无机材料学报 ›› 2022, Vol. 37 ›› Issue (9): 954-960.DOI: 10.15541/jim20210726

陈赛赛( ), 庞雅莉, 王娇娜, 龚䶮, 王锐, 栾筱婉, 李昕(

), 庞雅莉, 王娇娜, 龚䶮, 王锐, 栾筱婉, 李昕( )

)

收稿日期:2021-11-24

修回日期:2022-03-28

出版日期:2022-09-20

网络出版日期:2022-06-16

通讯作者:

李 昕, 教授. E-mail: clylx@bift.edu.cn作者简介:陈赛赛(1995-), 男, 硕士研究生. E-mail: chensaisai1995@163.com

基金资助:

CHEN Saisai( ), PANG Yali, WANG Jiaona, GONG Yan, WANG Rui, LUAN Xiaowan, LI Xin(

), PANG Yali, WANG Jiaona, GONG Yan, WANG Rui, LUAN Xiaowan, LI Xin( )

)

Received:2021-11-24

Revised:2022-03-28

Published:2022-09-20

Online:2022-06-16

Contact:

LI Xin, professor. E-mail: clylx@bift.edu.cnAbout author:CHEN Saisai (1995-), male, Master candidate. E-mail: chensaisai1995@163.com

Supported by:摘要:

石墨烯因其优异的导电性、优越的柔韧性和环境稳定性, 在可穿戴电子纺织品领域发挥了重要作用。本工作通过丝网印刷技术分别将自制的石墨烯浆料和复合热致变色油墨印在聚酯织物的正反面, 构筑了一种石墨烯基绿-黄可逆电热致变色织物。采用SEM、XRD以及FTIR等分析了织物的结构性质和变色原理, 采用红外热成像仪及全色差色度仪研究了织物的热学以及变色性能。结果表明:石墨烯电热致变色织物厚度约为250 μm, 在12 V电压下逐渐加热超过45 ℃, 焦耳热主要通过热传导至变色层, 结晶紫内酯的闭开环实现绿-黄可逆变色, 其变色响应时间约为15 s, 褪色响应时间约为27 s。石墨烯电热致变色织物经历30°~180°的弯曲角度后, 电压-电流曲线保持稳定。经200次加热/冷却循环后, 性能未发生明显衰退。本研究成功制备了颜色在绿-黄之间变化、响应迅速、循环性能良好的可逆电热致变色织物:石墨烯膜‖聚酯织物‖热致变色膜, 在军事伪装和可穿戴显示领域有一定的应用前景。

中图分类号:

陈赛赛, 庞雅莉, 王娇娜, 龚䶮, 王锐, 栾筱婉, 李昕. 绿-黄可逆电热致变色织物的制备及其性能[J]. 无机材料学报, 2022, 37(9): 954-960.

CHEN Saisai, PANG Yali, WANG Jiaona, GONG Yan, WANG Rui, LUAN Xiaowan, LI Xin. Preparation and Properties of Green-yellow Reversible Electro-thermochromic Fabric[J]. Journal of Inorganic Materials, 2022, 37(9): 954-960.

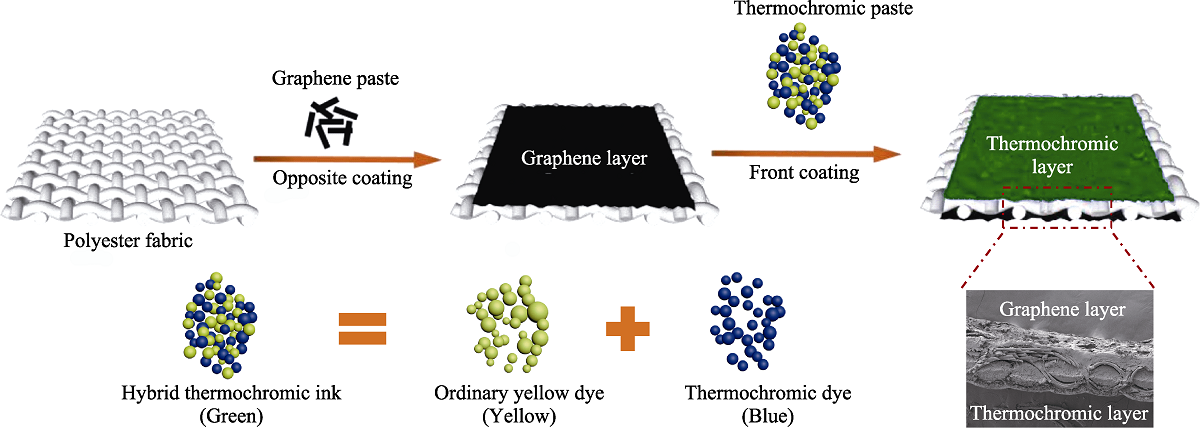

图1 石墨烯电热致变色织物制备过程以及热致变色油墨的组成

Fig. 1 Illustration of the preparation process of graphene electro-thermalchromic fabric and the composition of thermochromic ink

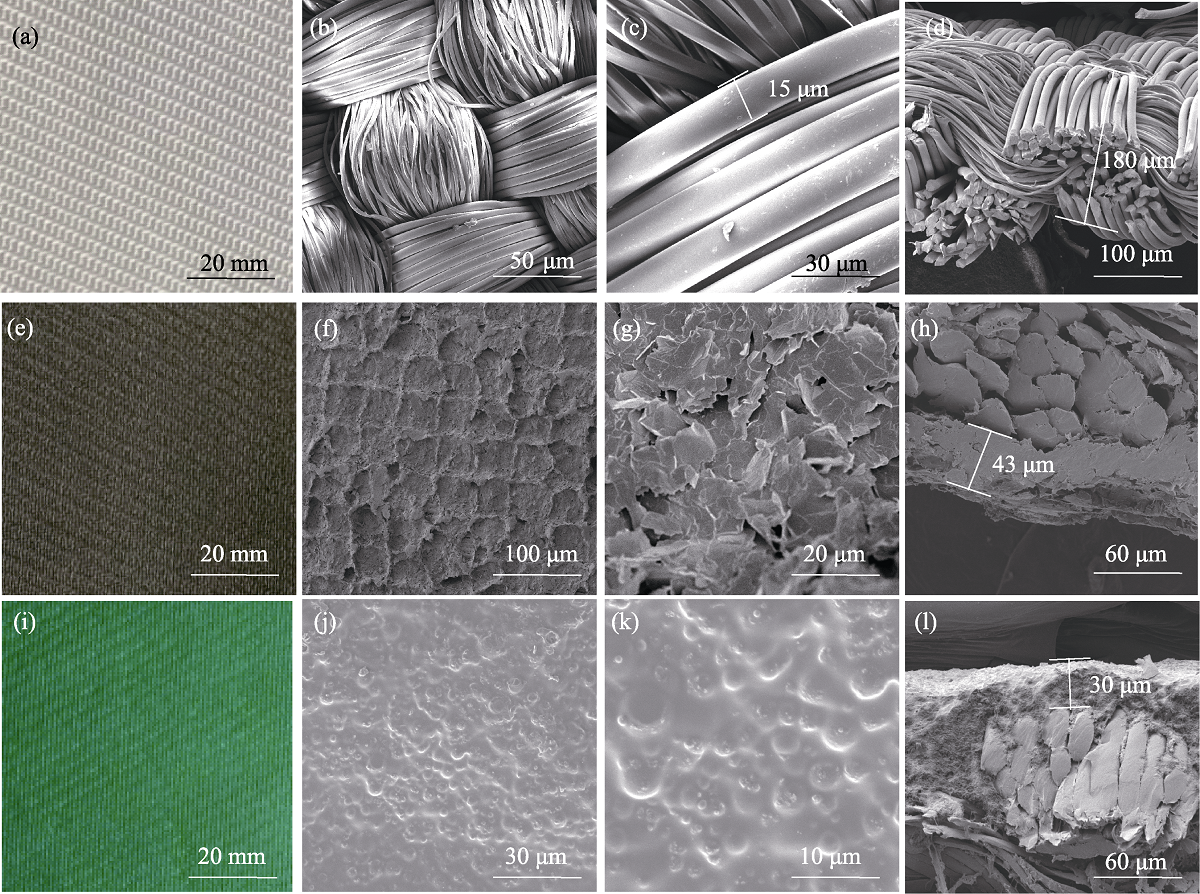

图2 空白聚酯织物、石墨烯导电层、热致变色层的数码照片和SEM照片

Fig. 2 Photographs and SEM images of a blank polyester fabric, graphene conductive layer and thermochromic layer (a, e, i) Photographs of a blank polyester fabric, graphene conductive layer and thermochromic layer at room temperature; (b, c, d) SEM images of the surface and cross section of the base polyester fabric at different magnifications; (f, g, h) SEM images of the surface and cross section of the graphene conductive layer at different magnifications; (j, k, l) SEM images of the surface and cross section of the thermochromic layer at different magnifications

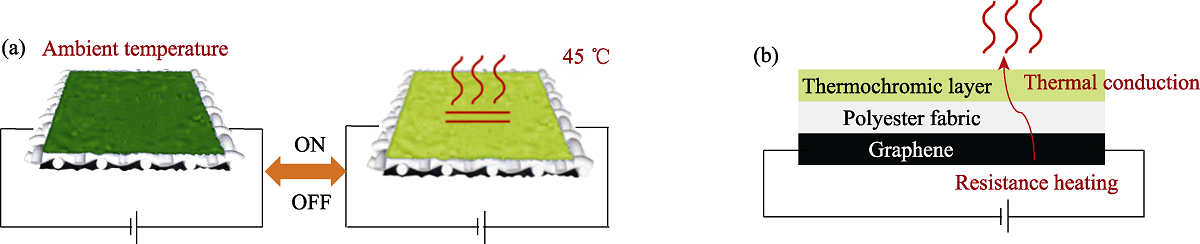

图4 石墨烯电热致变色织物的变色过程示意图(a)和传热方式示意图(b)

Fig. 4 Schematic diagram of the color change process (a) and schematic diagram of the heat transfer method (b) of graphene electro-thermochromic fabric

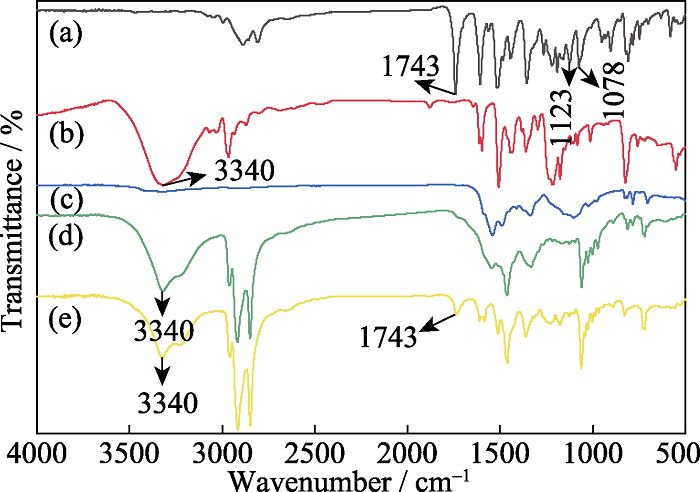

图5 结晶紫内酯(a), 双酚A(b), 荧光黄染料(c)和复合热致变色油墨加热前(d)后(e)的红外光谱图

Fig. 5 FT-IR spectra of CVL (a), BPA (b), fluorescent yellow dye (c) and hybrid thermochromic ink before (d) and after (e) heating

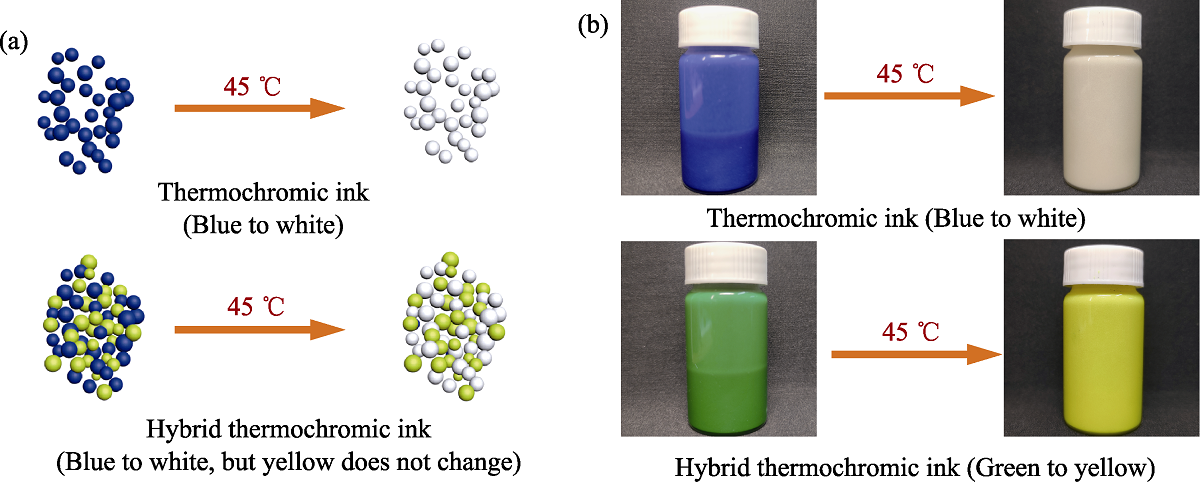

图6 热致变色油墨变色前后的示意图(a)及实物图(b)

Fig. 6 Schematic diagram (a) and physical image (b) of thermochromic ink before and after color change Colorful images are available on website

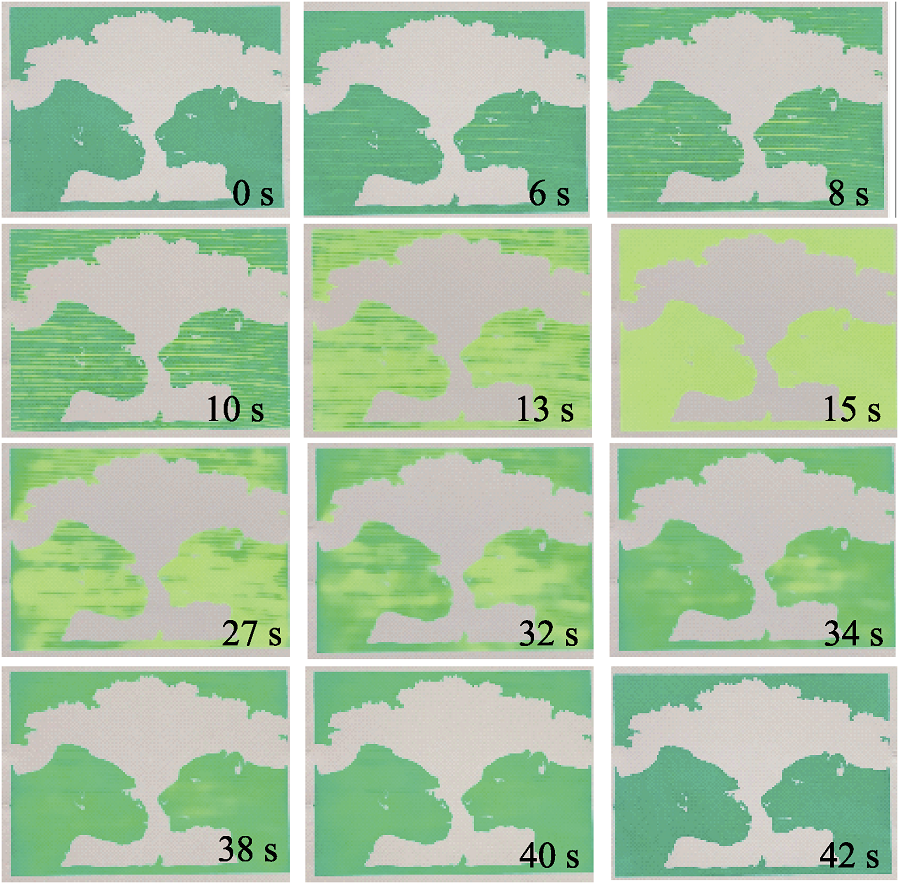

图7 在12V电压下, 石墨烯电热致变色织物在一个周期内颜色变化的数码照片

Fig. 7 Photographs of the the graphene electro-thermochromic fabric during a color-change cycle under an applied voltage of 12 V Colorful images are available on website

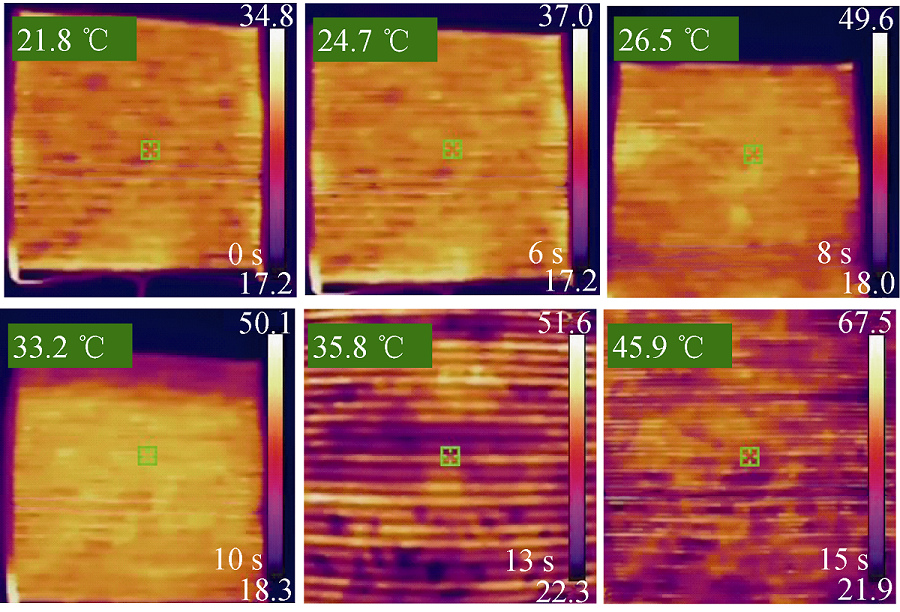

图8 在12V电压下, 石墨烯电热致变色织物在一个周期内的红外热成像图

Fig. 8 Thermal images of the graphene electro-thermochromic fabric during a cycle under an applied voltage of 12 V Colorful images are available on website

| Potential/V | x | y | Y |

|---|---|---|---|

| 0 | 0.0334 | 0.7485 | 5.04 |

| 12 | 0.4407 | 0.5402 | 53.15 |

表1 石墨烯电热致变色织物的色度参数

Table 1 Chromaticity parameters of graphene electro-thermochromic fabric

| Potential/V | x | y | Y |

|---|---|---|---|

| 0 | 0.0334 | 0.7485 | 5.04 |

| 12 | 0.4407 | 0.5402 | 53.15 |

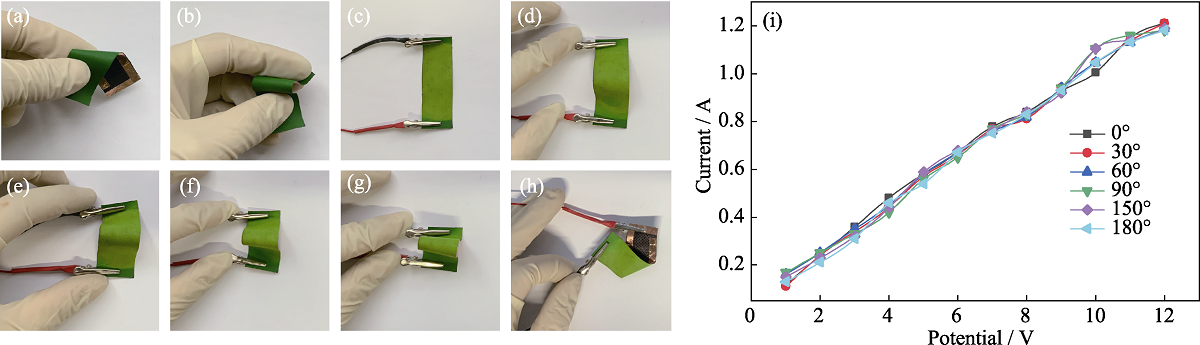

图11 石墨烯电热致变色织物的稳定性分析

Fig. 11 Stability analysis of graphene electro-thermochromic fabric (a,b) Photographs of the graphene electro-thermochromic fabric bent at a certain degree; (c-h) Images of the graphene electro-thermochromic fabric bending at 0°, 30°, 60°, 90°, 150°, and 180° after voltage being applied; (i) Current-voltage curves of the graphene electro-thermochromic fabric bended at different bending angles. Colorful figures are available on website

| [1] | WANG X, YUAN J, JANG X J. Research on preparation and performance of green camouflage aqueous foam. Acta Armamentarii, 2019, 40(10): 2136-2141. |

| [2] | YU K S, PENG J X. Color changing technology study of electronic ink based on interconversion between yellow and green. Protective Engineering, 2016, 38(1): 28-34. |

| [3] | GRANQVIST C G. Recent progress in thermochromics and electrochromics: a brief survey. Thin Solid Films, 2016, 614: 90-96. |

| [4] | LI M, JI S, PAN J, WU H, et al. Infrared response of self-heating VO2 nanoparticles film based on Ag nanowires heater. Journal of Materials Chemistry A, 2014, 2: 20470-20473. |

| [5] |

MALTI A, BROOKE R, LIU X, et al. Freestanding electrochromic paper. Journal of Materials Chemistry C, 2016, 4(41): 9680-9686.

DOI URL |

| [6] | CHEN Y, XU Z, SUN J L. Commercialization of large area electrochromic smart glasses: present and future. Journal of Functional Materials, 2013, 44(17): 2441-2446. |

| [7] | WEI Y X, CHEN M, LIU M W. Recent process and application of electrochromism. Journal of Aeronautical Materials, 2016, 36(3): 108-123. |

| [8] | SONG X L, LI Z M, CHEN J W. Smart applications of thermochromic materials for intelligent society: latest development and future perspective. Fine Chemicals, 2020, 37(3): 452-461. |

| [9] |

POTUCK A, MEYERS S, LEVITT A, et al. Development of thermochromic pigment based sportswear for detection of physical exhaustion. Fashion Practice, 2016, 8(2): 279-295.

DOI URL |

| [10] | GENG X, LI W, WANG Y, et al. Reversible thermochromic microencapsulated phase change materials for thermal energy storage application in thermal protective clothing. Applied Energy, 2018, 217: 281-294. |

| [11] |

ZHU X, LIU Y, LI Z. Thermochromic microcapsules with highly transparent shells obtained through in-situ polymerization of urea formaldehyde around thermochromic cores for smart wood coatings. Scientific Reports, 2018, 8(1): 4015.

DOI URL |

| [12] | ZHANG Y, LIU H, NIU J. Development of reversible and durable thermochromic phase-change microcapsules for real-time indication of thermal energy storage and management. Applied Energy, 2020, 264: 114729. |

| [13] |

LAFORGUE A. Electrically controlled colour-changing textiles using the resistive heating properties of PEDOT nanofibers. Journal of Materials Chemistry, 2010, 20(38): 8233-8235.

DOI URL |

| [14] | LAFORGUE A, ROUGET G, DUBOST S, et al. Multifunctional resistive-heating and color-changing monofilaments produced by a single-step coaxial melt-spinning process. ACS Applied Materials & Interfaces, 2012, 4(6): 3163-3168. |

| [15] | WENG W, CHEN P, HE S, et al. Smart electronic textiles. Angewante Chemie International Edition, 2016, 55: 6140-6169. |

| [16] |

ZHANG B, HOU Y C, WANG H P, et al. Preparation and performance of reduced graphene oxide functionalized flexible and multicolor electrothermal chromatic films. Journal of Inorganic Materials, 2018, 33(11): 1232-1236.

DOI |

| [17] | GE F, FEI L, ZHANG J, et al. The electrical-triggered high contrast and reversible color-changing Janus fabric based on double side coating. ACS Applied Materials & Interfaces, 2020, 12(19): 21854-21862. |

| [18] |

GUO Y, DUN C, XU J, et al. Ultrathin, washable, and large-area graphene papers for personal thermal management. Small, 2017, 13(44): 1702645.

DOI URL |

| [19] | REN W C, GAO L B, MA L P. Preparation of graphene by chemical vapor deposition. New Carbon Materials, 2011, 26(1): 10. |

| [20] |

ZKAYALAR S, E ADGÜZEL, AKSOY S A, et al. Reversible color-changing and thermal-energy storing nanocapsules of three- component thermochromic dyes. Materials Chemistry and Physics, 2020, 252(3): 123162.

DOI URL |

| [21] | SONG Y F. Preparation and Properties of Organic Reversible Thermochromic Materials Microcapsules. Tianjin: Master's Thesis of Tianjin University, 2018. |

| [1] | 孙铭, 邵溥真, 孙凯, 黄建华, 张强, 修子扬, 肖海英, 武高辉. RGO/Al复合材料界面性质第一性原理研究[J]. 无机材料学报, 2022, 37(6): 651-659. |

| [2] | 安琳, 吴淏, 韩鑫, 李耀刚, 王宏志, 张青红. 非贵金属Co5.47N/N-rGO助催化剂增强TiO2光催化制氢性能[J]. 无机材料学报, 2022, 37(5): 534-540. |

| [3] | 王虹力, 王男, 王丽莹, 宋二红, 赵占奎. 功能化石墨烯担载型AuPd纳米催化剂增强甲酸制氢反应[J]. 无机材料学报, 2022, 37(5): 547-553. |

| [4] | 董淑蕊, 赵笛, 赵静, 金万勤. 离子化氨基酸对氧化石墨烯膜渗透汽化过程中水选择性渗透的影响[J]. 无机材料学报, 2022, 37(4): 387-394. |

| [5] | 蒋丽丽, 徐帅帅, 夏宝凯, 陈胜, 朱俊武. 缺陷调控石墨烯复合催化剂在氧还原反应中的作用[J]. 无机材料学报, 2022, 37(2): 215-222. |

| [6] | 吴静, 余立兵, 刘帅帅, 黄秋艳, 姜姗姗, ANTON Matveev, 王连莉, 宋二红, 肖蓓蓓. NiN4/Cr修饰的石墨烯电化学固氮电极[J]. 无机材料学报, 2022, 37(10): 1141-1148. |

| [7] | 李铁, 李玥, 王颖异, 张珽. 石墨烯-铁酸铋纳米晶复合材料的制备及其催化性能研究[J]. 无机材料学报, 2021, 36(7): 725-732. |

| [8] | 向晖, 全慧, 胡艺媛, 赵炜骞, 徐波, 殷江. 类石墨烯单层结构ZnO和GaN的压电特性对比研究[J]. 无机材料学报, 2021, 36(5): 492-496. |

| [9] | 李豪, 唐志红, 卓尚军, 钱荣. 基于ZIF8/rGO的高性能NO2室温传感器[J]. 无机材料学报, 2021, 36(12): 1277-1282. |

| [10] | 何俊龙, 宋二红, 王连军, 江莞. DFT方法研究一氧化氮在铬掺杂石墨烯上的吸附行为[J]. 无机材料学报, 2021, 36(10): 1047-1052. |

| [11] | 张伟,高鹏,侯成义,李耀刚,张青红,王宏志. 基于ZnO复合材料的芯片式pH和温度传感器[J]. 无机材料学报, 2020, 35(4): 416-422. |

| [12] | 罗燚,冯军宗,冯坚,姜勇刚,李良军. 新型碳材料质子交换膜燃料电池Pt催化剂载体的研究进展[J]. 无机材料学报, 2020, 35(4): 407-415. |

| [13] | 赵超锋, 金佳人, 霍英忠, 孙陆, 艾玥洁. 氧化石墨烯吸附水体中酚类有机污染物的分子动力学模拟[J]. 无机材料学报, 2020, 35(3): 277-283. |

| [14] | 张塞, 邹英桐, 陈中山, 李冰峰, 顾鹏程, 文涛. 可见光驱动RGO/g-C3N4活化过硫酸盐降解水中双酚A[J]. 无机材料学报, 2020, 35(3): 329-336. |

| [15] | 高天, 肖庆林, 许晨阳, 王学斌. 发泡法制备二维材料泡沫体的进展[J]. 无机材料学报, 2020, 35(12): 1315-1326. |

| 阅读次数 | ||||||

|

全文 |

|

|||||

|

摘要 |

|

|||||