无机材料学报 ›› 2023, Vol. 38 ›› Issue (11): 1331-1337.DOI: 10.15541/jim20230121

鲁志强1,2( ), 刘可可1,2, 李强1,2, 胡芹1,2, 冯利萍1,2, 张清杰2, 吴劲松2,3, 苏贤礼1,2(

), 刘可可1,2, 李强1,2, 胡芹1,2, 冯利萍1,2, 张清杰2, 吴劲松2,3, 苏贤礼1,2( ), 唐新峰1,2(

), 唐新峰1,2( )

)

收稿日期:2023-03-09

修回日期:2023-05-09

出版日期:2023-06-02

网络出版日期:2023-06-02

通讯作者:

唐新峰, 教授. E-mail: tangxf@whut.edu.cn;作者简介:鲁志强(1996-), 男, 硕士研究生. E-mail: luzhiqiangmail@whut.edu.cn

基金资助:

LU Zhiqiang1,2( ), LIU Keke1,2, LI Qiang1,2, HU Qin1,2, FENG Liping1,2, ZHANG Qingjie2, WU Jinsong2,3, SU Xianli1,2(

), LIU Keke1,2, LI Qiang1,2, HU Qin1,2, FENG Liping1,2, ZHANG Qingjie2, WU Jinsong2,3, SU Xianli1,2( ), TANG Xinfeng1,2(

), TANG Xinfeng1,2( )

)

Received:2023-03-09

Revised:2023-05-09

Published:2023-06-02

Online:2023-06-02

Contact:

TANG Xinfeng, professor. E-mail: tangxf@whut.edu.cn;About author:About author: LU Zhiqiang (1996-), male, Master candidate. E-mail: luzhiqiangmail@whut.edu.cn

Supported by:摘要:

晶粒细化是提高Bi0.5Sb1.5Te3合金力学性能的有效途径, 但是粉末冶金过程中晶粒细化导致的类施主效应会严重劣化材料热电性能, 制约了Bi0.5Sb1.5Te3基合金在微型热电器件中的应用。本研究围绕p型Bi0.5Sb1.5Te3基合金, 采用实验结合理论计算系统研究了粉末冶金制备过程中研磨和脱附气氛对烧结样品中类施主效应和电热输运性能的影响规律和机制。Bi0.5Sb1.5Te3基合金破碎研磨过程中粉体表面产生缺陷

中图分类号:

鲁志强, 刘可可, 李强, 胡芹, 冯利萍, 张清杰, 吴劲松, 苏贤礼, 唐新峰. p型多晶Bi0.5Sb1.5Te3合金类施主效应与热电性能[J]. 无机材料学报, 2023, 38(11): 1331-1337.

LU Zhiqiang, LIU Keke, LI Qiang, HU Qin, FENG Liping, ZHANG Qingjie, WU Jinsong, SU Xianli, TANG Xinfeng. Donor-like Effect and Thermoelectric Performance in p-Type Bi0.5Sb1.5Te3 Alloy[J]. Journal of Inorganic Materials, 2023, 38(11): 1331-1337.

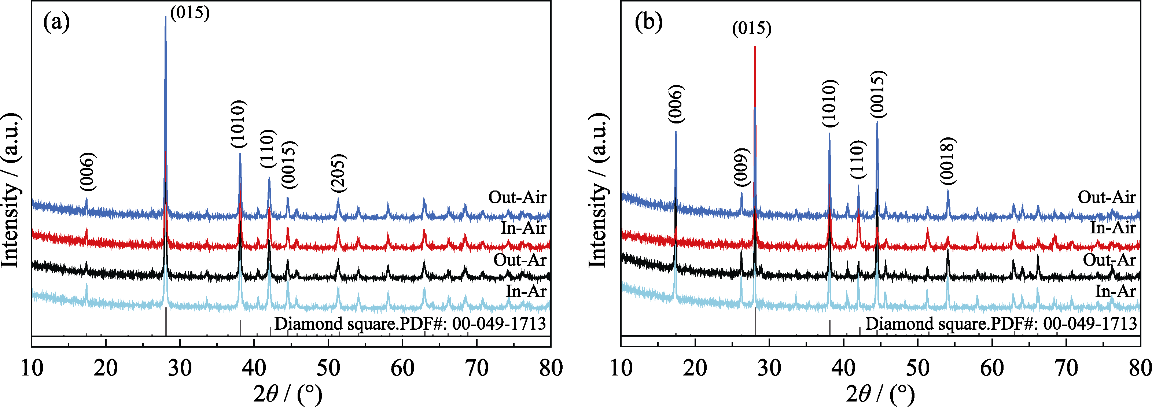

图1 (a)不同气氛处理烧结样品的粉体XRD图谱和(b)垂直于烧结压力方向的块体XRD图谱

Fig. 1 (a) Powder XRD patterns of sintered samples with powders treated in different atmospheres, and (b) XRD patterns of bulk samples measured perpendicular to the sintered pressing direction

| Sample | F | σ/(×104, S•m−1) | S/(μV•K−1) | n/(×1019, cm−3) | μ/(cm2•V−1•s−1) | κ/(W•m−1•K−1) | m*/m0 | ZT | ZTave |

|---|---|---|---|---|---|---|---|---|---|

| In-Ar | 0.076 | 17.50 | 150 | 4.49 | 243 | 1.49 | 0.93 | 0.78 | 0.92 |

| Out-Ar | 0.074 | 15.55 | 160 | 3.88 | 249 | 1.45 | 0.91 | 0.82 | 0.86 |

| In-Air | 0.078 | 12.92 | 172 | 3.31 | 243 | 1.28 | 0.89 | 0.90 | 0.81 |

| Out-Air | 0.072 | 12.36 | 177 | 3.21 | 240 | 1.23 | 0.89 | 0.94 | 0.87 |

表1 不同气氛处理粉体烧结样品室温下的取向因子(F)、电导率(σ)、Seebeck系数(S)、载流子浓度(n)、迁移率(μ)、总热导率(κ)、有效质量(m*/m0)、热电优值ZT以及平均热电优值ZTave

Table 1 Orientation factor (F), conductivity (σ), Seebeck coefficient (S), carrier concentration (n), mobility (μ), total thermal conductivity(κ), effective mass (m*/m0), and thermoelectric value ZT of the samples treated with different atmospheres at room temperature and average thermoelectric value ZTave

| Sample | F | σ/(×104, S•m−1) | S/(μV•K−1) | n/(×1019, cm−3) | μ/(cm2•V−1•s−1) | κ/(W•m−1•K−1) | m*/m0 | ZT | ZTave |

|---|---|---|---|---|---|---|---|---|---|

| In-Ar | 0.076 | 17.50 | 150 | 4.49 | 243 | 1.49 | 0.93 | 0.78 | 0.92 |

| Out-Ar | 0.074 | 15.55 | 160 | 3.88 | 249 | 1.45 | 0.91 | 0.82 | 0.86 |

| In-Air | 0.078 | 12.92 | 172 | 3.31 | 243 | 1.28 | 0.89 | 0.90 | 0.81 |

| Out-Air | 0.072 | 12.36 | 177 | 3.21 | 240 | 1.23 | 0.89 | 0.94 | 0.87 |

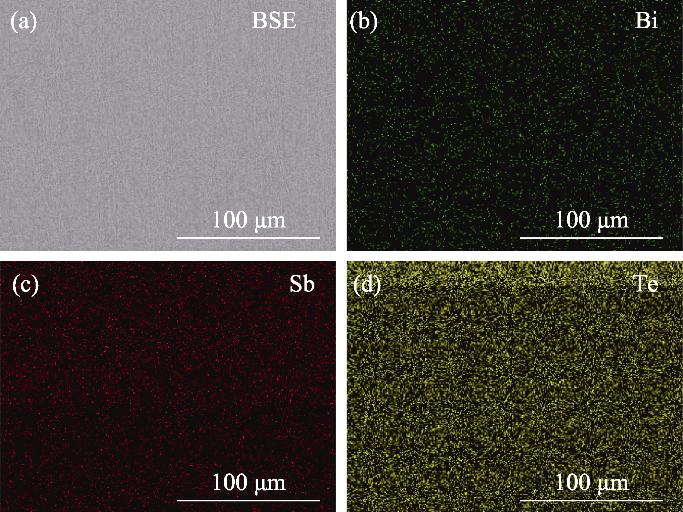

图3 In-Ar样品垂直于烧结压力方向抛光表面的(a)背散射电子像以及(b)Bi、(c)Sb和(d)Te元素的面扫描EDS能谱图

Fig. 3 (a) Backscattered electron images, (b) Bi, (c) Sb, and (d) Te elemental distribution mappings on the polished surface of In-Ar sample via EDS along the direction perpendicular to the sintering pressure

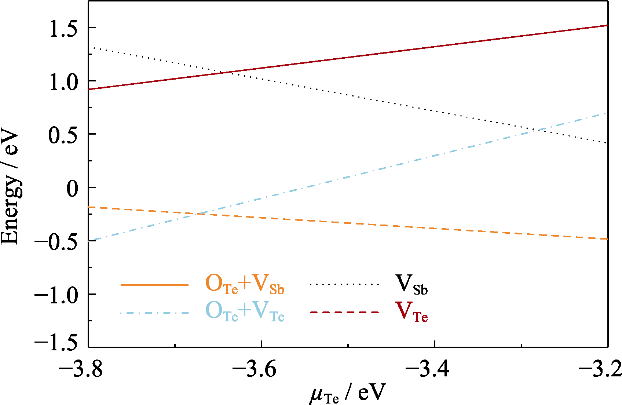

图4 不同Te化学势条件下Bi0.5Sb1.5Te3合金中存在的复杂缺陷的形成能

Fig. 4 Formation energy with complex defects presented in Bi0.5Sb1.5Te3 alloys at different Te chemical potentials

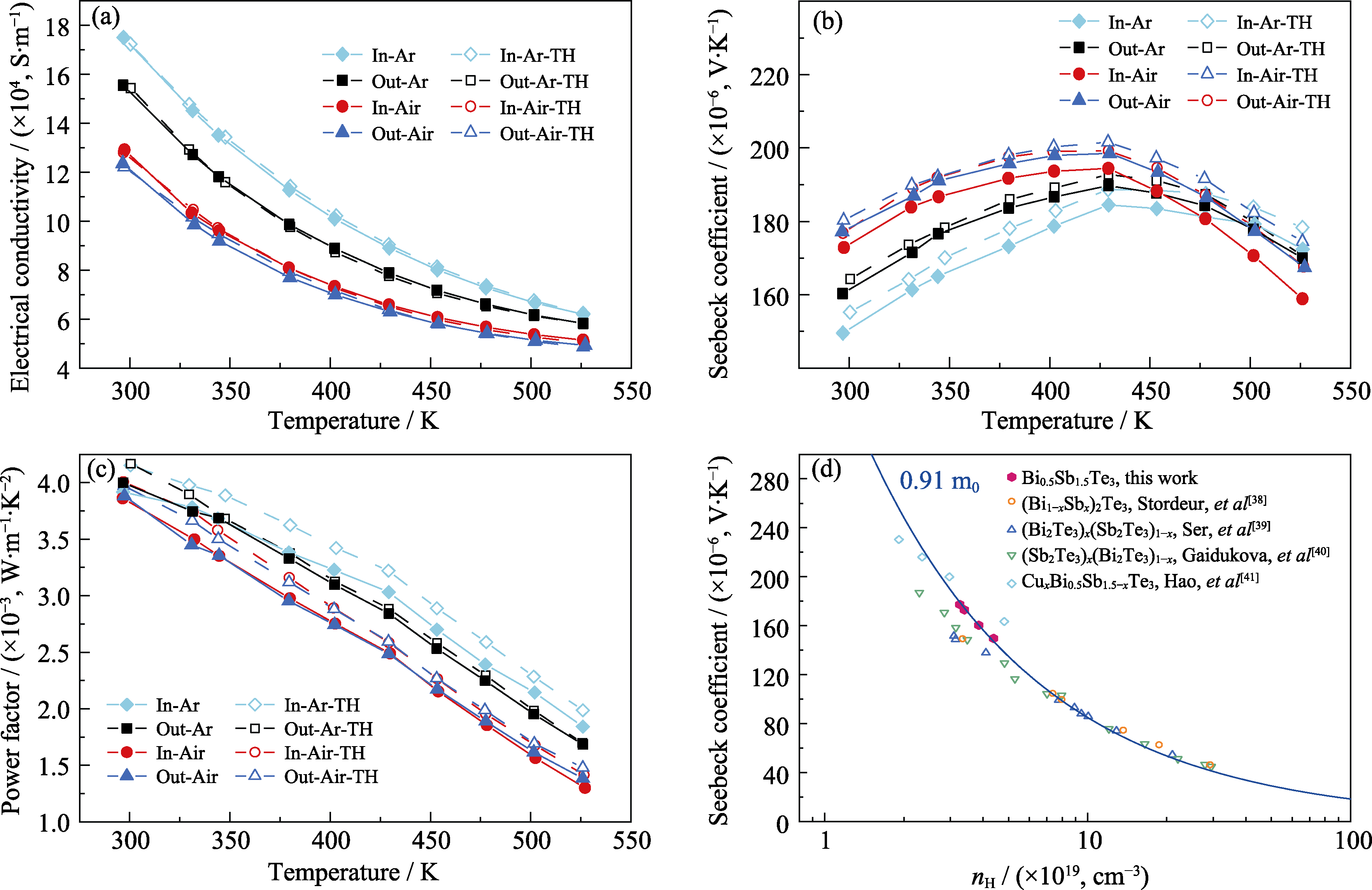

图5 不同气氛处理样品垂直烧结压力方向的(a)电导率、(b)Seebeck系数、(c)功率因子随温度变化的关系曲线, (d) 室温下Bi-Sb-Te合金的Seebeck系数与载流子浓度的关系曲线(Pisarenko曲线)

Fig. 5 Temperature dependence of (a) electrical conductivity, (b) Seebeck coefficient, (c) power factor for samples treated with different atmospheres along the direction perpendicular to the sintering pressure, (d) relationship between Seebeck coefficient and carrier concentration (Pisarenko curve) at room temperature for Bi-Sb-Te alloy

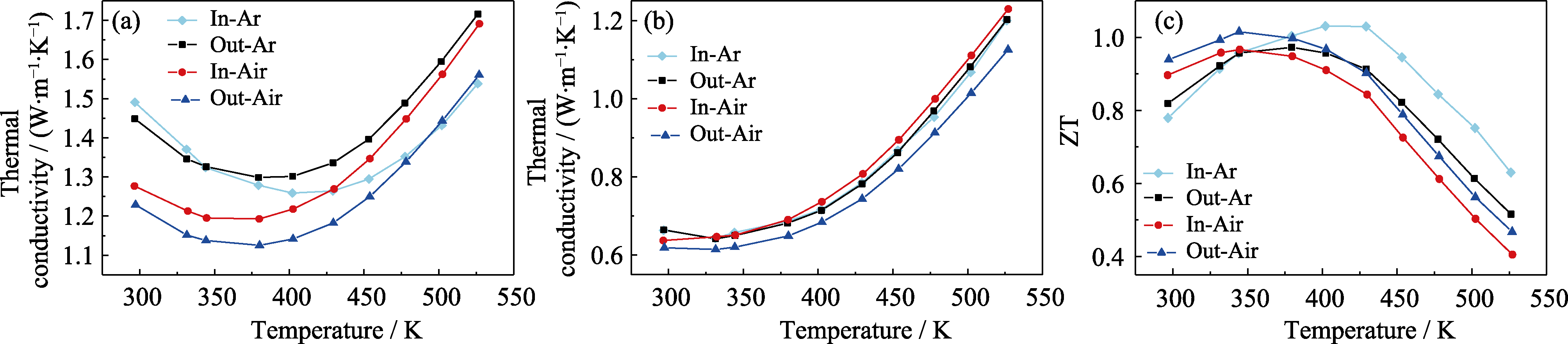

图6 不同气氛处理样品垂直烧结压力方向的(a)总热导率、(b)晶格热导率与双极热导率之和以及(c)热电优值ZT随温度变化曲线

Fig. 6 Temperature dependence of (a) total thermal conductivity, (b) sum of lattice thermal conductivity and bipolar thermal conductivity, (c) thermoelectric merit ZT for samples treated with different atmospheres along the direction perpendicular to the sintering pressure

| [1] | IMASATO K, KANG S D, SNYDER G J. Exceptional thermoelectric performance in Mg3Sb0.6Bi1.4 for low-grade waste heat recovery. Energy & Environmental Science, 2019, 12(3): 965. |

| [2] |

YANG X, SU X, YAN Y, et al. Structures and thermoelectric properties of (GeTe)nBi2Te3. Journal of Inorganic Materials, 2021, 36(1): 75.

DOI URL |

| [3] |

GONG H, SU X, YAN Y, et al. Ultra-fast synthesis of Cu2S thermoelectric materials under pulsed electric field. Journal of Inorganic Materials, 2019, 34(12): 1295.

DOI |

| [4] |

REN P, WANG C, ZI P, et al. Effect of Te and In co-doping on thermoelectric properties of Cu2SnSe3compounds. Journal of Inorganic Materials, 2022, 37(10): 1079.

DOI URL |

| [5] | SHI W, WANG D, SHUAI Z. High-performance organic thermoelectric materials: theoretical insights and computational design. Advanced Electronic Materials, 2019, 5(11): 1079. |

| [6] |

CHEN L D, XIONG Z, BAI S Q. Recent progress of thermoelectric nano-composites. Journal of Inorganic Materials, 2010, 25(6): 561.

DOI URL |

| [7] | CHEN Y, HOU X, MA C, et al. Review of development status of Bi2Te3-based semiconductor thermoelectric power generation. Advances in Materials Science and Engineering, 2018, 2018: 1210562. |

| [8] |

KAJIHARA T, MAKINO K, LEE Y H, et al. Study of thermoelectric generation unit for radiant waste heat. Materials Today: Proceedings, 2015, 2(2): 804.

DOI URL |

| [9] |

TANG X, LI Z, LIU W, et al. A comprehensive review on Bi2Te3- based thin films: thermoelectrics and beyond. Interdisciplinary Materials, 2022, 1(1): 88.

DOI URL |

| [10] |

KIM F, KWON B, EOM Y, et al. 3D printing of shape-conformable thermoelectric materials using all-inorganic Bi2Te3-based inks. Nature Energy, 2018, 3(4): 301.

DOI |

| [11] |

ZHU Y K, WU P, GUO J, et al. Achieving a fine balance in mechanical properties and thermoelectric performance in commercial Bi2Te3 materials. Ceramics International, 2020, 46(10): 14994.

DOI URL |

| [12] |

DAI Y J, HU H M, GE T S, et al. Investigation on a mini-CPC hybrid solar thermoelectric generator unit. Renewable Energy, 2016, 92: 83.

DOI URL |

| [13] |

CHAO W H, TSENG S C, YANG P H, et al. Enhanced thermoelectric properties of Bi2Te3 doping Zn4Sb3 by combinatorial approach. Surface and Coatings Technology, 2013, 231: 34.

DOI URL |

| [14] |

FANG T, LI X, HU C, et al. Complex band structures and lattice dynamics of Bi2Te3-based compounds and solid solutions. Advanced Functional Materials, 2019, 29(28): 1900677.

DOI URL |

| [15] | SHI Q, LI J, ZHAO X, et al. Comprehensive insight into p-type Bi2Te3-based thermoelectrics near room temperature. ACS Applied Materials & Interfaces, 2022, 14(44): 49425. |

| [16] |

LI Y, CAI K, HUANG B, et al. Use of molecular dynamics simulations to study the effects of nanopores and vacancies on the mechanical properties of Bi2Te3. Journal of Electronic Materials, 2013, 43(6): 1824.

DOI URL |

| [17] |

REN F, MENCHHOFER P, KIGGANS J, et al. Development of thermoelectric fibers for miniature thermoelectric devices. Journal of Electronic Materials, 2015, 45(3): 1412.

DOI URL |

| [18] |

TANG X, YAN Y, XIAO Y, et al. Effect of surface treatment of n-type Bi2Te3-based materials on the properties of thermoelectric units. Journal of Inorganic Materials, 2023, 38(2): 163.

DOI URL |

| [19] | ZHENG Y, TAN X Y, WAN X, et al. Thermal stability and mechanical response of Bi2Te3-based materials for thermoelectric applications. ACS Applied Materials & Interfaces, 2019, 3(3): 2078. |

| [20] |

FAN X A, YANG J Y, ZHU W, et al. Effect of nominal Sb2Te3 content on thermoelectric properties of p-type (Bi2Te3)x(Sb2Te3)1-x alloys by MA-HP. Journal of Physics D: Applied Physics, 2006, 39(23): 5069.

DOI URL |

| [21] |

GÜLER E, GÜLER M. Theoretical prediction of the structural, elastic, mechanical and phonon properties of bismuth telluride under pressure. International Journal of Modern Physics B, 2015, 29(31): 1550222.

DOI URL |

| [22] |

IVANOVA L D, PETROVA L I, GRANATKINA Y V, et al. Thermoelectric materials based on Sb2Te3-Bi2Te3 solid solutions with optimal performance in the range 100-400 K. Inorganic Materials, 2007, 43(9): 933.

DOI URL |

| [23] |

KIM H S, HEINZ N A, GIBBS Z M, et al. High thermoelectric performance in (Bi0.25Sb0.75)2Te3 due to band convergence and improved by carrier concentration control. Materials Today, 2017, 20(8): 452.

DOI URL |

| [24] |

STEPANOV N P, KALASHNIKOV A A, ULASHKEVICH Y V. Plasma screening of the fundamental absorption edge in crystals of Bi2Te3-Sb2Te3 solid solutions with more than 80mol% Sb2Te3. Optics and Spectroscopy, 2014, 117(3): 401.

DOI URL |

| [25] | FAN X A, YANG J Y, CHEN R G, et al. Phase transformation and thermoelectric properties of p-type (Bi2Te3)0.25(Sb2Te3)0.75prepared by mechanical alloying and hot pressing. Materials Science and Engineering: A, 2006, 438: 190. |

| [26] |

ALIEV I I, MAMEDOVA N A, SADYGOV F M, et al. Investigation of the chemical interaction in the Sb2Te3-InSe system and the properties of the obtained phases. Russian Journal of Inorganic Chemistry, 2020, 65(10): 1585.

DOI |

| [27] |

FENG S K, LI S M, FU H Z. Probing the thermoelectric transport properties of n-type Bi2Te3 close to the limit of constitutional undercooling. Chinese Physics B, 2014, 23(11): 117202.

DOI URL |

| [28] |

WANG S Y, XIE W J, TANG X F. Effects of preparation techniques on the thermoelectric properties and pressive strengths of n-type B2Te3 based materials. Journal of Inorganic Materials, 2010, 25(6): 609.

DOI URL |

| [29] |

YE S, HWANG J D, CHEN C M. Strong anisotropic effects of p-type Bi2Te3 element on the Bi2Te3/Sn interfacial reactions. Metallurgical and Materials Transactions A, 2015, 46(6): 2372.

DOI URL |

| [30] |

ZHAO L D, ZHANG B P, LI J F, et al. Thermoelectric and mechanical properties of nano-SiC-dispersed Bi2Te3 fabricated by mechanical alloying and spark plasma sintering. Journal of Alloys and Compounds, 2008, 455(1/2): 259.

DOI URL |

| [31] |

KIM H C, OH T S, HYUN D B. Thermoelectric properties of the p-type Bi2Te3-Sb2Te3-Sb2Se3alloys fabricated by mechanical alloying and hot pressing. Journal of Physics and Chemistry of Solids, 2000, 61(5): 743.

DOI URL |

| [32] |

NAVRÁTIL J, STARÝ Z, PLECHÁČEK T. Thermoelectric properties of p-type antimony bismuth telluride alloys prepared by cold pressing. Materials Research Bulletin, 1996, 31(12): 1559.

DOI URL |

| [33] |

SHIN H S, HA H P, HYUN D B, et al. Thermoelectric properties of 25%Bi2Te3-75%Sb2Te3 solid solution prepared by hot-pressing method. Journal of Physics and Chemistry of Solids, 1997, 58(4): 671.

DOI URL |

| [34] |

SCHULTZ J M, MCHUGH J P, TILLER W A. Effects of heavy deformation and annealing on the electrical properties of Bi2Te3. Journal of Applied Physics, 1962, 33(8): 2443.

DOI URL |

| [35] | ZHANG Q, GU B, WU Y, et al. Evolution of the intrinsic point defects in bismuth telluride-based thermoelectric materials. ACS Applied Materials & Interfaces, 2019, 11(44): 41424. |

| [36] | TAO Q, WU H, PAN W, et al. Removing the oxygen-induced donor-like effect for high thermoelectric performance in n-type Bi2Te3-based compounds. ACS Applied Materials & Interfaces, 2021, 13(50): 60216. |

| [37] |

LOTGERING F K. Topotactical reactions with ferrimagnetic oxides having hexagonal crystal structures. Journal of Inorganic and Nuclear Chemistry, 1959, 9(2): 113.

DOI URL |

| [38] |

STORDEUR M, STÖLZER M, SOBOTTA H, et al. Investigation of the valence band structure of thermoelectric (Bi1-xSbx)2Te3 single crystals. Physica Status Solidi B, 1988, 150(1): 165.

DOI URL |

| [39] | EROFEEV R S, OVECHKINA V N. Energy spectrum of solid solutions of Bi2Te3-Sb2Te3system. Inorganic Materials, 1981, 17(10): 1316. |

| [40] | GAIDUKOVA V S, EROFEEV R S, OVECHKINA V N. Characteristics of the energy spectrum of solid solutions in the SbTe-BiTe system. Inorganic Materials, 1981, 17(2): 169. |

| [41] |

HAO F, QIU P, SONG Q, et al. Roles of Cu in the enhanced thermoelectric properties in Bi0.5Sb1.5Te3. Materials (Basel), 2017, 10(3): 251.

DOI URL |

| [1] | 汪波, 余健, 李存成, 聂晓蕾, 朱婉婷, 魏平, 赵文俞, 张清杰. Gd/Bi0.5Sb1.5Te3热电磁梯度复合材料的服役稳定性[J]. 无机材料学报, 2023, 38(6): 663-670. |

| [2] | 贺丹琪, 魏明旭, 刘蕤之, 汤志鑫, 翟鹏程, 赵文俞. 一步法制备重费米子YbAl3热电材料及其性能提升[J]. 无机材料学报, 2023, 38(5): 577-582. |

| [3] | 林思琪, 李艾燃, 付晨光, 李荣斌, 金敏. Zintl相Mg3X2(X=Sb, Bi)基晶体生长及热电性能研究进展[J]. 无机材料学报, 2023, 38(3): 270-279. |

| [4] | 江润璐, 吴鑫, 郭昊骋, 郑琦, 王连军, 江莞. UiO-67基导电复合材料的制备及其热电性能研究[J]. 无机材料学报, 2023, 38(11): 1338-1344. |

| [5] | 程成, 李建波, 田震, 王鹏将, 康慧君, 王同敏. In2O3/InNbO4复合材料的热电性能研究[J]. 无机材料学报, 2022, 37(7): 724-730. |

| [6] | 娄许诺, 邓后权, 李爽, 张青堂, 熊文杰, 唐国栋. Ge掺杂MnTe材料的热电输运性能[J]. 无机材料学报, 2022, 37(2): 209-214. |

| [7] | 刘丹, 赵亚欣, 郭锐, 刘艳涛, 张志东, 张增星, 薛晨阳. 退火条件对磁控溅射MgO-Ag3Sb-Sb2O4柔性薄膜热电性能的影响[J]. 无机材料学报, 2022, 37(12): 1302-1310. |

| [8] | 任培安, 汪聪, 訾鹏, 陶奇睿, 苏贤礼, 唐新峰. Te与In共掺杂对Cu2SnSe3热电性能的影响[J]. 无机材料学报, 2022, 37(10): 1079-1086. |

| [9] | 逯旭, 侯绩翀, 张强, 樊建锋, 陈少平, 王晓敏. Mg含量对Mg3(1+z)Sb2化合物热电传输性能的影响[J]. 无机材料学报, 2021, 36(8): 835-840. |

| [10] | 杨枭, 苏贤礼, 鄢永高, 唐新峰. (GeTe)nBi2Te3的结构与热电性能研究[J]. 无机材料学报, 2021, 36(1): 75-80. |

| [11] | 李周, 肖翀. 异层等价离子双掺杂策略优化BiCuSeO的热电性能[J]. 无机材料学报, 2019, 34(3): 294-300. |

| [12] | 胡慧珊, 杨君友, 辛集武, 李思慧, 姜庆辉. SnO的歧化反应对SnTe热电性能的优化[J]. 无机材料学报, 2019, 34(3): 315-320. |

| [13] | 黄志成, 姚瑶, 裴俊, 董金峰, 张波萍, 李敬锋, 尚鹏鹏. n型SnS热电材料的制备与性能研究[J]. 无机材料学报, 2019, 34(3): 321-327. |

| [14] | 檀小芳, 端思晨, 王泓翔, 吴庆松, 李苗苗, 刘国强, 徐静涛, 谈小建, 邵和助, 蒋俊. 多掺杂协同调控碲化锡热导率和功率因子提升热电性能[J]. 无机材料学报, 2019, 34(3): 335-340. |

| [15] | 刘虹霞, 李文, 张馨月, 李娟, 裴艳中. (Ag2Se)1-x(Bi2Se3)x的热电性能研究[J]. 无机材料学报, 2019, 34(3): 341-348. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||