. 锂离子电池复合碳负极材料及其制备方法. 中国C01B31/02, CN 200610060814, 2006.05.19. |

| [20] | 肖峰, 孙华军. 一种锂离子二次电池的负极及包括该负极的锂离子二次电池. 中国H01M10/40, CN 200510002208, 2005. 01. 17. |

| [21] | PENG P, SUN Y Q, JIANG F M.Thermal analyses of LiCoO2 lithium-ion battery during oven tests.Heat Mass Transfer., 2014, 50(10): 1405-1416. |

| [22] | BABALIEVSKI F.Cluster counting: the Hoshen-Kopelman algorithm versus spanning tree approaches.J. Modern Phys. , 1998, 9(1): 43-60. |

| [23] | DELERUE J F, PERRIER E, YU Z Y, et al.New algorithms in 3D image analysis and their application to the measurement of a spatialized pore size distribution in soils.Phys. Chem. Earth A: Solid Earth Geodesy, 1999, 24(7): 639-644. |

| [24] | CHEOLWOONG L, BO Y, YIN L L, et al.Geometric characteristics of three dimensional reconstructed anode electrodes of lithium- ion batteries.Energies, 2014, 7(4): 2558-2572. |

| [25] | THIELE S, ZENGERLE R, ZIEGLER C.Nano-morphology of a polymer electrolyte fuel cell catalyst layer-imaging, reconstruction and analysis.Nano Res., 2011, 4(9): 849-860. |

| [1] | YANG Zhuo, LU Yong, ZHAO Qing, CHEN Jun. X-ray Diffraction Rietveld Refinement and Its Application in Cathode Materials for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2023, 38(6): 589-605. |

| [2] | ZHU Hezhen, WANG Xuanpeng, HAN Kang, YANG Chen, WAN Ruizhe, WU Liming, MAI Liqiang. Enhanced Lithium Storage Stability Mechanism of Ultra-high Nickel LiNi0.91Co0.06Al0.03O2@Ca3(PO4)2 Cathode Materials [J]. Journal of Inorganic Materials, 2022, 37(9): 1030-1036. |

| [3] | FENG Kun, ZHU Yong, ZHANG Kaiqiang, CHEN Zhang, LIU Yu, GAO Yanfeng. Boehmite Nanosheets-coated Separator with Enhanced Performance for Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(9): 1009-1015. |

| [4] | SU Nana, HAN Jingru, GUO Yinhao, WANG Chenyu, SHI Wenhua, WU Liang, HU Zhiyi, LIU Jing, LI Yu, SU Baolian. ZIF-8-derived Three-dimensional Silicon-carbon Network Composite for High-performance Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(9): 1016-1022. |

| [5] | WANG Yang, FAN Guangxin, LIU Pei, YIN Jinpei, LIU Baozhong, ZHU Linjian, LUO Chengguo. Microscopic Mechanism of K+ Doping on Performance of Lithium Manganese Cathode for Li-ion Battery [J]. Journal of Inorganic Materials, 2022, 37(9): 1023-1029. |

| [6] | CHEN Ying, LUAN Weiling, CHEN Haofeng, ZHU Xuanchen. Multi-scale Failure Behavior of Cathode in Lithium-ion Batteries Based on Stress Field [J]. Journal of Inorganic Materials, 2022, 37(8): 918-924. |

| [7] | WANG Yutong, ZHANG Feifan, XU Naicai, WANG Chunxia, CUI Lishan, HUANG Guoyong. Research Progress of LiTi2(PO4)3 Anode for Aqueous Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2022, 37(5): 481-492. |

| [8] | LI Kunru, HU Xinghui, ZHANG Zhengfu, GUO Yuzhong, HUANG Ruian. Three-dimensional Porous Biogenic Si/C Composite for High Performance Lithium-ion Battery Anode Derived from Equisetum Fluviatile [J]. Journal of Inorganic Materials, 2021, 36(9): 929-935. |

| [9] | WANG Ying, ZHANG Wenlong, XING Yanfeng, CAO suqun, DAI Xinyi, LI Jingze. Performance of Amorphous Lithium Phosphate Coated Lithium Titanate Electrodes in Extended Working Range of 0.01-3.00 V [J]. Journal of Inorganic Materials, 2021, 36(9): 999-1005. |

| [10] | WANG Yanan, LI Hua, WANG Zhengkun, LI Qingfeng, LIAN Chen, HE Xin. Progress on Failure Mechanism of Lithium Ion Battery Caused by Diffusion Induced Stress [J]. Journal of Inorganic Materials, 2020, 35(10): 1071-1087. |

| [11] | Jian-Huang KE, Kai XIE, Yu HAN, Wei-Wei SUN, Shi-Qiang LUO, Jin-Feng LIU. Morphology Controlling of the High-voltage Cathode Materials with Different Co-solvents [J]. Journal of Inorganic Materials, 2019, 34(6): 618-624. |

| [12] | GUO Rong-Nan, HAN Wei-Qiang. Effects of Structure and Properties of Polar Polymeric Binders on Lithium-ion Batteries [J]. Journal of Inorganic Materials, 2019, 34(10): 1021-1029. |

| [13] | LI Bo, HAO Wen, WEN Xiao-Gang. Semi-hollow/Solid ZnMn2O4 Microspheres: Synthesis and Performance in Li Ion Battery [J]. Journal of Inorganic Materials, 2018, 33(3): 307-312. |

| [14] | BAI Xue-Jun, LIU Chan, HOU Min, WANG Biao, CAO Hui, FU Jun-Jie. Silicon/CNTs/Graphene Free-standing Anode Material for Lithium-ion Battery [J]. Journal of Inorganic Materials, 2017, 32(7): 705-712. |

| [15] | ZHAI Li-Li, ZHANG Jiang, LI Xuan-Ke, CONG Ye, DONG Zhi-Jun, YUAN Guan-Ming. F127 Template on Pore Structure and Electrochemical Performances of Mesoporous SnO2 [J]. Journal of Inorganic Materials, 2016, 31(6): 588-596. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||