无机材料学报 ›› 2024, Vol. 39 ›› Issue (9): 992-1004.DOI: 10.15541/jim20240036

刘鹏东1( ), 王桢2,3,4, 刘永锋3, 温广武1,4(

), 王桢2,3,4, 刘永锋3, 温广武1,4( )

)

收稿日期:2024-02-28

修回日期:2024-03-11

出版日期:2024-09-20

网络出版日期:2024-05-08

通讯作者:

温广武, 教授. E-mail: wengw@sdut.edu.cn作者简介:刘鹏东(1999-), 男, 硕士研究生. E-mail: liupengdong_077@163.com

基金资助:

LIU Pengdong1( ), WANG Zhen2,3,4, LIU Yongfeng3, WEN Guangwu1,4(

), WANG Zhen2,3,4, LIU Yongfeng3, WEN Guangwu1,4( )

)

Received:2024-02-28

Revised:2024-03-11

Published:2024-09-20

Online:2024-05-08

Contact:

WEN Guangwu, professor. E-mail: wengw@sdut.edu.cnAbout author:LIU Pengdong (1999-), male, Master candidate. E-mail: liupengdong_077@163.com

Supported by:摘要:

光伏切割硅废料——硅泥, 因其低成本、二维片状结构和高比容量(4200 mAh·g-1)的优势成为300 Wh·kg-1以上高能量密度储能电池核心硅碳负极材料的理想原料之一。然而, 硅泥存在成分复杂、粒径较大、导电性差、稳定性低和电化学性能差的问题, 需要进行系统改性处理。本文综述了硅泥在锂离子电池中的应用研究进展。首先, 分析了硅泥中金属杂质和非金属杂质对电池性能的重要影响。其中金属杂质可通过磁选和酸洗去除, 非金属杂质可通过液-液萃取和热处理去除。其次, 详细阐述了纯化后硅泥的原始性能和改性方法。通过硅泥纳米化可以抑制其膨胀, 其中包括研磨、刻蚀、电热冲击和合金-脱合金等方式; 通过直接元素掺杂硅和掺杂硅表面碳层来提高导电性; 通过构建惰性层、导电层和一定作用的官能团等表面改性提高稳定性; 还可以通过硅碳复合获得稳固的机械支撑和保护。最后, 提出了基于硅泥为原料的硅基负极面临的挑战和研发方向, 展望了未来发展前景, 旨在为硅泥变废为宝提供参考, 推动高能量密度锂离子电池快速发展。

中图分类号:

刘鹏东, 王桢, 刘永锋, 温广武. 硅泥在锂离子电池中的应用研究进展[J]. 无机材料学报, 2024, 39(9): 992-1004.

LIU Pengdong, WANG Zhen, LIU Yongfeng, WEN Guangwu. Research Progress on the Application of Silicon Slurry in Lithium-ion Batteries[J]. Journal of Inorganic Materials, 2024, 39(9): 992-1004.

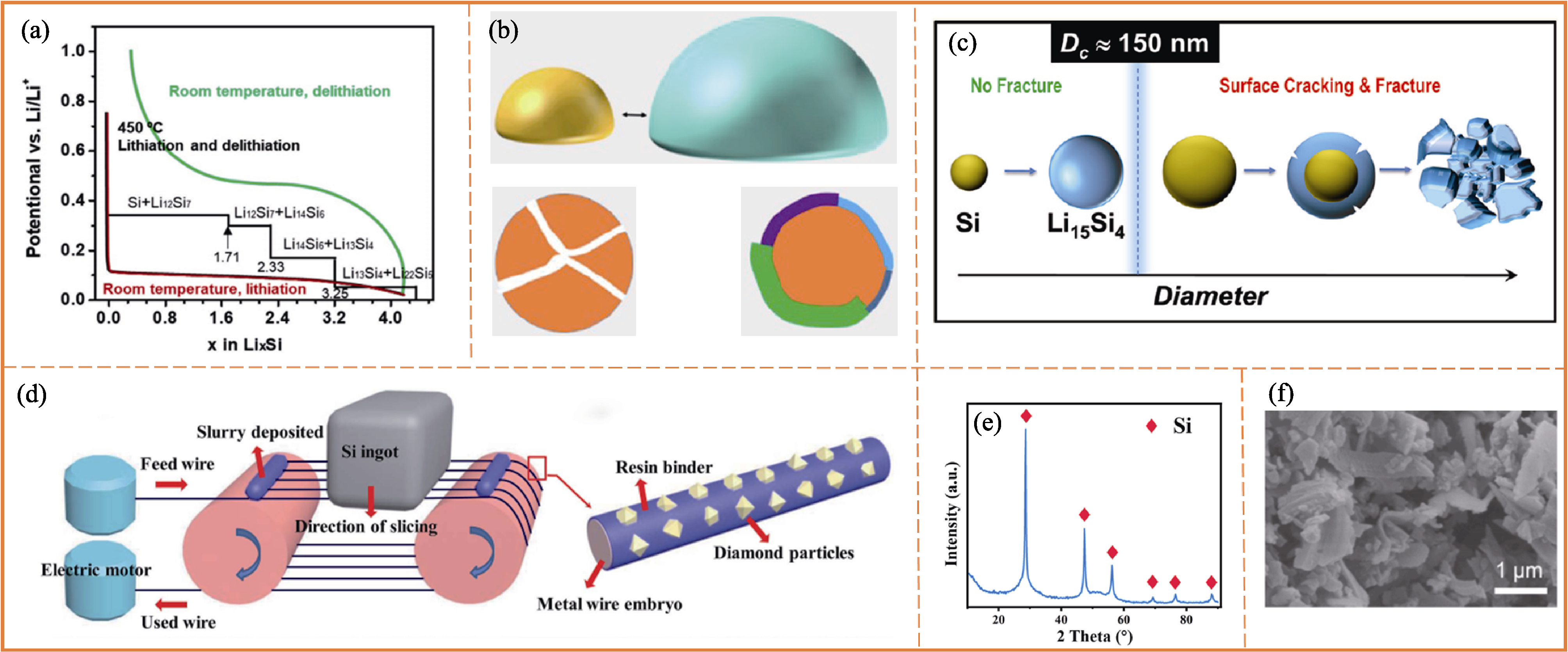

图1 硅负极存在的问题及硅泥的来源和特征

Fig. 1 Problems of Si anode and the sources and characteristics of silicon sludge (a) Lithiation/delithiation curves of Si anode at both 450 ℃ and room temperature[5]; (b) Problems in the process of Si anode lithiation/delithiation[8]; (c) Relationship between diameter size and cracking upon lithiation of individual nano silicon[9]; (d) Schematic of the multi-wire slicing of Si ingots and the typical diamond-wire saw[10]; (e) X-ray diffraction (XRD) pattern; (f) Scanning electron microscope (SEM) image of silicon sludge[13,16]

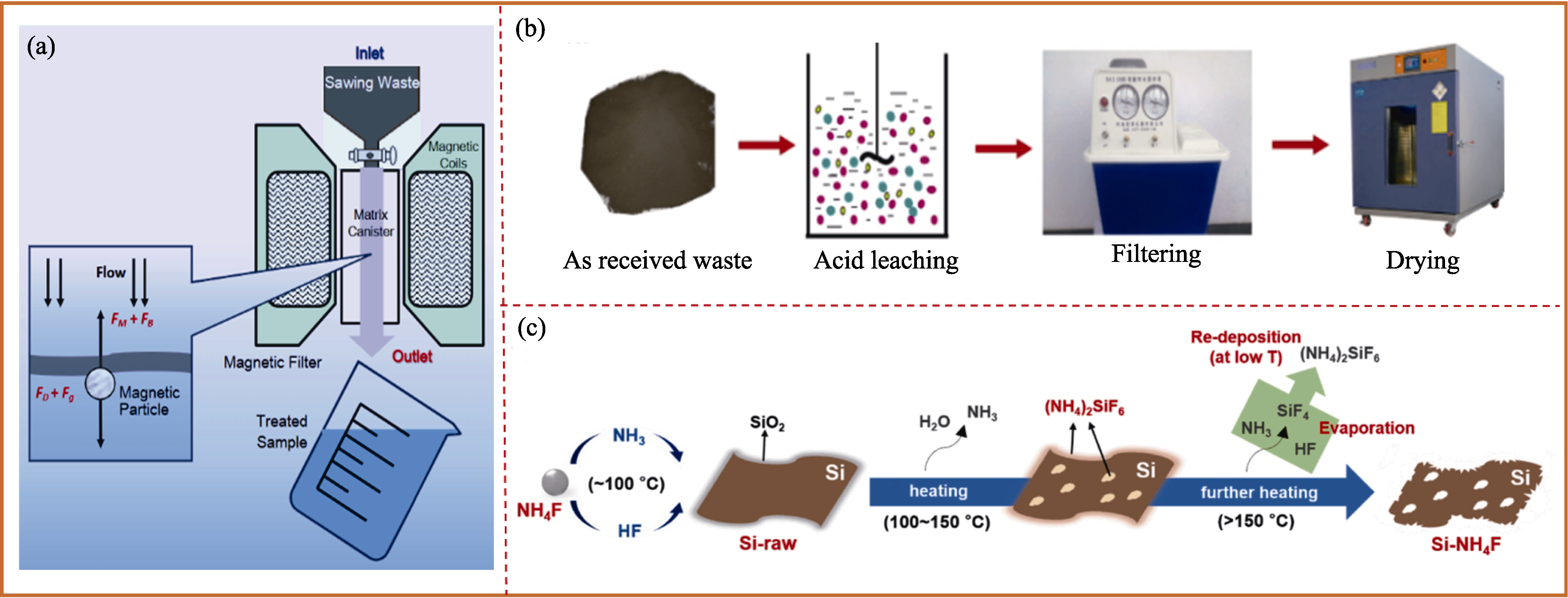

图2 硅泥中杂质的去除方式示意图

Fig. 2 Schematic diagram of removing impurities in silicon sludge (a) Magnetic separation equipment and schematic diagram of main forces exerted on a magnetic particle[24]; (b) Flow scheme of acid pickling[27]; (c) Reaction mechanism of removal of SiO2 through heat treatment of silicon sludge with NH4F[42]

| Current density/ (A·g-1) | First discharge capacity/ (mAh·g-1) | Cycle number | Capacity retention/% | Ref. |

|---|---|---|---|---|

| 0.8 | 1022.9 | 15 | 9.77 | [ |

| 0.05 | 3100 | 20 | 12.5 | [ |

| 0.2 | 3031.6 | 100 | 1.17 | [ |

| 0.1 | 1082 | 20 | 1.85 | [ |

| 0.1 | 2674.5 | 100 | 0.2 | [ |

表1 纯化硅泥电极的电化学性能

Table 1 Electrochemical performance of purified silicon sludge

| Current density/ (A·g-1) | First discharge capacity/ (mAh·g-1) | Cycle number | Capacity retention/% | Ref. |

|---|---|---|---|---|

| 0.8 | 1022.9 | 15 | 9.77 | [ |

| 0.05 | 3100 | 20 | 12.5 | [ |

| 0.2 | 3031.6 | 100 | 1.17 | [ |

| 0.1 | 1082 | 20 | 1.85 | [ |

| 0.1 | 2674.5 | 100 | 0.2 | [ |

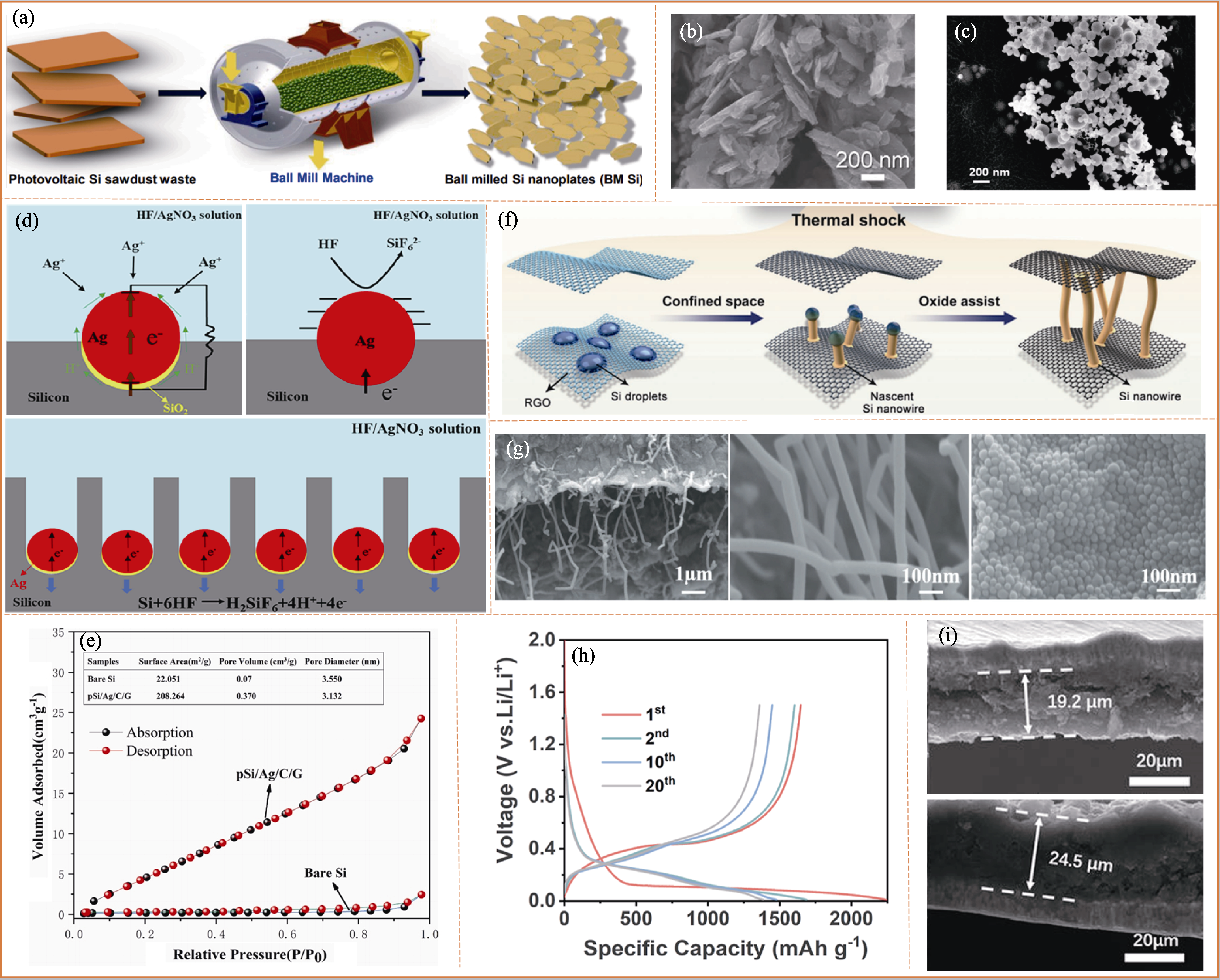

图3 不同方法硅泥纳米化的原理和表征

Fig. 3 Principle and characterization of nano-sized silicon sludge by different methods (a) Schematic diagram of preparing nano silicon by ball milling[59]; (b) SEM image of nano silicon prepared by stirring ball milling[61]; (c) SEM image of nano silicon prepared by transferred arc thermal plasma[62]; (d) Schematic diagram and (e) nitrogen adsorption-desorption isotherm of nano silicon by silver-assisted chemical etching[64]; (f) Schematic diagram and (g) SEM images of nano silicon by electrothermal shock method[66]; Nano silicon prepared by calcine dealloying: (h) charge-discharge curves and (i) SEM images of cross section for the working electrodes in the fresh and during initial lithiation process[67]

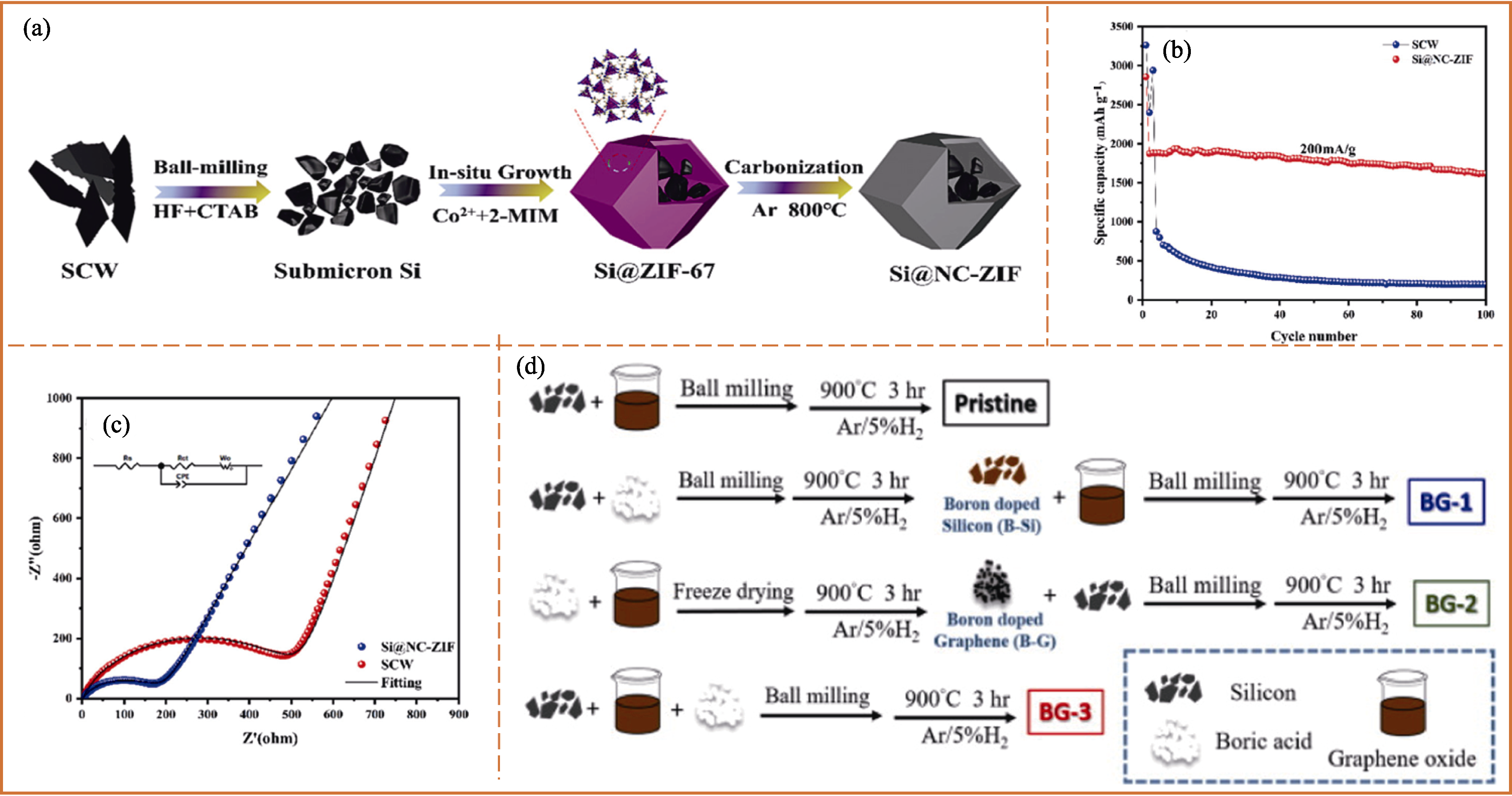

图4 硅泥的掺杂改性制备示意图及电化学性能

Fig. 4 Preparative schematic diagram and electrochemical performance of doping modified silicon sludge (a) Schematic diagram of the synthesis of Si@NC-ZIF composites[70]; (b) Cycling performance and (c) electrochemical impedance spectra of Si@NC-ZIF composites and silicon sludge[70]; (d) Flow scheme of silicon graphene composites prepared by boron doping[71]

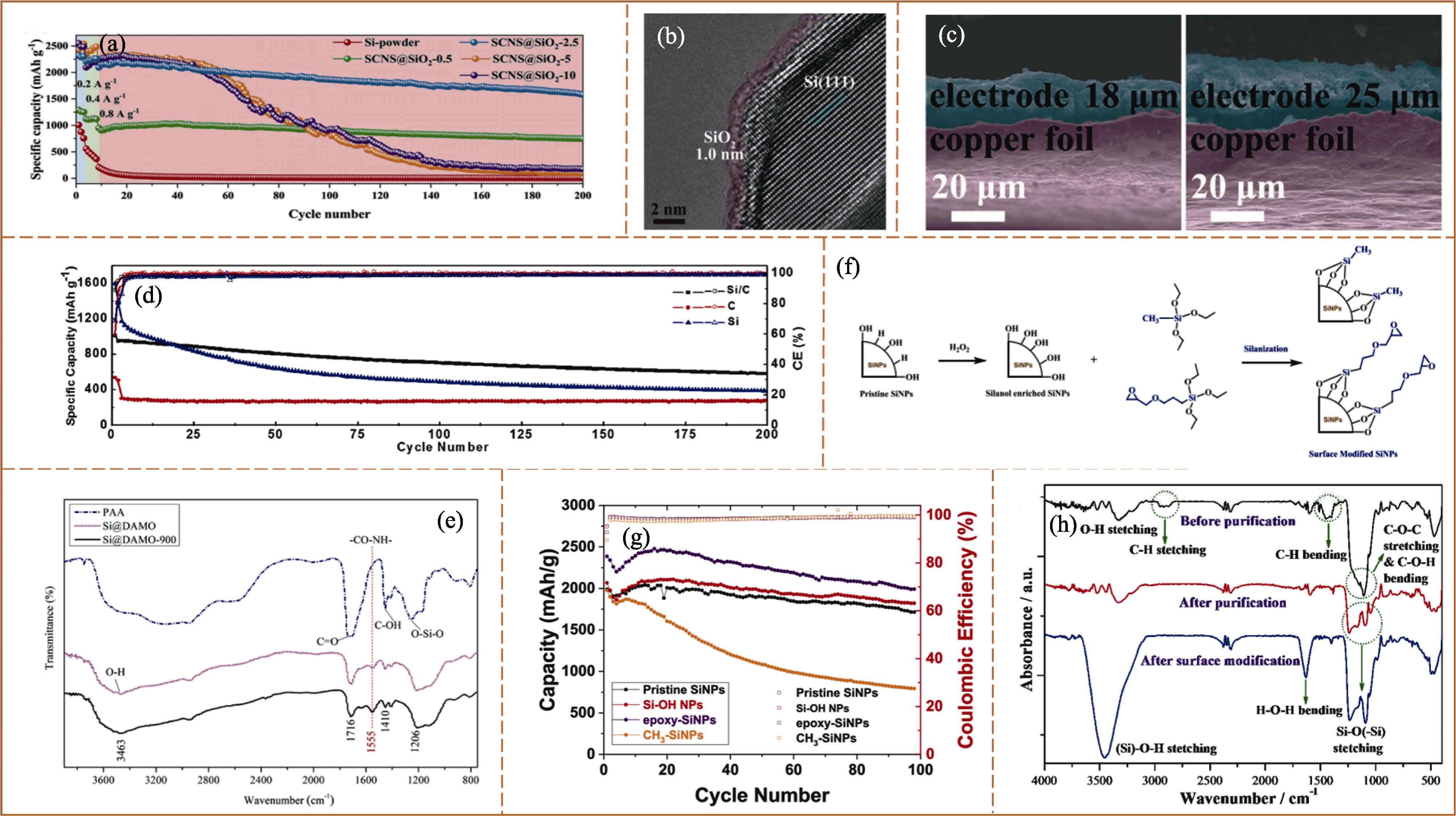

图5 硅泥表面改性原理及表征

Fig. 5 Principle and characterization of surface modification of silicon sludge (a) Cycling performance of silicon sludge with different etching concentrations of hydrofluoric acid[72]; SCNS@SiO2-2.5 composites: (b) transmission electron microscope image and (c) cross sectional SEM images of the electrodes before and after 200 cycles[72]; (d) Cycling performance of silicon carbon composites prepared by lignin and silicon sludge[73]; (e) Fourier transform infrared (FT-IR) spectra of silicon sludge surface before and after DAMO modification[76]; (f) Schematic diagram of two-step introduction of epoxy functional groups[77]; (g) Cycling performance of silicon anode with different surface groups[77]; (h) FT-IR spectra of silicon sludge surface before and after SiOx films modification[10]

| Modification method | Current density/(A·g-1) | Cycle number | Discharge capacity/(mAh·g-1) | Ref. |

|---|---|---|---|---|

| Nano silicon | 0.1 | 100 | 1480 | [ |

| N-doped carbon/silicon | 1 | 200 | 1139 | [ |

| S-doped carbon/silicon | 0.5 | 700 | 686.6 | [ |

| Integrated electrode material | 1 | 250 | 1447 | [ |

| Silicon/graphite/carbon composite | 0.1 | 400 | 741 | [ |

| Porous carbon/silicon composite | 0.2 | 200 | 1527 | [ |

| Silicon/graphene composite | 0.2 | 300 | 1656 | [ |

| Si/C core-shell structure | 0.42 | 200 | 1788.9 | [ |

| Si/CNTs/C core-shell structure | 0.84 | 300 | 720 | [ |

| Si@void@C hollow structure | 1 | 300 | 1164.4 | [ |

| Si@SiOx/Ag composite material | 0.5 | 200 | 1000 | [ |

| pSi/Ag/C/G composite material | 1 | 200 | 972 | [ |

| Si/TiSi2/G@C composite material | 0.8 | 120 | 943.8 | [ |

表2 不同改性方法制备的硅基负极电化学性能

Table 2 Electrochemical performance of silicon-based anode prepared by different modification methods

| Modification method | Current density/(A·g-1) | Cycle number | Discharge capacity/(mAh·g-1) | Ref. |

|---|---|---|---|---|

| Nano silicon | 0.1 | 100 | 1480 | [ |

| N-doped carbon/silicon | 1 | 200 | 1139 | [ |

| S-doped carbon/silicon | 0.5 | 700 | 686.6 | [ |

| Integrated electrode material | 1 | 250 | 1447 | [ |

| Silicon/graphite/carbon composite | 0.1 | 400 | 741 | [ |

| Porous carbon/silicon composite | 0.2 | 200 | 1527 | [ |

| Silicon/graphene composite | 0.2 | 300 | 1656 | [ |

| Si/C core-shell structure | 0.42 | 200 | 1788.9 | [ |

| Si/CNTs/C core-shell structure | 0.84 | 300 | 720 | [ |

| Si@void@C hollow structure | 1 | 300 | 1164.4 | [ |

| Si@SiOx/Ag composite material | 0.5 | 200 | 1000 | [ |

| pSi/Ag/C/G composite material | 1 | 200 | 972 | [ |

| Si/TiSi2/G@C composite material | 0.8 | 120 | 943.8 | [ |

| [1] | KIM T, SONG W T, SON D Y, et al. Lithium-ion batteries: outlook on present, future, and hybridized technologies. Journal of Materials Chemistry A, 2019, 7(7): 2942. |

| [2] | LI J Y, XU Q, LI G, et al. Research progress regarding Si-based anode materials towards practical application in high energy density Li-ion batteries. Materials Chemistry Frontiers, 2017, 1(9): 1691. |

| [3] |

ZHANG Y X, WU B R, MU G, et al. Recent progress and perspectives on silicon anode: synthesis and prelithiation for LIBs energy storage. Journal of Energy Chemistry, 2022, 64: 615.

DOI |

| [4] | DEVIC T, LESTRIEZ B, ROUÉ L. Silicon electrodes for Li-ion batteries. Addressing the challenges through coordination chemistry. ACS Energy Letters, 2019, 4(2): 550. |

| [5] | GUO J P, DONG D Q, WANG J, et al. Silicon-based lithium ion battery systems: state of the art from half and full cell viewpoint. Advanced Functional Materials, 2021, 31(34): 2102546. |

| [6] | MA J Y, SUNG J, LEE Y, et al. Strategic pore architecture for accommodating volume change from high Si content in lithium-ion battery anodes. Advanced Energy Materials, 2020, 10(6): 1903400. |

| [7] | XIA M T, CHEN B J, GU F, et al. Ti3C2Tx MXene nanosheets as a robust and conductive tight on Si anodes significantly enhance electrochemical lithium storage performance. ACS Nano, 2020, 14(4): 5111. |

| [8] | WU F X, MAIER J, YU Y. Guidelines and trends for next- generation rechargeable lithium and lithium-ion batteries. Chemical Society Reviews, 2020, 49(5): 1569. |

| [9] |

LIU X H, ZHONG L, HUANG S, et al. Size-dependent fracture of silicon nanoparticles during lithiation. ACS Nano, 2012, 6(2): 1522.

DOI PMID |

| [10] | ZHANG L Y, ZHANG L, ZHANG J, et al. Robust polymeric coating enables the stable operation of silicon micro-plate anodes recovered from photovoltaic industry waste for high-performance Li-ion batteries. Journal of Materials Chemistry A, 2015, 3(30): 15432. |

| [11] | YANG X F, CHEN X F, QIU J Y, et al. Controllable synthesis of silicon/carbon hollow microspheres using renewable sources for high energy lithium-ion battery. Journal of Solid State Chemistry, 2021, 296: 121968. |

| [12] |

JANG H D, KIM H, CHANG H, et al. Aerosol-assisted extraction of silicon nanoparticles from wafer slicing waste for lithium ion batteries. Scientific Reports, 2015, 5: 9431.

DOI PMID |

| [13] | CHEN G, LI Y, SHENG W, et al. Al2O3 and CaO as sintering aids: a strategy to remove impurity boron and SiO2 surface-layer of diamond wire saw silicon waste. Separation and Purification Technology, 2021, 270: 118823. |

| [14] | DROUICHE N, CUELLAR P, KERKAR F, et al. Recovery of solar grade silicon from kerf loss slurry waste. Renewable and Sustainable Energy Reviews, 2014, 32: 936. |

| [15] | LIU R P, XIANG D P. Recycling photovoltaic silicon waste for fabricating porous mullite ceramics by low-temperature reaction sintering. Journal of the European Ceramic Society, 2021, 41(12): 5957. |

| [16] | MA Y C, HUANG A M, LI Y, et al. Simple preparation of Si/N- doped carbon anodes from photovoltaic industry waste for lithium- ion batteries. Journal of Alloys and Compounds, 2022, 890: 161792. |

| [17] | 楼平, 管敏渊, 彭蒙蒙, 等. 铁磁杂质对锂离子电池自放电和电化学性能的影响. 功能材料与器件学报, 2021, 27: 361. |

| [18] | 李路, 胡安生. 锂离子电池中金属及金属氧化物引发自放电的研究. 广东化工, 2021, 48: 23. |

| [19] | 郑留群, 万里鹏, 陈珠惠, 等. 杂质对锂离子电池自放电的影响. 电池, 2022, 52: 419. |

| [20] | LEI Y, QIU P, CHEN K, et al. Mechanism of ZrB2 formation in Al-Si alloy and application in Si purification. ACS Sustainable Chemistry & Engineering, 2019, 7(15): 12990. |

| [21] | WEI K, YANG S, WAN X, et al. Review of silicon recovery and purification from saw silicon powder. JOM, 2020, 72(7): 2633. |

| [22] | SHI J, SHENG L Q, LI J W, et al. Green synthesis of high- performance porous carbon coated silicon composite anode for lithium storage based on recycled silicon kerf waste. Journal of Alloys and Compounds, 2022, 919: 165854. |

| [23] | YANG F, YU W Z, WEN J L, et al. Oxygen removal and silicon recovery from polycrystalline silicon kerf loss by combining vacuum magnesium thermal reduction and hydrochloric acid leaching. Journal of Environmental Management, 2023, 338: 117829. |

| [24] | BOUTOUCHENT-GUERFI N, BOUSSOURDI M A, LAMI A, et al. Dry magnetic separation on the recovery of metal fragments from kerf slurry waste produced during the manufacture of photovoltaic solar cells. Silicon, 2020, 13(1): 149. |

| [25] | TSAI T H, WU Y F. Recovery of submicron-sized silicon-rich powder from silicon sawing waste for electrocatalyst of methanol electrooxidation. International Journal of Electrochemical Science, 2018, 13(7): 6880. |

| [26] | LIU S N, HUANG K, ZHU H M. Removal of Fe, B and P impurities by enhanced separation technique from silicon-rich powder of the multi-wire sawing slurry. Chemical Engineering Journal, 2016, 299: 276. |

| [27] | LIU Y, KONG J, ZHUANG Y X, et al. Recycling high purity silicon from solar grade silicon cutting slurry waste by carbothermic reduction in the electric arc furnace. Journal of Cleaner Production, 2019, 224: 709. |

| [28] |

YANG S C, WEI K X, MA W H, et al. Kinetic mechanism of aluminum removal from diamond wire saw powder in HCl solution. Journal of Hazardous Materials, 2019, 368: 1.

DOI PMID |

| [29] | WANG K, TAN Y, LI P T, et al. Recycling Si waste cut from diamond wire into high performance porous Si@SiO2@C anodes for Li-ion battery. Journal of Hazardous Materials, 2021, 407: 124778. |

| [30] | KONG J, JIN X, LIU Y, et al. Study on the kinetics of iron removal from silicon diamond-wire saw cutting waste: comparison between heterogeneous and homogeneous reaction methods. Separation and Purification Technology, 2019, 221: 261. |

| [31] | 王宇, 尹盛, 肖成章, 等.硅材料湿法提纯理论分析及工艺优化. 太阳能学报, 1995: 174. |

| [32] | YANG S C, WAN X H, WEI K X, et al. A new sustainable concept for silicon recovery from diamond wire saw silicon powder waste: source control and comprehensive conservation. Journal of Cleaner Production, 2022, 358: 131961. |

| [33] | YANG S C, WAN X H, WEI K X, et al. Occurrence state and dissolution mechanism of metallic impurities in diamond wire saw silicon powder. ACS Sustainable Chemistry & Engineering, 2020, 8(33): 12577. |

| [34] | WU C Y, KUO P H, DUH J G. Reviving of silicon waste with N-doped carbon core-shell structure prepared by vapor deposition polymerization of polypyrrole applied in lithium-ion battery. Surface and Coatings Technology, 2021, 421: 127418. |

| [35] | HOU S Y, TIE S N, JIANG M, et al. Microwave-assisted acid leaching for recovery of silicon from diamond-wire cutting waste Slurry. JOM, 2020, 72(7): 2656. |

| [36] | WANG K, XUE B, TAN Y, et al. Recycling of micron-sized Si powder waste from diamond wire cutting and its application in Li-ion battery anodes. Journal of Cleaner Production, 2019, 239: 117997. |

| [37] | WAGNER N P, TRON A, TOLCHARD J R, et al. Silicon anodes for lithium-ion batteries produced from recovered kerf powders. Journal of Power Sources, 2019, 414: 486. |

| [38] |

YANG H L, LIU I T, LIU C E, et al. Recycling and reuse of kerf-loss silicon from diamond wire sawing for photovoltaic industry. Waste Management, 2019, 84: 204.

DOI PMID |

| [39] | VAZQUEZ-PUFLEAU M, CHADHA T S, YABLONSKY G, et al. Elimination of carbon contamination from silicon kerf using a furnace aerosol reactor methodology. Industrial & Engineering Chemistry Research, 2015, 54(22): 5914. |

| [40] | YANG F, YU W Z, RAO Z T, et al. A new strategy for de-oxidation of diamond-wire sawing silicon waste via the synergistic effect of magnesium thermal reduction and hydrochloric acid leaching. Journal of Environmental Management, 2022, 317: 115424. |

| [41] | 孙海鸥, 赵梅玉, 李晓平, 等.一种熔盐法处理硅废料制备锂离子电池负极材料的方法: CN116387497B. 2023-07-28. |

| [42] | WANG S E, JANG I, KANG Y C, et al. Residual silica removal and nanopore generation on industrial waste silicon using ammonium fluoride and its application to lithium-ion battery anodes. Chemical Engineering Journal, 2021, 419: 129389. |

| [43] | HE Q, YU J, WANG Y H, et al. Silicon nanoparticles prepared from industrial wastes as high-performing anode materials for lithium ion batteries. Solid State Ionics, 2018, 325: 141. |

| [44] | YANG T Y, YANG G, TANG Y K, et al. Porous silicon from industrial waste engineered for superior stability lithium-ion battery anodes. Journal of Nanoparticle Research, 2021, 23: 209. |

| [45] | YU C L, TIAN X H, XIONG Z C, et al. High stability of sub-micro-sized silicon/carbon composites using recycling silicon waste for lithium-ion battery anode. Journal of Alloys and Compounds, 2021, 869: 159124. |

| [46] | SU Y X, LV Y Y, HABIBIPOUR M R, et al. Dynamic stable interface between CNT and nanosilicon for robust anode with large capacity and high rate performance. Energy Storage Materials, 2023, 61: 102892. |

| [47] | WU F, DONG Y, SU Y F, et al. Benchmarking the effect of particle size on silicon anode materials for lithium-ion batteries. Small, 2023, 19(42): 2301301. |

| [48] | YAN Z, JIANG J, ZHANG Y, et al. Scalable and low-cost synthesis of porous silicon nanoparticles as high-performance lithium-ion battery anode. Materials Today Nano, 2022, 18: 100175. |

| [49] | TANG F Q, TAN Y, JIANG T T, et al. Phosphorus-doped silicon nanoparticles as high performance LIB negative electrode. Journal of Materials Science, 2022, 57(4): 2803. |

| [50] | DI F, ZHOU W M, YANG H M, et al. Surface modification and functional structure space design to improve the cycle stability of silicon based materials as anode of lithium ion batteries. Coatings, 2021, 11(9): 1047. |

| [51] | CHAE S J, XU Y B, YI R, et al. A micrometer-sized silicon/carbon composite anode synthesized by impregnation of petroleum pitch in nanoporous silicon. Advanced Materials, 2021, 33(40): 2103095. |

| [52] | SU H P, LI X R, LIU C W, et al. Scalable synthesis of micrometer-sized porous silicon/carbon composites for high- stability lithium-ion battery anodes. Chemical Engineering Journal, 2023, 451: 138394. |

| [53] | ZHANG W Y, SHI H F, WANG C D, et al. Synthesizing copper-doped silicon/carbon composite anode as cost-effective active materials for Li-ion batteries. Journal of Physics and Chemistry of Solids, 2023, 179: 111387. |

| [54] | YU Q, GE P P, LIU Z H, et al. Ultrafine SiOx/C nanospheres and their pomegranate-like assemblies for high-performance lithium storage. Journal of Materials Chemistry A, 2018, 6(30): 14903. |

| [55] | MA T Y, YU X G, CHENG X L, et al. Confined solid electrolyte interphase growth space with solid polymer electrolyte in hollow structured silicon anode for Li-ion batteries. ACS Applied Materials & Interfaces, 2017, 9(15): 13247. |

| [56] | KELLER C, DESRUES A, KARUPPIAH S, et al. Effect of size and shape on electrochemical performance of nano-silicon-based lithium battery. Nanomaterials, 2021, 11(2): 307. |

| [57] | XU Z L, LIU X M, LUO Y S, et al. Nanosilicon anodes for high performance rechargeable batteries. Progress in Materials Science, 2017, 90: 1. |

| [58] | HAN X, ZHANG Z Q, CHEN S Y, et al. Low temperature growth of graphitic carbon on porous silicon for high-capacity lithium energy storage. Journal of Power Sources, 2020, 463: 228245. |

| [59] | ZHANG Y F, MA H Y, YU C M, et al. Si nanoplates prepared by ball milling photovoltaic silicon sawdust waste as lithium-ion batteries anode material. Materials Letters, 2023, 331: 133469. |

| [60] | ZHANG S Y, XIE J, ZHANG P, et al. Low-cost and scalable preparation of nano-Si from photovoltaic waste silicon for high-performance Li-ion battery anode. Functional Materials Letters, 2021, 14(6): 2151033. |

| [61] |

KASUKABE T, NISHIHARA H, KIMURA K, et al. Beads-milling of waste Si sawdust into high-performance nanoflakes for lithium-ion batteries. Scientific Reports, 2017, 7(1): 42734.

DOI PMID |

| [62] | JIN E M, KIM M S, KIM T Y, et al. Upcycling of silicon scrap collected from photovoltaic cell manufacturing process for lithium-ion batteries via transferred arc thermal plasma. Energy, 2023, 262: 125447. |

| [63] | 李绍元, 张嘉昆, 马文会, 等.等离子活化切割硅废料制备多孔硅/碳/纳米金属复合负极材料的方法: CN111785944B. 2023-04-28. |

| [64] | WANG L, XI F S, ZHANG Z, et al. Recycling of photovoltaic silicon waste for high-performance porous silicon/silver/carbon/ graphite anode. Waste Management, 2021, 132: 56. |

| [65] | ZHANG Z, XI F S, LI S Y, et al. High-performance Si/nano- Cu/CNTs/C anode derived from photovoltaic silicon waste: a potential photovoltaic-energy storage strategy. Materials Today Energy, 2021, 20: 100671. |

| [66] | LU J J, LIU S L, LIU J H, et al. Millisecond conversion of photovoltaic silicon waste to binder-free high silicon content nanowires electrodes. Advanced Energy Materials, 2021, 11(40): 2102103. |

| [67] | CHEN M Y, DUAN P X, ZHONG Y J, et al. Constructing a sheet-stacked Si/C composite by recycling photovoltaic Si waste for Li-ion batteries. Industrial & Engineering Chemistry Research, 2022, 61(7): 2809. |

| [68] | MA Q, ZHAO Z Q, ZHAO Y, et al. A self-driven alloying/dealloying approach to nanostructuring micro-silicon for high-performance lithium-ion battery anodes. Energy Storage Materials, 2021, 34: 768. |

| [69] | 洪捐.一种利用硅废料制备镓掺杂纳米硅颗粒的方法: CN113471422B. 2023-07-07. |

| [70] | WANG M Y, XI F S, LI S Y, et al. ZIF-67-derived porous nitrogen-doped carbon shell encapsulates photovoltaic silicon cutting waste as anode in high-performance lithium-ion batteries. Journal of Electroanalytical Chemistry, 2023, 931: 117210. |

| [71] | WU Z Y, WU C Y, DUH J G. Facile synthesis of boron-doped graphene-silicon conductive network composite from recycling silicon for lithium-ion batteries anodes materials. Materials Letters, 2021, 296: 129875. |

| [72] | HU T J, ZHOU H C, ZHOU X Y, et al. Silicon cutting waste derived silicon nanosheets with adjustable native SiO2 shell for highly-stable lithiation/delithiation. Small, 2022, 19(7): 2204690. |

| [73] | LIU W W, LIU J, ZHU M H, et al. Recycling of lignin and Si waste for advanced Si/C battery anodes. ACS Applied Materials & Interfaces, 2020, 12(51): 57055. |

| [74] | PHAM T K, SHIN J, SONG H, et al. Application of Si particles recycled from industrial waste for Si/rGO electrode composition for lithium rechargeable battery production. Molecular Crystals and Liquid Crystals, 2020, 707(1): 147. |

| [75] | SHI J, JIANG X S, BAN B Y, et al. Carbon nanotubes-enhanced lithium storage capacity of recovered silicon/carbon anodes produced from solar-grade silicon kerf scrap. Electrochimica Acta, 2021, 381: 138269. |

| [76] | LIANG J H, FAN Z Q, CHEN S, et al. A novel three-dimensional cross-linked net structure of submicron Si as high-performance anode for LIBs. Journal of Alloys and Compounds, 2021, 860: 158433. |

| [77] | JIANG S S, HU B, SAHORE R T, et al. Surface-functionalized silicon nanoparticles as anode material for lithium-ion battery. ACS Applied Materials & Interfaces, 2018, 10(51): 44924. |

| [78] | JUNG C H, CHOI J, KIM W S, et al. A nanopore-embedded graphitic carbon shell on silicon anode for high performance lithium ion batteries. Journal of Materials Chemistry A, 2018, 6(17): 8013. |

| [79] | JEONG S, LI X L, ZHENG J M, et al. Hard carbon coated nano-Si/graphite composite as a high performance anode for Li-ion batteries. Journal of Power Sources, 2016, 329: 323. |

| [80] | LU B, MA B J, YU R Z, et al. Photovoltaic monocrystalline silicon waste-derived hierarchical silicon/flake graphite/carbon composite as low-cost and high-capacity anode for lithium-ion batteries. ChemistrySelect, 2017, 2(12): 3479. |

| [81] | DUAN H, XU H, WU Q, et al. Silicon/graphite/amorphous carbon as anode materials for lithium secondary batteries. Molecules, 2023, 28(2): 464. |

| [82] | LIU X, LIU H T, DAI X Q, et al. Scalable silicon@sulfur-doped carbon composites via a low-cost facile method for high- performance lithium-ion battery anodes. Journal of Alloys and Compounds, 2023, 946: 169330. |

| [83] | SHAO R, NIU J, ZHU F, et al. A facile and versatile strategy towards high-performance Si anodes for Li-ion capacitors: concomitant conductive network construction and dual-interfacial engineering. Nano Energy, 2019, 63: 103824. |

| [84] | SHI J, JIANG X S, SUN J F, et al. Recycled silicon-based anodes with three-dimensional hierarchical porous carbon framework synthesized by a self-assembly CaCO3 template method for lithium ion battery. Journal of Alloys and Compounds, 2021, 858: 157703. |

| [85] | PHAM T K, SHIN J H, KARIMA N C, et al. Application of recycled Si from industrial waste towards Si/rGO composite material for long lifetime lithium-ion battery. Journal of Power Sources, 2021, 506: 230244. |

| [86] | FAN Z Q, ZHENG S S, HE S, et al. Preparation of micron Si@C anodes for lithium ion battery by recycling the lamellar submicron silicon in the kerf slurry waste from photovoltaic industry. Diamond and Related Materials, 2020, 107: 107898. |

| [87] | WANG C D, NIU X X, WANG D H, et al. Simple preparation of Si/CNTs/C composite derived from photovoltaic waste silicon powder as high-performance anode material for Li-ion batteries. Powder Technology, 2022, 408: 117744. |

| [88] | MA Q, QU J K, CHEN X, et al. Converting micro-sized kerf-loss silicon waste to high-performance hollow-structured silicon/carbon composite anodes for lithium-ion batteries. Sustainable Energy & Fuels, 2020, 4(9): 4780. |

| [89] | ZHANG J K, LI S Y, XI F S, et al. Si@SiOx/Ag composite anodes with high initial Coulombic efficiency derive from recyclable silicon cutting waste. Chemical Engineering Journal, 2022, 447: 137563. |

| [90] | ZHANG Y C, CHEN M Y, CHEN Z Y, et al. A novel Si/TiSi2/ G@C composite as anode material with excellent lithium storage performances. Materials Letters, 2021, 299: 130078. |

| [1] | 魏相霞, 张晓飞, 徐凯龙, 陈张伟. 增材制造柔性压电材料的现状与展望[J]. 无机材料学报, 2024, 39(9): 965-978. |

| [2] | 杨鑫, 韩春秋, 曹玥晗, 贺桢, 周莹. 金属氧化物电催化硝酸盐还原合成氨研究进展[J]. 无机材料学报, 2024, 39(9): 979-991. |

| [3] | 黄洁, 汪刘应, 王滨, 刘顾, 王伟超, 葛超群. 基于微纳结构设计的电磁性能调控研究进展[J]. 无机材料学报, 2024, 39(8): 853-870. |

| [4] | 陈乾, 苏海军, 姜浩, 申仲琳, 余明辉, 张卓. 超高温氧化物陶瓷激光增材制造及组织性能调控研究进展[J]. 无机材料学报, 2024, 39(7): 741-753. |

| [5] | 王伟明, 王为得, 粟毅, 马青松, 姚冬旭, 曾宇平. 以非氧化物为烧结助剂制备高导热氮化硅陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 634-646. |

| [6] | 蔡飞燕, 倪德伟, 董绍明. 高熵碳化物超高温陶瓷的研究进展[J]. 无机材料学报, 2024, 39(6): 591-608. |

| [7] | 吴晓晨, 郑瑞晓, 李露, 马浩林, 赵培航, 马朝利. SiCf/SiC陶瓷基复合材料高温环境损伤原位监测研究进展[J]. 无机材料学报, 2024, 39(6): 609-622. |

| [8] | 赵日达, 汤素芳. 多孔碳陶瓷化改进反应熔渗法制备陶瓷基复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 623-633. |

| [9] | 方光武, 谢浩元, 张华军, 高希光, 宋迎东. CMC-EBC损伤耦合机理及一体化设计研究进展[J]. 无机材料学报, 2024, 39(6): 647-661. |

| [10] | 张幸红, 王义铭, 程源, 董顺, 胡平. 超高温陶瓷复合材料研究进展[J]. 无机材料学报, 2024, 39(6): 571-590. |

| [11] | 张慧, 许志鹏, 朱从潭, 郭学益, 杨英. 大面积有机-无机杂化钙钛矿薄膜及其光伏应用研究进展[J]. 无机材料学报, 2024, 39(5): 457-466. |

| [12] | 李宗晓, 胡令祥, 王敬蕊, 诸葛飞. 氧化物神经元器件及其神经网络应用[J]. 无机材料学报, 2024, 39(4): 345-358. |

| [13] | 程节, 周月, 罗薪涛, 高美婷, 骆思妃, 蔡丹敏, 吴雪垠, 朱立才, 袁中直. 蛋黄壳结构FeF3·0.33H2O@N掺杂碳纳米笼正极材料的构筑及其电化学性能[J]. 无机材料学报, 2024, 39(3): 299-305. |

| [14] | 鲍可, 李西军. 化学气相沉积法制备智能窗用热致变色VO2薄膜的研究进展[J]. 无机材料学报, 2024, 39(3): 233-258. |

| [15] | 胡梦菲, 黄丽萍, 李贺, 张国军, 吴厚政. 锂/钠离子电池硬碳负极材料的研究进展[J]. 无机材料学报, 2024, 39(1): 32-44. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||