Journal of Inorganic Materials ›› 2014, Vol. 29 ›› Issue (12): 1339-1344.DOI: 10.15541/jim20140410

• Orginal Article • Previous Articles

BAI Ming-Min1, LI Wei-Xin1,2, LI Yan-Hui1, ZHAO Wei1, RAO Ping-Gen1

Received:2014-08-12

Published:2014-09-28

Online:2014-11-20

About author:BAI Ming-Min(1986-), female, candidate of PhD. E-mail: 75403890@qq.com

Supported by:CLC Number:

BAI Ming-Min, LI Wei-Xin, LI Yan-Hui, ZHAO Wei, RAO Ping-Gen. Preparation and Properties of Hot-pressed Al2O3/Al-steel Mesh-Al Laminated Composites[J]. Journal of Inorganic Materials, 2014, 29(12): 1339-1344.

| Samples | Thickness/µm | Diameter of steel wire/µm | Tensile strength/MPa | Melting temperature/℃ |

|---|---|---|---|---|

| 60# steel mesh | 222 | 146 | 78.8±4.2 | 1500-1600 |

| 200#steel mesh | 122 | 85 | 116.2±9.2 | |

| 400#steel mesh | 103 | 59 | 107.0±4.1 | |

| Al foil | 100 | - | 59.7±5.5 | 660 |

Table 1 Properties of steel meshes and Al foil

| Samples | Thickness/µm | Diameter of steel wire/µm | Tensile strength/MPa | Melting temperature/℃ |

|---|---|---|---|---|

| 60# steel mesh | 222 | 146 | 78.8±4.2 | 1500-1600 |

| 200#steel mesh | 122 | 85 | 116.2±9.2 | |

| 400#steel mesh | 103 | 59 | 107.0±4.1 | |

| Al foil | 100 | - | 59.7±5.5 | 660 |

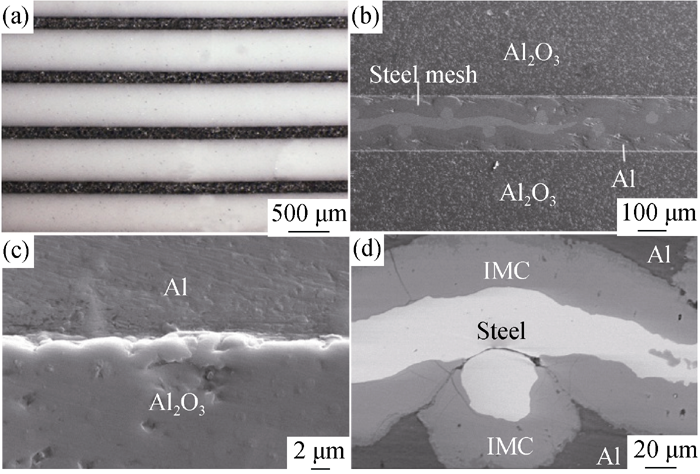

Fig. 2 Optical micrograph and SEM images of the laminated composites (a) Optical micrograph image; (b) Mesoscale image; (c) Interface of Al2O3/Al; (d) Interface of Al/steel

| Samples | Bending strength σ/MPa | Fracture toughness KIc/(MPa·m1/2) | Work-of-fracture γ/(J·m-2) | Bond strength BS/MPa |

|---|---|---|---|---|

| Al2O3 | 300±24 | - | 13±3 | - |

| A/Al-60-Al | 241.3±6.6 | 14.1±1.1 | 3066.5±395.5 | 22.3±1.9 |

| A/Al-200-Al | 254.2±10.7 | 15.5±1.4 | 3844.4±406.2 | 43.9±1.5 |

| A/Al-400-Al | 255.4±9.1 | 12.8±1.3 | 2959.2±224.3 | 22.9±1.2 |

Table 2 Mechanical properties of laminated composites

| Samples | Bending strength σ/MPa | Fracture toughness KIc/(MPa·m1/2) | Work-of-fracture γ/(J·m-2) | Bond strength BS/MPa |

|---|---|---|---|---|

| Al2O3 | 300±24 | - | 13±3 | - |

| A/Al-60-Al | 241.3±6.6 | 14.1±1.1 | 3066.5±395.5 | 22.3±1.9 |

| A/Al-200-Al | 254.2±10.7 | 15.5±1.4 | 3844.4±406.2 | 43.9±1.5 |

| A/Al-400-Al | 255.4±9.1 | 12.8±1.3 | 2959.2±224.3 | 22.9±1.2 |

| Samples | Impact energy/J | Peak load, Pi/kN | Time to peak load, Ti /ms | Deflection at peak load, Di/mm | Absorbed energy at peak load, Ei/J | Absorbed energy, E/J | Damage situation |

|---|---|---|---|---|---|---|---|

| A/Al-60-Al | 15 | 6.23 | 0.22 | 0.44 | 1.41 | 13.5 | Penetrated |

| A/Al-200-Al | 15 | 6.47 | 1.77 | 2.58 | 12.20 | 15.0 | Not penetrated |

| A/Al-400-Al | 15 | 7.07 | 0.31 | 0.62 | 1.88 | 15.0 | Not penetrated |

Table 3 Impact parameters for impacted specimens

| Samples | Impact energy/J | Peak load, Pi/kN | Time to peak load, Ti /ms | Deflection at peak load, Di/mm | Absorbed energy at peak load, Ei/J | Absorbed energy, E/J | Damage situation |

|---|---|---|---|---|---|---|---|

| A/Al-60-Al | 15 | 6.23 | 0.22 | 0.44 | 1.41 | 13.5 | Penetrated |

| A/Al-200-Al | 15 | 6.47 | 1.77 | 2.58 | 12.20 | 15.0 | Not penetrated |

| A/Al-400-Al | 15 | 7.07 | 0.31 | 0.62 | 1.88 | 15.0 | Not penetrated |

| [1] | LAUNEY M E, MUNCH E, ALSEM D H, et al.A novel biomimetic approach to the design of high-performance ceramic-metal composites. Journal of the Royal Society Interface, 2010, 7(46): 741-753. |

| [2] | CAO H C, EVANS AG.On crack extension in ductile/brittle laminates. Acta Metallurgica et Materialia, 1991, 39(12): 2997-3005. |

| [3] | CHEN Z, MECHOLSKY J.Control of strength and toughness of ceramic/metal laminates using interface design. Journal of Materials Research, 1993, 8(9): 2362-2369. |

| [4] | HEATHCOTE J, ODETTE G, LUCAS G, et al.On the microm-echanics of low temperature strength and toughness of intermet-allic/metallic microlaminate composites. Acta Materialia, 1996, 44(11): 4289-4299. |

| [5] | MCNANEY J, CANNON R, RITCHIE R.Fracture and fatigue- crack growth along aluminum-alumina interfaces. Acta Materialia, 1996, 44(12): 4713-4728. |

| [6] | LOURDIN P, JUVÉ D, TRÉHEUX D. Nickel-alumina bonds: mechanical properties related to interfacial chemistry. Journal of the European Ceramic Society, 1996, 16(7): 745-752. |

| [7] | MARKAKI A, CLYNE T.Energy absorption during failure of layered metal foam/ceramic laminates. Materials Science and Engineering: A, 2002, 323(1/2): 260-269. |

| [8] | ZUO K H, JIANG D L, LIN Q L.Mechanical properties of Al2O3/Ni laminated composites. Materials Letters, 2006, 60(9/10): 1265-1268. |

| [9] | ZUO K H, JIANG D L, LIN Q L, et al.Improving the mechanical properties of Al2O3/Ni laminated composites by adding Ni particles in Al2O3 layers. Materials Science and Engineering: A, 2007, 443(1/2): 296-300. |

| [10] | ZUO S, WEI Y.Microstructure observation and mechanical beh-avior modeling for limnetic nacre. Acta Mechanica Sinica, 2008, 24(1): 83-89. |

| [11] | MEKKY W, NICHOLSON P S.R-curve modeling for Ni/Al2O3 laminates. Composites Part B: Engineering, 2007, 38(1): 35-43. |

| [12] | GUEDES A, PINTO A, VIEIRA M, et al.Multilayered interface in Ti/Macor machinable glass-ceramic joints. Materials Science and Engineering: A, 2001, 301(2): 118-124. |

| [13] | FERRARI B, SÁNCHEZ-HERENCIA A J, MORENO R. Nickel- alumina graded coatings obtained by dipping and EPD on nickel substrates. Journal of the European Ceramic Society, 2006, 26(12): 2205-2212. |

| [14] | MEKKY W, NICHOLSON P S.The fracture toughness of Ni/Al2O3 laminates by digital image correlation II: Bridging- stresses and R-curve models. Engineering Fracture Mechanics, 2006, 73(5): 583-592. |

| [15] | HWU K, DERBY B.Fracture of metal/ceramic laminates—I. Transition from single to multiple cracking. Acta Materialia, 1999, 47(2): 529-543. |

| [16] | HWU K, DERBY B.Fracture of metal/ceramic laminates—II. Crack growth resistance and toughness. Acta Materialia, 1999, 47(2): 545-563. |

| [17] | PATERAS S, HOWARD S, CLYNE T. The contribution of bridging ligament rupture to energy absorption during fracture of metal-ceramic laminates. Key Engineering Materials, 1996, 127-131: 1127-1136. |

| [18] | MARKAKI A, CLYNE T.Characterisation of imapct response of metallic foam/ceramic laminates. Materials Science and Techn-ology, 2000, 16(7/8): 785-791. |

| [19] | MARKAKI A, CLYNE T.The effect of cell wall microstructure on the deformation and fracture of aluminium-based foams. Acta Mater, 2001, 49(9): 1677-1686. |

| [20] | LI WX, BAI MM, LU Y, et al.Preparation and properties of Al2O3/Steel-epoxy laminated composites. Journal of Inorganic Materials, 2013, 28(4): 453-458. |

| [21] | HUANG K M, LI W X, XIE B H, et al.Preparation and mecha-nical properties of Al2O3/Al laminated ceramic matrix composites. Journal of Wuhan University of Technology-Mater. Sci. Ed., 2011, 26(5): 891-896. |

| [22] | AGUDO L, EYIDI D, SCHMARANZER C H, et al.Intermetallic FexAly-phases in a steel/Al-alloy fusion weld. Journal of Materials Science, 2007, 42(9): 4205-4214. |

| [23] | BOUAYAD A, GEROMETTA C, BELKEBIR A, et al.Kinetic interactions between solid iron and molten aluminium. Materials Science and Engineering: A, 2003, 363(1/2): 53-61. |

| [24] | BOUCHE K, BARBIER F, COULET A.Intermetallic compound layer growth between solid iron and molten aluminium. Materials Science and Engineering: A, 1998, 249(1/2): 167-175. |

| [25] | BERMEJO R, BAUDIN C, MORENO R, et al.Processing optimi-zation and fracture behavior of layered ceramic composites with highly compressive layers. Composites Science and Technology, 2007, 67(9): 1930-1938. |

| [26] | BERMEJO R, BAUDIN C, SANCHEZ-HERNCIA A J, et al. Residual stresses, strength and toughness of laminates with diffe-rent layer thickness ratios. Acta Materialia, 2006, 54(18): 4547-4575. |

| [27] | HUANG Y, ZHANG H.The role of metal plasticity and interfacial strength in the cracking of metal/ceramic laminates. Acta Metal-lurgica et Materialia, 1995, 43(4): 1523-1530. |

| [1] | LIU Wenlong, ZHAO Jin, LIU Juan, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Microwave Drying of Spontaneous-Coagulation-Cast Wet Alumina Green Body [J]. Journal of Inorganic Materials, 2023, 38(4): 461-468. |

| [2] | WANG Shiwei. Progress of Spontaneous Coagulation Casting of Ceramic Slurries Based on Hydrophobic Interaction [J]. Journal of Inorganic Materials, 2022, 37(8): 809-820. |

| [3] | XIA Qian, SUN Shihao, ZHAO Yiliang, ZHANG Cuiping, RU Hongqiang, WANG Wei, YUE Xinyan. Effect of Boron Carbide Particle Size Distribution on the Microstructure and Properties of Reaction Bonded Boron Carbide Ceramic Composites by Silicon Infiltration [J]. Journal of Inorganic Materials, 2022, 37(6): 636-642. |

| [4] | WANG Xingang, YANG Qingqing, LIN Genlian, GAO Wei, QIN Fulin, LI Rongzhen, KANG Zhuang, WANG Xiaofei, JIANG Danyu, YAN Jina. High Temperature Tensile Property of Domestic 550-grade Continuous Alumina Ceramic Fiber [J]. Journal of Inorganic Materials, 2022, 37(6): 629-635. |

| [5] | ZHOU Ganghuai, LIU Yao, SHI Yuan, LIU Shaojun. Slurry Preparation and Stereolithography for Activated Alumina Catalyst Carrier [J]. Journal of Inorganic Materials, 2022, 37(3): 297-302. |

| [6] | ZENG Yong, ZHANG Zijia, SUN Lijun, YAO Haihua, CHEN Jiming. Atmosphere Debinding Heat Treatment of 3D Printed Alumina Ceramics [J]. Journal of Inorganic Materials, 2022, 37(3): 333-337. |

| [7] | WEI Hailang, CAO Xueqiang, DENG Longhui, JIANG Jianing. Thermodynamic Properties and Thermal Cycling Lifetimes of LaMeAl11O19/YSZ Thermal Barrier Coatings [J]. Journal of Inorganic Materials, 2022, 37(12): 1259-1266. |

| [8] | HAO Hongjian, LI Haiyan, WAN Detian, BAO Yiwang, LI Yueming. Enhanced Flexural Strength and Thermal Shock Resistance of Alumina Ceramics by Mullite/Alumina Pre-stressed Coating [J]. Journal of Inorganic Materials, 2022, 37(12): 1295-1301. |

| [9] | PENG Fei, JIANG Yonggang, FENG Jian, CAI Huafei, FENG Junzong, LI Liangjun. Research Progress on Alumina Aerogel Composites for High-temperature Thermal Insulation [J]. Journal of Inorganic Materials, 2021, 36(7): 673-684. |

| [10] | LIANG Hanqin, YIN Jinwei, ZUO Kaihui, XIA Yongfeng, YAO Dongxu, ZENG Yuping. Mechanical and Dielectric Properties of Hot-pressed Si3N4 Ceramics with BaTiO3 Addition [J]. Journal of Inorganic Materials, 2021, 36(5): 535-540. |

| [11] | LI Longbin, XUE Yudong, HU Jianbao, YANG Jinshan, ZHANG Xiangyu, DONG Shaoming. Influence of SiC Nanowires on the Damage Evolution of SiCf/SiC Composites [J]. Journal of Inorganic Materials, 2021, 36(10): 1111-1117. |

| [12] | FENG Mingxing, WANG Bin, XU Pengyu, TU Bingtian, WANG Hao. Predicting Thermomechanical Properties of MgAl2O4 Transparent Ceramic Based on Bond Valence Models [J]. Journal of Inorganic Materials, 2021, 36(10): 1067-1073. |

| [13] | ZHANG Xiao-Yang, PENG Hai-Bo, LIU Feng-Fei, ZHAO Yan, SUN Meng-Li, GUAN Ming, ZHANG Bing-Tao, DU Xin, YUAN Wei, WANG Tie-Shan. Mechanical Properties of Borosilicate Glass with Different Irradiation of Heavy Ions [J]. Journal of Inorganic Materials, 2019, 34(7): 741-747. |

| [14] | Jin-Jie WU, Yan LI, Ren-Chu WEI, Jian-Xin WANG, Shu-Xin QU, Jie WENG, Wei ZHI. Bioactivity and Mechanical Stability of Hydroxyapatite Ceramicsunder Micro-vibration Environment [J]. Journal of Inorganic Materials, 2019, 34(4): 417-424. |

| [15] | HAN Hai-Bo, WANG You-He, LI Kang, LEI Jie, LIU Dan-He, YAN Zi-Feng. Acetic Acid Leaching on the Structure, Acidity and Performance of HMOR Catalyst [J]. Journal of Inorganic Materials, 2019, 34(2): 179-185. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||