Journal of Inorganic Materials ›› 2015, Vol. 30 ›› Issue (6): 581-587.DOI: 10.15541/jim20140621

• Orginal Article • Previous Articles Next Articles

LIU Jing1, 2, LIU Jun1, LI Jiang2, LIN Li1, 2, PAN Yu-Bai2, CHENG Xiao-Nong1, GUO Jing-Kun2

Received:2014-12-01

Revised:2015-02-13

Published:2015-06-04

Online:2015-05-22

About author:LIU Jing. E-mail: liujing53302@163.com

Supported by:CLC Number:

LIU Jing, LIU Jun, LI Jiang, LIN Li, PAN Yu-Bai, CHENG Xiao-Nong, GUO Jing-Kun. Influence of Ball Milling Speed on Microstructure and Optical Transparency of Nd:YAG Ceramics[J]. Journal of Inorganic Materials, 2015, 30(6): 581-587.

| Ball milling speed/(r·min-1) | 70 | 90 | 110 | 130 | 150 | 170 |

|---|---|---|---|---|---|---|

| SBET /(m2·g-1) | 5.833 | 6.275 | 6.985 | 7.295 | 7.370 | 7.412 |

Table 1 Specific surface areas (SBET) of powder mixtures ball milled at different speeds for 10 h

| Ball milling speed/(r·min-1) | 70 | 90 | 110 | 130 | 150 | 170 |

|---|---|---|---|---|---|---|

| SBET /(m2·g-1) | 5.833 | 6.275 | 6.985 | 7.295 | 7.370 | 7.412 |

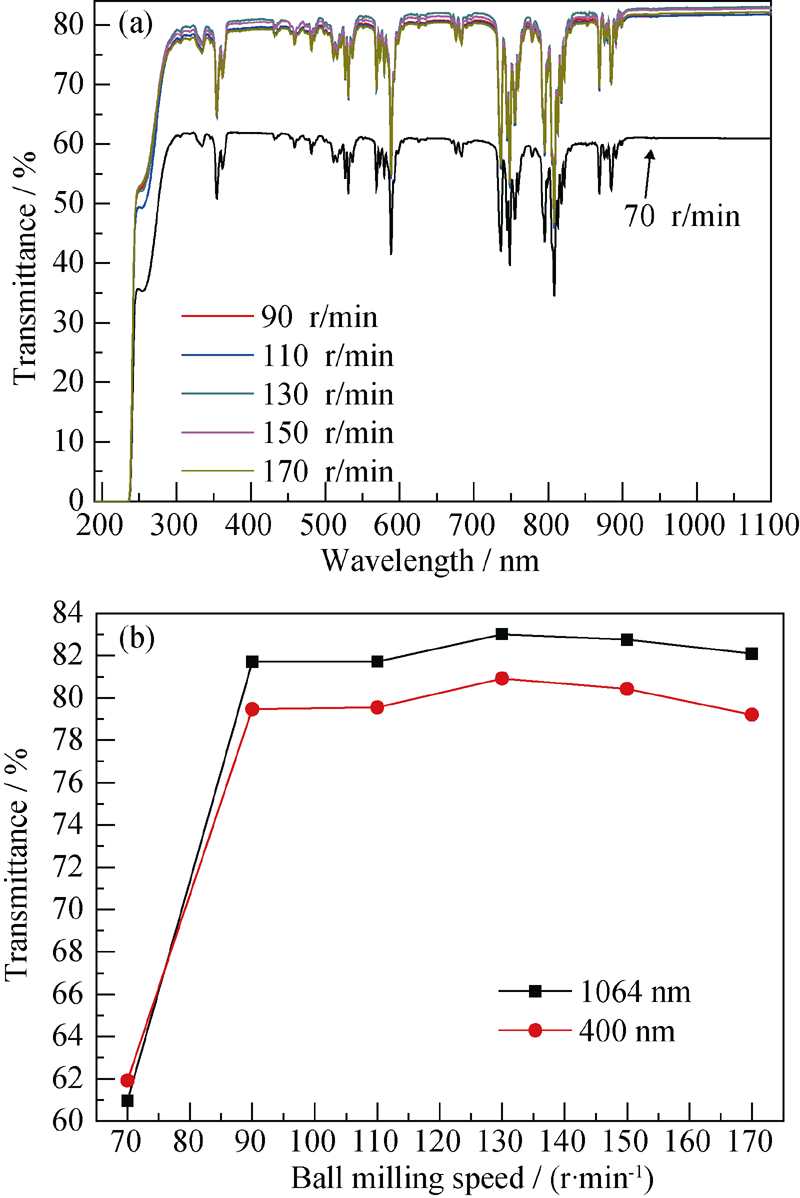

Fig. 4 In-line transmittances of Nd:YAG ceramics sintered at 1760℃ for 50 h from powder mixtures ball milled at different speeds (a) 190-1100 nm; (b) 1064 and 400 nm

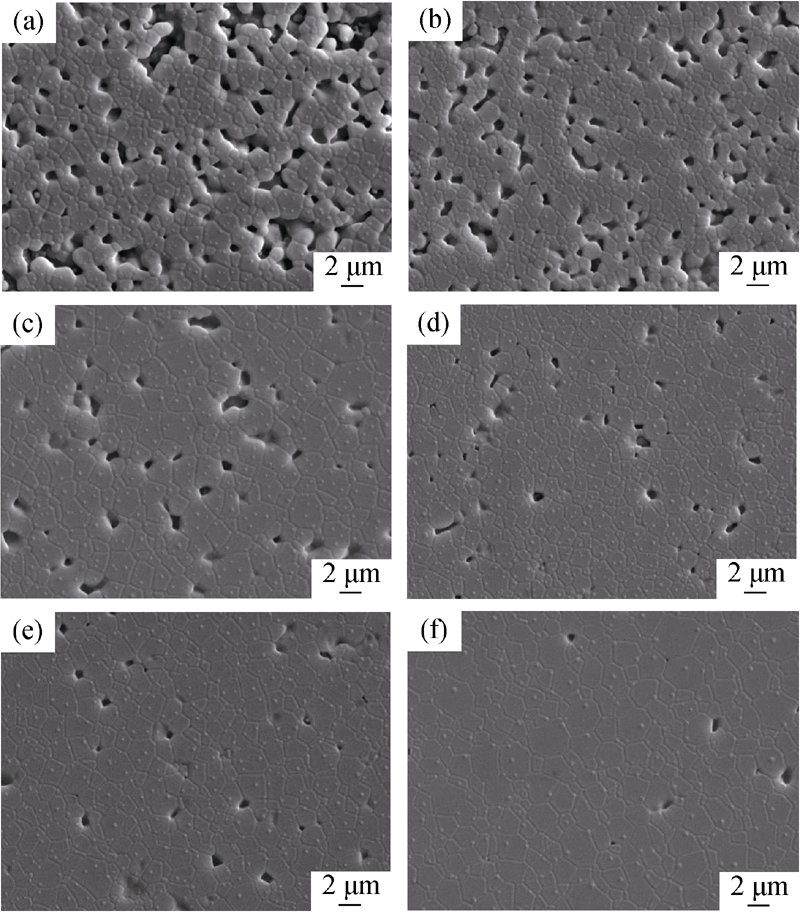

Fig. 7 SEM micrographs of ceramics sintered at 1600℃ for 2 h from powder mixtures ball milled at different speeds for 10 h (a) 70 r/min; (b) 90 r/min; (c) 110 r/min; (d) 130 r/min; (e) 150 r/min; (f) 170 r/min

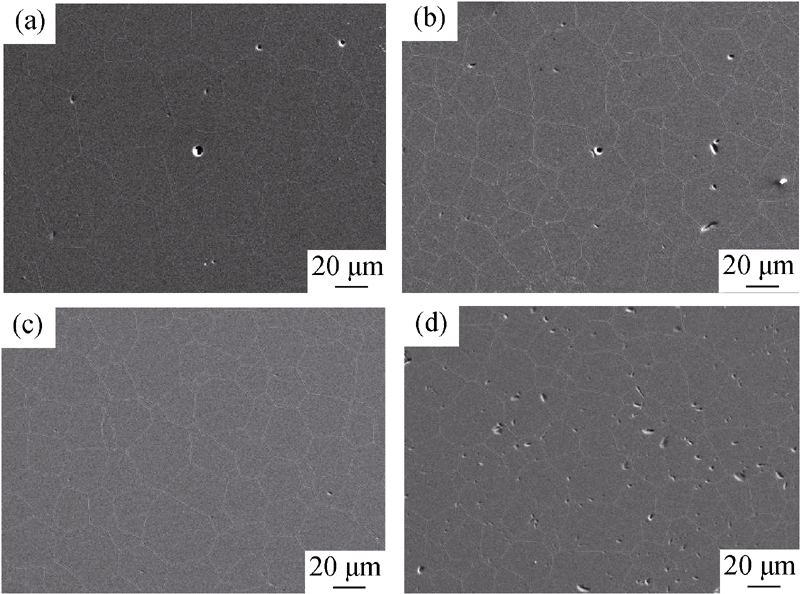

Fig. 10 EPMA micrographs of ceramics sintered at 1760℃ for 50 h from powder mixtures ball milled at different speeds (a) 70 r/min; (b) 90 r/min; (c) 130 r/min; (d) 170 r/min

| [1] | IKESUE A, AUNG Y L, TAIRA T, et al.Progress in ceramic lasers.Annu. Rev. Mater. Res., 2006, 36: 397-429. |

| [2] | IKESUE A, AUNG Y L.Ceramic laser materials.Nat. Photonics, 2008, 2(12): 721-727. |

| [3] | LI J, PAN Y B, ZENG Y P, et al.The history, development, and future prospects for laser ceramics: a review.Int. J. Refract. Met. Hard Mater., 2013, 39: 44-52. |

| [4] | YAGI H, YANAGITANI T, TAKAICHI K, et al.Characterizations and laser performances of highly transparent Nd3+: Y3Al5O12 laser ceramics.Opt. Mater., 2007, 29(10): 1258-1262. |

| [5] | IKESUE A, FURUSATO I, KAMATA K.Fabrication of polycrystalline, transparent YAG ceramics by a solid-state reaction method.J. Am. Ceram. Soc., 1995, 78(1): 225-228. |

| [6] | LU J R, UEDA K, YAGI H, et al.Neodymium doped yttrium aluminum garnet(Y3Al5O12)nano-crystalline ceramics—a new generation of solid state laser and optical materials.J. Alloys Compd., 2002, 341(1-2): 220-225. |

| [7] | BOULON G.Fifty years of advances in solid-state laser materials.Opt. Mater., 2012, 34(3): 499-512. |

| [8] | LI X D, LI J G, XIU Z M, et al.Transparent Nd: YAG ceramics fabricated using nanosized γ-alumina and yttria powders.J. Am. Ceram. Soc., 2009, 92(1): 241-244. |

| [9] | TANG F, CAO Y G, HUANG J Q, et al.Fabrication and laser behavior of composite Yb:YAG ceramic.J. Am. Ceram. Soc., 2012, 95(1): 56-59. |

| [10] | ZHANG W, LU T, MA B, et al.Improvement of optical properties of Nd: YAG transparent ceramics by post-annealing and post hot isostatic pressing.Opt. Mater., 2013, 35(12): 2405-2410. |

| [11] | CHEN J C, LI J, XU J L, et al.4350 W quasi-continuous-wave operation of a diode face-pumped ceramic Nd: YAG slab laser.Opt. Laser Technol., 2014, 63: 50-53. |

| [12] | LEE S H, KOCHAWATTANA S, MESSING G L, et al.Solid-state reactive sintering of transparent polycrystalline Nd: YAG.J. Am. Ceram. Soc., 2006, 89(6): 1945-1950. |

| [13] | LI J, WU Y S, PAN Y B, et al.Fabrication, microstructure and properties of highly transparent Nd:YAG laser ceramics.Opt. Mater., 2008, 31(1): 6-17. |

| [14] | SERANONI M, PIANCASTELLI A, COSTA A L, et al.Improvements in the production of Yb:YAG transparent ceramic materials: spray drying optimization. Opt. Mater., 2012, 34(6): 995-1001. |

| [15] | LIU W B, ZHANG W X, LI J, et al.Synthesis of Nd: YAG powders leading to transparent ceramics: the effect of MgO dopant.J. Eur. Ceram. Soc., 2011, 31(4): 653-657. |

| [16] | LI J, CHEN F, LIU W B, et al.Co-precipitation synthesis route to yttrium aluminum garnet (YAG) transparent ceramics.J. Eur. Ceram. Soc., 2012, 32(11): 2971-2979. |

| [17] | LV Y H, ZHANG W, LIU H, et al.Synthesis of nano-sized and highly sinterable Nd: YAG powders by the urea homogeneous precipitation method.Powder Technol., 2012, 217: 140-147. |

| [18] | CHEN X T, LU T C, WEI N, et al.Effect of ball-milling granulation with PVB adhesive on the sinterability of co-precipitated Yb: YAG nanopowders.J. Alloys Compd., 2014, 589: 448-454. |

| [19] | LI J, LIU W B, JIANG B X, et al.Synthesis of nanocrystalline yttria powder and fabrication of Cr, Nd:YAG transparent ceramics.J. Alloys Compd., 2012, 515: 49-56. |

| [20] | LIU B L, LI J, IVANOV M, et al.Solid-state reactive sintering of Nd:YAG transparent ceramics: the effect of Y2O3 powders pretreatment.Opt. Mater., 2014, 36(9): 1591-1597. |

| [21] | LI J, LIU J, LIU B L, et al.Influence of heat treatment of powder mixture on the microstructure and optical transmission of Nd:YAG transparent ceramics.J. Eur. Ceram. Soc., 2014, 34(10): 2497-2507. |

| [22] | EPICIER T, BOULON G, ZHAO W, et al.Spatial distribution of the Yb3+ rare earth ions in Y3Al5O12 and Y2O3 optical ceramics as analyzed by TEM.J. Mater. Chem., 2012, 22: 18221-18229. |

| [23] | STEVENSON A J, KUPP E R, MESSING G L.Low temperature, transient liquid phase sintering of B2O3-SiO2-doped Nd:YAG transparent ceramics.J. Mater. Res., 2011, 26(09): 1151-1158. |

| [24] | YANG H, QIN X P, ZHANG J, et al.Fabrication of Nd:YAG transparent ceramics with both TEOS and MgO additives.J. Alloys Compd., 2011, 509(17): 5274-5279. |

| [25] | GUO W, CAO Y G, HUANG Q F, et al.Fabrication and laser behaviors of Nd:YAG ceramic microchips. J. Eur. Ceram. Soc., 2011, 31(13): 2241-2246. |

| [26] | BA X W, LI J, ZENG Y P, et al.Transparent Y3Al5O12 ceramics produced by an aqueous tape casting method.Ceram. Int., 2013, 39(4): 4639-4643. |

| [27] | GE L, LI J, ZHOU Z W, et al.Fabrication of composite YAG/Nd: YAG/YAG transparent ceramic for planar waveguide laser.Opt. Mater. Express, 2014, 4(5): 1042-1049. |

| [28] | FU Y L, LI J, LIU Y, et al.Effect of air annealing on the optical properties and laser behavior of Nd:YAG transparent ceramics.Opt. Mater. Express, 2014, 4(10): 2108-2115. |

| [29] | LIU J, LIN L, LI J, et al.Effects of ball milling time on microstructure evolution and optical transparency of Nd:YAG ceramics.Ceram. Int., 2014, 40: 9841-9851. |

| [30] | STEVENSON A J, LI X, MARTINEZ M A, et al.Effect of SiO2 on densification and microstructure development in Nd:YAG transparent ceramics.J. Am. Ceram. Soc., 2011, 94(5): 1380-1387. |

| [31] | BOULESTEIX R, MAîTRE A, BAUMARD J F, et al. The Effect of silica doping on neodymium diffusion in yttrium aluminum garnet ceramics: implications for sintering mechanisms.J. Eur. Ceram. Soc., 2009, 29(12): 2517-2526. |

| [32] | KOCHAWATTANA S, STEVENSON A, LEE S H, et al.Sintering and grain growth in SiO2 doped Nd:YAG.J. Eur. Ceram. Soc., 2008, 28(7): 1527-1534. |

| [1] | HE Danqi, WEI Mingxu, LIU Ruizhi, TANG Zhixin, ZHAI Pengcheng, ZHAO Wenyu. Heavy-Fermion YbAl3 Materials: One-step Synthesis and Enhanced Thermoelectric Performance [J]. Journal of Inorganic Materials, 2023, 38(5): 577-582. |

| [2] | WU Shuang, GOU Yanzi, WANG Yongshou, SONG Quzhi, ZHANG Qingyu, WANG Yingde. Effect of Heat Treatment on Composition, Microstructure and Mechanical Property of Domestic KD-SA SiC Fibers [J]. Journal of Inorganic Materials, 2023, 38(5): 569-576. |

| [3] | ZHANG Ye, ZENG Yuping. Progress of Porous Silicon Nitride Ceramics Prepared via Self-propagating High Temperature Synthesis [J]. Journal of Inorganic Materials, 2022, 37(8): 853-864. |

| [4] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [5] | HONG Du, NIU Yaran, LI Hong, ZHONG Xin, ZHENG Xuebin. Tribological Properties of Plasma Sprayed TiC-Graphite Composite Coatings [J]. Journal of Inorganic Materials, 2022, 37(6): 643-650. |

| [6] | XU Puhao, ZHANG Xiangzhao, LIU Guiwu, ZHANG Mingfen, GUI Xinyi, QIAO Guanjun. Microstructure and Mechanical Properties of SiC Joint Brazed by Al-Ti Alloys as Filler Metal [J]. Journal of Inorganic Materials, 2022, 37(6): 683-690. |

| [7] | HUANG Longzhi, YIN Jie, CHEN Xiao, WANG Xinguang, LIU Xuejian, HUANG Zhengren. Selective Laser Sintering of SiC Green Body with Low Binder Content [J]. Journal of Inorganic Materials, 2022, 37(3): 347-352. |

| [8] | WU Xishi, ZHU Yunzhou, HUANG Qing, HUANG Zhengren. Effect of Pore Structure of Organic Resin-based Porous Carbon on Joining Properties of Cf/SiC Composites [J]. Journal of Inorganic Materials, 2022, 37(12): 1275-1280. |

| [9] | SUN Luchao, ZHOU Cui, DU Tiefeng, WU Zhen, LEI Yiming, LI Jialin, SU Haijun, WANG Jingyang. Directionally Solidified Al2O3/Er3Al5O12 and Al2O3/Yb3Al5O12 Eutectic Ceramics Prepared by Optical Floating Zone Melting [J]. Journal of Inorganic Materials, 2021, 36(6): 652-658. |

| [10] | HUANG Xinyou, LIU Yumin, LIU Yang, LI Xiaoying, FENG Yagang, CHEN Xiaopu, CHEN Penghui, LIU Xin, XIE Tengfei, LI Jiang. Fabrication and Characterizations of Yb:YAG Transparent Ceramics Using Alcohol-water Co-precipitation Method [J]. Journal of Inorganic Materials, 2021, 36(2): 217-224. |

| [11] | ZHANG Junmin, CHEN Xiaowu, LIAO Chunjin, GUO Feiyu, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Optimizing Microstructure and Properties of SiCf/SiC Composites Prepared by Reactive Melt Infiltration [J]. Journal of Inorganic Materials, 2021, 36(10): 1103-1110. |

| [12] | ZHU Danyang, QIAN Kang, CHEN Xiaopu, HU Zewang, LIU Xin, LI Xiaoying, PAN Yubai, MIHÓKOVÁ Eva, NIKL Martin, LI Jiang. Fine-grained Ce,Y:SrHfO3 Scintillation Ceramics Fabricated by Hot Isostatic Pressing [J]. Journal of Inorganic Materials, 2021, 36(10): 1118-1124. |

| [13] | CHEN Lei,WANG Kai,SU Wentao,ZHANG Wen,XU Chenguang,WANG Yujin,ZHOU Yu. Research Progress of Transition Metal Non-oxide High-entropy Ceramics [J]. Journal of Inorganic Materials, 2020, 35(7): 748-758. |

| [14] | WU Xiaojun,YANG Jie,ZHENG Rui,ZHANG Zhaofu,YANG Yi. Effect of Ablation Surface Microstructure on Plasma Arc Ablation Properties of C/C Throat Insert Fabricated via CVI+HPIC Methods [J]. Journal of Inorganic Materials, 2020, 35(6): 654-660. |

| [15] | DONG Lijia, GUO Xiaojie, LI Xue, CHEN Chaogui, JIN Yang, AHMED Alsaedi, TASAWAR Hayat, ZHAO Qingzhou, SHENG Guodong. Microscopic Insights into pH-dependent Adsorption of Cd(II) on Molybdenum Disulfide Nanosheets [J]. Journal of Inorganic Materials, 2020, 35(3): 293-300. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||