无机材料学报 ›› 2022, Vol. 37 ›› Issue (10): 1116-1122.DOI: 10.15541/jim20210745

所属专题: 【生物材料】骨骼与齿类组织修复

收稿日期:2021-12-07

修回日期:2022-01-25

出版日期:2022-10-20

网络出版日期:2022-06-16

通讯作者:

李祥, 副研究员. E-mail: xiangliwj@sjtu.edu.cn作者简介:张航(1994-), 男, 博士研究生. E-mail: hangzhang@sjtu.edu.cn

基金资助:

ZHANG Hang1( ), HAN Kunyuan2, DONG Lanlan1, LI Xiang1(

), HAN Kunyuan2, DONG Lanlan1, LI Xiang1( )

)

Received:2021-12-07

Revised:2022-01-25

Published:2022-10-20

Online:2022-06-16

Contact:

LI Xiang, associate professor. E-mail: xiangliwj@sjtu.edu.cnAbout author:ZHANG Hang (1994-), male, PhD candidate. E-mail: hangzhang@sjtu.edu.cn

Supported by:摘要:

β-磷酸三钙(β-TCP)具有生物降解性和生物相容性, 但其固有的脆性限制了其在承重种植体中的应用。为进一步提高β-TCP的力学性能和生物相容性, 本研究以纳米黏土(Nano clay, NC)为添加剂, 采用数字光处理(Digital light processing, DLP)技术制备了β-TCP/NC(TNC)复合支架, 支架TNC10多孔结构孔径为200~300 μm。当加入NC含量为10%(质量分数)时, 支架(TNC10)各结构特征的烧结收缩最小。加入NC不会改变TCP的物相成分, 且支架表面均匀分布Si、Mg元素。加入NC可以提高TCP支架的压缩强度, NC(粒径<500 nm)融合在TCP颗粒的间隙中, 对比纯TCP支架, TNC10支架的压缩强度提高了10%。另外, TNC10 组较纯TCP的比表面积增加2倍以上。TNC降解速率更快, 可以持续释放Ca、Mg、Si、Li等离子, 并且TNC降解液保持弱碱性的环境。研究结果表明: 加入NC对β-TCP支架的力学强度、降解性能均具有一定的促进作用。利用DLP方法打印的具有良好的理化性能的多孔生物陶瓷支架在骨修复领域有巨大应用前景。

中图分类号:

张航, 韩坤原, 董兰兰, 李祥. DLP打印β-磷酸三钙/纳米黏土复合支架的制备与表征[J]. 无机材料学报, 2022, 37(10): 1116-1122.

ZHANG Hang, HAN Kunyuan, DONG Lanlan, LI Xiang. Preparation and Characterization of β-tricalcium Phosphate/Nano Clay Composite Scaffolds via Digital Light Processing Printing[J]. Journal of Inorganic Materials, 2022, 37(10): 1116-1122.

| Materials and reagent | Chemical agent | Dosage/% (in mass) |

|---|---|---|

| Ceramic powder | β-TCP | 50-60 |

| Resin monomer | PEG200DA | 20-40 |

| Crosslinking agent | 3,3-Dimethylacrylic acid | 2-4 |

| Dispersant | DCA-1228 | 0.3-1.0 |

| Photoinitiator | TPO | 0.5 |

| Nano clay | Laponite | 0-10 |

表1 制备多孔生物陶瓷的主要原料与试剂

Table 1 Main raw materials and reagents for preparation of porous bioceramics

| Materials and reagent | Chemical agent | Dosage/% (in mass) |

|---|---|---|

| Ceramic powder | β-TCP | 50-60 |

| Resin monomer | PEG200DA | 20-40 |

| Crosslinking agent | 3,3-Dimethylacrylic acid | 2-4 |

| Dispersant | DCA-1228 | 0.3-1.0 |

| Photoinitiator | TPO | 0.5 |

| Nano clay | Laponite | 0-10 |

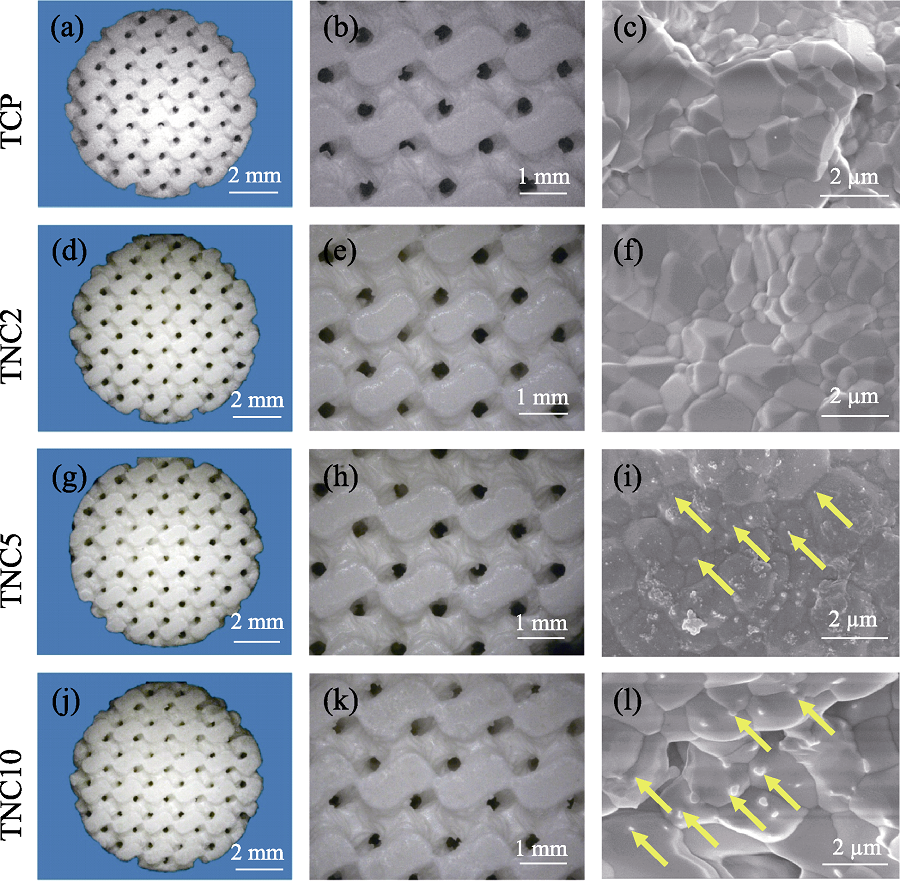

图2 支架表面形貌

Fig. 2 Surface morphologies of scaffold (a, d, g, j) Microscope photos of scaffolds; (b, e, h, k) Microscope photos of scaffolds; (c, f, i, l) SEM images of scaffolds

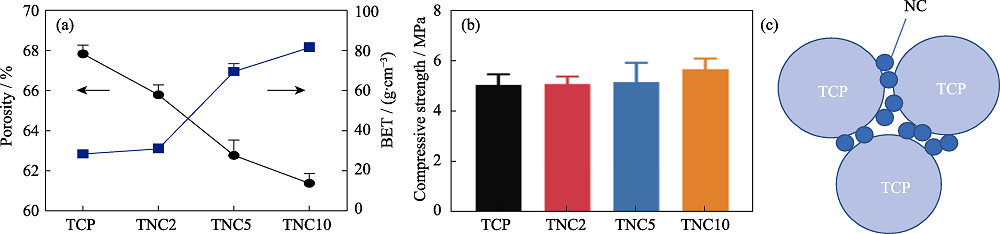

图5 支架力学性能分析

Fig. 5 Mechanical property analysis of porous scaffolds (a) Porosity and specific surface area of the scaffolds; (b) Compression strength of the scaffolds; (c) Schematic diagram of NC enhanced TCP

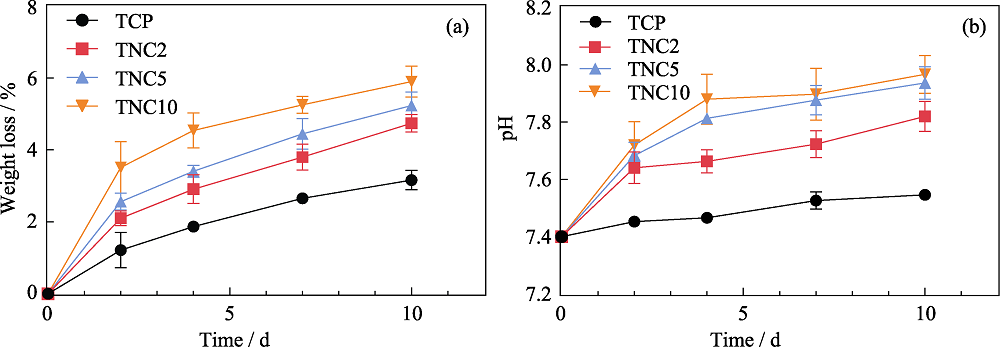

图6 支架降解后的失重和pH变化情况

Fig. 6 Weight loss and pH change after scaffold degradation (a) Weight loss of scaffold after soaking in SBF for different time; (b) pH change of SBF after soaking the scaffolds

| [1] |

GAO C, WEI P, PEI F, et al. Nano SiO2 and MgO improve the properties of porous β-TCP scaffolds via advanced manufacturing technology. International Journal of Molecular Sciences, 2015, 16(4): 6818-6830.

DOI URL |

| [2] | LIU J, GAO C, FENG P, et al. Selective laser sintering of β-TCP/nano-58S composite scaffolds with improved mechanical properties. Materials & Design, 2015, 84: 395-401. |

| [3] |

LIU J, SHEN X, TANG S, et al. Improvement of rBMSCs responses to poly(propylene carbonate) based biomaterial through incorporation of nanolaponite and surface treatment using sodium hydroxide. ACS Biomaterials Science and Engineering, 2020, 6(1): 329-339..

DOI PMID |

| [4] | ZHANG Y H, CHEN M J, DAI Z B, et al. Sustained protein therapeutics enabled by self-healing nanocomposite hydrogels for non-invasive bone regeneration. J. Biomaterials Science, 2020, 8: 682-693. |

| [5] |

ZIMINSKA M, CHALANQUI M J, CHAMBERS P, et al. Nanocomposite-coated porous templates for engineered bone scaffolds: a parametric study of layer-by-layer assembly conditions. Biomedical Materials, 2019, 14(6): 065008.

DOI URL |

| [6] |

LEE C U, HWANG H S, KIM S, et al. Inspired by nature: facile design of nanoclay-organic hydrogel bone sealant with multifunctional properties for robust bone regeneration. Advanced Functional Materials, 2020, 30: 2003717.

DOI URL |

| [7] |

ZHAI X Y, HOU C Y, PAN H B, et al. Nanotechnology, nanoclay incorporated polyethylene-glycol nanocomposite hydrogels for stimulating in vitro and in vivo osteogenesis. Journal of Biomedical Nanotechnology, 2018, 14(4): 662-674.

DOI URL |

| [8] | GAO W, SUN L, ZHANG Z, et al. Progress, preparation, characterization and evaluation of biomass-based siliconcontaining composite scaffolds for bone repair. Chemical Industry and Engineering Progress, 2019, 38(10): 4595-4605. |

| [9] | DONG Q S, YANG L, JIANG H Q, et al. 3D-cubic interconnected porous Mg-based scaffolds for bone repair. Journal of Magnesium and Alloys, 2021, 9(4): 1336-1345. |

| [10] |

MIGUEZ-PACHECO V, BÜTTNER T, MAON A, et al. Development and characterization of lithium-releasing silicate bioactive glasses and their scaffolds for bone repair. Journal of Non-Crystalline Solids, 2016, 432(15): 65-72.

DOI URL |

| [11] |

PAREDES C, MARTÍNEZ-VÁZQUEZ F J, PAJARES A, et al. Novel strategy for toughening robocast bioceramic scaffolds using polymeric cores. Ceramics International, 2019, 45(15): 19572-19576.

DOI URL |

| [12] | LIU F H. Synthesis of bioceramic scaffolds for bone tissue engineering by rapid prototyping technique. Journal of Sol Gel Science & Technology, 2012, 64(3): 704-710. |

| [13] |

CHEN Q Z, THOUAS G A. Fabrication and characterization of Sol-Gel derived 45S5 Bioglass®-ceramic scaffolds. Acta Biomaterialia, 2011, 7(10): 3616-3626.

DOI URL |

| [14] |

ZHANG G, JIANG J, WANG H, et al. Continuous DLP-based ceramic 3D printing using a composite oxygen-rich film. Journal of Manufacturing Processes, 2021, 64(8): 341-348.

DOI URL |

| [15] |

MA Y, DAI H, HUANG X, et al. 3D printing of bioglass-reinforced β-TCP porous bioceramic scaffolds. Journal of Materials Science, 2019, 54: 10437-10446.

DOI URL |

| [16] |

GAO Y, DING J. Low solid loading, low viscosity, high uniform shrinkage ceramic resin for stereolithography based additive manufacturing. Procedia Manufacturing, 2020, 48: 749-754.

DOI URL |

| [17] |

LIU W, LI M, NIE J, et al. Technology, synergy of solid loading and printability of ceramic paste for optimized properties of alumina via stereolithography-based 3D printing. Journal of Materials Research and Technology, 2020, 9(5): 11476-11483.

DOI URL |

| [18] |

SHUAI X, ZENG Y, LI P, et al. Fabrication of fine and complex lattice structure Al2O3 ceramic by digital light processing 3D printing technology. Journal of Materials Science, 2020, 55(3): 6771-6782.

DOI URL |

| [19] |

XH A, HDA C, YH A, et al. Development of a high solid loading β-TCP suspension with a low refractive index contrast for DLP-based ceramic stereolithography. Journal of the European Ceramic Society, 2020, 41(6): 3743-3754.

DOI URL |

| [20] |

ARIFIN A, SULONG A B, MUHAMAD N, et al. Material processing of hydroxyapatite and titanium alloy (HA/Ti) composite as implant materials using powder metallurgy: a review. Materials & Design, 2014, 55: 165-175.

DOI URL |

| [21] |

SEZER N, EVIS Z, KO M. Additive manufacturing of biodegradable magnesium implants and scaffolds: review of the recent advances and research trends. Journal of Magnesium and Alloys, 2020, 9(12): 392-415.

DOI URL |

| [22] |

FUH L J, HUANG Y J, CHEN W C, et al. Preparation of micro-porous bioceramic containing silicon-substituted hydroxyapatite and beta-tricalcium phosphate. Materials Science and Engineering C, 2017, 75: 798-806.

DOI URL |

| [23] | CHEN Y, WANG X, BING M, et al. 3D-printed bioactive Ca3SiO5 bone cement scaffolds with nano surface structure for bone regeneration. ACS Applied Materials & Interfaces, 2017, 9(7): 5757. |

| [24] |

COCKERILL I, SU Y, SINHA S, et al. Porous zinc scaffolds for bone tissue engineering applications: a novel additive manufacturing and casting approach. Materials Science and Engineering C, 2020, 110: 110738.

DOI URL |

| [25] |

MARYAM T, KINSELLA J M, GUINTO G C, et al. Silicon-doped hydroxyapatite prepared by a thermal technique for hard tissue engineering applications. Ceramics International, 2018, 44(15): 17612-17622.

DOI URL |

| [26] |

HE F, TIAN Y. Improvements in phase stability and densification of β-tricalcium phosphate bioceramics by strontium-containing phosphate-based glass additive. Ceramics International, 2018, 44(10): 11622-11627.

DOI URL |

| [27] |

CHEN Q, BAINO F, SPRIANO S, et al. Modelling of the strength-porosity relationship in glass-ceramic foam scaffolds for bone repair. Journal of the European Ceramic Society, 2014, 34(11): 2663-2673.

DOI URL |

| [28] |

BIAN W, LI D, LIAN Q, et al. Fabrication of a bio-inspired β-tricalcium phosphate/collagen scaffold based on ceramic stereolithography and gel casting for osteochondral tissue engineering. Rapid Prototyping Journal, 2012, 18(1): 68-80.

DOI URL |

| [29] |

SARKAR K, RAHAMAN M, AGARWAL S, et al. Degradability and in vivo biocompatibility of doped magnesium phosphate bioceramic scaffolds. Materials Letters, 2020, 259: 126892.

DOI URL |

| [1] | 黄 萍, 李 鹏, 赵军胜, 屈树新, 冯 波, 翁 杰. 机械活化增强多孔磷酸钙骨水泥支架的研究[J]. 无机材料学报, 2015, 30(4): 432-438. |

| [2] | 巩梦安, 饶群力, 王鸿烈. 造孔剂和发泡剂结合法制备氟化羟基磷灰石多孔支架研究[J]. 无机材料学报, 2014, 29(3): 289-293. |

| [3] | 曹烈虎, 禹宝庆, 伍国胜, 苏佳灿. 掺杂钠硅磷灰石水泥多孔支架用于骨缺损再生修复[J]. 无机材料学报, 2011, 26(6): 591-596. |

| [4] | 郭来阳, 张靖微, 赵 婧, 汪建新, 翁 杰, 张 聪. 具有良好贯通性的颗粒造孔支架的制备及表征[J]. 无机材料学报, 2011, 26(1): 17-21. |

| [5] | 王志伟, 苏佳灿, 马玉海, 张 欣, 曹烈虎, 李 明. 纳米非计量磷灰石/聚合物复合支架的制备和性能研究[J]. 无机材料学报, 2010, 25(5): 500-506. |

| [6] | 谢 林,陈晓峰,赵娜如,郭常亮. 有机泡沫浸渍法制备多孔生物玻璃支架的研究[J]. 无机材料学报, 2009, 24(2): 280-284. |

| [7] | 刘欣,姚爱华,王德平,黄文hai,付海罗,赵荻,吕维加,潘浩波. 硼硅酸盐生物活性玻璃多孔支架的制备[J]. 无机材料学报, 2008, 23(2): 322-326. |

| [8] | 魏杰,刘昌胜,洪华,袁媛,陈芳萍. 新型可降解钙磷骨水泥多孔支架研究[J]. 无机材料学报, 2006, 21(4): 958-964. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||