无机材料学报 ›› 2023, Vol. 38 ›› Issue (4): 461-468.DOI: 10.15541/jim20220469

刘文龙1,2( ), 赵瑾1,2(

), 赵瑾1,2( ), 刘娟1,2, 毛小建1,2, 章健1,2, 王士维1,2(

), 刘娟1,2, 毛小建1,2, 章健1,2, 王士维1,2( )

)

收稿日期:2022-08-09

修回日期:2022-11-25

出版日期:2023-04-20

网络出版日期:2022-12-09

通讯作者:

赵瑾, 助理研究员. E-mail: zhaojin@mail.sic.ac.cn;作者简介:刘文龙(1997-), 男, 硕士研究生. E-mail: liuwenlong20@mails.ucas.ac.cn

LIU Wenlong1,2( ), ZHAO Jin1,2(

), ZHAO Jin1,2( ), LIU Juan1,2, MAO Xiaojian1,2, ZHANG Jian1,2, WANG Shiwei1,2(

), LIU Juan1,2, MAO Xiaojian1,2, ZHANG Jian1,2, WANG Shiwei1,2( )

)

Received:2022-08-09

Revised:2022-11-25

Published:2023-04-20

Online:2022-12-09

Contact:

ZHAO Jin, lecturer. E-mail: zhaojin@mail.sic.ac.cn;About author:LIU Wenlong (1997-), male, Master candidate. E-mail: liuwenlong20@mails.ucas.ac.cn

Supported by:摘要:

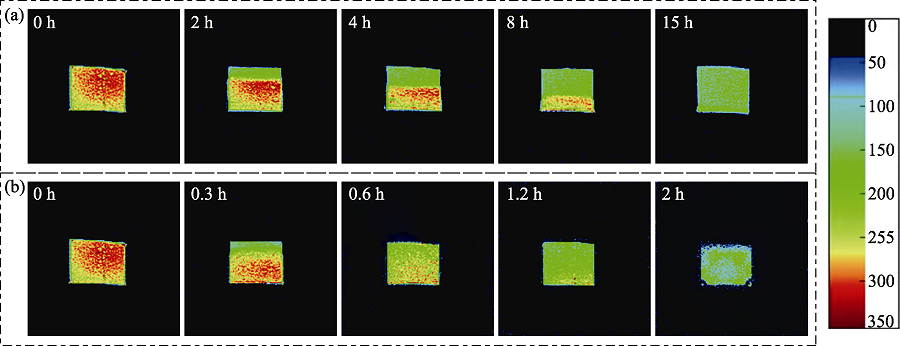

为了解决常规干燥(控温控湿)过程中坯体出现水分梯度问题, 利用微波干燥法来干燥湿坯。通过对比常规干燥(温度: 40 ℃; 湿度: 60%)和微波干燥的方式, 研究了湿坯的重量损失、线性收缩、表面温度和水分分布。与常规干燥相比, 采用微波干燥(功率250 W)时, 干燥结束时间和停止收缩时间分别缩短至1/6.8和1/6。在微波干燥过程中, 样品表面温度随时间延长先升高后降低, 与体内水分密切相关。而在常规干燥过程中, 温度保持恒定在40 ℃。采用低场核磁共振(NMR)成像技术表征湿坯内部的水分分布情况发现: 在微波干燥过程中, 水分分布更均匀, 表明微波干燥时湿坯的干燥应力更低。在1550 ℃下烧结6 h后, 微波干燥制备得到的氧化铝陶瓷具有更高的抗弯强度, 且标准差更小。

中图分类号:

刘文龙, 赵瑾, 刘娟, 毛小建, 章健, 王士维. 微波干燥自发凝固成型氧化铝湿坯[J]. 无机材料学报, 2023, 38(4): 461-468.

LIU Wenlong, ZHAO Jin, LIU Juan, MAO Xiaojian, ZHANG Jian, WANG Shiwei. Microwave Drying of Spontaneous-Coagulation-Cast Wet Alumina Green Body[J]. Journal of Inorganic Materials, 2023, 38(4): 461-468.

| Drying method | Microwave power/W | CRP/ h | Residual water after CRP/% (in vol.) | Residual water after drying/% (in vol.) |

|---|---|---|---|---|

| Conventional | — | 10 | (20.4±1.5) | 0.8 |

| Microwave | 250 | 1.8 | (11.2±1.4) | 0.6 |

| 400 | 1.3 | (9.4±1.4) | 0.5 | |

| 550 | 1.0 | (7.7±0.7) | 0.4 |

Table 1 CRP and residual water (after CRP and drying) of samples

| Drying method | Microwave power/W | CRP/ h | Residual water after CRP/% (in vol.) | Residual water after drying/% (in vol.) |

|---|---|---|---|---|

| Conventional | — | 10 | (20.4±1.5) | 0.8 |

| Microwave | 250 | 1.8 | (11.2±1.4) | 0.6 |

| 400 | 1.3 | (9.4±1.4) | 0.5 | |

| 550 | 1.0 | (7.7±0.7) | 0.4 |

| Drying method | Microwave power/W | Shrinkage stop time/h | Shrinkage/% |

|---|---|---|---|

| Conventional | — | 6.0 | (4.9±0.1) |

| Microwave | 250 | 1.0 | (5.2±0.1) |

| 400 | 0.7 | (5.1±0.1) | |

| 550 | 0.5 | (4.8±0.1) |

Table 2 Shrinkage stop time and shrinkage of samples

| Drying method | Microwave power/W | Shrinkage stop time/h | Shrinkage/% |

|---|---|---|---|

| Conventional | — | 6.0 | (4.9±0.1) |

| Microwave | 250 | 1.0 | (5.2±0.1) |

| 400 | 0.7 | (5.1±0.1) | |

| 550 | 0.5 | (4.8±0.1) |

Fig. 7 Moisture distributions of wet alumina green bodies in the drying process (a) Conventional drying for 0, 2, 4, 8, and 15 h; (b) 250-W microwave drying for 0, 0.3, 0.6, 1.2, and 2 h

| [1] |

YANG Y, SHIMAI S, WANG S. Room-temperature gelcasting of alumina with a water-soluble copolymer. Journal of Materials Research, 2013, 28(11):1512.

DOI URL |

| [2] |

CHEN H, SHIMAI S, ZHAO J, et al. Hydrophobic coagulation of alumina slurries. Journal of the American Ceramic Society, 2021, 104(1):284.

DOI URL |

| [3] |

SUN Y, SHIMAI S, PENG X, et al. A method for gelcasting high-strength alumina ceramics with low shrinkage. Journal of Materials Research, 2014, 29(2):247.

DOI URL |

| [4] | WU C, YU Z, SOKOLOV A S, et al. Tailoring magnetic properties of self-biased hexaferrites using an alternative copolymer of isobutylene and maleic anhydride. AIP Advances, 2018, 8(5):221. |

| [5] | WANG F, YIN J, YAO D, et al. Fabrication of porous SiC ceramics through a modified gelcasting and solid state sintering. Materials Science and Engineering A--Structural Materials Properties Microstructure and Processing, 2016, 654: 292. |

| [6] |

WANG L, AN L, ZHAO J, et al. High-strength porous alumina ceramics prepared from stable wet foams. Journal of Advanced Ceramics, 2021, 10(4):852.

DOI |

| [7] |

SUN Y, SHIMAI S, PENG X, et al. Fabrication of transparent Y2O3 ceramics via aqueous gelcasting. Ceramics International, 2014, 40(6):8841.

DOI URL |

| [8] | ZHANG P, LIU P, SUN Y, et al. Aqueous gelcasting of the transparent MgAl2O4 spinel ceramics. Journal of Alloys and Compounds, 2015, 646: 833. |

| [9] |

WANG J, ZHANG F, CHEN F, et al. Fabrication of aluminum oxynitride (c-AlON) transparent ceramics with modified gelcasting. Journal of the American Ceramic Society, 2014, 97(5):1353.

DOI URL |

| [10] |

CHEN H, ZHAO J, SHIMAI S, et al. High transmittance and grain-orientated alumina ceramics fabricated by adding fine template particles. Journal of Advanced Ceramics, 2022, 11(4):582.

DOI |

| [11] |

YOUNG A C, OMATETE O O, JANNEY M A, et al. Gelcasting of alumina. Journal of the American Ceramic Society, 1991, 74(3):612.

DOI URL |

| [12] | BAADER F H, GRAULE T J, GAUCKLER L J. Direct coagulation casting-a new green shape technique. 2. Application to alumina. Industrial Ceramics, 1996, 16(1):36. |

| [13] | GRAULE T J, GAUCKLER L J, BAADER F H. Direct coagulation casting-a new green shaping technique. 1. Processing principles. Industrial Ceramics, 1996, 16(1):31. |

| [14] |

SCHERER G W. Theory of drying. Journal of the American Ceramic Society, 1990, 73(1):3.

DOI URL |

| [15] | OMATETE O O, STREHLOW R A, WALLS C A. Drying of gelcast ceramics. United States, 1991, 26(2):101. |

| [16] |

MA L G, HUANG Y, YANG J L, et al. Control of the inner stresses in ceramic green bodies formed by gelcasting. Ceramics International, 2006, 32(2):93.

DOI URL |

| [17] |

BARATI A, KOKABI M, FAMILI M H N. Drying of gelcast ceramic parts via the liquid desiccant method. Journal of the European Ceramic Society, 2003, 23(13):2265.

DOI URL |

| [18] |

BILBAO-SAINZ C, ANDRES A, FITO P. Hydration kinetics of dried apple as affected by drying conditions. Journal of Food Engineering, 2005, 68(3):369.

DOI URL |

| [19] |

SHIRAI T, YASUOKA M, HOTTA Y, et al. Rapid microwave drying for slip cast bodies. Journal of the Ceramic Society of Japan, 2006, 114(1326):217.

DOI URL |

| [20] |

OZKAN I A, AKBUDAK B, AKBUDAK N. Microwave drying characteristics of spinach. Journal of Food Engineering, 2007, 78(2):577.

DOI URL |

| [21] |

VONGPRADUBCHAI S, RATTANADECHO P. Microwave and hot air drying of wood using a rectangular waveguide. Drying Technology, 2011, 29(4):451.

DOI URL |

| [22] |

CHONG C H, FIGIEL A, LAW C L, et al. Combined drying of apple cubes by using of heat pump, vacuum-microwave, and intermittent techniques. Food and Bioprocess Technology, 2014, 7(4):975.

DOI URL |

| [23] |

ITAYA Y, OKOUCHI K, MORI S. Effect of heating modes on internal strain-stress formation during drying of molded ceramics. Drying Technology, 2001, 19(7):1491.

DOI URL |

| [24] | ESIN A, MAHMUTYAZICIOGLU N, ALTINTAS S. Drying and sintering of ceramic based parts using microwave heating. Key Engineering Materials, 2004, 268(3):731. |

| [25] |

SHIRAI T, ISOBE T, YASUOKA M, et al. Rapid microwave drying for wet green body using nanosized particles. Journal of the Ceramic Society of Japan, 2007, 115(1343):440.

DOI URL |

| [26] |

HEMANTHAKUMARI P N, SATAPATHY L N. A comparison of the effects of microwave versus conventional drying on the mechanical properties distribution of dried green porcelains. International Journal of Applied Ceramic Technology, 2008, 5(1):94.

DOI URL |

| [27] |

ZHANG L, MCCARTHY M J. NMR study of hydration of navy bean during cooking. Lwt-Food Science and Technology, 2013, 53(2):402.

DOI URL |

| [28] |

BORISJUK L, ROLLETSCHEK H, NEUBERGER T. Surveying the plant's world by magnetic resonance imaging. Plant Journal, 2012, 70(1):129.

DOI URL |

| [29] |

ISHIDA N, KOIZUMI M, KANO H. The NMR microscope: a unique and promising tool for plant science. Annals of Botany, 2000, 86(2):259.

DOI URL |

| [30] |

DADALI G, APAR D K, OZBEK B. Microwave drying kinetics of okra. Drying Technology, 2007, 25(4/5/6):917.

DOI URL |

| [1] | 张祥松, 刘业通, 王永瑛, 武子瑞, 刘振中, 李毅, 杨娟. 自组装制备PtIr合金气凝胶及其高效电催化氨氧化性能[J]. 无机材料学报, 2023, 38(5): 511-520. |

| [2] | 靳喜海, 董满江, 阚艳梅, 梁波, 董绍明. 透明AlON陶瓷凝胶浇注成型及其无压烧结制备[J]. 无机材料学报, 2023, 38(2): 193-198. |

| [3] | 李文俊, 王皓, 涂兵田, 谌强国, 郑凯平, 王为民, 傅正义. 宽光谱透过Mg0.9Al2.08O3.97N0.03透明陶瓷的制备与性能研究[J]. 无机材料学报, 2022, 37(9): 969-975. |

| [4] | 王士维. 基于疏水作用的陶瓷浆料自发凝固成型研究进展[J]. 无机材料学报, 2022, 37(8): 809-820. |

| [5] | 王晓俊, 许文, 刘润路, 潘辉, 朱申敏. 水凝胶负载的纳米银/氮化碳光催化剂的制备及性能研究[J]. 无机材料学报, 2022, 37(7): 731-740. |

| [6] | 王新刚, 杨青青, 林根连, 高巍, 秦福林, 李荣臻, 康庄, 王小飞, 蒋丹宇, 闫继娜. 国产550级连续氧化铝陶瓷纤维的高温拉伸性能研究[J]. 无机材料学报, 2022, 37(6): 629-635. |

| [7] | 周港怀, 刘耀, 石原, 刘绍军. 活性氧化铝催化剂载体的光固化浆料制备与成型[J]. 无机材料学报, 2022, 37(3): 297-302. |

| [8] | 曾勇, 张子佳, 孙立君, 姚海华, 陈继民. 3D打印氧化铝陶瓷的气氛脱脂热处理工艺研究[J]. 无机材料学报, 2022, 37(3): 333-337. |

| [9] | 郝鸿渐, 李海燕, 万德田, 包亦望, 李月明. 莫来石/氧化铝预应力涂层增强氧化铝的弯曲强度和抗热震性能[J]. 无机材料学报, 2022, 37(12): 1295-1301. |

| [10] | 罗艺, 夏书海, 牛波, 张亚运, 龙东辉. 柔性有机硅气凝胶的制备及其高温无机化转变研究[J]. 无机材料学报, 2022, 37(12): 1281-1288. |

| [11] | 吴爱军, 朱敏, 朱钰方. 含铜硅酸钙纳米棒复合水凝胶用于肿瘤治疗和皮肤伤口愈合性能研究[J]. 无机材料学报, 2022, 37(11): 1203-1216. |

| [12] | 吕庆洋, 张玉亭, 顾学红. 超声辅助溶胶-凝胶法制备中空纤维TiO2超滤膜[J]. 无机材料学报, 2022, 37(10): 1051-1057. |

| [13] | 彭飞, 姜勇刚, 冯坚, 蔡华飞, 冯军宗, 李良军. 耐高温氧化铝气凝胶隔热复合材料研究进展[J]. 无机材料学报, 2021, 36(7): 673-684. |

| [14] | 张晓山, 王兵, 吴楠, 韩成, 吴纯治, 王应德. 高温隔热用微纳陶瓷纤维研究进展[J]. 无机材料学报, 2021, 36(3): 245-256. |

| [15] | 郭小炜, 李玉妍, 陈南春, 王秀丽, 解庆林. 负载二甲酸钾缓释抗菌微球的构建[J]. 无机材料学报, 2021, 36(2): 181-187. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||