Journal of Inorganic Materials ›› 2014, Vol. 29 ›› Issue (12): 1246-1252.DOI: 10.15541/jim20140185

• Orginal Article • Previous Articles Next Articles

YANG Nai-Tao1, SHEN Yi-Chi1, YAN Wei1, MENG Xiu-Xia1, TAN Xiao-Yao2, MA Zi-Feng3

Received:2014-04-14

Revised:2014-05-23

Published:2014-12-20

Online:2014-11-20

Supported by:CLC Number:

YANG Nai-Tao, SHEN Yi-Chi, YAN Wei, MENG Xiu-Xia, TAN Xiao-Yao, MA Zi-Feng. Microstructure and Performance of Anode for Microtubular Solid Oxide Fuel Cells[J]. Journal of Inorganic Materials, 2014, 29(12): 1246-1252.

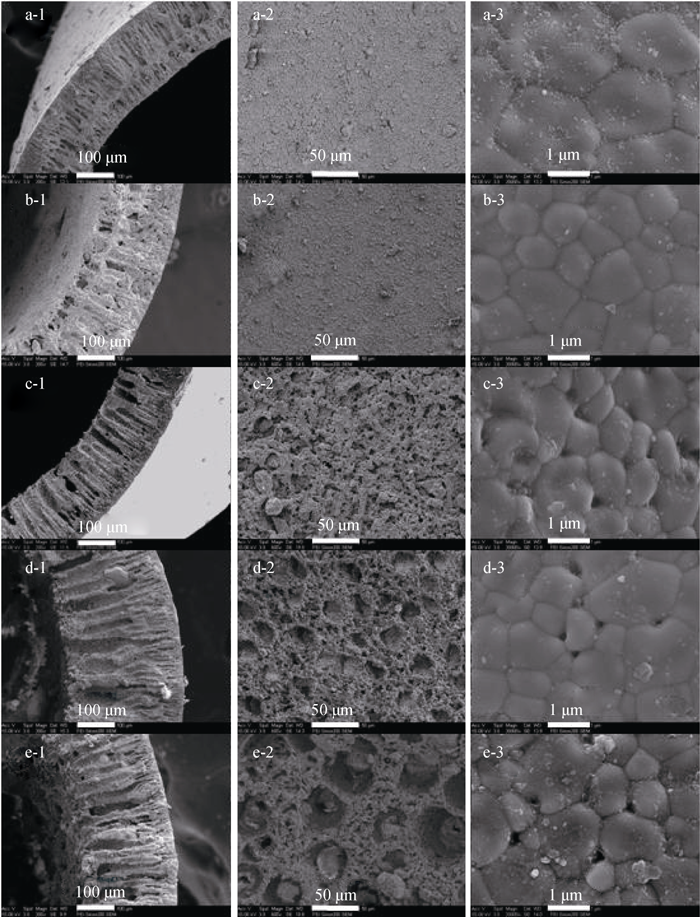

Fig. 1 Microstructures of YSZ/NiO-YSZ dual-layer hollow fibers (1450℃) Internal coagulant was (a) pure ethanol, (b) 70wt% ehanol/30 wt% NMP, (c) 50wt% ehanol/50 wt% NMP, (d) 30wt% ehanol/70wt% NMP and (e) pure NMP; 1-cross-section, 2-inner surface, 3-outer surface

| Substance/mixtures | δ | δd | δp | δh |

|---|---|---|---|---|

| PESf | 21.9 | 17.6 | 10.4 | 7.8 |

| NMP | 22.9 | 18 | 12.3 | 7.2 |

| H2O | 47.9 | 15.5 | 16.0 | 42.3 |

| Ethanol(EtOH) | 26.0 | 15.8 | 8.8 | 19.4 |

| EtOH/NMP=7: 3 | 24.8 | 16.46 | 9.85 | 15.74 |

| EtOH/NMP=5: 5 | 24.0 | 16.9 | 10.55 | 13.3 |

| EtOH/NMP=3: 7 | 23.3 | 17.34 | 11.25 | 10.86 |

Table 1 Solubility parameters of the solvent and non-solvent

| Substance/mixtures | δ | δd | δp | δh |

|---|---|---|---|---|

| PESf | 21.9 | 17.6 | 10.4 | 7.8 |

| NMP | 22.9 | 18 | 12.3 | 7.2 |

| H2O | 47.9 | 15.5 | 16.0 | 42.3 |

| Ethanol(EtOH) | 26.0 | 15.8 | 8.8 | 19.4 |

| EtOH/NMP=7: 3 | 24.8 | 16.46 | 9.85 | 15.74 |

| EtOH/NMP=5: 5 | 24.0 | 16.9 | 10.55 | 13.3 |

| EtOH/NMP=3: 7 | 23.3 | 17.34 | 11.25 | 10.86 |

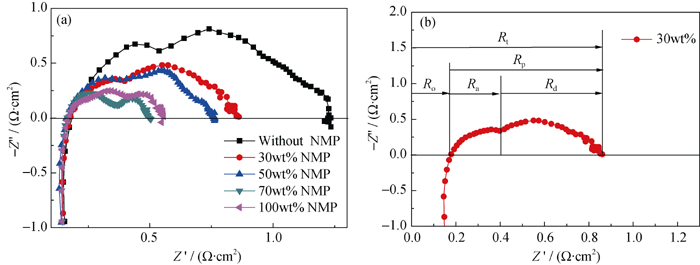

Fig. 7 EIS of MT-SOFC based asymmetric anode at OCV (800℃) (a) Ratio of NMP/ethanol; (b) Total resistance(Rt), polarization resistance, activation resistance(Ra), and diffusion resistance (Rd)

| NMP | Ro/Ω | Ra/Ω | Rt/Ω | Rp/Ω | Rd/Ω | (Ra/Rp)×100 | (Rd/Rp)×100 |

|---|---|---|---|---|---|---|---|

| 0 | 0.16 | 0.37 | 1.22 | 1.06 | 0.69 | 34.91 | 65.09 |

| 30wt% | 0.16 | 0.23 | 0.86 | 0.70 | 0.47 | 32.86 | 67.14 |

| 50wt% | 0.16 | 0.22 | 0.76 | 0.60 | 0.38 | 36.67 | 63.33 |

| 70wt% | 0.16 | 0.21 | 0.50 | 0.34 | 0.13 | 61.76 | 38.24 |

| 100wt% | 0.16 | 0.26 | 0.56 | 0.40 | 0.14 | 65.00 | 35.00 |

Table 2 Resistance vs internal coagulants for MT-SOFC

| NMP | Ro/Ω | Ra/Ω | Rt/Ω | Rp/Ω | Rd/Ω | (Ra/Rp)×100 | (Rd/Rp)×100 |

|---|---|---|---|---|---|---|---|

| 0 | 0.16 | 0.37 | 1.22 | 1.06 | 0.69 | 34.91 | 65.09 |

| 30wt% | 0.16 | 0.23 | 0.86 | 0.70 | 0.47 | 32.86 | 67.14 |

| 50wt% | 0.16 | 0.22 | 0.76 | 0.60 | 0.38 | 36.67 | 63.33 |

| 70wt% | 0.16 | 0.21 | 0.50 | 0.34 | 0.13 | 61.76 | 38.24 |

| 100wt% | 0.16 | 0.26 | 0.56 | 0.40 | 0.14 | 65.00 | 35.00 |

| [1] | KENDALL K.Progress in microtubular solid oxide fuel cells. International Journal of Applied Ceramic Technology, 2010, 7: 1-9. |

| [2] | LAWLOR V.Review of the micro-tubular solid oxide fuel cell (Part II: Cell design issues and research activities). Journal of Power Sources, 2013, 240: 421-441. |

| [3] | LAWLOR V, GRIESSER S, BUCHINGER G, et al.Review of the micro-tubular solid oxide fuel cell. Journal of Power Sources, 2009, 193: 387-399. |

| [4] | SUZUKI T, LIANG B, YAMAGUCHI T, et al.One-step sintering process of gadolinia-doped ceria interlayer-scandia-sta-b-ilized zirconia electrolyte for anode supported microtubular solid oxide fuel cells. Journal of Power Sources, 2012, 199: 170-173. |

| [5] | LEI Z, ZHU Q, HAN M.Fabrication and performance of directMethane SOFC with a Cu-CeO2 based anode. Acta Phys. Chim. Sin., 2010, 26(3): 583-588. |

| [6] | LUO T, SHI J, WANG S R, et al.Optimization of the solid oxide fuel cell anode by tape casting. Journal of Inorganic Materials, 2014, 29(2): 203-208. |

| [7] | CHEN J, ZENG F, WANG S, et al.The key materials and the stacks of SOFCs. Progess in Chemistry, 2011, 23: 463-469. |

| [8] | LI J.Solid oxide fuel cells: development status and key technologies. Journal of Functional Materials and devices, 2007, 13: 683-690. |

| [9] | WILLIAMS M C, STRAKEY J, SUDOVAL W U S. DOE fossil energy fuel cells program. Journal of Power Sources, 2006, 159: 1241-1247. |

| [10] | ZHEN Y D, TOK A I Y, JIANG S P, et al. Fabrication and performance of gadolinia-doped ceria-based intermediate- temperat-ure solid oxide fuel cells. Journal of Power Sources, 2008, 178: 69-74. |

| [11] | CHEN L, YAO M, XIA C.Anode substrate with continuous porosity gradient for tubular solid oxide fuel cells. Electroch-emistry Communications, 2014, 38: 114-116. |

| [12] | MENG X, YANG N, YIN Y, et al.Fabrication techniques and stack assembling methods for micro tubularsolid oxide fuel cells. CIESC Journal, 2011, 62: 2977-2986. |

| [13] | TANNER C W, FUNG K Z, VIRKAR A V.The effect of porous composite electrode structure on solid oxide fuel cell performance: I. Theoretical Analysis. Journal of The Electrochemical Society, 1997, 144: 21-30. |

| [14] | OTHMAN M H D, DROUSHIOTIS N, WU Z, et al. High- performance, anode-supported, microtubular SOFC prepared from single-step-fabricated, dual-layer hollow fibers. Advanced Materials, 2011, 23: 2480-2483. |

| [15] | MENG X, GONG X, YIN Y, et al.Microstructure tailoring of YSZ/Ni-YSZ dual-layer hollow fibers for micro-tubular solid oxide fuel cell application. International Journal of Hydrogen Energy, 2013, 38: 6700-6788. |

| [16] | LIU Y, LIU N, TAN X.Preparation of microtubular solid oxide fuel cells based on highly asymmetric structured electrolyte hollow fibers. Science China Chemistry, 2011, 54: 850-855. |

| [17] | YIN W, MENG B, MENG X, et al.Highly asymmetric yttria stabilized zirconia hollow fibre membranes. Journal of Alloys and Compounds, 2009, 476: 566-570. |

| [18] | TAN X, LIU N, MENG B, et al.Oxygen permeation behavior of La0.6Sr0.4Co0.8Fe0.2O3 hollow fibre membranes with highly conce-ntrated CO2 exposure. Journal of Membrane Science, 2012, 389: 216-222. |

| [19] | YANG N, TAN X, MA Z.A phase inversion/sintering process to fabricate nickel/yttria-stabilized zirconia hollow fibers as the anode support for micro-tubular solid oxide fuel cells. Journal of Power Sources, 2008, 183: 14-19. |

| [20] | GONG X, MENG X X, YANG N T, et al.Electrolyte thickness control and its effect on YSZ/Ni-YSZ dual-layer hollow fibres. Journal of Inorganic Materials, 2013, 28: 1108-1114. |

| [21] | OTHMAN M H D, WU Z, DROUSHIOTIS N, et al. Morph-ological studies of macrostructure of Ni-CGO anode hollow fibres for intermediate temperature solid oxide fuel cells. Journal of Membrane Science, 2010, 360: 410-417. |

| [22] | JIN C, YANG C, CHEN F.Effects on microstructure of NiO-YSZ anode support fabricated by phase-inversion method. Journal of Membrane Science, 2010, 363: 250-255. |

| [23] | KINGSBURY B F K, LI K. A morphological study of ceramic hollow fibre membranes. Journal of Membrane Science, 2009, 328: 134-140. |

| [24] | YOUNG T H, CHEN L W.Pore formation mechanism of mem-branes from phase inversion process. Desalination, 1995, 103: 233-247. |

| [25] | YANG C, REN C, YU L, et al.High performance intermediate temperature micro-tubular SOFCs with Ba0.9Co0.7Fe0.2Nb0.1O3−δ as cathode. International Journal of Hydrogen Energy, 2013, 38: 15348-15353. |

| [26] | LEHNERT W, MEUSINGER J, THOM F.Modelling of gas transport phenomena in SOFC anodes. Journal of Power Sources, 2000, 87: 57-63. |

| [1] | ZHANG Xiaoshan, WANG Bing, WU Nan, HAN Cheng, WU Chunzhi, WANG Yingde. Micro-nano Ceramic Fibers for High Temperature Thermal Insulation [J]. Journal of Inorganic Materials, 2021, 36(3): 245-256. |

| [2] | LIU Jinyun, ZHANG Yuting, HONG Zhou, LIU Hua, WANG Shengxian, GU Xuehong. Fabrication of Dual-layer Hollow Fiber Ceramic Composite Membranes by Co-extrusion [J]. Journal of Inorganic Materials, 2020, 35(12): 1333-1339. |

| [3] | WANG Xiao-Lei, ZHANG Yu-Ting, GAO Bing, ZHANG Chun, GU Xue-Hong. Preparation and Characterization of NaA Zeolite Membranes on Inner-surface of Four-channel Ceramic Hollow Fibers [J]. Journal of Inorganic Materials, 2018, 33(3): 339-344. |

| [4] | LIU Zheng-Kun, ZHU Jia-Wei, JIN Wan-Qin. Preparation and Characterization of Mixed-conducting Supported Hollow Fiber Membrane [J]. Journal of Inorganic Materials, 2015, 30(6): 621-626. |

| [5] | ZHANG Yu-Yue, LIN Jie, MIAO Guo-Shuan, GAO Jian-Feng, CHEN Chu-Sheng, XIA Chang-Rong, ZHAN Zhong-Liang, WANG Shao-Rong. Phase Inversion Tape Casting and Electrochemical Performance of Solid Oxide Fuel Cell Anode [J]. Journal of Inorganic Materials, 2015, 30(12): 1291-1294. |

| [6] | CHEN Yuan-Yuan, SHI Zhen-Zhou, ZHANG Chun, GU Xue-Hong. Effect of Coagulation Bath in Phase Inversion on Microstructure of Hollow Fiber Porous Al2O3 Support [J]. Journal of Inorganic Materials, 2014, 29(2): 143-148. |

| [7] | CUI Bo, WANG Hong-Zhi, LI Yao-Gang, ZHANG Qing-Hong. Synthesis and Properties of Hollow CaSi2O2N2:Eu2+ Luminescence Fibers [J]. Journal of Inorganic Materials, 2014, 29(10): 1029-1033. |

| [8] | SHANG Shuang-Yin, FANG Hong, REN Chun-Lei, YANG Ping-Hua, CHEN Chu-Sheng. Preparation and Characterization of Hydrophobic Porous Yttria-stabilized Zirconia Hollow Fiber for Water Desalination [J]. Journal of Inorganic Materials, 2013, 28(4): 393-397. |

| [9] | YANG Chun-Li, XU Qi-Ming, GONG Ming, LIU Wei. Simulation of Oxygen Permeability of Dual-phase Hollow Fiber Membrane [J]. Journal of Inorganic Materials, 2012, 27(9): 951-955. |

| [10] | LIU Peng-Chao, MA Jing-Hong, YANG Shu-Guang, GONG Jing-Hua, XU Jian. Research Progress on the Preparation of Ceramic Hollow Fiber Membranes by Nonsolvent Induced Phase Separation [J]. Journal of Inorganic Materials, 2012, 27(7): 673-679. |

| [11] | SONG Fu-Zhan,LIU Jin-Yong,MENG Xian-Feng,SHEN Xiang-Qian,XIANG Jun. Preparation and Characterization of M-type Strontium Ferrite Hollow Fibers [J]. Journal of Inorganic Materials, 2009, 24(4): 721-726. |

| [12] | CHEN Xin-Zhi,YU Ling-Hui,LIU Qiao-Sheng,WANG Hai-Hui,LI Zhong. Preparation and Application of Perovskite Hollow Fiber Oxygen Permeable Membrane [J]. Journal of Inorganic Materials, 2008, 23(6): 1216-1220. |

| [13] | JIANG Jin-Long,TAO Hui-Qing,ZENG Chang-Feng,ZHANG Li-Xiong,XU Nan-Ping. Preparation of Magnetic ZSM-5/Ni Hollow Fibers Using Poly (vinylidene fluoride) Hollow Fiber Microfiltration Membranes as Templates [J]. Journal of Inorganic Materials, 2008, 23(3): 475-480. |

| [14] | TAN Xiao-Yao,MENG Bo,YANG Nai-Tao. Preparation and Characteristics of Ceramic Hollow Fiber Membranes for Oxygen Permeation [J]. Journal of Inorganic Materials, 2006, 21(1): 245-249. |

| [15] | LI Jian-Sheng,HAO Yan-Xia,WANG Lian-Jun,ZHAO Bao-Chang. Preparation of Strengthened Alumina Hollow Fiber Membrane by RBAO Technique [J]. Journal of Inorganic Materials, 2002, 17(1): 180-184. |

| Viewed | ||||||

|

Full text |

|

|||||

|

Abstract |

|

|||||