无机材料学报 ›› 2023, Vol. 38 ›› Issue (11): 1316-1322.DOI: 10.15541/jim20230127

所属专题: 【能源环境】燃料电池(202312)

田煜彬1( ), 田超凡1, 李森1, 赵永鑫1, 邢涛2, 李智2,3, 陈萧如1, 向帅蓉1, 代鹏程1(

), 田超凡1, 李森1, 赵永鑫1, 邢涛2, 李智2,3, 陈萧如1, 向帅蓉1, 代鹏程1( )

)

收稿日期:2023-03-13

修回日期:2023-05-28

出版日期:2023-06-16

网络出版日期:2023-06-16

通讯作者:

代鹏程(1986-), 男, 副教授. E-mail: dpcapple@upc.edu.cn作者简介:田煜彬(1997-), 男, 硕士研究生. E-mail: yubinpeach@163.com

基金资助:

TIAN Yubin1( ), TIAN Chaofan1, LI Sen1, ZHAO Yongxin1, XING Tao2, LI Zhi2,3, CHEN Xiaoru1, XIANG Shuairong1, DAI Pengcheng1(

), TIAN Chaofan1, LI Sen1, ZHAO Yongxin1, XING Tao2, LI Zhi2,3, CHEN Xiaoru1, XIANG Shuairong1, DAI Pengcheng1( )

)

Received:2023-03-13

Revised:2023-05-28

Published:2023-06-16

Online:2023-06-16

Contact:

DAI Pengcheng (1986-), male, associate professor. E-mail: dpcapple@upc.edu.cnAbout author:TIAN Yubin (1997-), male, Master candidate. E-mail: yubinpeach@163.com

Supported by:摘要:

气体扩散层(GDL)是质子交换膜燃料电池(PEMFCs)的关键部件之一, 成本占燃料电池膜电极的40%~50%。开发低成本、高性能的GDL生产工艺, 可以降低燃料电池成本, 推动燃料电池商业化进程。本研究以纤维素棉布为原料, 通过铁基化合物的催化石墨化作用, 在较低温度(1500 ℃)下生成了一种高导电、高孔隙率的柔性生物质碳布。碳布由相互连接的微米级碳纤维组成, 形成了丰富的孔道, 其孔隙率为76.93%。经过铁基化合物催化, 碳纤维的表面原位生成了大量碳纳米管团簇, 增加了碳布的导电性, 使其平面电阻率降低至34 mΩ·cm, 垂直电阻率在 2 MPa压力下降低至2.8 mΩ·cm, 性能达到商业碳布的标准。生物质碳布作为气体扩散层的燃料电池在0.7 A·cm-2电流密度处功率密度达到0.4 W·cm-2, 超过了相同催化剂(Pt)负载量的商业碳布(0.34 W·cm-2)的电池功率密度。本研究制备的生物质碳布制备简单、价格低廉、性能优秀, 为开发低成本、高性能气体扩散层提供了新的思路。

中图分类号:

田煜彬, 田超凡, 李森, 赵永鑫, 邢涛, 李智, 陈萧如, 向帅蓉, 代鹏程. 高导电性生物质碳布的制备及其燃料电池气体扩散层性能[J]. 无机材料学报, 2023, 38(11): 1316-1322.

TIAN Yubin, TIAN Chaofan, LI Sen, ZHAO Yongxin, XING Tao, LI Zhi, CHEN Xiaoru, XIANG Shuairong, DAI Pengcheng. Biomass-derived High-conductivity Carbon Cloth: Preparation and Application as Gas Diffusion Layers in Fuel Cells[J]. Journal of Inorganic Materials, 2023, 38(11): 1316-1322.

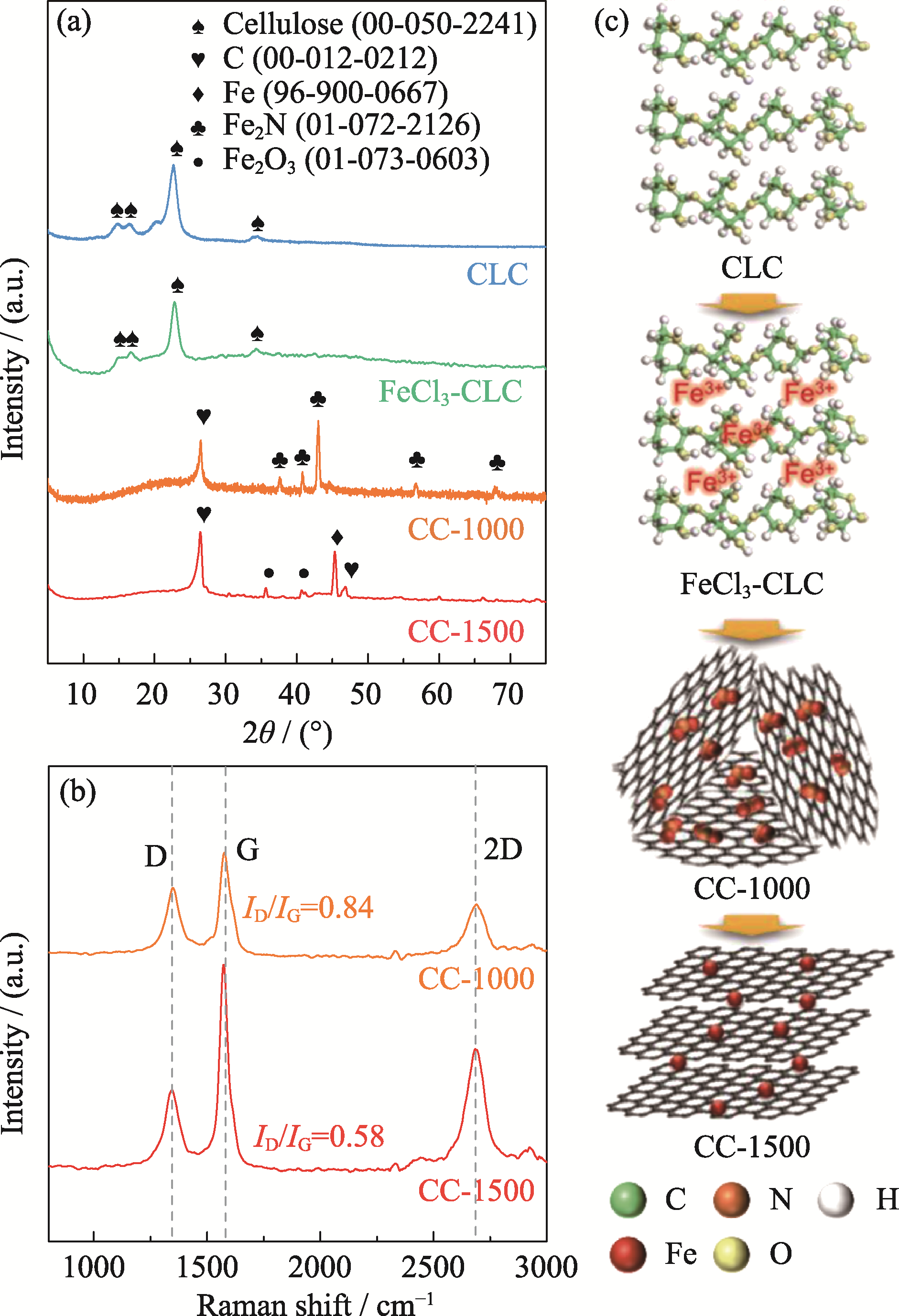

图2 生物质碳布的XRD谱图(a), Raman谱图(b)和微观制备流程图(c)

Fig. 2 XRD patterns (a), Raman patterns (b) and microcosmic preparative process (c) of biomass-derived carbon cloth

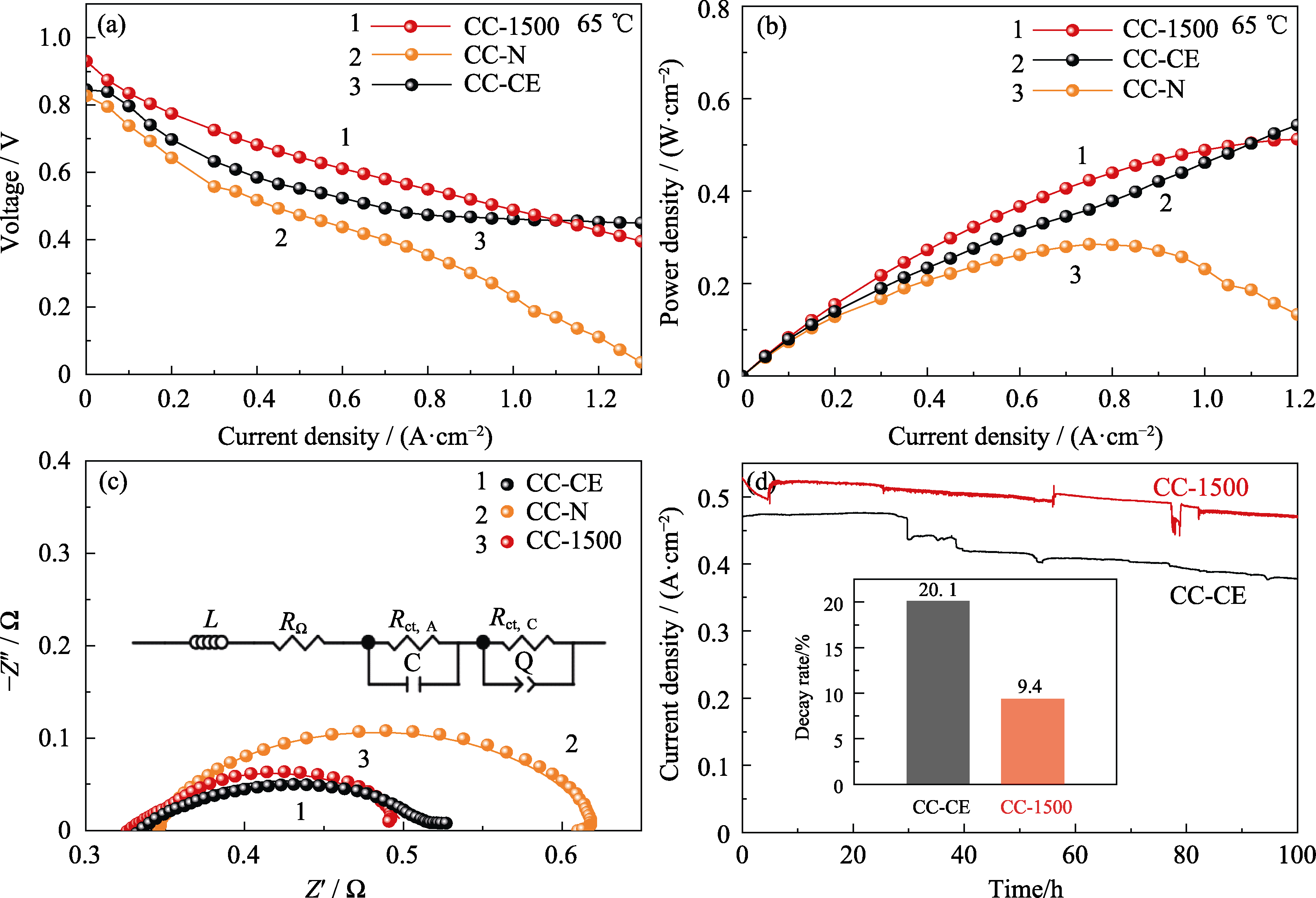

图7 不同GDL的极化曲线(a), 功率密度曲线(b), 65 ℃、0.6 V下的阻抗曲线(c)和耐腐蚀曲线(d)

Fig. 7 Polarization curves (a) and power density curves (b), EIS plots (c), and long-term durability tests at 0.6 V, 65 ℃(d) of PEMFCs using different GDLs C: Capacitor; Q: Inductor

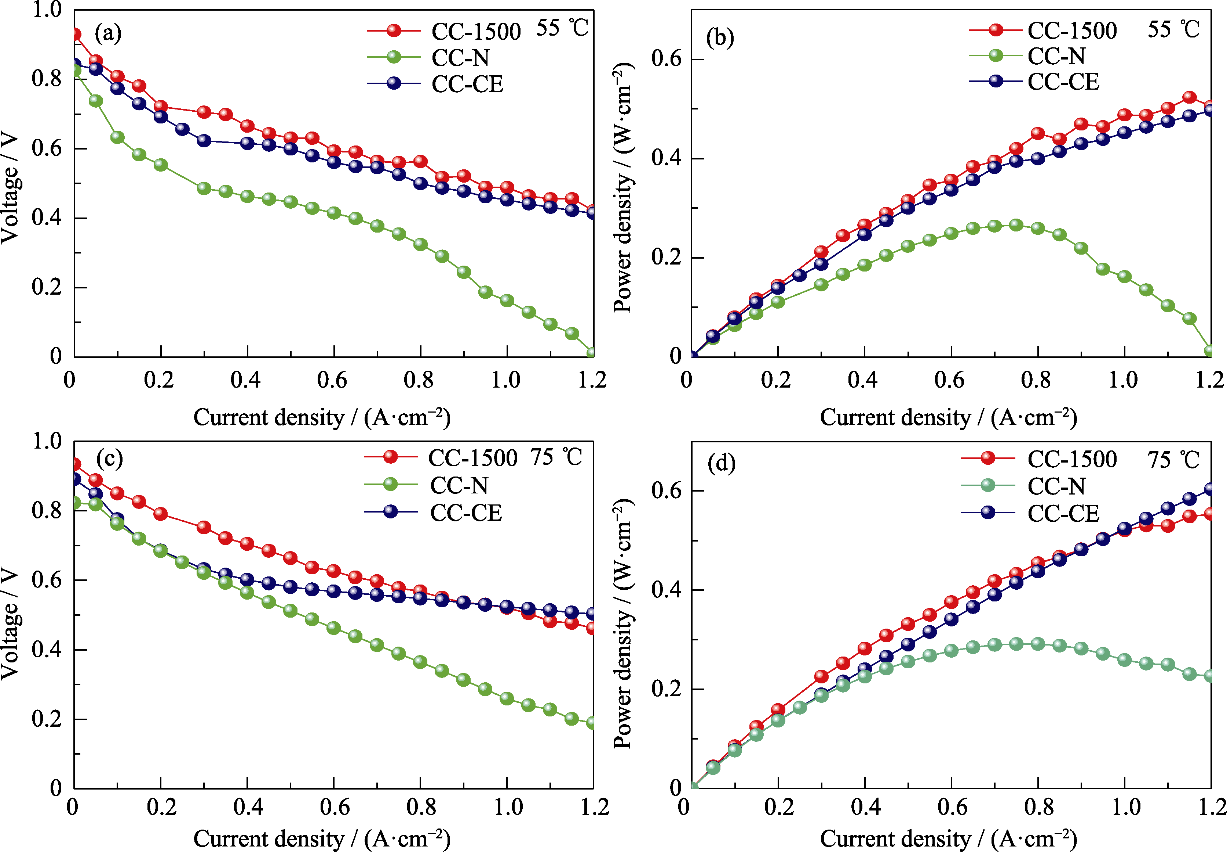

图S9 不同GDL在55和75 ℃的极化曲线(a, c), 功率密度曲线(b, d)

Fig. S9 Polarization curves(a, c) and power density curves (b, d) of PEMFCs using different GDLs at 55 and 75 ℃

| GDL | RΩ/Ω | Rct,A/Ω | Rct,C/Ω |

|---|---|---|---|

| CC-1500 | 0.3123 | 0.0832 | 0.1047 |

| CC-CE | 0.3301 | 0.0658 | 0.1322 |

| CC-N | 0.3442 | 0.1081 | 0.1659 |

表S1 CC-1500、CC-CE和CC-N的EIS拟合数据

Table S1 EIS fitting data of CC-1500, CC-CE and CC-N

| GDL | RΩ/Ω | Rct,A/Ω | Rct,C/Ω |

|---|---|---|---|

| CC-1500 | 0.3123 | 0.0832 | 0.1047 |

| CC-CE | 0.3301 | 0.0658 | 0.1322 |

| CC-N | 0.3442 | 0.1081 | 0.1659 |

| [1] |

ZHANG J, WANG B, JIN J, et al. A review of the microporous layer in proton exchange membrane fuel cells: materials and structural designs based on water transport mechanism. Renewable and Sustainable Energy Reviews, 2022, 156: 111998.

DOI URL |

| [2] |

YOON K R, KIM J M, LEE K A, et al. Activity-stability benefits of Pt/C fuel cell electrocatalysts prepared via remote CeO2 interfacial doping. Journal of Power Sources, 2021, 496: 229798.

DOI URL |

| [3] |

VAN DAO D, ADILBISH G, LEE I H, et al. Enhanced electrocatalytic property of Pt/C electrode with double catalyst layers for PEMFC. International Journal of Hydrogen Energy, 2019, 44(45): 24580.

DOI URL |

| [4] |

PARK S, LEE J W, POPOV B N. A review of gas diffusion layer in PEM fuel cells: materials and designs. International Journal of Hydrogen Energy, 2012, 37(7): 5850.

DOI URL |

| [5] |

SIM J, KANG M, MIN K. Effects of basic gas diffusion layer components on PEMFC performance with capillary pressure gradient. International Journal of Hydrogen Energy, 2021, 46(54): 27731.

DOI URL |

| [6] |

PARK S B, PARK Y I. Fabrication of gas diffusion layer (GDL) containing microporous layer using flourinated ethylene prophylene (FEP) for proton exchange membrane fuel cell (PEMFC). International Journal of Precision Engineering and Manufacturing, 2012, 13(7): 1145.

DOI URL |

| [7] |

ZHAO H, KWAK J H, ZHANG Z C, et al. Studying cellulose fiber structure by SEM, XRD, NMR and acid hydrolysis. Carbohydrate Polymers, 2007, 68(2): 235.

DOI URL |

| [8] |

XIA L, NI M, HE Q, et al. Optimization of gas diffusion layer in high temperature PEMFC with the focuses on thickness and porosity. Applied Energy, 2021, 300: 117357.

DOI URL |

| [9] |

YUSOF N, ISMAIL A F. Post spinning and pyrolysis processes of polyacrylonitrile (PAN)-based carbon fiber and activated carbon fiber: a review. Journal of Analytical and Applied Pyrolysis, 2012, 93: 1.

DOI URL |

| [10] |

KO T H, LIAO Y K, LIU C H. Effects of graphitization of PAN-based carbon fiber cloth on its use as gas diffusion layers in proton exchange membrane fuel cells. New Carbon Materials, 2007, 22(2): 97.

DOI URL |

| [11] |

OUYANG T, CHEN Y, JIANG Z, et al. Evaluation of low density and highly thermal conductive carbon bonded carbon fiber network with mesophase pitch as binder. Journal of Inorganic Materials, 2019, 34(10): 1030.

DOI |

| [12] |

RAHAMAN M S A, ISMAIL A F, MUSTAFA A. A review of heat treatment on polyacrylonitrile fiber. Polymer Degradation and Stability, 2007, 92(8): 1421.

DOI URL |

| [13] |

YANG H, TU H C, CHIANG I L. Carbon cloth based on PAN carbon fiber practicability for PEMFC applications. International Journal of Hydrogen Energy, 2010, 35(7): 2791.

DOI URL |

| [14] |

MATHUR R B, MAHESHWARI P H, DHAMI T L, et al. Processing of carbon composite paper as electrode for fuel cell. Journal of Power Sources, 2006, 161(2): 790.

DOI URL |

| [15] |

WEI J, NING F, BAI C, et al. An ultra-thin, flexible, low-cost and scalable gas diffusion layer composed of carbon nanotubes for high-performance fuel cells. Journal of Materials Chemistry A, 2020, 8(12): 5986.

DOI URL |

| [16] |

YANG Y, KONG L, LU J, et al. A highly conductive MXene-based rubber composite with relatively stable conductivity under small deformation and high sensing sensitivity at large strain. Composites Part A: Applied Science and Manufacturing, 2023, 170: 107545.

DOI URL |

| [17] |

GAN H, FENG Y, DAI P, et al. Heteroatom-doped biochar for direct dehydrogenation of propane to propylene. Journal of Inorganic Materials, 2022, 37(10): 1058.

DOI |

| [18] | HE W, MA R, ZHU Y, et al. Renewable porous carbons prepared by KOH activation as oxygen reduction electrocatalysts. Journal of Inorganic Materials, 2019, 34(10): 1115. |

| [19] |

GELFOND J, MENG T, LI S, et al. Highly electrically conductive biomass-derived carbon fibers for permanent carbon sequestration. Sustainable Materials and Technologies, 2023, 35: e00573.

DOI URL |

| [20] |

DANG D, ZENG R, CHEN X, et al. Natural wood derived robust carbon sheets with perpendicular channels as gas diffusion layers in air-breathing proton exchange membrane fuel cells (PEMFCs). Catalysis Communications, 2021, 159: 106351.

DOI URL |

| [21] |

NAVARRO A J, GOMEZ M A, DAZA L, et al. Production of gas diffusion layers with cotton fibers for their use in fuel cells. Scientific Reports, 2022, 12: 4219.

DOI PMID |

| [22] |

FU X, LI T, TANG L, et al. Reticulated polyaniline nanowires as a cathode microporous layer for high-temperature PEMFCs. International Journal of Hydrogen Energy, 2021, 46(12): 8802.

DOI URL |

| [23] |

SUN W, LIU C, LI Y, et al. Rational construction of Fe2N@C yolk-shell nanoboxes as multifunctional hosts for ultralong lithium-sulfur batteries. ACS Nano, 2019, 13(10): 12137.

DOI URL |

| [24] |

ZHAO Y, FROST R L, MARTENS W N, et al. XRD, TEM and thermal analysis of Fe doped boehmite nanofibres and nanosheets. Journal of Thermal Analysis and Calorimetry, 2007, 90(3): 755.

DOI URL |

| [25] |

NO Y S, CHOI H K, KIM J S, et al. Layer number identification of CVD-grown multilayer graphene using Si peak analysis. Scientific Reports, 2018, 8: 571.

DOI |

| [26] |

CHEN Z, REN W, GAO L, et al. Three-dimensional flexible and conductive interconnected graphene networks grown by chemical vapour deposition. Nature Materials, 2011, 10(6): 424.

DOI PMID |

| [27] |

SUN Z, ZHENG M, HU H, et al. From biomass wastes to vertically aligned graphene nanosheet arrays: a catalyst-free synthetic strategy towards high-quality graphene for electrochemical energy storage. Chemical Engineering Journal, 2018, 336: 550.

DOI URL |

| [28] |

JIN H, ZHOU H, LI W, et al. In situ derived Fe/N/S-codoped carbon nanotubes from ZIF-8 crystals as efficient electrocatalysts for the oxygen reduction reaction and zinc-air batteries. Journal of Materials Chemistry A, 2018, 6(41): 20093.

DOI URL |

| [29] |

XU J, LIANG G, CHEN D, et al. Iron and nitrogen doped carbon derived from ferrocene and ZIF-8 as proton exchange membrane fuel cell cathode catalyst. Applied Surface Science, 2022, 573: 151607.

DOI URL |

| [30] |

LU F, FAN K, CUI L, et al. Engineering FeN4 active sites onto nitrogen-rich carbon with tubular channels for enhanced oxygen reduction reaction performance. Applied Catalysis B: Environmental, 2022, 313: 121464.

DOI URL |

| [31] | QI C Z, WU X, LIU J, et al. Highly conductive calcium ion-reinforced MXene/sodium alginate aerogel meshes by direct ink writing for electromagnetic interference shielding and Joule heating. Journal of Materials Science & Technology, 2023, 135: 213. |

| [32] |

JIN Y, MA Z, WU M, et al. Preparation of MXene with high conductivity and its application on conductive fabrics. Applied Nanoscience, 2022, 12(8): 2317.

DOI |

| [33] | GONG X, XIONG Z, CHEN X, et al. Multifunctional superamphiphobic cotton fabrics with highly efficient flame retardancy, self-cleaning, and electromagnetic interference shielding. ACS Applied Materials & Interfaces, 2023, 15(2): 3395. |

| [34] |

YANG M, CHEN P, QU X, et al. Robust neural interfaces with photopatternable, bioadhesive, and highly conductive hydrogels for stable chronic neuromodulation. ACS Nano, 2023, 17(2): 885.

DOI URL |

| [35] |

SHU L, WANG Z, ZHANG X F, et al. Highly conductive and anti-freezing cellulose hydrogel for flexible sensors. International Journal of Biological Macromolecules, 2023, 230: 123425.

DOI URL |

| [36] |

XU Q, ZHAO J, CHEN Y, et al. Effects of gas permeation on the sealing performance of PEMFC stacks. International Journal of Hydrogen Energy, 2021, 46(73): 36424.

DOI URL |

| [37] |

KIM K N, KANG J H, LEE S G, et al. Lattice Boltzmann simulation of liquid water transport in microporous and gas diffusion layers of polymer electrolyte membrane fuel cells. Journal of Power Sources, 2015, 278: 703.

DOI URL |

| [38] |

ANTOLINI E, PASSOS R R, TICIANELLI E A. Effects of the carbon powder characteristics in the cathode gas diffusion layer on the performance of polymer electrolyte fuel cells. Journal of Power Sources, 2002, 109(2): 477.

DOI URL |

| [39] |

KRAYTSBERG A, EIN-ELI Y. Review of advanced materials for proton exchange membrane fuel cells. Energy & Fuels, 2014, 28(12): 7303.

DOI URL |

| [40] |

DU H Y, WANG C H, HSU H C, et al. High performance of catalysts supported by directly grown PTFE-free micro-porous CNT layer in a proton exchange membrane fuel cell. Journal of Materials Chemistry, 2011, 21: 2512.

DOI URL |

| [1] | 郭天民, 董江波, 陈正鹏, 饶睦敏, 李明飞, 李田, 凌意瀚. 中温固体氧化物燃料电池的高熵双钙钛矿阴极材料: 兼容性与活性研究[J]. 无机材料学报, 2023, 38(6): 693-700. |

| [2] | 姚仪帅, 郭瑞华, 安胜利, 张捷宇, 周国治, 张国芳, 黄雅荣, 潘高飞. 原位负载Pt-Co高指数晶面催化剂的制备及其电催化性能[J]. 无机材料学报, 2023, 38(1): 71-78. |

| [3] | 吴秋琴, 姚奋发, 金传洪, 郑遗凡. 碳纳米管内填充生长超细一维亚化学计量比氧化钨纳米线[J]. 无机材料学报, 2022, 37(4): 413-419. |

| [4] | 甘洪宇, 冯燕, 杨德鸿, 田煜彬, 李阳, 邢涛, 李智, 赵学波, 代鹏程. 杂原子掺杂生物质碳催化丙烷直接脱氢制丙烯[J]. 无机材料学报, 2022, 37(10): 1058-1064. |

| [5] | 樊帅, 金天, 张山林, 雒晓涛, 李成新, 李长久. Li2O烧结助剂对固体氧化物燃料电池LSGM电解质烧结特性及离子电导率的影响[J]. 无机材料学报, 2022, 37(10): 1087-1092. |

| [6] | 刘芳芳, 传秀云, 杨扬, 李爱军. 氮/硫共掺杂对纤水镁石模板碳纳米管电化学性能的影响[J]. 无机材料学报, 2021, 36(7): 711-717. |

| [7] | 曹丹,周明扬,刘志军,颜晓敏,刘江. 阳极支撑质子导体电解质固体氧化物燃料电池的制备及其性能研究[J]. 无机材料学报, 2020, 35(9): 1047-1052. |

| [8] | 董龙浩,张海军,张俊,吴文浩,贾全利. 碳纳米管改性海泡石多孔陶瓷及其高效油水分离性能研究[J]. 无机材料学报, 2020, 35(6): 689-696. |

| [9] | 夏天, 孟燮, 骆婷, 占忠亮. 固体氧化物燃料电池LaxSr2-3x/2Fe1.5Ni0.1Mo0.4O6-δ阳极性能研究[J]. 无机材料学报, 2020, 35(5): 617-622. |

| [10] | 罗燚,冯军宗,冯坚,姜勇刚,李良军. 新型碳材料质子交换膜燃料电池Pt催化剂载体的研究进展[J]. 无机材料学报, 2020, 35(4): 407-415. |

| [11] | 李亚辉, 张建峰, 曹惠杨, 张欣, 江莞. 二维碳化钛/碳纳米管负载铂钌粒子的制备及电催化性能研究[J]. 无机材料学报, 2020, 35(1): 79-85. |

| [12] | 李凯, 李霄, 李箭, 谢佳苗. 基于应力分析Ni-Fe合金支撑固体氧化物燃料电池结构稳定性研究[J]. 无机材料学报, 2019, 34(6): 611-617. |

| [13] | 汪维, 苑莉莉, 丘倩媛, 周明扬, 刘美林, 刘江. 流延法制备单片式直接碳固体氧化物燃料电池组及其性能研究[J]. 无机材料学报, 2019, 34(5): 509-514. |

| [14] | 何王涛, 马汝广, 朱钰方, 杨明杰, 王家成. 氢氧化钾活化制备可再生多孔碳及其电催化氧还原性能研究[J]. 无机材料学报, 2019, 34(10): 1115-1122. |

| [15] | 夏天, 孟燮, 骆婷, 占忠亮. Ca掺杂Sr2Fe1.5Mo0.5O6-δ材料的合成与作为对称固体氧化物燃料电池电极催化剂的性能研究[J]. 无机材料学报, 2019, 34(10): 1109-1114. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||